CNC machining plays a crucial role in auto parts manufacturing for the future. Every modern high-performance vehicle, from a factory-fresh sports car to a custom-built race machine, has a secret weapon, and that’s precision. And the precision you see isn’t just an accident of nature, but the result of a highly advanced process called CNC machining. But you might be wondering what exactly CNC machining is. And why has it become the gold standard for critical auto parts?

| Evidence Type | Description |

| Precision | CNC machines are pretty much like mini-factory lines – they use computer instructions to make really accurate parts that meet all the required standards. |

| Efficiency | These machines work on their own and without stopping, which means they can make stuff quicker and cut down on waste. |

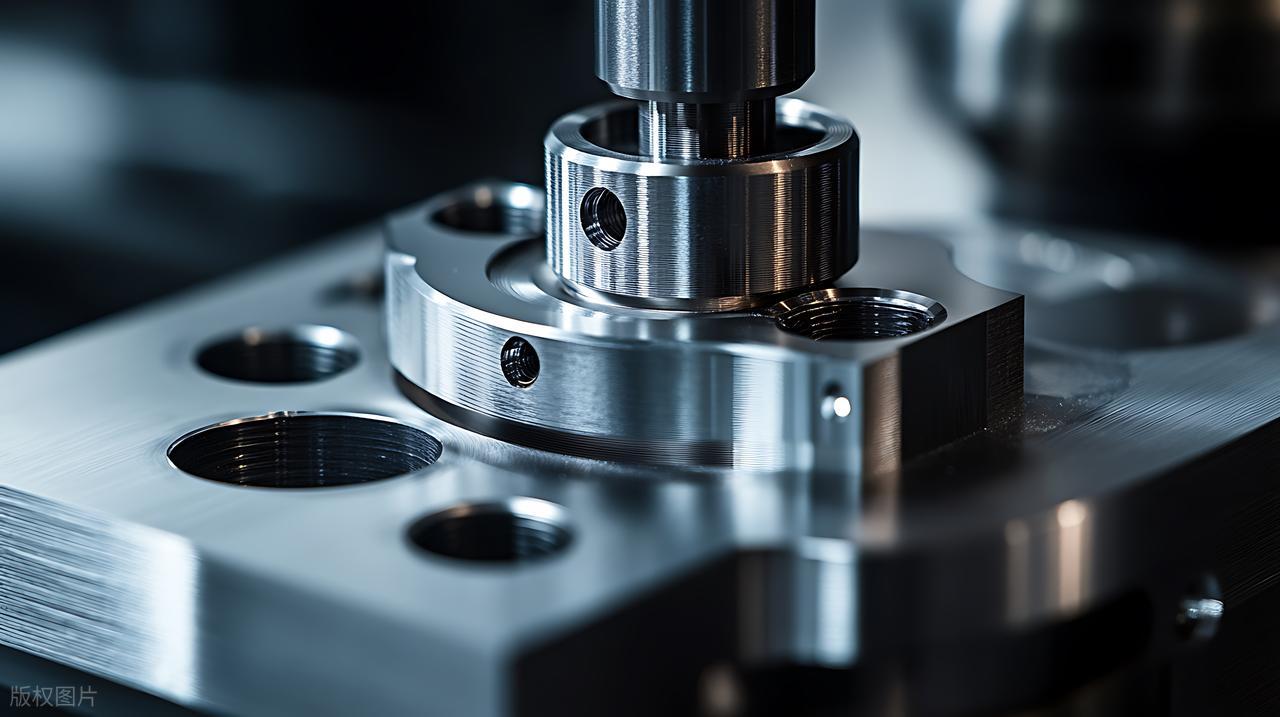

CNC Machining in Auto Parts Manufacturing

Essential Role in Auto Production

CNC machining is very important in making auto parts. We totally get it, you need auto parts that fit well and work every time. CNC machining is great for turning computer designs into real parts. These parts are made with great accuracy. When you see a car engine or brakes, you can see the careful work that’s gone into them.

NOBLE is a top machining company in China. We use state-of-the-art CNC machines to cut and shape materials. These machines work with tiny measurements. Your parts meet the strictest rules for safety and performance. If you need a special piston or gear, CNC machining guarantees it will match the design. There are no mistakes or surprises.

- It basically takes computer designs and turns them into step-by-step instructions for the machines.

- It makes parts that have to meet tight rules, even for hard shapes.

- It does the same job over and over with few errors.

- It works with lots of materials, like metals and composites.

Did you know? The CNC machine tools market is expected to reach an incredible $123 billion by 2034! It’s so great to see that more and more people are on the lookout for precise auto parts!

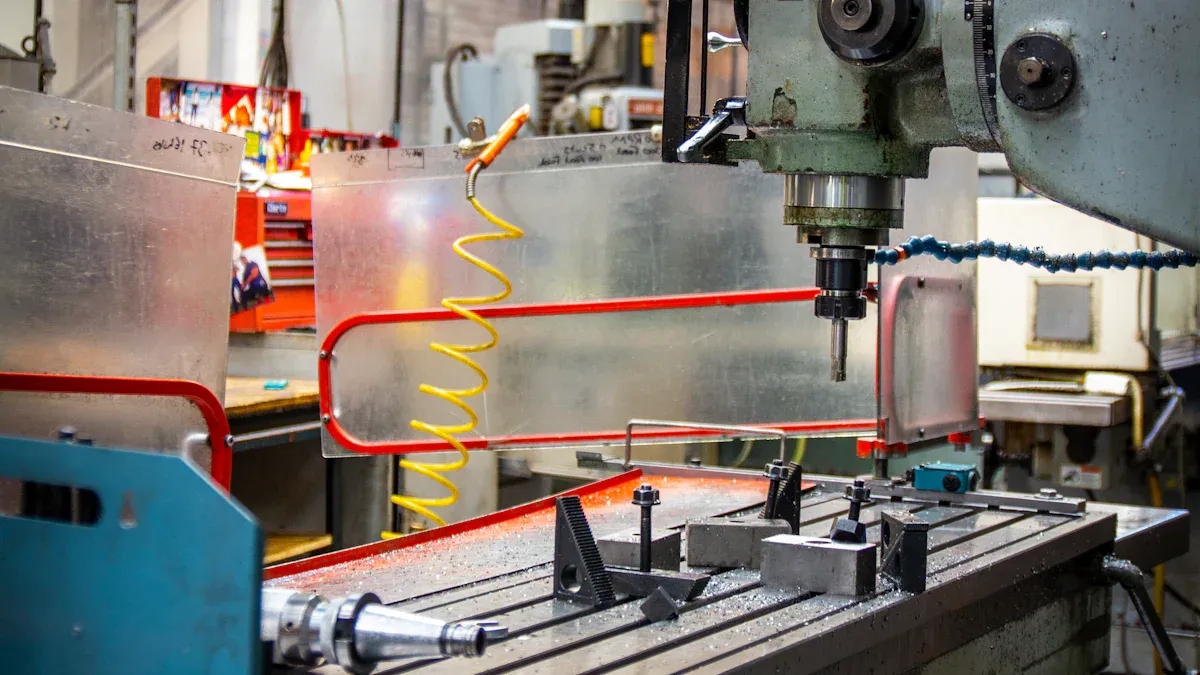

Integration with Modern Manufacturing

Auto parts factories use CNC machining with other smart tools. Robots and AI help make things faster and with fewer mistakes. Machine learning can change the process as it works. This makes sure every part is just right.

NOBLE is a leader in China for smart machining. We use CNC machines and other tools like multi-axis machines, laser cutters, and 3D printers. This allows you to create parts that were previously impossible. NOBLE is the answer if you need a light battery case or a strong rotor.

- Multi-axis machines are the best way to make hard designs.

- IoT and AI are the key to making them better.

- Additive manufacturing and CNC machining are the fastest ways to make and finish parts.

Pick NOBLE, and you will get more than parts. You get a team that knows the future of auto parts making. You can go from a test part to many parts quickly. Every part will be exactly what you need.

CNC Machining Benefits for Auto Parts Manufacturing

Precision and Consistency

Every auto part needs to fit well and work right. CNC machining helps make sure this happens. Special computer programs and accurate machines match each part to your design. CNC machining can make parts to a tiny level, sometimes just a few microns. This guarantees that your engine, brake,s and transmission will always work perfectly.

Tight Tolerances

Sensors keep an eye on the machines while they’re running. If something goes wrong, the system fixes it in no time. This stops mistakes before they happen. NOBLE uses these smart systems for top brands like Land Rover and BYD. You get good quality whether you need one part or many.

Material Flexibility

You may need strong metal parts or light composite ones. CNC machining can easily produce both. Our selection range for CNC machining auto parts includes aluminum, steel, titanium, copper, and plastics such as ABS and polycarbonate. CNC machines also work with carbon fiber and glass fiber. This lets you make auto parts that are tough, light, and ready for anything.

Metals and Composites

NOBLE’s custom machining works with many materials. With a wide range of materials to choose from, you can quickly switch between metals and composites—perfect for rapid prototyping! You’ll save significant time and money while getting the product that meets your exact needs.

| Benefit | Description |

| Flexibility | CNC machines can switch jobs quickly and make new parts in no time. |

| Cost Efficiency | Machines get the job done, so you end up paying less for workers and getting more done. |

| Consistency | CNC machining makes sure that the components are always spot on and sturdy. |

| Complex Design | Machines can make hard shapes that old ways just can’t. |

| Reduced Human Error | Automation means fewer mistakes and better parts. |

Complex Shapes and Customization

Making parts with curves or holes is hard by hand. CNC machining makes everything simple. Five-axis machines can easily create complex shapes and intricate details. You can use them to make machine housings, gearboxes, instrument panels, and battery trays—don’t have to compromise on precision.

Rapid Prototyping

Need a test part in a hurry? CNC machining can do it. You go from computer plan to finished part in just days. NOBLE’s fast service lets you try new ideas quickly. You can make strong and accurate parts, even in small batches. So, go ahead and modify the designs and start making more parts ASAP.

- CNC machining works pretty much on its own, day and night, with hardly any help.

- You’ll pay your workers less and make more parts.

- You always get parts that meet the strict rules.

Auto Parts Manufacturing with CNC Machining

Engine Parts

Cylinder Heads, Pistons

When you look under a car’s hood, you see engine parts. These parts need to be very exact. As we all know, the cylinder head and piston have to fit together perfectly for the engine to work efficiently over a long period of time. CNC machining technology makes sure these components meet design specs exactly, with accurate machining right down to the smallest details.

Here are some engine parts made with CNC machining:

- Cylinder heads

- Engine blocks

- Pistons

- Valves

NOBLE is a top company in China. You can trust NOBLE components. Our custom manufacturing process guarantees that each part meets the highest standards. Our components are guaranteed to deliver outstanding performance and reliable operation, even under the most demanding conditions.

Transmission Components

Gears, Shafts

Transmission parts like gears and shafts do hard jobs. They have to bear heavy loads while making sure they keep going. If you want gear changes to be smooth and the gears and driveshafts to last, you need robust components. CNC machining is used to make these components to a high standard, producing gear tooth profiles that are perfect and surfaces on drive shafts that are like mirrors.

| Advantage | Description |

| High efficiency | Gear and rack transmissions are effective and allow precise control of the positions. |

| High torque | These auto parts can handle a lot of force, so they’re perfect for heavy cars. |

| Adaptable | These parts can handle a lot of force, so they’re perfect for heavy cars. |

| High performance | Threaded drives turn force into movement for many uses. |

| High precision | You get parts that are always accurate. |

Our team of engineers possesses exceptional expertise in auto parts manufacturing. With over a decade of experience in auto parts manufacturing, you can confidently entrust your automotive component production projects to NOBLE. Many car makers use NOBLE for testing and making lots of parts.

Suspension and Steering

Control Arms, Knuckles

Suspension and steering parts help your car drive well. You’ve got to be really careful when you’re making parts like control arms and knuckles. Even small mistakes can cause bad alignment or tyre wear. CNC machining is great for making parts to a high standard.

These machining methods can help you out:

- CNC milling makes mounts and brackets that fit really tightly.

- CNC turning is great for making round parts like bushings that fit really well.

- 5-axis CNC machining shapes knuckles with perfect angles.

- CNC drilling makes it super easy to put holes in the right spots. That makes the assembly a breeze.

Here’s what happens:

- Mounting points stay right where they should be, making sure your suspension works like a dream.

- The bushing holes line up perfectly, ensuring your parts last a long time.

- Removing extra material makes parts lighter, so your car handles better – how great is that?

Brake System

Calipers, Rotors

You want your car to stop safely each time. Brake system parts like calipers and rotors are so important, and it’s great to know that they’re in perfect condition. CNC machining is the key to making these important parts so accurate. When you pick NOBLE, a top company in China, you know you’re getting the best! Our calipers and rotors meet the toughest safety rules, so you can be sure you’re getting the best quality.

And here’s how CNC machining can help you with brake system parts.

| Applications | Advantages |

| Piston Bores | High precision and repeatability |

| Mounting Holes | Handles complex shapes |

| Outer Surfaces | Good for many and custom designs |

You get calipers with smooth piston bores. Rotors have flat friction surfaces. CNC turning is amazing – it keeps the flatness at an incredible ±0.015 mm, which is why the brakes work so well. The thickness is always below 0.010 mm, which means less shaking and noise. Surface grinding gives a smooth finish between 0.8 and 3.2 microns. Precision drilling is amazing! It puts holes in the right spots, with an accuracy of ±0.050 mm. Milling makes air channels with a channel width accuracy of ±0.100 mm, which is really impressive!

- We totally get it, you want the same great quality for every brake part, and that’s exactly what CNC machining can deliver.

- Hey, just so you know, you can get loads of different parts, and there are some really special designs too!

- We know how important it is to keep your brakes working well, and NOBLE is here to help.

Tip: NOBLE’s custom work makes sure every caliper and rotor fits your needs.

Electric Vehicle Parts

Battery Housings, Motor Parts

Electric cars need parts that are light, strong, and exact. We know how important it is that battery housings and motor parts fit well and last long. And the good news is that CNC machining makes this happen! NOBLE is a company that uses smart machines to make battery packs, motor housings, and cooling systems. They have very strict rules that they follow.

Here’s how CNC machining helps make electric car parts:

| Application | Description |

| Battery Packs | We make cells, rotary shafts and plates, and they do it all with care. |

| Motor Components | We’ve got all the machined housings and shafts you could need for top work. |

| Cooling Systems | The key to effective heat control lies in the hard parts. |

| Weight Reduction | We’ve got special dies and machines that can make panels lighter. |

| Tight Tolerances | We make sure our parts are always spot on, so you can rest assured they’ll be safe and perfect. |

You can get battery cases that are made to fit your phone perfectly, so they’ll protect your phone and last for ages. Motor housings have to be made to a tight set of rules to reduce noise and improve performance. Cooling systems use custom machining to keep things cool. CNC machining also makes parts lighter, so your electric car can go further.

- If you take care of your electric car, it’ll stay safe and work well.

- You can build more cars quickly with Fast Making.

- Everything functions in the same way every single time.

- You can switch up designs quickly when you’ve got new ideas.

- We can all do our bit for the planet by cutting down on waste and using energy more efficiently.

NOBLE’s skill as a Chinese machining company helps you meet new electric car needs. You get parts that help you think of new ideas and perform well.

Note: Electric cars need perfect parts. NOBLE’s CNC machining gives you the careful work you want.

Custom and Performance Parts

Prototypes, Upgrades

You may want to try a new design or make your car better. CNC machining makes it a breeze to create custom and special parts. NOBLE is great at making test parts and small batches, so you can go from idea to real part in no time.

Here are some custom auto parts you can get from NOBLE:

- Engine blocks, valve covers, and intake manifolds

- Transmission housings and gearbox flanges

- Suspension brackets and control arms

- Dashboard parts and inside trim

- Custom racing accessories and mounts

- Aerodynamic parts for racing

You’ll start with test components that are just right for the job. And if any modifications or updates are needed, our friendly engineers will be there to help you. And when it’s time for some new equipment for those exciting competitions or special projects, NOBLE’s super-careful craftsmanship will make sure you’re all set.

- Try out new ideas quickly with our fast test parts.

- Custom machining is great for making special parts for any job.

- NOBLE knows what they’re doing, so you can expect great results every time.

Want to stand out on the track or street? NOBLE’s custom machining is the perfect way to turn your ideas into high-performance auto parts.

Innovation in Auto Parts Manufacturing

Agile Prototyping

You want to try new ideas quickly. CNC machining is the perfect solution for you! Amazingly, it can transform a computer design into a real part in just a few days! This fast process will help you stay ahead of the game when it comes to making cars. NOBLE is a top machining company in China. We use rapid prototyping to help you change designs in a flash! The great thing is that you can test, change, and test again as many times as you like, without having to wait.

Here’s how CNC machining helps with fast and flexible prototyping:

| Aspect | Description |

| Consistency | Each prototype matches your plan, so you know what works. |

| Reduced Lead Times | You get the parts you need faster, so your project stays on track. |

| Fast Adjustments | You can change your design and see results fast. |

| Waste Minimization | Less waste means you spend less on each prototype. |

| Supply Chain Agility | You can react to market changes without slowing down. |

NOBLE’s custom machining lets you order small batches for testing. Less waste means you spend less on each prototype. Many big car brands use NOBLE’s fast prototyping to launch new cars sooner.

Lightweight and High-Performance Designs

You want cars that go farther and work better. Have you ever thought about CNC machining? It’s such a cool thing because you can use strong, light materials like aluminium, titanium and carbon fibre. These materials make parts lighter and tougher, which is great news! NOBLE’s super-duper machines are the real deal when it comes to creating those tricky, complex shapes that help your car perform like a dream. You get engine blocks, turbochargers, and battery housings that are a bit tight in the fit.

Why not have a look at how CNC machining can help you bring your new designs to life?

| Innovation Type | Description |

| CNC Machining | It makes exact shapes for high-performance car parts. |

| Multi-Axis Machining | It makes hard designs without any extra steps. |

| Lightweight Materials | It uses metals and composites to keep it light and fast. |

| Precision Machining | Just make sure you get every part in place and working well, even when you’re dealing with some of the more challenging jobs. |

Supply Chain Efficiency

You want your parts on time and at a good price. We all know how important it is to have a well-oiled supply chain, and CNC machining can really help with that. It uses automation and accuracy to make sure everything runs smoothly, so you can relax and focus on other important things. You’ll get fewer mistakes and less waste. We know how important it is to keep costs down without compromising on quality. That’s why we’re so excited to tell you about NOBLE’s smart solutions. They’re great value for money and will help you to achieve your goals.

Here’s how CNC machining can help your supply chain:

- It’ll always give you the exact parts you need.

- Uses less raw material, so it’s better for the environment.

- Reduces labour costs by using machines for tough jobs.

- Gets you those parts in the nick of time, so you can meet those tight deadlines.

- Changes in a flash when you need fresh designs, making sure customers stay happy.

NOBLE works with big car brands to make things run better. You can let them handle the difficult parts and focus on new ideas. With NOBLE’s support, you’ll get high-quality parts, faster launches, and a stronger business.

Fancy trying something new? NOBLE’s CNC machining turns your plans into real parts, from test to full production.

CNC Machining vs. Traditional Manufacturing

Speed and Efficiency

You want your auto parts quickly. CNC machining is much faster than the old ways. CNC machines are great because they can operate 24/7 using computer instructions, which means you can get hold of the automotive parts you need in no time at all. On the other hand, traditional manufacturing relies on skilled workers, manual setup, and supervision, which slows down production and makes each automotive part take longer to make.

Here’s a quick way of comparing how CNC machining and traditional methods stack up:

| Feature | CNC Machining | Traditional Manufacturing |

| Speed | Faster production cycles | Time-consuming and labor-intensive |

| Efficiency | Higher output, less waste | More expensive, more manual labor |

| Precision | Tight tolerances, high accuracy | Prone to human error |

| Customization | Quick changes, flexible jobs | Good for unique, one-off designs |

| Initial Investment | Higher upfront costs | Lower initial costs |

Quality and Precision

We all want our car parts to fit perfectly, right? CNC machining gives you this accuracy every time. NOBLE’s CNC-machined automotive components are spot on, with tolerances as precise as ±0.005 millimetres. This level of accuracy is really important for parts like fuel injectors, gears, and brake discs.

Let’s see the main differences:

- CNC machining is really accurate and precise, so you can be sure that every part will be spot on.

- Complex shapes and exact sizes are easy for CNC machines.

- You get the same results, even for thousands of parts.

- Traditional methods aren’t great at complex designs and can make mistakes.

- Manual work can lead to errors and inconsistent quality.

NOBLE’s team of engineers conducts meticulous quality inspections on every single part. You can always expect consistently superior results, whether it’s the very first auto parts or the 10,001st.

Cost Comparison

You want to save money and get good value. CNC machining is the answer. Automation is the key to lowering labour costs and cutting mistakes. Machines work with little help, so you spend less on workers. You get more parts for your money, especially on big orders.

Here’s what you need to know:

- CNC machining is faster and more accurate. This means each part costs less.

- Automation is the key to reducing mistakes and cutting costs.

- Traditional manufacturing requires skilled workers, which naturally comes at a higher cost.

- CNC machines can run all day. This means more parts can be produced quickly.

- CNC machining is the most cost-effective way to produce large-scale projects.

NOBLE is a brilliant machining company in China. Our smart processes and skilled team will save you money and get you good quality. You get the best of both worlds, with new tech and expert service, whether it’s test parts or big orders.

Contact NOBLE for Auto Parts Machining

Why Choose NOBLE

You need a partner who really gets how auto parts are manufactured. NOBLE is a top machining company in China. We’ve got so much more to offer than just components. Here at NOBLE, we offer some of the best manufacturing and custom machining services around. Our team really gets what you need, and we’re here to help. NOBLE has worked with big brands for many years. We always stick to the industry’s strictest standards. No matter if it’s rapid prototyping or high-volume production, every project shows just how skilled our NOBLE engineers are.

NOBLE works with NOBLE Plastics to use robots and automation. This makes CNC machining even better, which is great news all round! You get parts that are spot on and always the same, which is great. NOBLE is flexible, so you can trust them for any car project. We’ve got your back, whether you’re dealing with one test part or thousands of finished parts.

Services Overview

You need help at every step of making car parts. NOBLE gives you many services for auto parts machining. And if you’re looking for something really special, you can use our advanced CNC machining and custom work to create something unique. Our team is super-careful to make sure every part is just right using smart tools.

So, let me give you a quick rundown of what NOBLE does:

| Service Offered | Description |

| CNC Machining | Makes car parts that meet hard rules. |

| Custom Laser Cutting | Cuts car parts with great care. |

| Welding | Welds metal parts to make them strong. |

| Scalable Manufacturing | Makes lots of parts for big car companies. |

| Fast Prototyping | Makes new parts quickly for testing. |

| Just-in-Time Manufacturing | Delivers parts on time to help your factory. |

You can see how NOBLE compares to other companies:

| Company | Services Offered |

| Noble Auto | Makes special parts for better car performance. |

| TurboHoses RD, Inc. | Makes parts for special cars and helps with upgrades. |

You get good results, whether you need one part or many.

Get Started

Are you ready to start your project? You can contact NOBLE and work with a trusted company in China. The steps are quite simple. You send your idea or drawing. Our team at NOBLE is here to help you choose the best service for you. We’re there for you every step of the way, chatting away and making sure you’re doing okay.

- Just send us your design or whatever you need.

- Get advice on materials and machining.

- Get a quick idea of the price and time.

- Go for it and get making those parts!

- Keep an eye on your order, and you’ll get updates on its progress until it arrives.

NOBLE’s special skills mean they can get test parts and large orders finished quickly. You get high-quality CNC-machined car parts that fit your needs.

Visit NOBLE’s official website to begin. You can have a chat with our Chief Engineer, Gavin, to find out how our work could help your automotive project.

CNC machining is great for manufacturing auto parts fast and accurately. It can make lots of different parts, like gears and lights. The parts are always the same size and shape. You can test new ideas and make real parts quickly. This is good for making cars better.CNC machining helps you try new ideas and start making parts fast.

NOBLE is a top machining company in China. We’re super careful when we make our components, and we’re really precise. When you need strong, top-notch car parts, NOBLE’s got your back. Our team is here to help you with whatever you need, and we’re always happy to offer our expert advice.

FAQ

So, what even is CNC machining, and why is it important for auto parts?

Have you ever wondered how those amazingly precise parts are shaped? Well, it’s all thanks to CNC machining, where clever computers control the tools to make it happen! This makes parts very accurate, which is great! You can always rely on the auto parts to fit perfectly every time. NOBLE is a top company in China. We make parts for big car brands with great care.

How does NOBLE ensure precision manufacturing for my project?

We love what we do, and we do love our customers. So, we make sure that every single part we deliver meets the highest standards by using only the most advanced CNC machine tools and conducting regular quality inspections. Its team is all about following the industry standards, and they use cool sensor technology to spot any problems early on.

Can I order custom machining for unique auto parts?

Yes! You can send your design or idea to NOBLE. Our friendly experts are here to help you customise the components you need for testing or upgrades. And if you need a lot of them, we can definitely help with that, too!

What materials can CNC machining handle for auto parts?

You’ll be pleased to know that aluminium, steel, and titanium are the most commonly used materials in the industry. You can also choose composites like carbon fiber. NOBLE’s CNC machining works with many materials. You get parts that are strong, light, or that handle heat well, which is great!

How fast can NOBLE deliver prototypes or production parts?

NOBLE offers fast prototyping. And the best thing is, you can get your hands on prototype parts in just a few days! And for those big orders, our super-efficient process is there to make sure everything gets to you right on time. If you need any more information, please feel free to take a look at our website, where you’ll find lots of helpful customer case studies.

Why should I choose a Chinese machining provider like NOBLE?

You’ll get expert help, good prices, and quick service. We know how important it is to get projects finished quickly, and we’re here to help! We’re so happy to say that big car brands trust NOBLE for quality and good results.

Does NOBLE have experience with electric auto parts?

Yes! We have supplied battery housings, motor components, and cooling systems for electric vehicles to our customers. Our most advanced machining technology helps you meet new regulatory requirements and achieve development goals for electric vehicles.

How does NOBLE help reduce costs in auto parts manufacturing?

Here at NOBLE, we’re always looking for ways to help you save money and reduce waste. That’s why we use smart machines and automation to make things easier for you! You save money on each part. I’m so happy to tell you that their process will help you get more value from every single project!