Think about this. You get a batch of injection parts from the molder. Each one looks flawless. The surfaces are smooth, the dimensions are perfect. They passed every quality check at the press.

Then your assembly line tries to use them. The parts don’t snap together. They require a fiddly alignment. A simple operation now needs an extra tool or a second worker. The part was made perfectly, but it’s a failure in the final product. This costly problem happens when you only think about the injection mold and the molding process. There must be a way to resolve this issue. Production can’t keep failing, but we must be prepared for it when it does. Our core philosophy is this: Design for Molding ensures that parts are manufactured correctly, and Design for Assembly ensures that parts function properly within the finished product. Mastering both simultaneously is the only way to ensure successful injection molding projects, which is why DFM and DFA have become so important.

What is a DFM Report? The Foundation of Efficient Mold Design

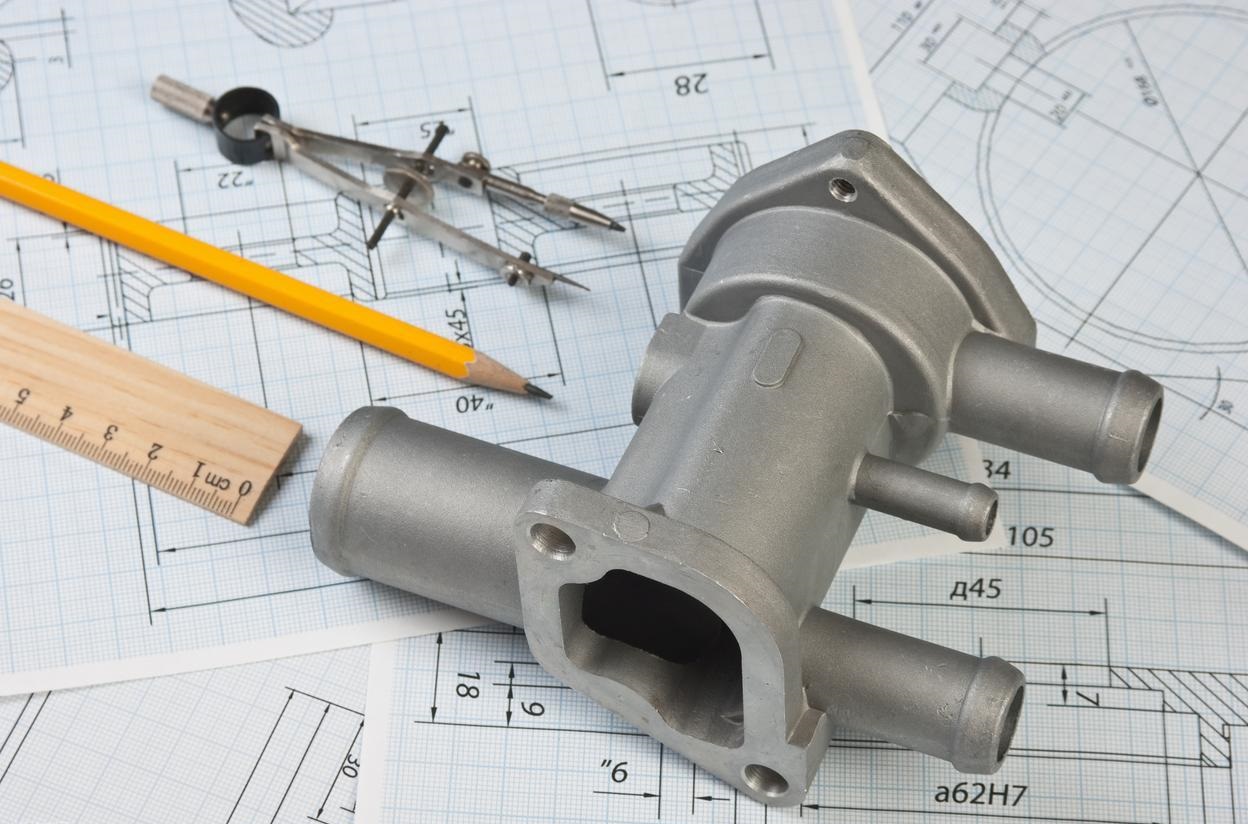

In injection molding, it means one thing: shaping the part to make the mold easier to build. The geometry of the part you design decides everything about the tool. It controls the complexity. It sets the final cost.

The goal is practical. You want a mold that is simpler. You want it to be tougher and more reliable on the production floor. Most of all, you need it to be cost-effective to make and to run. Good DFM report (Design for Manufacturing) work makes that outcome possible.

When applying the DFM report, you are really asking questions about the mold. Every answer becomes an instruction for the mold maker.

- Does the part’s shape allow for a basic two-plate mold? Or will it force the toolmaker to add complex, expensive sliders and lifters?

- Are the draft angles on the part steep enough? This isn’t just about looks. It’s an instruction for how the part will eject from the mold without getting damaged.

- Is the wall thickness uniform? This is a direct order for the mold’s internal systems. Even walls mean the plastic fills easily and cools evenly. This allows for a simpler, more efficient design of the cooling channels inside the mold.

The practical takeaway is critical. Every single DFM report suggestion you make—about a radius, a thickness, an angle—is not just a part change. It is a direct command for how the mold must be designed and built. You are writing the mold maker’s blueprint.

What is DFA? Designing for the End Product

Right, let’s take a look at the DFA report( Design for Assembly). It’s all about making a product easy to put together.

Have you ever thought about the final assembly line? The DFA report is all about designing the parts so they fit quickly and logically. You’re focusing on the person or machine doing the assembly.

The main goal is obvious. The idea is to cut the assembly time down. The idea is to reduce the total number of parts in the box. You need to bring down the labour costs. The design should make the build fast and foolproof.

- Can you combine several separate parts into one more complex molded piece? Fewer parts mean fewer assembly steps.

- Does the order of assembly make sense? An operator should not need extra tools or have to constantly reposition the product.

- Are smart features built into the parts? Things like snap-fits, guiding ramps, and alignment bosses make assembly intuitive and mistake-proof.

Here’s the crucial connection. A DFA report decision—like combining three parts into one—solves an assembly problem. But it immediately creates a new injection mold design problem. That new, more complex part now has to be manufacturable. This is where the DFM report comes back in. The mold engineer must now figure out how to build a tool that can actually make this consolidated part. The DFA report and the DFM report are in a constant dialogue. One defines the challenge, and the other must find a way to meet it.

DFM vs. DFA: A Side-by-Side Comparison for Engineers

Next, we will conduct a more intuitive side-by-side comparison. Think of DFM and DFA as two sides of the same coin: the DFM report focuses on part manufacturing, while the DFA report centres on part usage. The table below details the key areas that each one emphasises.

| Aspect | DFM (Design for Manufacturability) | DFA (Design for Assembly) |

| Primary Focus | Optimizing the part and its mold for production. | Optimizing the joining of parts into a final product. |

| Key Objective | Reduce part production cost and injection mold design complexity. | Reduce product assembly cost, time, and total part count. |

| Main Driver | Process & Mold Capability (what the injection molding machine and tool can do). | Assembly Logic & Ergonomics (how a person or robot builds it). |

The difference is clear. DFM report asks, “Can the mold make this part well and cheaply?” DFA report asks, “Can someone put this part into the product easily?” You need to answer both.

The Synergy: Where Mold Design Meets Product Design

That’s where the real challenge comes in. You might be wondering: Which is more powerful, DFM or DFA? To be honest, there’s no need to compare. The highest value isn’t just from DFM or DFA, but from where they meet. When it comes to the design and final assembly of molds, it’s important to keep these processes in mind at the same time.

Here’s a real-world example: DFA report analysis showed that three separate metal brackets and fasteners should be combined into a single plastic assembly. This solution is smart—it reduces part count while cutting assembly time.

But there are new challenges: this plastic part has really complex geometry, with chamfers and hidden features. How can it be injection molded?

This is where DFM report and injection mold design know-how are really important. Mold designers take a look at the DFA report-generated part and might use strategies like: placing the parting lines in a clever way within the mold; designing live hinge structures in the material; and planning gate locations really carefully to make sure the part is filled evenly and achieve the required strength.

At the end of the day, it’s the result that counts. With the combined analysis and recommendations of DFM and DFA, you’ll end up with a superior product. It all comes down to the dual mission of injection mold design: to produce flawless parts while ensuring they snap into place seamlessly within the final product. This makes the mold the perfect connection between parts that can be easily manufactured and assembled.

Implementing an Integrated DFM/DFA Workflow

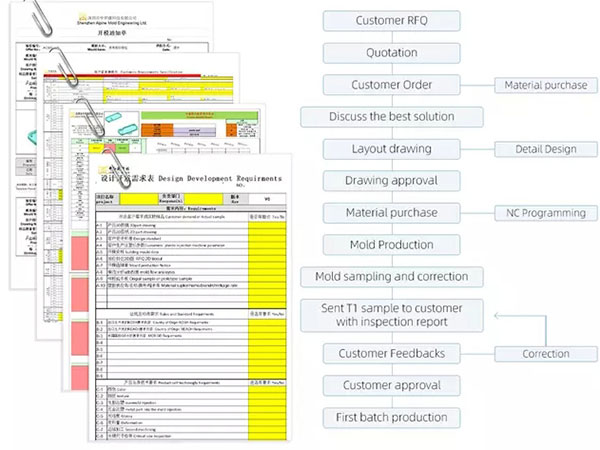

Putting this into practice requires a clear plan. You can’t just hope for synergy. You have to build it into your development process. This workflow makes the collaboration between injection mold design and product design systematic.

Step 1: Set Goals Early

Don’t begin with a CAD model. Begin with the requirements. Sit down with manufacturing and assembly managers. Define the hard targets first: how many seconds for assembly, the maximum acceptable part cost, and the required annual volume. This sets the guardrails. Every design decision that follows, from part consolidation to material choice, must serve these goals.

Step 2: Engage Cross-Functional Teams

With the goals set, form the team. This is not a handoff. The injection mold design engineer must be a core member from the first product design review. Their knowledge of tooling—what creates undercuts, what affects cooling time, what increases mold cost—is not a later constraint. It is vital for early-stage guidance. A DFA idea that creates an impossible mold is useless. Catching that early saves months.

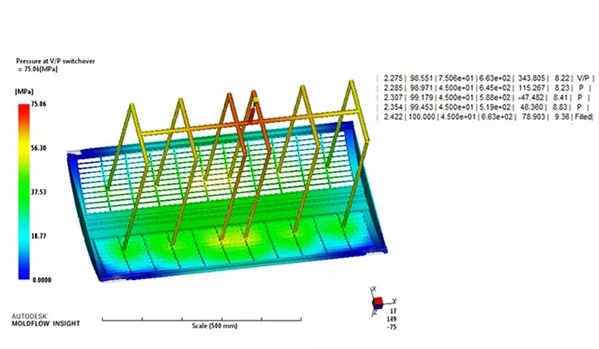

Step 3: Use Prototyping Wisely

Prototyping is your reality check, but use the right tool for the question. For manufacturability, use mold flow simulation software long before cutting metal. It will show filling issues, weld lines, and sink marks. For assembly, create simple but functional prototypes. Give them to a technician on the floor with a stopwatch. Can they assemble it intuitively, with the expected tools, in the target time? This step bridges the digital design and the physical world.

Step 4: Iterate Relentlessly

The first design will not be perfect. Feedback will come in loops. The mold feasibility study might show that a beautiful snap-fit is too risky to mold consistently. That’s not a dead end—it’s a request for a design iteration. Maybe the snap-fit needs a slight draft angle or a thicker living hinge. The updated DFA report choice then goes back to the injection mold designer for another check. This cycle continues until you find the optimal balance: a part that is excellent to mold and trivial to assemble.

Following these steps turns a theoretical concept into a concrete process. It forces the necessary conversations and creates the tangible feedback needed to build a product that is both manufacturable and easy to put together. The result is a smoother launch, fewer production headaches, and a more competitive final product.

Conclusion: Building Better Products from the Mold Up

So, what does this mean for your next product launch? The idea’s there, but it’s the execution that’ll make or break it.

Final Summary

To put it bluntly: DFM report makes sure that the injection mold design will produce a consistent, high-quality part. The DFA report is your guarantee that this part will fit perfectly into a quality, easy-to-build product. One focuses on creation, and the other on integration. You can’t have a successful outcome without both.

Powerful Takeaway

The lesson here is practical. It’s a high cost to treat injection mold design as a late-stage formality. You’ll get true optimisation – the kind that’ll shave weeks off your timeline and dollars off your unit cost – only when injection mold design is a key part of the product design process right from the start. From the outset, the designer’s vision for assembly needs to be shaped by the mold engineer’s take on how feasible it is.

Call to Action

The next step is all about getting stuck in. Next time you’re working on a project, try making a conscious shift. Have a look at every sketch and 3D model, and see them through this dual lens at the same time. But don’t go it alone. The best thing to do is to pick a manufacturing partner who can provide this analysis as part of a joined-up service. Look for a team that knows how to design molds really well and can do a thorough DFA report review. That partnership is the best way to make a better product and make sure it’s built right from the start. This is how you go from theory to results.

Contact NOBLE for Expert Mold Design & Optimization

Work together with NOBLE’s engineers to get the most out of DFM and DFA in your next injection molding project. Here at NOBLE, we’re all about taking complex product ideas and turning them into real-world solutions that are easy to put together, affordable, and easy to manufacture.

Comprehensive DFM Report Analysis

We start with your part design. Our engineers conduct a full review focused on your mold. This isn’t just a checklist. We analyze the geometry for optimal plastic flow, efficient cooling, and reliable ejection. The goal is a robust, simple mold that produces high-quality parts consistently, right from the first production run.

Strategic DFA Report Consultation

At the same time, we look at the bigger picture. We work with you to simplify the entire product. The aim is to cut part count and assembly steps. Often, this means consolidating several components into one smarter molded part. We then immediately validate that the new, more complex part through our DFM report process to ensure it’s moldable. The two reviews happen together.

Concurrent Engineering Partnership

This is our core belief. The best results come from working together early. Involve us during your initial concept phase. We’ll ensure both injection mold design principles (DFM) and assembly logic (DFA) are built into the product from the first sketches. This collaboration prevents expensive, time-consuming redesigns later and gets you to market faster.

Our Full Manufacturing Support

Our commitment doesn’t end with design advice. NOBLE provides complete manufacturing to bring your product to life.

- High-Precision Mold Manufacturing: We build the high-performance injection molds we design, using advanced machining and strict quality control.

- End-to-End Production: We handle everything from prototyping to full-scale mass production, managing the entire process.

- Secondary Operations & Assembly: We offer finishing, painting, welding, and full product assembly. You can receive units that are box-ready.

The Next Step is Simple

Ready to see how this integrated approach works for your design? Contact NOBLE for a free, initial design review and quote. Let our expertise in injection mold design, DFM, and DFA create a smoother, faster path to launching your product successfully.

FAQs

When is the best time to start a DFM/DFA review?

Try to start as early as you can. The best time to bring us on board is when you’re in the early stages of your project, like when you’re coming up with ideas or making prototypes. Early feedback lets you make big improvements that save money and boost performance. At this stage, changes are pretty straightforward. Once the design is locked, it’s expensive and slow to make changes.

If the DFA report reduces parts, does it always make the mold more expensive?

Not always. Just think about the total cost. Combining parts might mean a more complex single mold. It does away with the need for two or three other, simpler molds. Best of all, it reduces assembly labour time and complexity. We’ve crunched the numbers. Our engineers look at the total system cost—tooling, production, assembly—to find the best option. The idea is to find the lowest total cost, not just the cheapest mold.

What’s in it for me – besides the obvious benefits – when it comes to a DFM report?

You’ll get a document that’s practical, and you can actually use it. It shows you where there might be problems with the injection mold design. It gives clear recommendations for changes, often marked up directly on your drawings. It’s great because it explains the why. It shows how each change will improve part quality, simplify the injection mold design, lower tooling cost, or reduce the piece price. It’s a plan for a better, more manufacturable part.

Do you think you could help with some issues I’m having with my design?

Yes. We often do this kind of troubleshooting analysis. If you’re struggling with high scrap rates, warping, sinks, or assembly issues, we can take a look at the current part and injection mold design. We figure out what went wrong and come up with a fix, whether that’s a tweak to the design or a new mold. It’s a straightforward way to fix ongoing production issues.

How is your approach different from a standard mold shop?

We’re an engineering partner first and foremost. Usually, a standard shop will just give you a price to build the mold for your design as you sent it. Our process is a bit different. First, we’ll look at how to improve the design to create more overall value. We’re always looking for ways to save you money on the mold, on each part, and on assembly before we quote or build anything. We’re not just building your design, we’re helping you build a better one. That’s the difference with a design-led manufacturer.