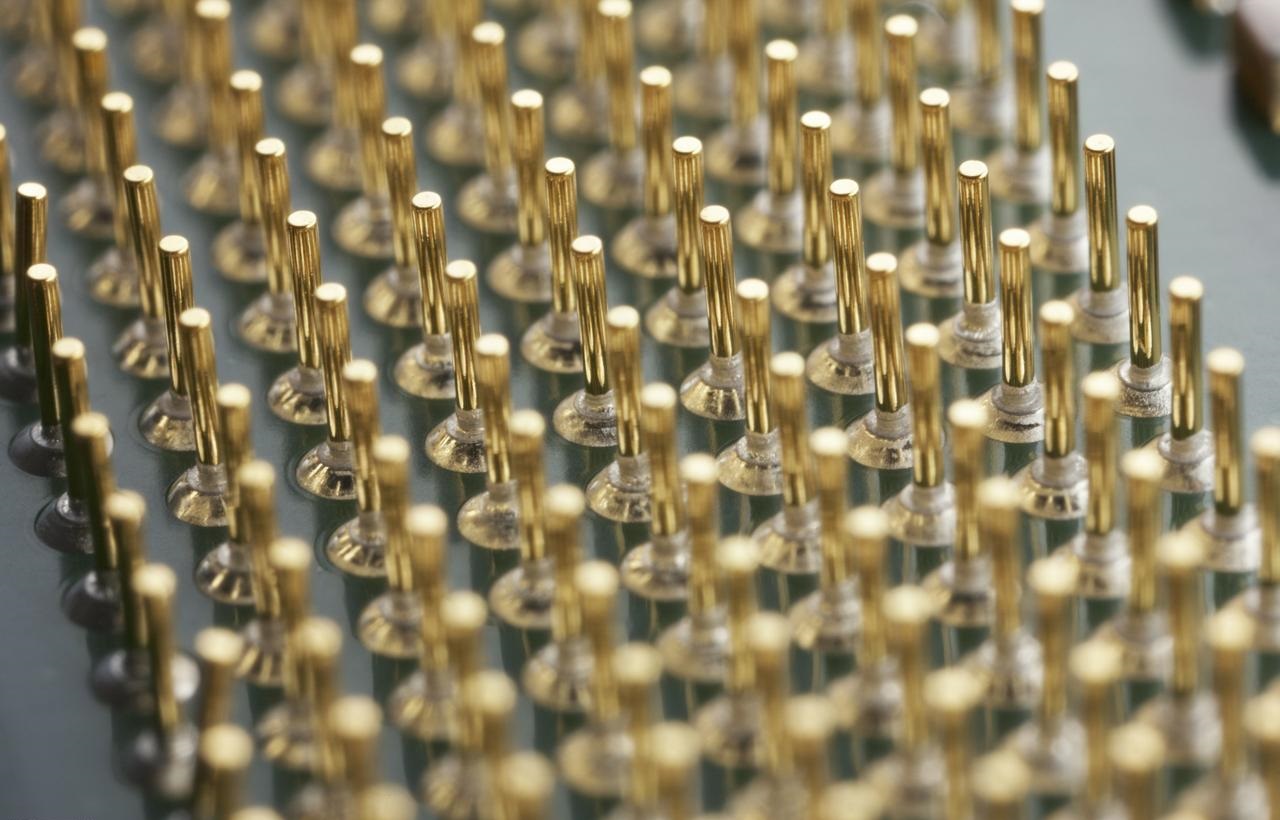

Here’s a guide to surface defects in CNC-machined brass. Brass is usually pretty easy to machine, but surface imperfections can still happen. Some flaws not only make them look bad, but can also cause them to malfunction and reduce their value. This handy guide is for anyone involved in machining, like operators, manufacturers buying parts, and quality inspectors doing checks. We look at the most common types of defect, what causes them, and how to fix them.

Why Brass Defects Occur – Material & Process Factors

The Double-Edged Sword of Machinability

Brass is well-known for being easy to machine. This is its biggest advantage. But this same thing is also the root of most surface problems. The problem is down to the brass being soft. When you’re cutting it, it can sometimes form a sort of gummy, continuous chip. When the conditions aren’t right, this soft material doesn’t cleanly shear away. Instead, it can weld itself to the cutting edge of your tool. This is known as a built-up edge. It’s basically just a small, hardened lump of brass that’s stuck to your insert. You’re no longer cutting with a sharp edge; you’re rubbing and smearing with a dull, irregular one. This can lead to surface defects. That built-up edge tears at the material instead of slicing it. It pushes and smears soft brass across the freshly machined surface, leaving behind a rough, torn finish. So, the things that make brass easy to machine also mean you’ve got to be careful with your speeds, feeds, and tool condition. If you don’t keep an eye on the process, the material will end up working against you.

The Root Cause Categories

Inherent Material Issues

The problem starts with the raw stock. This covers any defects in the brass billets or bars before they reach your machine. Things like porosity from casting, inconsistent alloy mix, or pre-existing surface scales and inclusions are worth thinking about. You can’t just machine them out; you have to stop them by using better material.

Machining Process Errors

This is the most common category. The defect is created by the cutting action itself. It’s usually down to the wrong speeds or feeds, a worn or wrong tool, poor coolant application, or unstable setup. Things like built-up edge, chatter marks, and tear-outs can happen here. The machine and the programmer are responsible.

Post-Processing & Handling Mistakes

The part was machined to a high standard, but then got damaged. This includes scratches from not handling it properly, staining from dirty cleaning solutions, or corrosion from not drying and oiling it after washing. The problem crops up when you’re away from the machine, whether it’s deburring, cleaning, or storage.

Environmental & Service Damage:

Finally, defects can also show up later, during the part’s actual life. This is tarnish or corrosion caused by moisture or chemicals. It might be worn from friction or impact during assembly. The problem isn’t with the part itself, but with the environment it’s used in.

A Troubleshooting Guide to Common Defects & Fixes

Tool Marks, Chatter, and Rough Surfaces

You’ll see that the surface isn’t smooth. You’ll see the lines from the tool path. Sometimes there’s a wavy, patterned texture. Other times, it’s just generally rough, lacking brass’s typical fine finish.

Why This Happens

It’s almost always down to the machining setup:

- Dull or wrong tools: If you’ve got the wrong tools for the job, you’re going to get a bad result. The cutting edge is rubbing, not shearing.

- Incorrect speeds/feeds: If it’s too slow, there’s a chance of rubbing; if it’s too fast, there’s a chance of vibration.

- Poor rigidity: If the tool overhangs too much or the workpiece is loose, it can vibrate and make a noise.

- Machine vibration: If the spindles are worn or the foundations are unstable, this can cause the cut to vibrate.

To Fix Existing Parts

You’ll need to do a secondary process to refinish the surface. Here are some of the most common ones:

- Vibratory Tumbling: This is great for small parts, and it’ll even out minor lines and burrs.

- Abrasive Blasting: You can use fine media like glass bead or plastic abrasive to create a uniform matte finish.

- Manual Polishing: You just need to use progressively finer abrasive pads or compounds by hand or on a wheel.

To Prevent It Next Time

The idea is to get it right as soon as it comes out of the machine.

Use sharp, dedicated tools: Ideally, they should be sharp and polished carbide inserts designed for non-ferrous metals. And whatever you do, never use a tool that’s seen better days from cutting steel.

Optimise CNC parameters: Brass likes higher surface speeds and moderate to light feed rates. This makes sure you get a clean cut every time.

Max out the rigidity: Try to make the tool holder overhang as short as you can. Make sure you’ve got good workholding equipment (like a vice with solid jaws, not just hand-tightened clamps). Make sure the machine itself is in good nick.

Porosity, Pinholes, and Inclusions

Small, random pits or holes on the machined surface. Sometimes you’ll see specks of a different, non-metallic material embedded in the brass. The crucial point is this flaw was hidden inside the raw stock; machining just cut down to it and revealed it.

Why This Happens

It’s pretty rare for this to be the machinist’s fault. It’s all down to the raw material. Porosity and pinholes are caused by gas bubbles that get trapped when the metal is first made. Inclusions are bits of slag or refractory material (like silicon oxides) from the melting process that got sealed into the billet or bar.

To Fix Existing Parts

If it’s just a cosmetic issue, you can try filling the voids with a metallic epoxy or filler, then sanding and re-polishing the area. This is a patch.

When we’re talking about a structural, pressure-bearing, or critical tolerance component, porosity usually means the part is a loss. We’ve got to get rid of it. You can’t reliably fill a hole and restore the material’s strength.

Here’s what you need to do to stop it from happening again:

We should help stop the spread of germs before the material even gets to the shop.

Source quality material: Make sure you’re buying brass from suppliers who know what they’re doing and can provide a reliable casting process.

Specify certifications: We’ll need material test reports that show the chemical composition and soundness of the material.

Take a look at the important stock: For really important jobs, it’s a good idea to think about non-destructive testing methods like ultrasonic inspection on the raw billets to find any hidden voids before you start machining.

Scratches, Dings, and Handling Damage

There might be random gouges, scuffs, or deep lines on the surface. These marks don’t follow the tool path we programmed. You might also see small dents or deformations, especially on softer brass alloys.

Why This Happens

This damage happens after the machining is done. It’s all down to contact. Things like parts knocking against each other in a bin, tools or fixtures scraping the surface during de-burring, or abrasive dust and chips being dragged across the part during handling or cleaning are all common sources.

To Fix Existing Parts

You need to remove the material around the scratch evenly. To get rid of the scratch, start with a fine-grit sandpaper, like 600 grit, and sand the area until the scratch is gone. Then, move on to finer grits (800, 1000, 1500, 2000) to get rid of the sanding marks. Then, to polish it off, just use a brass compound on a soft wheel or cloth to restore the shine.

To Prevent It Next Time

Change your handling protocol. Make sure you have a clean handling procedure where finished parts never touch. You can use protective films, soft foam padding, or individual slots in trays. Make sure you’ve got containers for machined parts that are clean and specific, and keep them separate from raw stock or deburring areas. Just be careful and treat the finished surface as fragile from the moment it comes off the machine.

Staining, Discoloration, and Tarnishing

The brass will lose its shine. You might see localised water spots or blotches, smudges from fingerprints that have etched into the surface, or an overall dulling and darkening of the material, changing its colour from bright gold to muted brown or black.

Why This Happens

This is a chemical reaction, not a mechanical one. Moisture and acids are the main causes. Just a heads-up: water from coolant or washing can leave mineral spots on surfaces when it dries. The oils and acids in our skin will attack the brass, leaving permanent fingerprint marks. Over time, exposure to oxygen and moisture in the air causes a gradual, uniform oxidation—this is what gives old brass its tarnished look.

To Fix Existing Parts

For fingerprints or water spots, use a chemical cleaner designed for brass. For mild tarnish, you can use a homemade solution of diluted white vinegar or lemon juice. Just apply it, gently rub the area, then rinse it thoroughly with clean water straight away. Make sure you dry it off completely with compressed air or a soft cloth. You’ll usually need to polish it to restore the shine, as the cleaning process can make the surface matte.

To Prevent It Next Time

Keep an eye on the environment and how it’s being handled. Make sure you give the parts a really good clean and dry them off properly as soon as you’re done machining. If you’re storing or displaying parts, apply a clear protective coating. For a warm luster, try a paste wax, or for a durable, hands-off barrier, use a clear lacquer. It’s really important to get into the habit of wearing clean, lint-free cotton or nitrile gloves whenever you’re handling machined brass. This stops fingerprints before they start.

Stress Corrosion Cracking (SCC) and Dezincification

This is a serious problem. You might see a network of very fine, branching cracks, like tiny lightning bolts, on the surface. That’s Stress Corrosion Cracking. When it comes to dezincification, the surface looks kind of spongy and porous, and sometimes you can see a reddish copper colour through it, like the zinc has been leached out of the brass alloy.

Why This Happens

Both are failures caused by the wrong environment. They need a certain mix of things to happen: the part needs to be under internal tensile stress (often from bending, forming, or even tight assembly), and it needs to be exposed to a corrosive agent. For SCC, ammonia or water with high chlorides are common agent. Stagnant water with low pH or high oxygen content is usually what you’re dealing with when it comes to dezincification. The material and the environment just don’t mix.

To Fix Existing Parts

These are usually pretty disastrous. If a part’s got visible stress cracks or severe dezincification, there’s no reliable repair for use. You can’t restore the material’s integrity by filling or welding it. The defective part needs to be scrapped and replaced.

To Prevent It Next Time

Prevention is all about thinking ahead when it comes to choosing materials and processes.

Keep stress under control: If you’re dealing with parts that are going to be bent or put under a lot of stress, it’s best to use brass that’s been professionally stress-relieved after machining.

Choose the Right Alloy: Make sure you match the brass to the final environment. For example, use arsenical Admiralty brass (C44300) or other inhibited alloys for parts that are exposed to water, as they resist dezincification.

Apply a Barrier: If you can’t avoid the environment, make sure you apply a high-quality protective coating, like a proper electroplated layer or a durable industrial paint, to completely isolate the brass from the corrosive agent.

Building a Defect-Prevention Workflow

You need a system to stop defects. A good workflow catches problems before they happen, not after. Here’s a practical, three-part system for any shop running brass.

The Pre-Machining Checklist

Just a heads-up: don’t start the spindle until you’ve checked three things. First things first, let’s take a look at the raw material. Keep an eye out for obvious scale, deep scratches, or discolouration on the stock. Next, make sure your tools are all good to go. You’ve got to be sharp and dedicated when it comes to non-ferrous metals, so don’t even think about using a tool that’s been worn down on steel. Thirdly, you need to check that the machine is stable. Make sure the vise or fixture is tight, the tool holder isn’t overhanging too much, and there’s no excessive play in the spindle. It’ll save you hours of rework.

In-Process Best Practices

While the job is running, just control the variables. Use a clean cutting fluid designed for brass or aluminium; old, contaminated coolant can stain. Make sure you use an air blast or enough coolant to get rid of the chips so they don’t get recut and scratch the surface. Most importantly, don’t set it and forget it. Just do a regular quality check on the first part, and then do spot-checks on parts as you go through the process. Keep an eye on the parameters early on.

Post-Machining Protocol

The part’s most vulnerable right after machining. Set up a strict protocol. Give the parts a quick clean to get rid of all the coolant and chips. Then dry them completely with compressed air. Then, handle them with care – use gloves, protective foam, or individual slots. And whatever you do, don’t throw finished parts into a bin together. Then, just choose the right final step for the part’s job. You might find that a simple vibratory tumble is enough to get the job done. Any decorative piece needs a good polish and a protective wax or lacquer. Sometimes, all an industrial component needs is a bit of anti-tarnish oil. Make sure the finish matches the function every time.

Conclusion: The Path to Flawless Brass

If you want to machine flawless brass, you need both science and discipline. The key to success is choosing the right alloy, setting precise speeds and feeds, and using sharp tools. The way you work is all about discipline and craftsmanship—how you handle the parts, maintain your machines, and follow each step without cutting corners.

Remember, the time you spend preventing a defect is an investment. The time spent fixing one is just pure cost. Reworking can waste material, labour, and machine time. It’s better to prevent problems than to deal with them after they’ve happened.

The last step is to make this systematic. Don’t just react to problems. So, go ahead and build the checklists and protocols we talked about into your standard operating procedure. When something goes wrong, use a logical process to find the root cause. Was it the material, the machining, the handling, or the environment? Just fix the system, not just the part. That’s how you get brass components that are always top-notch.

From Design to Perfection: Let NOBLE Machines Your Brass Projects

You’ve seen what it takes to get brass machining right. It demands knowledge, the right equipment, and tight control over every step. For a critical project where quality cannot be compromised, partnering with a specialist is the surest way to turn your design into a perfect part.

At NOBLE, we specialize in high-precision CNC machining for brass and non-ferrous metals. We take your design and execute it with the specific techniques and attention this material demands, delivering finished components that meet the exact standard you require.

Our Services for Brass Machining

- Precision CNC Machining: We’ve got advanced CNC mills and lathes that are programmed for non-ferrous materials. This covers everything from complex one-off prototypes to full-scale production runs. We’re all about making sure everything we do is accurate and consistent, every single time.

- Expert Surface Finishing: We’ll take care of the post-processing for you. This includes tumbling for uniform deburring, polishing for a mirror shine, abrasive blasting for a consistent matte texture, and applying protective coatings like lacquer, powder coating, or plating. We match the finish to the part’s function and aesthetic needs.

- Design for Manufacturability (DFM) Support: We don’t just build to print, we build to last. Our engineers can do DFM analysis for your brass designs. We spot potential problems early on and suggest practical changes to improve how easy the machine is to use, reduce costs, and make sure the surface quality is top-notch right from the first cut. We’ll help you design for success.

Ready to Start Your Project?

Check out our website, get an instant quote, see what we can do, or talk to our engineering team about how we can make your brass components with precision and care.

FAQ

Do you know if you can buff out any scratches on brass?

Yeah, just a few little scratches on the surface. You can often buff them out with a compound. Deep gouges are a whole other story. They usually need sanding first to level the material, which removes metal and can change the part’s critical dimensions.

What’s the best way to get brass surfaces clean before putting a transparent coating on?

The surface has to be totally clean and activated properly. First things first, get rid of all the grease using a solvent-based degreaser. Then, use a weak acid immersion method to get rid of any oxidation layers and trace contaminants. Make sure you rinse it thoroughly with deionized water to get rid of any water spot residue. Then, make sure it’s completely dry by heating it or using clean, dry air. You’ve got to be really careful with this process; any residue left behind will cause the coating to fail.

Does all brass eventually tarnish? Any ideas on how to stop it?

Yeah, all uncoated brass will tarnish; it’s just a natural chemical reaction with the air. If you want to stop it for good, you’ll need to seal it. Just apply a top-quality, clear automotive or marine-grade lacquer over a surface that’s been cleaned and prepared really well. This creates a barrier that oxygen and moisture can’t get through.

I was wondering if you know if small pores in a cast brass part are a sign of low quality?

Not always. There might be a bit of minor internal porosity that’s just part of the casting process. But if you can see or feel excessively porous surfaces, it usually means the casting process wasn’t controlled well. This porosity can act as a stress concentrator and significantly weaken the part, so it’s a real quality concern.

What’s the first thing I should check if I’m getting bad tool marks on every part?

Make sure your tools are sharp, and your rig is set up properly. It’s usually a dull tool that’s causing the problem. Just swap in a fresh, sharp insert. Next, make sure everything’s tight – shorten the tool overhang, check the workpiece is clamped securely, and make sure the machine itself isn’t vibrating too much. If you’ve got a loose setup, you’re going to get marks on the surface, no matter how sharp the tool is.