What is Extrusion Molding?

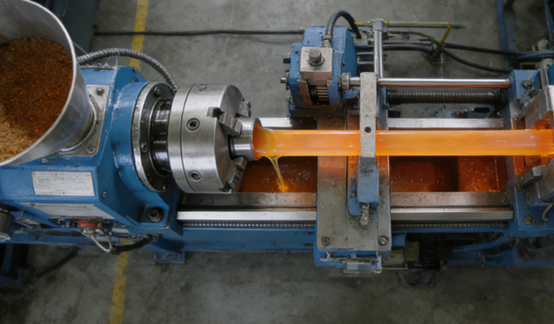

Extrusion molding is an efficient and widely applied manufacturing process. The core principle is to feed the heated, softened, or molten raw materials into the machine hopper. The material is strongly pushed forward in the extruder barrel by the rotating screw. During this process, due to the heat generated by external heating and screw shearing, the material is completely plasticized and melted.

The uniform melt is forced to pass through a mold with a specific opening shape under the pressure of the screw. The material continuously extruded from the die head acquires a fixed cross-sectional shape consistent with the die opening, just like toothpaste being extruded from a toothpaste tube. The extruded profiles are cooled and shaped, then straightened by a traction device and cut to the required length, ultimately obtaining continuous products with fixed cross-sectional shapes.

How Does Extrusion Molding Work?

Add Materials

Plastic pellets or powder are fed into the hopper of the extruder and continuously and stably supplied into the extruder barrel. Under the effect of gravity, the raw materials fall into the barrel and are captured by a rotating screw. The rotation of the screw not only conveys the material forward but also begins to compress and preheat it initially, preparing for the subsequent melting stage.

Melting the Material

When the material is pushed forward in the barrel by the screw, it undergoes intense heating and shearing effects. The heat comes from the electric heating coils wrapped around the outside of the barrel, which heat the barrel to a precise temperature above the melting point of the material.

The material itself is subjected to tremendous shear force and frictional force between the tight screw threads and the barrel wall. These mechanical energies are converted into heat, causing the material to melt thoroughly and uniformly from the inside into a viscous fluid. This process is called “plasticizing”.

Pressurization

The molten material is rapidly compressed under the pressure of the screw. The purpose of this step is to eliminate bubbles in the melt, mix any pigments or additives that may exist, and ensure that the viscosity, temperature, and pressure of the melt reach a completely uniform and stable state before passing through the mold, laying the foundation for high-quality extrusion.

Shaping

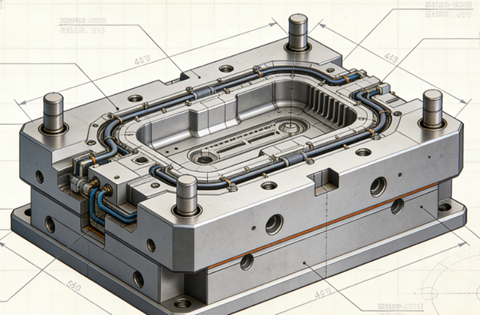

The fully homogenized high-temperature melt is forced through the mold installed at the front end of the barrel under the powerful pressure continuously applied by the screw. The internal flow channels of the mold have been precisely designed and polished, and the shape of their openings determines the cross-sectional profile of the final product.

Whether it is a circular tube, a complex hollow profile, or a flat sheet, when the melt flows through the mold, it will precisely present the shape of the inner hole of the mold, completing the transformation from an amorphous melt to a specific profile.

Cooling

The profiles extruded from the mold must be cooled and solidified immediately. Depending on the product, the cooling methods vary: pipes or profiles are often cooled through water tanks filled with cold water; Sheet materials may use a set of cold rolls.

The cooling system must be efficient and uniform to ensure that the product takes shape quickly, prevent it from sagging or twisting, and lock in its precise dimensions and shape.

Cutting

Once the profile cools and solidifies, it needs to be pulled away from the mold opening at a constant speed, and this task is accomplished by a traction device.

Traction devices are usually one or more pairs of tracks or rollers, which gently but firmly hold the product and provide a smooth pulling force. This pulling force must be perfectly synchronized with the extrusion speed of the screw to prevent product accumulation or excessive stretching. Finally, the continuously extruded products are sent to the cutting station, where they are automatically cut by saw blades or cutting machines according to the preset length to obtain the final finished products.

What Are the Common Materials Used in Extrusion Molding?

Polyethylene (PE)

Polyethylene is one of the most commonly used extruded plastics, mainly divided into high-density polyethylene and low-density polyethylene.

High-density polyethylene has high strength and chemical resistance, and is often used in the production of water pipes, gas pipes, and large containers. Low-density polyethylene is softer and more transparent, and is often used to make films, plastic bags, and wire insulation layers. Its excellent fluidity and machining stability make it highly suitable for high-speed extrusion production.

Polyvinyl Chloride (PVC)

Polyvinyl chloride is a multifunctional material, and its hardness can be adjusted through additives.

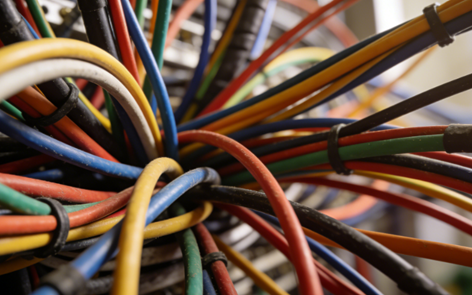

Rigid polyvinyl chloride is of high strength and corrosion resistance, and is widely used in door and window profiles, pipes,s and floors in the construction industry. Soft polyvinyl chloride is flexible and is often used in wire and cable sheaths, hoses,s and waterproof membranes.

Polyvinyl chloride requires precise temperature control during machining to prevent decomposition and the production of harmful gases.

Polypropylene (PP)

Polypropylene has excellent heat resistance and chemical stability, and its density is relatively low. It is often used to manufacture food packaging containers, automotive parts, and household items such as storage boxes and tableware.

The extrusion process of polypropylene requires a relatively high melt temperature, but its shrinkage rate is relatively high. Therefore, special attention should be paid to dimensional stability and deformation control during the cooling and shaping stage.

Polystyrene (PS)

Polystyrene is divided into general-purpose polystyrene and high-impact polystyrene. General-purpose polystyrene is transparent and relatively brittle, and is often used to make disposable tableware, CD cases, and display stands. High-impact polystyrene, due to its enhanced toughness, is often used as the inner lining of refrigerators and the outer shell of toys.

When extruding polystyrene, it should be noted that its melt strength is relatively low and it is not suitable for the production of thick-walled or complex hollow profiles.

Acrylonitrile Butadiene Styrene (ABS)

ABS resin combines strength, toughness, and surface gloss, and is an engineering plastic. It is widely used in automotive parts such as instrument panels, household appliance casings, and Lego bricks.

When ABS is extruded, the drying conditions need to be strictly controlled because of its strong hygroscopicity. Residual moisture can cause bubbles or silver streaks on the product surface during machining, affecting the quality of the finished product.

Thermoplastic Elastomers (TPE)

Thermoplastic elastomers possess the elasticity of rubber and the processability of plastic, and can be formed by extrusion without vulcanization. It is commonly used in sealing strips, hoses, grips, and sports equipment.

Thermoplastic elastomer materials are sensitive to temperature during extrusion. Excessively high temperatures can lead to degradation, while excessively low temperatures can affect fluidity. Therefore, an accurate temperature control system is required to ensure product performance.

What Are the Advantages of Extrusion Molding?

High Efficiency

Extrusion molding can achieve continuous production for 24 hours without interruption. The entire process from raw material input to the final product cutting is fully automated, with extremely high production efficiency. It is particularly suitable for manufacturing long-sized profiles, pipes, plates, etc. Unlike injection molding, it does not need to go through repeated mold opening and closing cycles. Therefore, the output per unit time of extrusion molding is large, making it suitable for the production of large-scale standardized products.

Low Production Cost

Extrusion molding is a continuous process with a high production speed, which reduces the unit consumption of equipment and energy. The mold structure is relatively simple, and the mold cost is much lower than that of injection molding and other processes. Meanwhile, the utilization rate of raw materials is high, and waste materials can be crushed and directly recycled and reused, further reducing material costs.

High Shape Flexibility

Extrusion molding can produce various complex and constant cross-section continuous profiles, such as hollow, multi-cavity, and special-shaped profiles, by changing different mold orifice types. The thickness, width, and shape of the product only need to be adjusted according to the mold and subsequent auxiliary machines, which is highly flexible.

Broad Material Compatibility

Extrusion molding applies to the vast majority of thermoplastics and can also be used for some thermosetting plastics, rubber, food raw materials, metals, etc. By adjusting the process parameters, materials with different rheological properties can be adapted.

Consistent Product Quality

Extrusion molding can produce products with highly consistent dimensions and physical properties along the length direction under stable process conditions. During the extrusion process, the melt undergoes thorough mixing, compression, and homogenization, resulting in a dense internal structure of the product, no seams, and reliable performance.

High Process Integration

The extrusion molding production line can conveniently integrate multiple subsequent processes to achieve “one-line molding”. For instance, during extrusion, online printing, embossing, and lamination can be carried out simultaneously, or it can be directly connected to downstream forming and welding equipment, reducing the need for intermediate links and secondary machining.

Limitations and Challenges of the Extrusion Molding

Product Shape Limitations

Extrusion molding can essentially only produce continuous profiles with constant cross-sectional shapes. It is unable to manufacture products with cross-sectional changes in the length direction or with complex three-dimensional structures. This type of product relies on other processes, such as injection molding.

Dimensional Accuracy Challenges

The material undergoes thermal expansion and contraction from the molten state to cooling and shaping, and is affected by multiple factors such as cooling uniformity and traction stability. It is highly challenging to maintain high-dimensional accuracy and shape stability of the product along the entire length direction, and the requirements for process control and mold design are extremely strict.

High Material Requirements

Extrusion molding has certain requirements for the thermal stability, melt strength, and fluidity of materials. For instance, some materials that are sensitive to high temperatures may degrade while remaining in the barrel. Materials with low melt strength may fail to maintain their shape after leaving the mold and are prone to sagging or breaking.

Initial Investment

Although the cost of a single set of molds in extrusion molding is relatively low, the total initial investment for a complete extrusion production line is relatively high. In addition, every time a product or mold is changed, time-consuming process parameter adjustments and material waste are required, making small-batch production not economically viable.

High Process Control Complexity

Extrusion is a continuous dynamic equilibrium process. Numerous parameters such as temperature, pressure and screw speed are interrelated and need to be precisely coordinated. Even the slightest fluctuation in any parameter may affect the size, appearance, or mechanical properties of the final product, which places high demands on the experience of the operators and the requirements of the automatic control system.

Surface Quality

The surface of extruded products is prone to defects such as flow marks, wavy patterns, and uneven gloss. These defects are usually related to the design of the mold runner, melt fracture, uneven cooling, or the inherent properties of the material. Obtaining high-quality surfaces requires extremely precise mold machining and process control.

Extrusion Molding vs Injection Molding

| Aspect | Extrusion Molding | Injection Molding |

| Process Principle | Continuously pushes melted material through a die to form a constant cross-sectional profile. | Injects melted material into a closed mold cavity, then cools to form a discrete part. |

| Tooling (Mold/Die) | Relatively simple die; lower cost. | Complex, two-part mold; higher cost. |

| Production Efficiency | High for long, uniform products; continuous operation. | High for mass production of identical parts; cyclic operation. |

| Material Flexibility | Suitable for a wide range of thermoplastics and some other materials. | Very wide range of thermoplastics, thermosets, and elastomers. |

| Design Flexibility | Limited to constant cross-sections. | High; can produce complex 3D shapes, undercuts, and fine details. |

| Initial Investment | Lower tooling cost, but the full line can be significant. | Higher mold cost, but per-part cost drops at high volumes. |

| Typical Applications | Pipes, window profiles, films, rods, sheets. | Electronic housings, automotive parts, toys, and bottle caps. |

Maintenance Tips for Extrusion Machinery

Regular Cleaning

After each machine shutdown or material change, the hopper, screw, and barrel must be thoroughly cleaned to prevent material residue and carbonization. Especially after machining heat-sensitive materials such as PVC, immediate cleaning is required. The mold runner should be cleaned with a dedicated copper brush or soft tool to avoid scratches. The dust on the heating coil and cooling fan also needs to be cleaned regularly to ensure the heat dissipation efficiency.

Temperature Control

Calibrate the thermocouples and heaters in each temperature zone every month to ensure that the actual temperature is consistent with the displayed value. Check the tightness of the heating coil to prevent local overheating due to poor contact. The cooling water channel must be kept unobstructed. The filter should be cleaned regularly to prevent scale from affecting the cooling efficiency.

Maintenance of Lubrication System

Change the lubricating oil of the reducer on time and check the oil level every day. Apply the specified type of grease to moving parts such as bearings and guide rails at the prescribed intervals. Regularly check the tension and alignment of the belt or coupling to prevent abnormal vibration.

Safety Checks

Regularly check whether the motor current is stable, clean the dust in the electrical cabinet, and tighten the terminal blocks. Test whether the emergency stop button, safety door switch, overload protection, and other safety devices are reliable and effective to ensure they meet the requirements of safe production.

Mold Storage

After the machine is shut down and the mold is removed, the residual molten material in the machine should be immediately removed, anti-rust treatment should be carried out, and it should be stored in a dry and constant-temperature dedicated rack. Before reinstallation, check the heating rod and the surface of the flow channel to ensure there is no damage or rust spots.

Applications of Extrusion Molding

Construction

A large number of plastic profiles used in construction, such as door and window profiles and decorative lines, are formed by extrusion. Complex cross-sectional structures can be obtained through mold design, meeting the requirements of strength, heat insulation, and aesthetics. The extrusion process also supports multi-chamber structures and co-extrusion technology, which helps to reduce material usage and enhance overall performance.

Wires and Cables

In the manufacturing of wires and cables, extrusion molding is used to cover insulating layers or sheaths around metal conductors, such as materials like PVC, XLPE, and TPU. This process can achieve continuous and uniform coating, ensuring stable electrical performance. It also features wear resistance, flame retardancy, and resistance to environmental aging, making it a key process in the fields of power, communication, and automotive wiring harnesses.

Medical Industry

Disposable or long-term medical consumables, such as infusion tubes and breathing tubes, are often manufactured by extrusion molding. This process can ensure high consistency in inner diameter and wall thickness, meet strict hygiene and biocompatibility requirements, and is suitable for continuous production in clean environments.

Plastic Pipe

One of the most typical applications of extrusion molding is various plastic pipes, such as PVC and PP pipes, which are widely used in water supply and drainage, gas transmission, agricultural irrigation, and power and communication protection. This process can continuously produce long-sized pipes with uniform wall thickness, stable dimensions, high production efficiency, and is convenient to meet different usage requirements, such as pressure resistance, corrosion resistance, and aging resistance, through formula adjustment.

NOBLE’s Extrusion Molding Services

Welcome to NOBLE, your trusted partner for precision extrusion molding solutions. We specialize in transforming raw plastic resins into high-performance, continuous profiles that meet the exacting demands of diverse industries.

Key Capabilities & Strengths:

- Wide Material Expertise: We process a broad range of thermoplastics, including PVC, PE, PP, ABS, PS, TPE, and engineering grades.

- Custom Profile Design: We excel at producing complex custom profiles, from simple tubes and rods to multi-chamber hollow designs.

- Full-Scale Production: We support projects ranging from prototyping to small-batch production.

- Precision & Consistency: Our controlled process and strict quality checks ensure every meter of your profile meets precise specifications for dimensions, strength, and finish.

- Value-Added Services: We offer secondary operations like cutting, drilling, punching, printing, and assembly to deliver finished components.

FAQ

What are the main types of extrusion dies?

A pipe/pipe die forms hollow tubes, using a mandrel to create the inner diameter. A flat sheet die produces wide, thin sheets with a wide, slit-like opening. A profile die has a complex opening to manufacture custom shapes like window frames or decking. A wire coating die applies a concentric layer of insulation directly onto a moving wire core. A blown film die is an upright cylinder with a circular opening used to make plastic film.

What materials are extrusion dies typically made from?

Dies are made from high-strength, wear-resistant metals to withstand high pressure, temperature, and abrasive plastics. Common materials include tool steels for general use, stainless steel for corrosion resistance with certain materials, and hardened alloys. Critical surfaces are often chrome-plated or nitrided to enhance hardness, reduce friction, and prevent material adhesion, ensuring a smooth product surface and longer die life.

What are common maintenance practices for extrusion dies?

Applying protective anti-corrosion coatings before storage prevents rust. Regular inspection for wear, scratches, or corrosion on critical surfaces is necessary. Dies should be stored in a dry, controlled environment. Proper handling prevents nicks or dents in the precise

How long does an extrusion die typically last?

The lifespan varies greatly based on the material processed, production volume, maintenance quality, and the die material itself. A well-maintained die processing non-abrasive resins like LDPE or HDPE can last for many years, even decades, of continuous production. Processing abrasive materials like wood-plastic composites (WPC) or certain PVC compounds can significantly reduce this lifespan, requiring refurbishment or replacement much sooner.

What are “die lines” and how can they be minimized?

Die lines are subtle, continuous vertical lines or marks on the extruded product’s surface, running in the machine direction. They are often caused by minor scratches, imperfections, or built-up residue on the die lip or land area. To minimize them, ensure the die is meticulously cleaned and polished.