Surface treatment is often the final, critical step. It’s not just about looks. You use it to make parts stick better in an assembly, or to completely stop rust and corrosion. Metal treatments are used the most. They have over 60% of the market. This is common in cars and factories. Plastics are used more and more in electronics and medical tools. Plasma treatment or resin precoating can make things stick up to 57% better. Let’s compare the common methods.

| Method | Adhesion Strength | Improvement |

| Titanate Coupling | 39.56 MPa | +50% |

| Plasma Treatment | +50% | N/A |

| Resin Precoating | +57% | N/A |

You’ll see this everywhere in manufacturing. They are used in custom machining for making things exactly right. A medical tool or a critical car component isn’t finished when it comes off the mill or lathe. It almost always gets a surface treatment.

Why Surface Treatment Is Important

Adhesion and Corrosion Protection

The entire point of surface treatment is performance and longevity. It doesn’t change the part’s core strength. Instead, it modifies the behavior of the very outer layer of plastic or metal. The atoms on the surface act differently from inside. This lets paint, glue, or coatings stick better. Plasma treatment can change the top layer of plastic. This creates a surface that glue can truly grip. The key advantage is that you don’t need aggressive, hazardous chemical baths. It’s a cleaner, safer process.

Let’s see how treatments help:

| Treatment Type | Effect on Adhesion | Effect on Corrosion Resistance |

| Plasma Treatment | No need for chemical primers | Makes metal less likely to rust by cleaning and activating the surface |

| Green Surface Coatings | Not explained in detail | Helps stop rust by covering the metal surface |

You find these benefits in machine shops and factories. For a material like aluminum, Chemical etching or plasma treatment actively changes the metal’s surface on a microscopic level. This process creates a texture or activates the surface chemistry. It’s like giving the material a better grip. This is important for custom medical parts. It turns a simple assembly into a secure, permanent connection.

Durability and Performance

The function goes far beyond just adhesion. Surface treatment is fundamentally about enhancing performance and extending lifespan. In precision work, a part needs to survive in the real world. You need it to resist wear. You must prevent rust. Processes like anodizing or powder coating build a protective shield right onto the part. This barrier actively blocks water, oxygen, and corrosive chemicals.

- Corrosion resistance is critical. It stops a part from degrading when exposed to harsh environments—inside an engine, or in a sterile medical washdown.

- Better adhesion is a foundational result. It ensures that any paint or final coating bonds permanently. Nothing peels or cracks.

- More durability helps parts handle heavy use, like in cars or hospitals. Treating the surface makes parts harder and less likely to wear out. This is vital in demanding applications, from automotive suspensions to reusable surgical instruments.

Finally, treatments often increase surface hardness. This directly reduces wear and tear. That is why car and medical companies use these methods. Parts simply last longer under stress.

Industrial Applications

Surface treatment is used in many industries. You’ll find it’s used in factories for car parts, medical tools, and electronics. Here’s what it does:

| Benefit | Description |

| Extended Component Lifespan | Makes surfaces stronger, so parts need less fixing and work better. |

| Improved Corrosion Resistance | Stops rust and keeps parts safe in tough places. |

| Enhanced Wear Resistance | Cuts down on friction and wear, so machines work longer. |

| Increased Energy Efficiency | Keeps materials strong, so machines use less energy over time. |

| Sustainability and Compliance | Uses eco-friendly choices, so there is less pollution and waste. |

You see the benefits in the parts themselves. In both standard CNC work and custom machining, for plastics and metals. Look at anodized aluminum on a car. It’s not just for a sleek look. That layer protects the metal underneath. It keeps the part functioning correctly and looking new for years.

Now, go into a hospital. The coatings on surgical tools aren’t optional. They create a surface that is safe for patients and can withstand repeated, aggressive sterilization. They make the tools easy to clean thoroughly.

Surface Treatment Methods Overview

The surface is the final frontier for performance. Whether you’re working with plastic or metal, you have options to change it. Each surface treatment method helps you get better results in CNC machining or in a factory. Let’s break down the common techniques. This will help you match the method to your needs on the shop floor.

Plastics Techniques

Plastics are everywhere — in medical devices, automotive interiors, and electronic housings. But often, the raw plastic surface isn’t ready. It’s too smooth or chemically inert. You need to treat it to add strength, enable bonding, or ensure a coating will last.

Flame Treatment

We pass the plastic part through a precise, controlled flame. This does two things. It burns off any microscopic contaminants. More importantly, it oxidizes the surface layer, making it chemically active. This new surface grips glue and paint far better. It’s a very fast process for large, simple parts. Factories use it for high-volume items like car bumpers or interior panels.

Plasma Treatment

The plasma thoroughly cleans the surface at a molecular level and also activates it. It’s a one-step cleaning and preparation process. The result is an exceptionally clean, bond-ready surface. Plasma treatment is common for medical tools and electronics.

Corona Treatment

Corona treatment uses high-voltage electricity to change the surface. This discharge changes the surface energy. It makes notoriously hard-to-bond plastics — like polypropylene (PP) or polyethylene (PE) — receptive to inks, paints, and adhesives. These are used in packaging and cars.

Chemical Etching

You dip the plastic in a chemical bath. The chemicals make the surface rougher. It’s used when you need an extremely strong, durable bond, such as for permanent medical implants or structural aerospace components.

Acrylic Binder Coating

You put a thin layer of acrylic binder on the plastic. It creates a consistent, adhesive-friendly surface on top of problematic plastics. It’s a practical solution for getting paint or glue to stick reliably to tricky materials without changing the bulk plastic’s properties.

| Technique | Effectiveness | Applications |

| Corona Treatment | Changes how the surface sticks, helps with bonding or printing | Polypropylene, polyethylene, packaging, automotive |

| Flame Treatment | Cleans surfaces with dirt | Large surfaces, high production rates, automotive, medical |

| Plasma Treatment | Makes surfaces ready for glue or coatings | Medical tools, electronics, precision manufacturing |

Metals Techniques

Metals almost always require a finish. The goals are clear: prevent corrosion, improve appearance, and create a surface that holds coatings permanently. Here are the main ones you will see in factories or custom machining.

Electroplating

You cover the metal with a thin layer of another metal using electricity. It provides a shiny, decorative finish and excellent corrosion resistance. You see it on automotive trim and surgical instruments that need a smooth, cleanable surface.

Powder Coating

A dry, powdered polymer is sprayed onto the electrically grounded metal part. The piece is then baked. The powder melts and cures into a uniform, thick, and extremely durable layer. It resists chipping, scratching, and fading. It’s the go-to for car frames, agricultural equipment, and industrial machinery housings.

Anodizing

You use electricity to make a protective layer on metals like aluminum. This grows a thick, hard, porous oxide layer from the metal itself. The result is superior corrosion resistance, increased surface hardness, and lasting color. It’s essential for automotive components and consumer electronics.

Phosphating

You dip the metal in a phosphate solution. It acts as a superb base for paint or oil, improving adhesion and adding a secondary layer of rust prevention. Factories use phosphating before painting cars or machines.

Passivation

You treat stainless steel with acid to remove iron. This restores the steel’s natural chromium-oxide layer, maximizing its innate corrosion resistance. Passivation is used for medical tools and food equipment.

Electroless Plating

This is a chemical process, not an electrical one. A nickel-phosphorus alloy is deposited evenly across the part through an autocatalytic reaction. The coating is uniform, even on complex geometries with deep holes or internal surfaces. It is good for complex shapes in precision manufacturing.

| Surface Treatment Method | Advantages | Limitations |

| Electroplating | Stops rust, conducts electricity, looks nice | Not for all materials, needs careful waste handling |

| Powder Coating | Good for the environment, tough, does not chip | Costs more to set up, not for very thin coatings |

| Anodizing | Hard, stops rust, looks good | Only for some metals can a scratch |

| Plasma Treatment | Helps glue stick, works on many materials | Needs special tools and skills |

Factories also use other methods like laser cleaning, abrasive blasting, and chemical etching. Your choice is driven by the metal, the part’s function, and the environment it must survive. Each method is a tool to ensure the part performs as designed for its entire lifespan.

Flame Surface Treatment

Process Overview

Flame treatment is a direct, physical process. You pass the part—plastic or sometimes metal—through a precise, controlled flame. First, the intense heat does an immediate cleaning job. It burns off oils, dust, and other microscopic contaminants. You start with a cleaner surface. It also adds new chemical groups to the surface. The flame sends ions and radicals to the surface. These tiny bits roughen the part and make more spots for things to stick. More importantly, it introduces oxygen from the air into the surface layer. This creates new polar chemical groups on the part’s outer molecules.

Why does that matter? These polar groups are magnet-like for adhesives, paints, and coatings. They form strong chemical bonds. The glue isn’t just sitting on the plastic anymore; it’s actively latching onto these new sites.

| Mechanism | Description |

| Oxygen Introduction | The flame puts oxygen on the surface. This helps the glue stick better. |

| Surface Cleaning | Dirt and oil burn away. The part is left clean. |

| Micro-etching | Charged particles make the surface rough. This gives more places to bond. |

| Functionalization | The flame breaks chemical bonds. It adds groups that help things stick. |

The treatment makes an otherwise inert material ready for a lasting connection. It’s fast, effective, and ideal for large, simple parts moving down a high-volume production line.

Pros and Cons

Flame surface treatment has good points and some bad ones. Let’s look at the clear trade-offs you make when choosing flame treatment on the line.

Pros:

- Speed and scale are the biggest advantages. You can treat large parts or high volumes quickly as they move down a conveyor. It’s efficient for big jobs.

- It’s highly effective on common, hard-to-bond plastics like polypropylene (PP) and polyethylene (PE), making them ready for painting or gluing.

- The result is a surface that grips paint, ink, and coatings much more reliably. You also get better wettability, meaning liquids like adhesives spread out evenly instead of beading up.

- It’s a proven choice for durable goods like automotive bumpers and certain high-volume medical components.

Cons:

- Precision is the main drawback. It’s a broad-brush method. It’s less exact and controlled than plasma treatment, which can be finely tuned.

- Safety is a constant concern. Using an open flame in a factory requires strict protocols, specialized equipment, and constant vigilance to prevent fires.

- Material compatibility is limited. You cannot use it on heat-sensitive or low-melting-point plastics. The part will warp or degrade.

- Process control is critical. Applying too much heat can damage the part’s surface or even weaken its underlying structure.

- There are environmental and health considerations. The burning process can produce emissions that need to be managed through proper ventilation or filtration systems.

| Aspect | Flame Treatment | Plasma Treatment |

| Effectiveness | Good for plastics that do not stick well | Works on more kinds of materials |

| Speed | Very fast | Slower but more controlled |

| Precision | Not always the same | Very exact |

| Safety | Fire risk | Safer |

| Environmental Impact | May cause emissions | Cleaner |

Tip: If you need to work fast and use tough plastics, flame surface treatment is a good choice. If you need a gentler option or are dealing with fragile items, plasma treatment might be worth considering.

Applications

Flame surface treatment is used in many industries. Car factories use it for bumpers and inside parts made from TPO plastics. Medical device manufacturers use it on durable plastic housings and components. Electronics makers use it to get better bonding. In packaging and printing, it’s essential. It is also used in optics to help coatings stay on lenses.

Where you’ll find it in action:

- In automotive plants, it’s standard for plastic bumpers and interior trim made from TPO. This simple step is what keeps the paint from chipping off later.

- Medical device manufacturers use it on durable plastic housings and components. The treatment ensures that the final protective or antimicrobial coating bonds permanently. The coating won’t flake during sterilization.

- For electronics, it prepares plastic casings and connectors. This guarantees that adhesives or shielding coatings stick properly, which is critical for both performance and durability.

- In packaging and printing, it’s essential. The process runs plastic films and labels through a flame just before ink or adhesive is applied. This makes the ink bond correctly and stops labels from peeling off containers.

- Even in optics and energy, it’s used. It prepares glass or acrylic surfaces for the anti-reflective, protective, or conductive coatings on lenses, displays, and solar panels.

If you’re finishing CNC-machined or custom-fabricated plastic parts that need painting, coating, or bonding, flame treatment is a reliable, fast option. It bridges the gap between machining and final assembly. For a busy factory, it’s a simple step that directly translates to a better, longer-lasting product by solving the fundamental problem of adhesion.

Plasma Surface Treatment

Process Overview

Plasma treatment sounds complex, but the concept is straightforward. Think of it as a precise, dry cleaning and activation process for the very top layer of a part. This gas changes the outside of the material. The inside stays the same. The surface gets better for glue and coatings.

Here’s what happens inside the chamber: The plasma makes charged particles. These hit the surface and clean off oils and dust. The surface gets new chemical groups. The major advantages are clear. It’s a dry process. You don’t need harsh chemical solvents or large volumes of water. It doesn’t generate chemical waste. It doesn’t thermally distort the part like a flame might, because the bulk material temperature stays low.

On the factory floor, it’s efficient. The cycle times are fast, and it integrates seamlessly into production lines for CNC-machined and custom parts, ensuring they are perfectly prepared for the next assembly or coating step.

Pros and Cons

Plasma surface treatment has many good points, but there are some downsides too. Let’s see how it compares to other ways:

| Aspect | Plasma Surface Treatment | Plasma Cleaning |

| Cost-Effectiveness | More cost-effective than chemical etching or sandblasting | Initially appears less expensive but incurs higher labor costs over time |

| Environmental Impact | More eco-friendly, uses fewer resources, and has no hazardous chemicals | Uses harsh chemicals that can harm the environment if not managed properly |

| Precision | Greater precision in treating materials, allowing for high-accuracy parts | Less precision compared to plasma surface treatment |

| Longevity of Results | Longer-lasting results due to the non-contact nature and deeper penetration | May require additional processing steps after cleaning |

Pros:

- You can fine-tune the plasma’s gas mixture, power, and exposure time to target a specific material and achieve an exact surface state.

- It’s an inherently clean and safe process for the operator.

- Because it doesn’t use dangerous chemicals for cleaning or etching, you eliminate the need for storing, handling, and disposing of hazardous materials.

- The surface modification is more than just cleaning; it’s a stable chemical change. This means the results are durable.

- Its precision makes it highly compatible with CNC machining and custom work.

Cons:

- The primary barrier is equipment. You need a specialized vacuum chamber, a gas delivery system, and a power generator.

- For some materials, particularly certain plastics with high outgassing or very low surface energy, you may need a pre-cleaning step or a specific gas recipe to get optimal results.

- This leads to the initial cost. The capital expenditure for a good plasma system is significantly higher than for a flame treater or a chemical bath setup.

Applications

Plasma surface treatment is used in many industries. You see it in cars, medical tools, packaging, and electronics. Here’s a simpler look at where you’ll see it used.

| Application Area | Description |

| Plastics | Common in automotive interiors, medical device housings, packaging films, and product assembly. The treatment makes plastics like polypropylene ready for inks, paints, and adhesives. |

| Ink Printing Adhesion | Enhances adhesion for various printing methods, crucial for successful ink application. |

| Flexible Packaging | Used on polyester and other plastic films. It improves ink adhesion for labels and packaging, resulting in sharper graphics and more durable print that survives handling. |

| Automotive Part Adhesion | It prepares bumpers, trims, and interior plastic parts for painting and bonding without using solvent-based primers, reducing waste and cost. |

| Wire & Cable Marking | Treats the insulation on wires and cables so that printed markings for identification bond strongly. |

| Folding Carton | Treats cardboard and paperboard surfaces. It cleans and activates the material, allowing adhesives to create a stronger bond in less time and often using less adhesive. |

| Textile Functionalization | Applied to synthetic fabrics. It increases the surface energy of fibers, improving their wettability. This leads to better dye uptake, brighter colors, and stronger adhesion for printed designs. |

| Battery Technology | Improves the efficiency of battery cells by enhancing the hydrophilicity of separators. |

| Solar Thin Film Cell Manufacturing | Cleans and activates surfaces during the production of photovoltaic layers. This ensures better adhesion between subsequent material layers. |

| Flexible / Rigid Flex Circuitry | It removes microscopic contaminants and oils left from fabrication, ensuring that coatings and laminates adhere without failure. |

| Printed Circuit Boards and Metal Cleaning | A critical cleaning step before conformal coating or soldering. It removes oxidation and organic residues from copper traces and metal contacts. |

| RFID Tags | This functionalizes the surface so the adhesive label bonds permanently and improves the electrical connection between the chip and the antenna. |

| Foams | Used on polyurethane and other foams before lamination or coating. It increases the surface tension of the foam, allowing adhesives to spread evenly and bond firmly without. |

You find plasma treatment in custom machining for medical devices. In that field, creating a perfectly clean surface and enabling a permanent bond are absolute requirements. Car factories use it to help paint, and coatings stick to bumpers and dashboards. In precision manufacturing, it serves a dual purpose. It ensures functionality—like a reliable adhesive seal—and enhances appearance.

In short, plasma surface treatment is a proven method for elevating product performance. If the goal is to manufacture top-tier, reliable goods, integrating this process is a strategic step toward that result.

Corona Surface Treatment

Process Overview

Corona surface treatment uses strong electricity to change the surface of plastics and some metals. You pass the material—often a film, sheet, or molded part—close to an electrode. This creates a powerful electric field. The energy in this field ionizes the surrounding air, turning it into a reactive plasma. This gas breaks apart oxygen in the air. The oxygen sticks to the surface and makes it more active. Inks, adhesives, and coatings can now form a strong, permanent bond.

- It solves the fundamental problem of bonding to difficult, low-energy plastics.

- It is designed for continuous, high-speed operation. You can treat entire rolls of film or large sheets, which is ideal for packaging and printing lines.

- The speed makes it perfect for high-volume factory environments where stopping the line is costly.

For a machine shop or custom manufacturer, you’d encounter this if you’re finishing plastic components that need printing, painting, or bonding. A treated part will hold ink sharply and form a permanent adhesive bond where an untreated part would fail.

Note: Corona treatment is popular for plastics in packaging, medical, and car industries. It provides a strong, reliable bond without solvents or liquid chemicals.

Pros and Cons

Corona surface treatment has some good points, but there are also problems. Here is a quick look:

| Aspect | Corona Surface Treatment | Other Methods (e.g., Plasma) |

| Surface Energy Increase | Makes the surface more active by adding oxygen. | Gives more control over how the surface changes. |

| Treatment Efficiency | Not as strong; works well for big, fast jobs. | Works better and fits into factory lines easily. |

| Control Over Chemistry | Less control because it uses air and many types of particles. | Uses special light, so you can control the changes better. |

| Operational Issues | Can cause static electricity, which attracts dust and can be unsafe. | Does not have these problems and is cleaner. |

| Material Compatibility | Best for soft materials and works on many sizes. | Has more limits on what it can treat. |

| Investment Requirement | Costs less to start, so it is good for some jobs. | Costs more at first but gives better results later. |

Corona treatment is a workhorse for volume, but it comes with specific limitations you must plan for. You do not get as much control as with plasma treatment.

- The main limitation is control and uniformity. The electrical discharge can be inconsistent, leading to uneven treatment.

- The process can generate static electricity that attracts dust and particulates to the surface.

- It can be too aggressive for delicate materials.

- Surface modification is relatively shallow and less stable over time compared to plasma treatment.

Tip: If you need a fast and cheap way to treat large areas, corona treatment is a smart pick.

Applications

You see corona surface treatment in many places. Its application is less about exotic materials and more about making common materials reliably functional.

- Most universal use is in the packaging and printing industry.

- In automotive manufacturing, it’s used on interior and exterior plastic trim.

- For medical devices, it prepares the surfaces of plastic tubes, fluid bags, and device housings.

- You’ll also find it in appliance manufacturing (on refrigerator or washing machine panels) and electronics.

- If your shop does custom or CNC machining of plastic parts, corona treatment becomes a valuable post-processing step.

For a medical device housing or an automotive interior part, the bond strength isn’t just about quality—it’s a safety and reliability requirement. Corona treatment provides that assurance in a fast, scalable way, helping your finished products meet the high standards of these industries.

Remember: Corona surface treatment is a quick and easy way to get your parts ready for the next step, whether you work in a big factory or a small shop.

Chemical Etching

Process Overview

Chemical etching shapes metals and plastics without heat or force. First, you cover the parts you want to keep with a photoresist mask. Then you dip the part in a chemical bath. The chemicals eat away at the open areas. This leaves the design you want. You can use chemicals like hydrochloric acid or ferric chloride. The type depends on the material.

Process control is everything. Temperature directly controls the etch rate. A hotter bath etches faster but can compromise the mask or cause undercutting. Agitation (stirring or spraying) ensures fresh etchant reaches the surface and carries away dissolved material, leading to a more uniform result.

Pros and Cons

Chemical etching is known for being accurate and flexible. You can make complex shapes without bending the material. This is why factories and precision shops like it. But it’s important to know the pros and cons before you decide.

| Advantages of Chemical Etching | Disadvantages of Chemical Etching |

| High precision (tolerances of ±0.025 mm) | Material waste due to dissolved material |

| Material flexibility (works with various metals and alloys) | Environmental concerns regarding chemical disposal |

| Reduced tooling costs (only requires a photochemical mask) | Limited material thickness (best for 0.025mm to 1.5mm) |

| Design flexibility (can create complex geometries) | Surface finish limitations may require additional processing |

| No material stress (no mechanical force or heat used) | Not suitable for non-metallic materials (only metals and alloys) |

- Chemical etching is great for getting sharp edges and clean lines. Waterjet cutting can sometimes make the edges blurry, but etching keeps them sharp.

- You don’t need to spend loads of money on tools; just get a mask and some chemicals.

- Just a heads-up: this product isn’t suitable for thick parts, and you’ve got to handle chemicals safely.

- Sometimes, you just need to add an extra step to make sure everything’s finished off nicely.

Applications

Chemical etching finds its niche where other methods struggle. It’s not about brute force; it’s about precision and preserving material integrity.

- In automotive and aerospace, it makes critical filtration components like fuel and injector filters.

- The medical industry relies on it heavily. Surgical blades, vascular stents, and the tiny channels in lab-on-a-chip devices are classic examples.

- In electronics, it’s used for electromagnetic shielding (EMI/RFI gaskets) and flexible circuits.

- For general precision manufacturing, it’s the go-to for producing flawless shims, spacers, and washers.

- It serves decorative and architectural purposes.

- In energy and heavy industry, it’s used for heat exchanger plates and turbine components.

If your project involves thin materials, extremely fine features, or metals that are brittle or hard to machine, chemical etching is a powerful alternative. Medical and car companies use it for parts that must meet strict rules. You get good results and lots of design choices.

Acrylic Binder Coating

Process Overview

Acrylic binder coatings are essentially a primer layer. You put a thin layer of acrylic binder on the surface. Think of the binder as a double-sided tape. One side bonds strongly to the tricky base material—whether it’s a slick plastic like polypropylene or a bare metal. There are different kinds of acrylic binders. Some make things harder and shinier.

Here is a table showing the main binder types and what they do:

| Binder Type | Key Features | Applications |

| Styrene-acrylic | Hardness, gloss, chemical resistance, and improved adhesion | Coatings, adhesives, construction materials |

| Pure acrylic | UV resistance, durability, and flexibility | Outdoor coatings, sealants, and masonry coatings |

| Core-shell acrylic | Custom mechanical properties, enhanced adhesion, and chemical resistance | Coatings, adhesives, custom solutions |

The newer formulations address past limitations directly. They are designed to be high-performance and more environmentally conscious, often eliminating compounds like APEO (alkylphenol ethoxylates) and heavy metals like zinc.

- Their protective qualities are superior.

- Most importantly, their adhesion is robust and broad.

- The process is also operator-friendly.

Pros and Cons

Acrylic binder coating has many good points, but there are some problems too.

| Advantages | Disadvantages |

| Cost-Effective | Ponding Water |

| UV Protection | Cold Temperature Applications |

| Easy to Install | Loss of Mil Thickness |

Pros:

- Doesn’t require massive capital investment in special machinery like plasma chambers.

- The UV protection it provides is a key functional benefit.

- Application methods like spraying, rolling, or dipping are straightforward.

Cons:

- Moisture sensitivity is a known issue, especially with older or lower-quality formulations.

- Applying the coating in cold or humid conditions can prevent proper curing.

- An uneven or too-thin layer will fail to provide adequate coverage and protection.

Applications

Acrylic binder coating is used in many places. Its use is widespread because it solves a common, practical need: creating a consistent, adhesive-friendly surface on almost any material. It’s less about high-tech modification and more about reliable preparation.

| Application Type | Description |

| Paints and Coatings | Decorative and industrial paints for metals and plastics |

| Textile Industry | Fabric coatings and textile printing |

| Construction Materials | Waterproof coatings and concrete sealants |

- It’s used as a waterproofing agent and sealer for concrete and masonry, and as a bonding layer for exterior insulation and finish systems (EIFS).

- Acrylic binders are key components in inks and laminating adhesives.

- For textiles and paper, it acts as a coating binder.

For medical devices, acrylic-based coatings are used to create smooth, chemically resistant, and cleanable surfaces on tools and equipment housings. This supports sterility and durability through repeated cleaning cycles.

Electroplating

Process Overview

Electroplating is a workhorse finishing process. It’s less about altering the base metal and more about cladding it with a completely different surface. You use electricity to move metal ions onto your part. The first step is absolutely critical: cleaning and preparation. Next, the prepared part is submerged in an electrolyte solution—a bath containing dissolved salts of the coating metal. The part connects to the negative side of a power supply. The metal you want to add goes on the positive side. When you turn on the power, metal ions move through the liquid. You can deposit a layer that is microns-thin and perfectly even, even on complex geometries.

Pros and Cons

Electroplating is powerful, but it’s a process with strict demands and real trade-offs.

Pros:

- The primary benefit is functional protection.

- Creates a cosmetically superior finish.

- Significantly enhance electrical conductivity.

- A major advantage is throwing power.

- Its material versatility is broad.

Cons:

- The biggest risk is adhesion failure.

- The process involves hazardous chemicals.

- Environmental impact and waste disposal are major concerns.

- The setup and cycle time for proper cleaning, rinsing, plating, and post-treatment is considerable.

- You cannot plate just any metal onto any other.

| Benefit | Description |

| Corrosion Resistance | Stops rust, good for car and medical parts |

| Decorative Finish | Makes parts shiny, used for car trim |

| Electrical Conductivity | Helps connectors in electronics and medical |

| Wear Resistance | Makes tools and machine parts last longer |

Applications

Electroplating is a foundational industrial process because it solves multiple problems at once. It’s not just a finish; it’s a functional upgrade applied directly to the part’s surface.

- Chrome plating on bumpers, grilles, and trim provides a hard, brilliant finish that resists corrosion and abrasion from road debris.

- Nickel plating on surgical tools enhances hardness for sharpness retention and can provide a smoother.

- Gold and silver plating on connectors and circuit board edge fingers.

- In aerospace and defense, specialized plating like cadmium or zinc-nickel is used on fasteners and structural components.

- Using gold or rhodium plating over base metals to achieve a precious appearance and tarnish resistance at a fraction of the cost of solid precious metal.

This step is how a machined stainless-steel surgical tool becomes autoclavable and wear-resistant. It’s how a copper electrical contact becomes solderable and long-lasting. The plating is what allows the part to meet the technical specifications and regulatory standards of its end-use industry.

Powder Coating

Process Overview

Powder coating gives metal parts a tough, colorful finish. Cleaning and pretreatment are the non-negotiable first steps, especially for machined parts. Next, dry, finely ground particles of pigment and polymer resin (epoxy, polyester, polyurethane) are fluidized in a hopper and sprayed through an electrostatic gun. This electrostatic attraction allows the powder to wrap around edges and coat the backside of parts with some uniformity. You place the coated part in an oven. This transforms the sticky melt into a hard, inert, and durable thermoset plastic coating. The part is then cooled.

For metal parts that need a robust, high-quality, and uniform protective finish—from automotive wheels and architectural aluminum to medical equipment and outdoor furniture—powder coating is very often the optimal, cost-effective choice in precision manufacturing. It delivers a finish that is as tough as it looks.

Pros and Cons

I will then show you why powder coating is a go-to solution, but also where its limits are.

Pros:

- The cured thermoset finish is exceptionally tough. It resists impact, abrasion, chemicals, and UV radiation far better than most liquid paints.

- It provides superior corrosion protection, especially when paired with the correct pretreatment (like zinc phosphate).

- From an aesthetic and functional standpoint, the range is vast.

- Operational efficiency is a major factor. The electrostatic application means almost no material is wasted.

- It is highly efficient for high-volume runs.

Cons:

- The capital investment is significant.

- Geometric limitations exist.

- Most plastics, wood, or composites cannot be powder-coated with standard processes.

- Changeover time is a genuine production consideration.

| Feature | Powder Coating | Liquid Paint |

| Durability | High | Lower |

| Color Choices | Many | Many |

| Environmental Impact | Low (no solvents) | Higher (uses solvents) |

| Application Speed | Fast for big batches | Slower |

| Surface Coverage | Thick, even | Can drip or run |

Applications

You find powder coating everywhere. Its application list is essentially a map of where metal meets the real world and needs to survive.

- Wheels, bumpers, brackets, and chassis components get a finish that can handle stone chips, road salt, brake dust, and UV exposure without failing.

- The medical sector relies on it for equipment that must withstand rigorous, daily chemical cleaning and abrasion.

- Machine frames, enclosure panels, and robotic arms are powder-coated.

- Bicycle frames, outdoor furniture, light fixtures, and playground equipment need a finish that combats weather, UV degradation, and physical impact

For any shop doing CNC machining or custom sheet metal fabrication, powder coating is the logical final step. It bridges the gap between a raw metal piece and a finished product. It provides the environmental seal, the color for branding or identification, and the wear resistance required for the part’s service life.

Anodizing

Process Overview

You may wonder how anodizing works. This surface treatment uses electricity and acid. The part, typically aluminum, is first meticulously cleaned and etched to prepare a uniform surface. First, you put the metal part in an acid bath. Then, you connect it to a power supply. Electricity makes oxygen form on the surface. The oxygen reacts with the metal. When you apply a direct current, oxygen ions in the electrolyte react with aluminium atoms at the surface, forming a layer of aluminium oxide that keeps growing.

For CNC and custom shops working with aluminum, anodizing is a critical value-added service. You machine the part, then anodize it to achieve the required hardness, corrosion resistance, and color. The oxide layer does not peel or chip.

Pros and Cons

Anodizing has many good points, but there are some downsides too.

Pros:

- The anodized layer is extremely hard (comparable to sapphire) and provides excellent resistance to corrosion and abrasion.

- The aesthetic quality is high.

- Its material suitability for critical industries is proven.

- It’s a highly repeatable and efficient batch process, making it cost-effective for large runs.

Cons:

- It is almost exclusively for aluminum, titanium, and a few other non-ferrous metals.

- It is a process-intensive operation.

- While the oxide layer is hard, it is also brittle.

- The initial investment and minimum costs can be high.

| Feature | Anodizing | Electroplating |

| Durability | High | Medium |

| Color Options | Many (with dyes) | Many |

| Rust Protection | Excellent | Good |

| Material Compatibility | Mostly aluminum | Many metals |

| Environmental Impact | Lower (no heavy metals) | Higher (uses chemicals) |

Applications

You see anodizing in many places. Anodizing is everywhere you need aluminum to be more than just aluminum. Its applications are defined by its unique combination of durability, cleanliness, and aesthetics.

Where It’s the Specified Finish:

- Car wheels, trim, and engine components benefit from its corrosion resistance.

- Surgical tools, instrument trays, and equipment housings are anodized.

- For consumer electronics, it’s the premium finish.

- In architecture and construction, anodized aluminum is used for curtain walls, window frames, and panels.

For a CNC or precision machining shop, anodizing is a vital post-processing step. You machine a part to its exact tolerances from aluminum, knowing that the anodizing process will add minimal dimensional change while transforming its surface properties.

Phosphating

Process Overview

Phosphating isn’t a final finish you see; it’s a critical preparatory layer you depend on. Think of it as a foundation for paint and a sacrificial barrier against corrosion. You dip the metal into a solution with phosphate salts. A chemical conversion reaction occurs at the surface. You see phosphating used a lot in factories that make car parts and medical tools. The acid in the solution gently etches the metal, and phosphate crystals grow from the solution, bonding tightly to the etched surface. It does not change the shape of the part, so you keep tight tolerances in precision manufacturing.

Did you know? If you’re finishing steel components that will be painted, powder-coated, or even just stored, phosphating is a highly effective and economical pretreatment step. It ensures the final finish performs as intended and the part beneath it remains protected.

Pros and Cons

Phosphating has some strong points, but you should know the downsides too.

| Pros | Cons |

| Stops rust and corrosion | Needs careful chemical handling |

| Makes paint stick better | Not for aluminum or non-ferrous metals |

| Works fast for big batches | Wastewater needs treatment |

| Low cost for large parts | The layer can wear off over time |

| Good for CNC machining jobs | Not as decorative as other coatings |

- Its primary benefit is creating an ideal bonding surface.

- It’s a fast and scalable batch process.

- Compared to other conversion coatings or plating processes, it is very cost-effective, especially for large runs.

- The process involves chemical handling and waste.

- While the coating is excellent for adhesion and corrosion resistance under a topcoat, its wear resistance as a standalone finish is limited.

Tip: If you want a simple way to protect steel parts in custom machining or precision manufacturing, phosphating is a smart choice.

Applications

You find phosphating in many industries. Car manufacturers use it for things like body panels, frames, and engine parts. Medical companies treat surgical tools and trays to stop rust. Factories use phosphating before painting or coating metal parts. Custom machining shops use phosphating for parts that need strong bonds and long life.

Common uses for phosphating:

- Car frames and body panels

- Engine blocks and gears

- Surgical trays and medical instruments

- Bolts, nuts, and fasteners

- Machine parts in precision manufacturing

- Metal furniture and shelving

Phosphating helps you get reliable results in a factory. You make parts that last longer and meet strict standards. It’s less suitable as a final finish for parts subject to direct mechanical wear, or for small shops that cannot manage the chemical waste stream. For those applications, a harder finish like plating or a thicker coating like powder coat applied over the phosphate might be the complete solution.

Passivation

Process Overview

Passivation doesn’t add a layer; it optimizes the metal’s own natural protective ability. The acid takes away the iron and dirt from the surface. Once the surface is purified, the chromium in the alloy reacts instantly with oxygen in the air or water to form a new, uniform, and fully passivated chromium-oxide layer. It prevents premature rust stains (rouging) and ensures the part meets the strict cleanliness and material standards of regulated industries.

Pros and Cons

Passivation has good points and some problems. Here is a quick look:

| Pros | Cons |

| Stops rust and corrosion | Only works on certain metals |

| Keeps surfaces clean | Needs careful chemical handling |

| No change to part shape | Not a decorative finish |

| Works for complex shapes | Wastewater needs treatment |

| Good for CNC machining jobs | May need repeat treatments |

You get a clean surface that resists rust. Passivation is a functional, not decorative, process. Its value is entirely in ensuring material integrity and long-term performance. Its effectiveness on complex geometries is total. The acid bath treats every surface it contacts uniformly, including internal passages and blind holes that other coatings cannot reach.

Applications

Passivation is used in loads of industries. Medical companies use it for surgical tools and implants. These parts must stay clean and rust-free. Car factories treat engine parts and bolts to stop rust. It’s the standard for any stainless steel component where corrosion initiation is unacceptable:

- Medical & Food: Where absolute cleanliness and material inertness are non-negotiable.

- Aerospace & Automotive: Where component failure from corrosion can be catastrophic.

- Electronics: To prevent conductive corrosion products from forming on sensitive components.

For any project where the silent, unseen threat of corrosion must be definitively stopped, passivation is not just an option—it is an essential specification for stainless steel components. It’s the baseline for durability in demanding environments.

Electroless Plating

Process Overview

The part is meticulously cleaned and then immersed in an aqueous solution containing metal salts, a reducing agent, and stabilizers. Unlike electroplating, no external electrical current is applied. The chemicals react with the metal’s surface. Electroless plating’s core advantage is its unique throwing power—the ability to deposit a perfectly uniform coating regardless of part geometry.

Pros and Cons

Electroless plating has many good points, but there are some downsides. Here is a quick look:

| Pros | Cons |

| Uniform coating on all surfaces | Chemical waste needs careful handling |

| Works on complex shapes and holes | Slower than electroplating |

| No need for electricity | Bath chemicals can be expensive |

| Good for metals and some plastics | Not as thick as some other coatings |

| Improves corrosion and wear resistance | Needs close control of bath chemistry |

Applications

Electroless plating is the specialist you call when the geometry is too complex for standard plating and the performance requirements are too high for a simple coating. In hospitals, it is used on surgical tools and implants. The smooth finish makes cleaning a breeze and keeps those pesky germs away!

Here are some common uses:

- Fuel injectors, transmission gears, and brake system components are prime examples.

- For surgical tools, the coating offers a hard, smooth, and chemically inert surface that stands up to repeated sterilization.

- For certain implants and instruments, electroless plating provides a biocompatible and corrosion-proof barrier.

- In electronics, it’s used for PCB (printed circuit board) through-holes and complex connectors.

- For fluid handling systems like pumps, valves, and hydraulic components, electroless nickel plating protects internal bores, threads, and sealing surfaces from corrosion and erosion, extending service life dramatically.

Its value proposition is uniformity and reliability in complex forms. When a part’s function depends on consistent surface properties everywhere—inside and out—and the environment is demanding (chemical, abrasive, or sterile), electroless plating is very often the top engineering choice. It’s a finish chosen for performance, not just appearance.

Comparing Surface Treatment Methods

Effectiveness

Different surface treatments work in different ways. The effectiveness of a surface treatment isn’t universal. It’s a specific solution for a specific problem. Some methods exist solely to create a bond. Others are there to fight wear or corrosion for years.

From a practical perspective, you need to match the method to the material and the part’s final job. There’s no single best answer.

Alright, let’s break this down.

| Surface Treatment Method | Material Type | What Makes It Effective |

| Thermal Spray Methods | Metals | Adds roughness for better bonding |

| Chemical Vapor Deposition | Metals | Needs a clean, smooth surface |

| Physical Vapor Deposition | Metals | Works best on even surfaces |

| Mechanical Treatments | Titanium Alloys | Changes the microstructure for strength |

| Electrochemical Treatments | Titanium Alloys | Improves friction and wear resistance |

Consider the heavy-duty options first. Thermal spray and vapor deposition are in a different league. They build up thick, extremely durable armor. You’ll see them on critical surfaces—turbine blades in jet engines, the bearing surfaces of a medical implant. The coating becomes part of the part’s function.

Now, for plastics, the game changes. The goal is often adhesion. Plasma and flame treatment are the standard here. You can get up to 57% stronger bonds. That’s the difference between a car emblem staying on and falling off. It’s why a medical device housing can be permanently sealed.

- By engineering the coating at the nanometer scale, they achieve remarkable hardness and corrosion resistance with less material.

- Surface preparation is everything. If you skip it, your coating might not work.

- The choice always comes back to the material you’re starting with and the life you expect the part to live.

Safety

Safety is very important when you use surface treatments. The processes that modify a part’s surface are powerful, and they don’t distinguish between the workpiece and your skin. You must respect the tools.

Here are some things to remember:

- You’re dealing with strong acids and solvents for cleaning and etching. Gloves, goggles, and respirators are not optional equipment. They are your primary interface with the job.

- A flame treater is a controlled fire. Plasma systems involve high voltage and potentially hazardous gases.

- Ventilation is engineering, not comfort.

- The tip is the core truth. Always wear the protective gear.

The “easy” job is the most dangerous one. It’s when you’re comfortable, when you’ve done it a hundred times, that you might skip a step. That’s the moment the process reminds you what it is. Safety isn’t about the procedure going right. It’s about being protected when, inevitably, something doesn’t.

Environmental Impact

Caring for the environment is important in factories and custom shops. The environmental impact of a surface treatment is now a core part of the selection process. It’s not just a side effect anymore; it’s a direct cost and a compliance issue.

We can split these methods into two rough groups: those that primarily create a waste disposal problem, and those that shift the burden to energy use and specialized handling.

- Look at powder coating. Its main environmental advantage is the complete lack of solvents. It does not use solvents, so there is less air pollution.

- Plasma and corona treatment are interesting. They’re dry. They use electricity and specialized gases, but they generate minimal chemical waste.

- Chemical etching and electroplating are defined by their waste streams. The spent baths are concentrated cocktails of heavy metals, acids, and other regulated chemicals. Treating this wastewater to meet discharge standards is complex and expensive.

- Similarly, passivation and phosphating use acids. The environmental risk is direct contamination of water if a spill or improper disposal occurs.

Industries under scrutiny, like medical and automotive, are actively moving towards what we call “greener” options. They’re choosing plasma over solvent-based primers. They’re specifying powder coating over wet paint.

The choice is becoming clearer. A process that minimizes liquid waste and avoids regulated chemicals isn’t just better for nature. It’s often simpler, safer, and more predictable to run in a modern factory.

| Method | Eco-Friendly? | Waste Produced | Special Disposal Needed? |

| Powder Coating | Yes | Minimal | No |

| Plasma Treatment | Yes | Very little | No |

| Chemical Etching | No | Hazardous chemicals | Yes |

| Electroplating | No | Heavy metals | Yes |

| Passivation | Somewhat | Acidic waste | Yes |

Cost

When you pick a surface treatment, cost is important. ou need the performance, but you must pay for it. The price tag isn’t just for the chemical bath or the powder. You’re paying for the entire system: the material prep, the energy, the skilled labor to run it, and the cost of dealing with what’s left over.

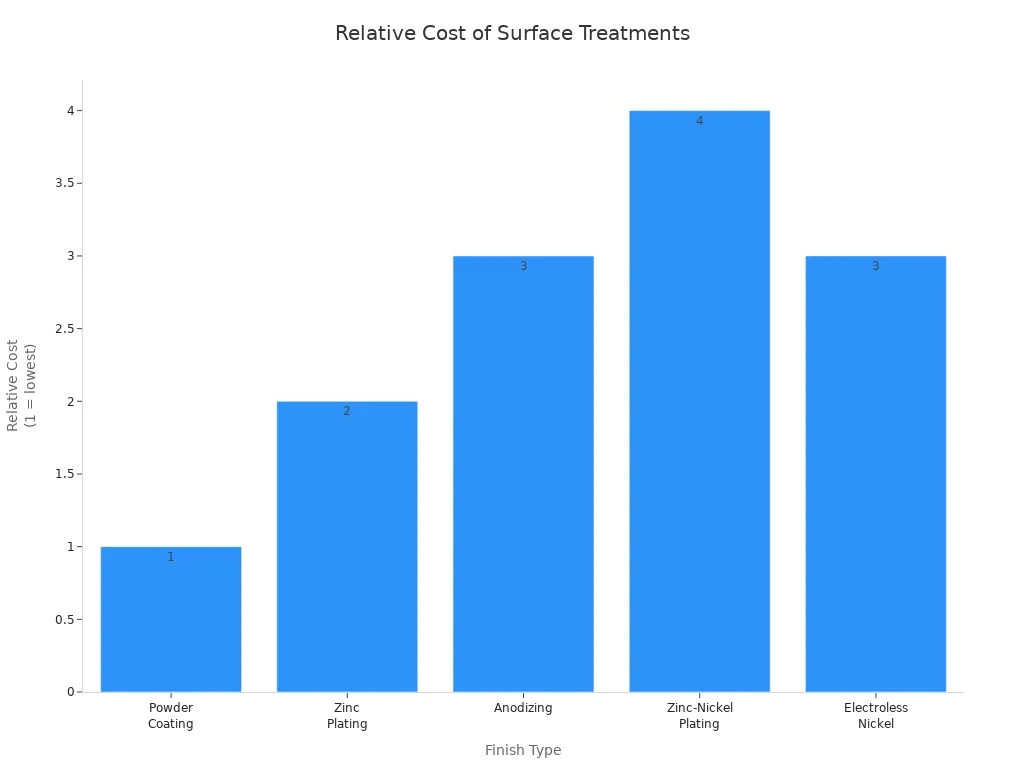

Let’s look at how much some finishes cost:

| Finish Type | Key Limitations |

| Powder Coating | Not electrically conductive |

| Zinc Plating | Limited color options |

| Anodizing | Aluminum only, fewer colors |

| Zinc-Nickel Plating | Higher cost, complex process |

| Electroless Nickel | Lower conductivity |

Look at it from a shop floor perspective. The cheapest route is often powder coating. Anodizing and zinc-nickel plating cost more. Why? The chemistry needs tight control. The electrical systems for anodizing are precise. Electroless nickel is in a higher bracket, especially for complex parts. The chemicals are expensive, and the bath requires constant monitoring. You’re not paying for electricity to plate, you’re paying for a sophisticated, self-driving chemical reaction. The value is the perfect, uniform coating on an impossible geometry. That precision has a premium.

Here’s a simple chart that shows these costs:

Big batches in a factory cost less for each part. Small custom jobs cost more. Part geometry is a massive cost driver. A simple, flat bracket is easy to rack and coat uniformly. A part with deep holes, internal passages, or sharp edges complicates everything. Rules for the environment can add extra costs for handling waste, especially with chemical etching or electroplating.

Material Compatibility

That’s the core of it. The material isn’t just a blank canvas. It dictates the rules. Choosing the wrong treatment for a plastic or metal is a guaranteed failure. You have to work with the material’s chemistry, not against it.

Here’s how that material-process pairing breaks down in practice:

For Plastics: It’s all about surface energy and heat tolerance. You’re trying to make an inert surface chemically active without destroying its shape.

- Plasma Treatment: Vacuum plasma is for the delicate, critical work. It’s a controlled environment for treating complex, tiny components like catheter hubs or sensor housings.

- Corona Treatment: Great for printing and covering plastics. It’s a surface-only change, perfect for making polyethylene or polypropylene receptive to ink or laminate without any thermal distortion.

- Flame Treatment: It’s for the tough, olefinic plastics like polypropylene (PP).

For Metals (and some dense plastics): The goals shift to material removal, deep cleaning, or adding a new layer.

- Chemical Etching: It’s for creating microscopic features in stainless steel for a fuel cell plate or defining circuits.

- Vapor Degreasing: It uses solvent vapors to dissolve oils and waxes left from machining.

- Laser Ablation: Good for cleaning and activating surfaces. Too much energy focused in one spot doesn’t just clean—it melts, vaporizes.

If you work in a CNC machining shop, you see plasma and flame treatments for plastics in medical tools. Car factories use anodizing for aluminum wheels and powder coating for steel frames.

You get the best results when you match your process to your material and your job. This helps your products meet strict rules in the medical and car industries.

Choosing NOBLE

Key Factors

When you pick a surface treatment, you want to make sure it fits your project. Let’s walk through those key factors like you’re holding the part in your hand.

- Material type: Is your part made of plastic or metal? Some treatments work better for one than the other.

- Application environment: Is there any chance your part will be exposed to heat, moisture, or chemicals? Just think about where it’ll be used.

- Here are the performance requirements: Does your part need to be rustproof, durable, or able to handle heavy loads? Pick a treatment that boosts strength.

- Things to think about the cost of: You want good results without spending too much. Some treatments cost more than others.

- Appearance requirements: Do you need a shiny finish or a certain colour? Some treatments can make parts look better.

- How long should your part last? That’s what we’re here to tell you. Pick a method that keeps it strong over time.

- Things to think about for the environment: Some treatments use strong chemicals. Others are safer for workers and nature.

Choose a reliable surface treatment supplier

When you need help with surface treatment, you want a partner who understands you. You need someone who gets the why behind the spec. NOBLE is a top Chinese manufacturer. We are more than just a supplier. We are a real partner.

NOBLE has many years of experience in CNC machining and custom machining. We’re a manufacturer that has been through the grind of CNC and custom machining for years. If you need a new medical device prototype, NOBLE can help you finish it fast. If your factory needs lots of car parts with good coatings, NOBLE makes big orders easy.

Look at our service breakdown from a practical angle.

- Expertise in Surface Treatment: Expertise in Surface Treatment means we have the equipment in-house: plasma chambers, powder lines, and anodizing tanks. This isn’t about having a brochure; it’s about having direct control over the process. You get consistency because they’re not farming it out.

- Fast Prototyping: Fast Prototyping is critical for innovation. It’s the ability to iterate. NOBLE’s team helps you go from idea to part fast.

- Efficient Mass Production: A good partner has systems for this—statistical process control on their coating lines, automated racking, and logistics that don’t introduce delays or damage.

- Service and Support: NOBLE’s team helps you choose the right surface treatment and delivers on time.

- Industry Experience: We’ve seen what makes a surgical tool corrode after five hundred autoclave cycles. We help car brands build strong, rust-proof parts.

You need someone who views the surface treatment not as a final, separate step, but as an integral part of the part’s performance. That’s the real choice. NOBLE gives you confidence for any job, big or small.

Here is a table to show what NOBLE gives you:

| NOBLE Advantage | What You Get | Example Application |

| Surface Treatment Know-How | Strong, lasting finishes for plastics and metals | Medical device coatings |

| Custom Machining | Fast, flexible prototyping and design changes | Automotive part samples |

| Precision Manufacturing | Tight tolerances and consistent quality | Factory mass production |

| Responsive Service | Quick answers and expert advice | Troubleshooting in production |

When you hand off a job, the last thing you want is to manage your supplier’s problems. Delays and quality issues aren’t just headaches—they break your production line and erode trust. NOBLE proposes to take that worry off the table. NOBLE’s team works with you to fix problems and deliver good results. It comes down to three aligned priorities: material, budget, and timeline.

If you want your next project to be easier, contact NOBLE. You’re not just buying a coating; you’re buying the certainty that comes with it. That’s how a project gets easier.

FAQ

What is the main reason to use surface treatment in CNC machining?

The main reason for surface treatment isn’t an extra step. It’s the final, functional requirement. A CNC machine produces a part with perfect dimensions. But that part is often incomplete. Its raw surface might corrode, reject paint, or wear out prematurely. Treatment makes it ready for the real world.

Which surface treatment works best for plastics in custom machining?

Plasma treatment gives great results for plastics. It cleans and gets plastic ready fast. You see plasma used in medical device factories and car dashboards. Plasma treatment helps glue and coatings stick without strong chemicals.

Can I use powder coating on plastic parts?

Rarely. The process requires the part to withstand oven temperatures around 400°F (200°C). This will warp, melt, or weaken most engineering plastics. You’re using the wrong tool.

How do I choose between anodizing and electroplating for metal parts?

Think about what you need. Anodizing is good for aluminum and gives a tough, colorful finish. Electroplating adds a shiny layer to many metals. Car wheels use anodizing. Medical connectors use electroplating for better electrical flow.

Are surface treatments safe for medical devices?

Safety for medical devices isn’t a maybe. It’s a certified requirement. Treatments like passivation for stainless steel or specific anodizing for aluminum are not just safe—they are mandatory. They create biocompatible, cleanable, and corrosion-proof surfaces. The key is validation. You don’t just run the part through a bath. You must document that the entire process—chemical concentrations, times, temperatures—meets strict standards like ISO 13485 or ASTM specs. The safety is in the controlled, repeatable protocol, not just the chemistry.

What is the most eco-friendly surface treatment for factories?

Plasma and powder coating are the most eco-friendly. We use fewer chemicals and make less waste. Many CNC shops and factories pick these to meet strict environmental rules, especially for cars.

How do I know if my part needs surface treatment?

If your part is a car frame, a surgical tool, or a circuit board housing, the answer is almost always yes. The environment demands it. When in doubt, consult your machining partner early. A good engineer won’t just ask for your CAD file; they’ll ask what the part needs to survive. Their job is to help you bridge the gap between a perfect prototype and a durable product.