CNC milling and CNC turning differ in a fundamental way. With milling, the cutting tool moves. The workpiece stays locked down. Turning flips that. The workpiece spins. The tool stays mostly in one place, just feeding in. That one distinction isn’t just technical—it defines everything. It dictates the geometry you can achieve with high accuracy. It dictates the speed of production on your floor. Think about a complex, custom component. Which machine do you walk it over to? The answer depends on this basic motion.

Multiple sectors—automotive, aerospace, medical—all want the same thing. More efficient production. Higher automation. The practical push is for machines that run themselves with extreme precision. Factories are bringing this tech in because they have to. It’s about staying competitive.

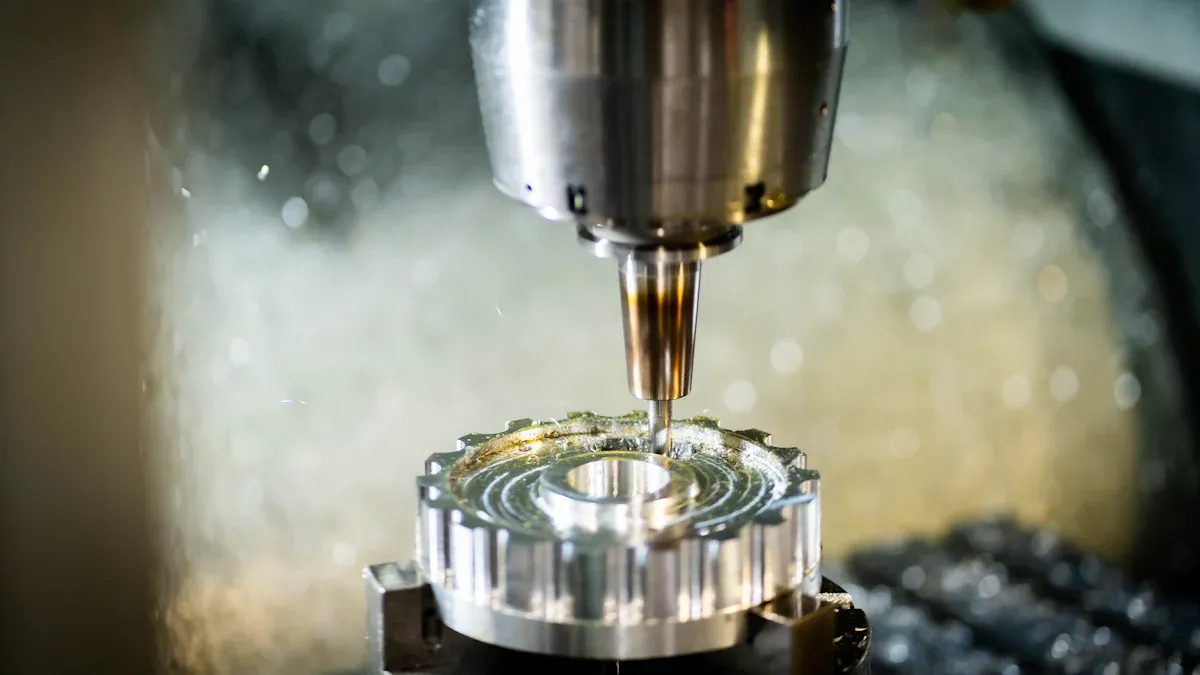

CNC Milling Overview

Definition

That’s a good way to put it—It’s a blend of old and new. Take the basic idea: a spinning cutter removing material from a block. That’s the traditional part. The innovation is the computer now directing everything. The exact path. The feed rate. The spindle speed. All of it.

The result is what you thought. You get part after part. Each one is identical to the last. Each one hits the precise dimensions you programmed. That repeatability is the entire point.

That capability is what sets it apart. Intricate geometries become possible. Holding very tight tolerances becomes routine. For custom, one-off jobs, it’s the method that gives you a chance. From the first cut to the last, you dictate the final product’s exact form. That’s the power of the process.

CNC Milling Process

Machine Setup

You start by setting up the machine. First, you secure the workpiece on the table. The machine holds the cutting tool in a spindle. You load the program into the computer. The program gives the machine its marching orders — literally, how to move the tool. That’s step one.

But the program isn’t everything. You’ve got to look at the hardware itself. Go over and physically check the alignment. Then, make sure every bolt is tight. Do not skip this. Here’s why it matters. Nothing happens before you confirm safety. That’s the rule in any factory. So, you double-check everything. Only then do you hit start.

Tool Movement

You hit start, and the tool spins up. That’s when the computer takes over, steering it exactly along the path you programmed. The workpiece? It stays put. The tool does all the traveling — up, down, side to side, even on angles. That range of motion is the key. It’s why you can cut so many different shapes and features from one setup. You can change the tool if you need a different cut. The computer’s job is precision. Every single move is calculated. There’s no guesswork. This accuracy, this repeatability, is the real reason CNC milling is everywhere in precision work. It simply gets it right, every time.

CNC Milling Features

Complex Shapes

The machine’s ability to create complex shapes comes from one thing: obedience. It follows the computer’s instructions without deviation. Think curves, precise holes, specific slots, internal pockets. If a part requires a high level of detail, this process is effective.

It’s worth noting that this reliability with complicated designs is the main draw. Many industries choose CNC milling for custom work for that exact reason. The process manages difficult geometry that other methods can’t.

Multi-Axis Capability

Some CNC milling machines have more than three axes. You might see machines with four, five, or even more axes. Each added axis unlocks a new way for the tool to move. Think of it as giving the cutter more angles of attack. You can machine incredibly complex parts in a single setup. The workpiece never needs to be repositioned. This does two critical things. It saves a huge amount of time. More importantly, it boosts accuracy because you eliminate the errors that come from moving and re-clamping the part. In a busy factory floor, that combination is everything. It changes your entire production flow.

Applications

You may wonder where CNC Milling is used. This process is important in many industries. It is most helpful where high accuracy and repeatability are needed. Let’s see some main ways CNC machining helps.

Medical Industry

Hospitals and clinics need parts that meet strict rules. You can’t afford a single mistake. Not here. A patient’s safety depends on it. Take a hip implant. Its surface must be perfectly smooth. The shape has to be exactly right, down to the micron. Any flaw can cause serious problems. This is where CNC machining is essential. It delivers that required precision consistently. Part after part. It makes them correctly, every single time. In one case, a factory in the United States made titanium bone plates with CNC Milling. The process allowed for customized processing. Each plate fits the patient’s body. Manual methods would not be as exact.

Automotive Industry

Car makers use CNC Milling for engine parts, transmission pieces, and dashboards. This process is used when factories need many parts that are all the same. Here’s the thing about tight tolerances. They’re non-negotiable. When parts fit exactly as designed, engines perform better. They also last significantly longer. Consider a factory in Detroit. They switched to CNC milling for their cylinder heads. The results were clear. Production speed increased. But the bigger win was the dramatic drop in waste. They stopped making out-of-spec parts.

Customized processing is also used in cars. Race teams need special parts for their cars. CNC milling enables them to produce these parts quickly. This gives them a competitive edge.

Other Common Uses

- Aerospace companies use CNC milling to make turbine blades and other strong parts.

- Electronics manufacturers use it for circuit boards and cases.

- Furniture designers use CNC machining to create intricate wood patterns.

Below is an overview of how different industries use CNC milling:

| Industry | Typical Products | Key Benefit |

| Medical | Implants, instruments | Precision manufacturing |

| Automotive | Engine parts, dashboards | Speed and repeatability |

| Aerospace | Turbine blades, brackets | Complex shapes |

| Electronics | Circuit boards, housings | Customized processing |

Look around. CNC milling is everywhere now. It helps you meet high standards. It’s how you hit high standards consistently. The machine doesn’t get tired or distracted. But here’s the real flexibility. It adapts to your specific needs. Need one unique, complex part? You can make it. Need ten thousand identical parts? You can make those, too, with the same exactness. It all comes down to control. You have direct, precise command over the final product. That’s the ultimate advantage.

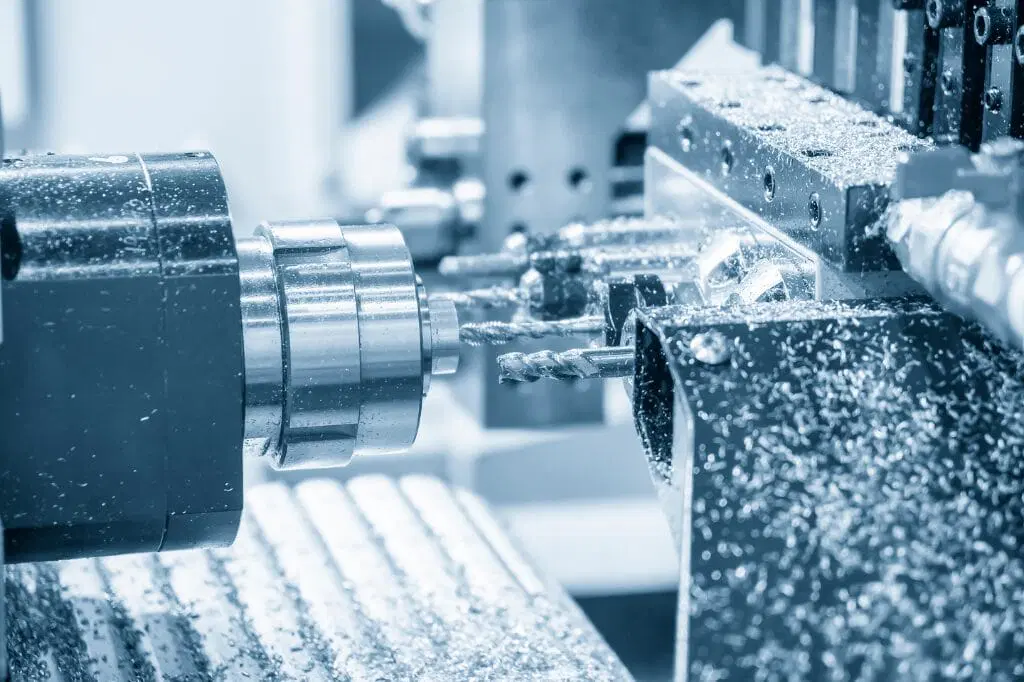

CNC Turning Overview

Definition

CNC turning is a type of CNC machining used to shape materials into round or cylindrical parts. You use a lathe machine controlled by a computer. The computer runs the show, telling the machine every move to make, every cut to take. You start by loading the raw material — metal, plastic, whatever — into the lathe. Then the machine spins the workpiece at high speed. A stationary cutting tool moves in and shapes it.

The outcome is simple: parts that fit. No fuss, no extra filing. They just mate together as intended. That’s why this process, CNC turning, is a cornerstone for precision work and custom jobs on the factory floor. It delivers reliable, exact results.

CNC Turning Process

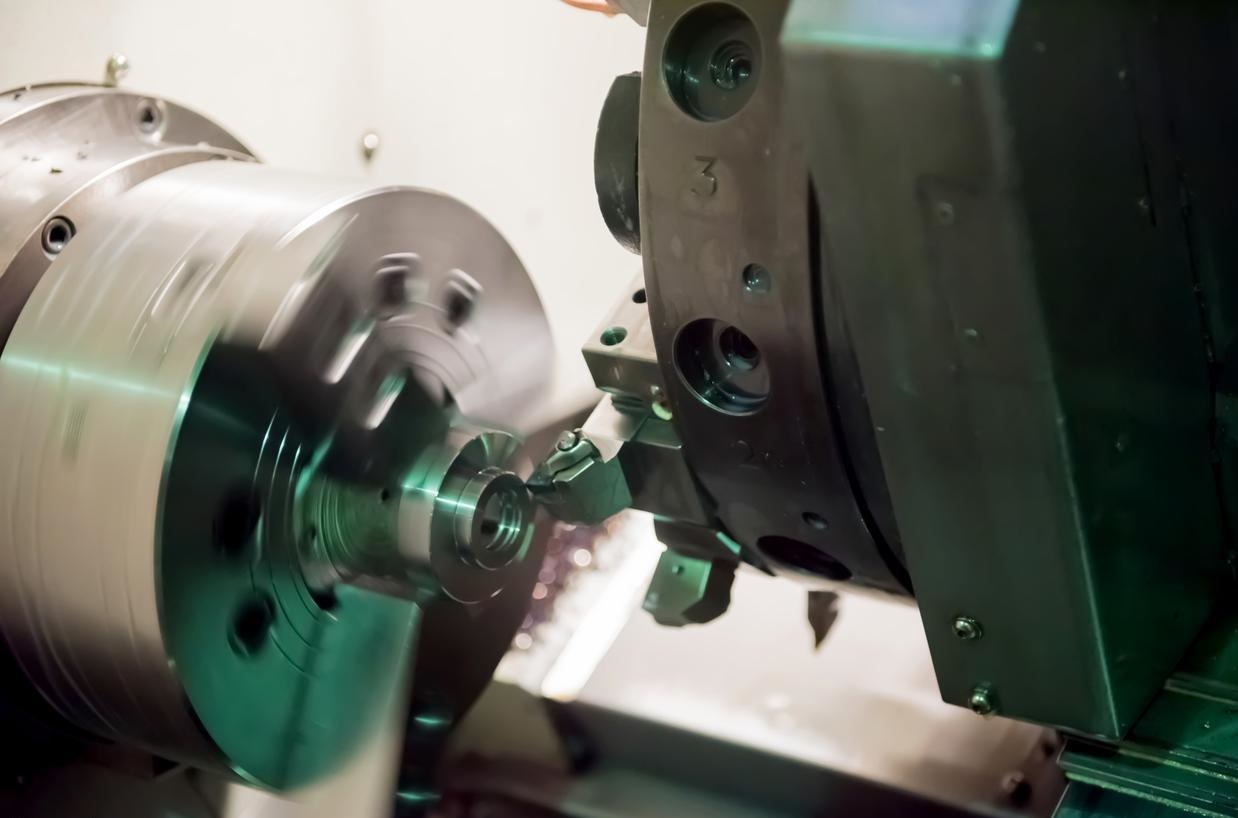

Workpiece Rotation

You start by securing the workpiece in the chuck of the lathe. Remember, with milling, the tool moves around a stationary part. Here, it’s the opposite. The workpiece rotates, and the tool mainly moves in a straight line. This spinning action is key. It allows the cutting tool to shear material away evenly, all around the part. You control everything from the computer. The speed, the direction. That digital control is how you nail the exact shape you’re after.

It’s worth notingthat this method is naturally suited for round, symmetric things. Think shafts, pins, tubes.

Tool Actions

The part spins. Meanwhile, the cutting tool traces its surface. You can direct the tool inward, toward the center. Or you can slide it sideways along the length. You’re not stuck with one motion. The computer program tells the tool where to go. You also aren’t stuck with one tool. Swap it out. Need a hole? Put in a drill. Need threads? Use a threading tool. The machine adapts.

The result is two-fold. You get a smooth finish. You also hit tight tolerances. That’s the practical takeaway. For high-volume runs where every piece must be the same, this method is ideal. It delivers consistency at scale.

CNC Turning Features

Cylindrical Parts

CNC turning is best for making cylindrical parts. Think rods, pins, bushings, rings. If the part is defined by being round, or if it spins around a central axis, this is your process. You get consistent results every time. Achieving precision isn’t just possible—the CNC turning machine is built for it. That’s why you’ll find these parts in critical areas: inside car engines, on airplanes, within medical devices.

So the rule is simple. If the part’s function involves spinning or rolling, don’t overcomplicate it. CNC turning is almost always the right choice. It’s made for that.

Speed Advantage

You get a big speed advantage with CNC turning. The fast spin is the engine of speed. This lets you finish parts quickly. For a large order, that efficiency adds up. Your factory can keep up with demand. You save money. You also cut down on wasted material. Here’s the key: the computer manages everything. This control means fewer human errors. Fewer mistakes. If boosting production is the goal, this isn’t just an option. It’s the logical step. CNC turning makes it happen.

Applications

You may ask where CNC turning is used. That’s correct. It’s a foundational process, not a niche one. Its strength is clear: producing round, symmetrical parts where the measurements can’t be off. Let’s look at a few concrete examples to see how this plays out.

Medical Industry

Hospitals and clinics rely on this for a reason. The parts are non-negotiable: bone screws, spinal rods, and dental implants. Each one must be perfectly smooth. Each one must be dimensionally exact. Patient safety depends on it. A factory in Minnesota makes titanium bone screws with CNC turning. Each screw meets strict medical standards. NOBLE’s role is flexible. We can adjust the size and modify the thread pattern. This customization is vital.

There’s data behind this, too. Look at medical device production in 2022. A clear trend emerged: the adoption of CNC machining led to a measurable drop in errors for implant manufacturing. The process itself reduces variables, and that shows in the results.

Automotive Industry

Car makers operate on volume. They need thousands of identical parts daily. Axles, pistons, bushings—CNC turning produces them fast and consistently. You get speed and reliability in your factory. Production time went down by 20%. Waste also dropped. Race teams tweak designs constantly, chasing more speed or greater strength. CNC machining handles these one-off changes without a problem. But both situations share the same non-negotiable: strict tolerances. The process ensures every part, whether for a family sedan or a race car, is made to exact specs.

Aerospace Industry

Airplane builders rely on it for critical components: drive shafts, high-strength fasteners, and landing gear parts. The stakes are as high as they get. These parts must handle stress and fit perfectly. Precision manufacturing is very important. A factory in Seattle uses CNC turning for landing gear pins. Each pin meets safety rules. Customized machining lets them change designs quickly.

Other Common Uses

- Electronics: Factories make connectors, pins, and housings.

- Oil and Gas: CNC turning makes valves and pipe fittings.

- Consumer Goods: Makers use CNC machining for bike axles and fishing reel spools.

Tip: If your shop needs a high volume of round parts, and the sizes have to be exact, CNC turning is your method. You get production speed, consistent accuracy, and customize each batch without retooling everything. It handles all three.

Here is a table showing how different industries use CNC turning:

| Industry | Typical Products | Key Benefit |

| Medical | Bone screws, implants | Precision manufacturing |

| Automotive | Pistons, axles, bushings | Speed and repeatability |

| Aerospace | Shafts, fasteners | Customized processing |

| Electronics | Connectors, pins | Tight tolerances |

| Oil & Gas | Valves, fittings | Durability |

CNC turning keeps a factory flexible. It allows you to pivot. You can take on custom prototypes and high-volume production runs using the same fundamental technology. In today’s market, that adaptability isn’t just an advantage. It’s a requirement for staying ready and competitive.

CNC Milling vs. CNC Turning Comparison

Process Differences

You may wonder how these two CNC machining methods are different. The difference comes down to movement. Which part is moving, and how? With CNC Milling, the cutting tool is the traveler. It spins and moves along multiple axes—X, Y, Z, and often more—around a stationary workpiece. It can even move at angles. With CNC Turning, the movement is reversed. The workpiece spins rapidly on a spindle. The cutting tool is mostly stationary, typically just feeding in a straight line along the length or radius of the part. You shape it by removing material in precise layers as it rotates.

If you work on a factory floor, you see the difference directly. CNC milling is what you use for cutting pockets, slots, and complex, tricky designs into a part. You can change tools during the job for different cuts. CNC turning is about speed and roundness. The spinning action produces smooth, cylindrical pieces quickly.

Look at the medical field. They use turning to make bone screws and spinal rods. These parts must be perfectly, consistently round to function safely. Now, in an automotive plant, both methods are at work. CNC milling machines the engine blocks, carving out the intricate channels for coolant and oil. Right alongside it, CNC turning produces the axles and pistons — parts where being perfectly round is absolutely critical for performance.

Part Types

You will notice each process is best for certain parts. CNC milling is for the detailed, multi-sided work. Think of a custom car bracket with mounting holes and contours. Or a surgical plate that must conform to a specific bone shape. These parts require flat surfaces, slots, pockets, and complex profiles. CNC Milling does these jobs well.

CNC turning is for the round forms. Anything cylindrical or tubular. Shafts, bushings, pins, rings. The process is fast, and every part in the batch is a perfect match for the first. Car makers need many pistons and axles that are all the same. This is critical in medicine. A bone screw or a dental implant must be flawlessly round and smooth. There’s no room for error. Turning delivers that exact size and finish consistently. For these high-stakes components, it’s the reliable choice.

Here’s a quick table to help you compare:

| Process | Best for Part Types | Example Industries |

| CNC Milling | Complex, flat, or angled shapes | Automotive, Medical |

| CNC Turning | Cylindrical, round, or tubular | Medical, Automotive |

Material Compatibility

You can use many materials in both CNC machining methods. CNC milling handles a wide range. Metals like aluminum, steel, and titanium are common. But it also works on plastics, composites, and even wood. This material flexibility is a big part of why it’s so good for custom, one-off parts.

CNC turning is also compatible with many materials. In medical manufacturing, you’re almost always looking at specific grades of titanium or stainless steel for implants and surgical tools. The material must be biocompatible, strong, and able to be machined to an extremely exact, mirror-smooth finish.

Take deep holes in a tough metal like hardened steel. CNC milling gives you the control for that. You can manage the depth, the feed rate, and the tool path precisely to avoid breaking a drill.

But if you need a long, thin rod made from stainless steel? CNC turning is the clear choice. The spinning action provides stability. It’s faster and produces a more consistent result without the part flexing or vibrating.

The truth is, both processes are compatible with a vast library of materials. Your final decision isn’t just about the metal or plastic. It’s a combination of three things: the part’s basic shape, the specific material, and the level of detail required.

Speed & Efficiency

CNC turning and CNC milling help your factory in different ways. Speed is the major advantage for turning when dealing with round parts. The rapid spin of the workpiece allows the cutting tool to shape it efficiently. You can make hundreds of the same part in less time. That’s why it’s the go-to method for high-volume runs in automotive and medical production.

CNC milling offers a different kind of advantage: flexibility and consolidation. The machine can swap tools automatically without a full stop. Multi-axis milling machines work on many sides of a part. This capability saves a significant amount of time and reduces handling errors. If a part requires multiple features like holes, slots, and contoured pockets, milling can often complete the entire job in one sequence. It streamlines complex work.

Precision & Cost

CNC turning hits the tight tolerances and creates the smooth, flawless finishes required. CNC milling achieves the same level of exactness, but for a different set of geometries. It masters flat surfaces, complex contours, and intricate shapes that aren’t symmetrical. Both methods are fundamental to modern precision manufacturing and custom work. The key is knowing which one to use. Neither is universally “better.” Each is the best tool for a specific type of job. Your choice comes down to the shape you need to create.

Here is a table to show how they compare:

| Process | Tolerances | Surface Finishes |

| CNC Turning | Tighter tolerances for round parts | Better surface finishes for round shapes |

| CNC Milling | High precision for tricky shapes | Accurate results for tight-tolerance parts |

Sometimes, the higher cost is simply the price of making the part at all. The real savings across both methods come from consistency. You save money by virtually eliminating mistakes. Scrap and rework plummet. CNC machining, whether turning or milling, ensures you get the correct part, every single time. That reliability is where the long-term value is proven.

Pros & Cons

Every process is a tool with specific strengths and trade-offs. You have to understand them to choose wisely:

| Advantages of CNC Milling | Disadvantages of CNC Milling |

| Makes parts exactly right, no human mistakes. | Wastes more material than additive processes. |

| Changes tools automatically to save time. | Needs skilled workers to run the machine. |

| Works with many materials. | Problems can happen with untrained workers. |

Both are pillars of precision and custom work. The decision isn’t about which is better overall. It’s about which one is the right fit for the specific part you need to make and the needs of your factory floor. You match the job to the machine.

Quick Comparison:

- CNC Milling Pros: Makes tricky shapes, works with many axes, uses many materials, and is very accurate.

- CNC Milling Cons: Wastes more material, needs skilled workers, and can cost more for hard jobs.

- CNC Turning Pros: Fast for round parts, gives tight tolerances, and keeps costs low for big batches.

- CNC Turning Cons: Only works for round shapes, not good for tricky features.

Choosing the Right Process

Decision Factors

You have several key factors to weigh when choosing a process for your shop. The goal is the best outcome for precision work and custom jobs. The right pick hinges on a few core considerations. Let’s break them down so you can make a clear decision.

- Part Geometry

Look at the shape. Is it round or tubular? Go with CNC turning. Is it flat, full of slots, or has complex angles? CNC milling offers far more options.

- Material Type

The raw material matters. Hard metals like titanium require specific handling. CNC milling handles tough cuts well. For creating long, smooth rods from bar stock, turning is often more effective.

- Production Volume

Consider your quantity. Need thousands of identical pieces? Turning is fast and repetitive. For small batches or prototype runs, milling provides greater flexibility.

- Tolerance and Finish

You need parts that fit and function. Turning excels at achieving tight tolerances and smooth finishes on round components. Milling delivers high precision for complex, multi-sided shapes.

- Cost and Efficiency

You must balance price and speed. Turning is typically more cost-efficient for accomplishing work that turning physically cannot do. The real efficiency is in using the right machine for the job.

Real-World Scenarios

Let’s see how these choices work in real factories. They show exactly how the choice is made on the factory floor.

Medical Industry Example

Take the medical factory. Bone screws are the classic turning job. They have to be perfectly round, smooth, and dimensionally exact. Turning delivers that tight fit and flawless finish at high speed. But for a custom hip plate? That’s a milling job. The plate has a complex, patient-specific shape with precisely located holes. Milling handles that intricate geometry in one setup, enabling true custom work. You can make thousands of screws fast.

Automotive Industry Example

Imagine you run a factory that makes engine parts. You need many pistons and axles every day. CNC turning churns out identical, round parts fast. But the engine block is a different story. It’s a single, complex part riddled with channels, pockets, and mounting surfaces. Only milling can machine all those different features in one coordinated sequence, allowing for design updates without retooling the entire line.

| Scenario | Best Process | Why It Works |

| Bone screws (medical) | CNC turning | Round shape, tight tolerance |

| Custom hip plate | CNC Milling | Complex geometry, customized holes |

| Engine pistons (auto) | CNC turning | High volume, repeatability |

| Engine block channels | CNC Milling | Multi-feature, precision cuts |

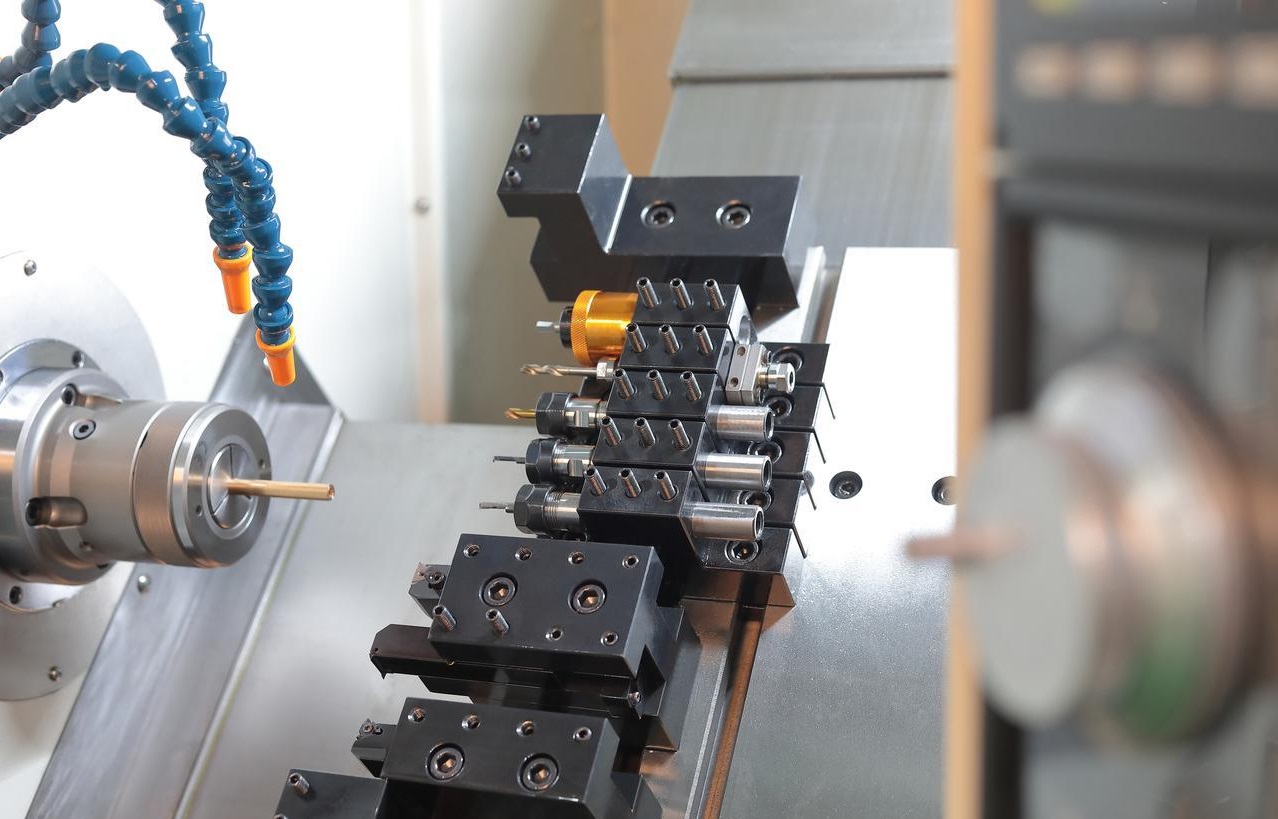

Hybrid Machining

Sometimes you need both processes to finish the job. Hybrid machining combines both processes in a single machine setup. The goal is simple: save time and increase efficiency. It’s the ideal solution for a part that isn’t just one or the other — a part that has both round features and complex, milled details.

Here’s how it typically works.

- First, the machine acts as a lathe. It uses turning operations to create the primary round form — the base cylinder, for instance.

- Then, without ever unclamping the part, the same machine switches modes. It now acts as a milling center. It adds the slots, drills the holes, or cuts the angled faces.

The major advantage is clear. You never move the workpiece. This eliminates the errors that come from repositioning and re-clamping. You get better alignment between features. You also complete the entire job much faster, as you’ve removed the handling and queue time between two separate machines.

Hybrid solutions help you meet strict rules in precision manufacturing. Your factory stays ready for new jobs and tough tasks. You get the speed of CNC turning and the choices of CNC Milling.

Now you see the clear divide. They are different tools for different jobs. Milling handles the complex, intricate shapes. Turning specializes in fast, precise round parts. That single choice — milling or turning — fundamentally shapes how your production line operates.

- Use milling for the difficult geometries. Use turning for the cylindrical forms. It’s that simple.

- Ensure your chosen material is compatible with the process. Not every metal or plastic behaves the same under a spinning cutter versus a stationary tool.

- Think practically about the job’s real needs. What level of precision is non-negotiable? What’s the required finish?

CNC technology keeps getting better. See how it helps your factory:

| Year | Development | Impact on Milling and Turning |

| 1956 | APT programming language | Setup is faster, and work is more efficient |

| 1960s | Software in CNC operations | Parts are more exact, and mistakes are fewer |

| Present | CAD/CAM integration | Designs change quickly, and custom work is easier |

Pick the process that matches your part and what you want to do. The manufacturing process of CNC machining will continue to evolve, resulting in enhanced customisation, efficiency, and intelligence across all factories.

Contact NOBLE for CNC Milling and Turning Services

NOBLE is a leading CNC lathe parts machining service company in China, always providing highly reliable CNC lathe parts machining service for multiple industries. Our CNC lathe parts machining technology method helps customers solve complex parts machining problems to meet customers’ various needs.

Rapid Lead Times

Equipped with advanced CNC lathes, we can provide high-precision, fast CNC lathe parts within 3 days at the fastest.

Professional 5-axis CNC machining machinists and team

NOBLE has domestically advanced lathe machining equipment, is equipped with several experienced professional CNC lathe operators, and uses advanced CNC lathe machining technology to complete your complex, high-precision parts and prototypes in a short time.

Various Materials & Surface Finishes

Choose from over 50 certified metal and plastic materials suitable for CNC turning. Abundant choices for surface finishing on solid metal or plastic turned parts in accordance with all critical design specifications.

24/7 Engineering Support

No matter where you are, you can get our 24/7 engineering support all year round. Our experienced engineer can provide you with the most appropriate solution to your part design, material selection, surface finishing options, and even lead time.

Work with Us in 4 Simple Steps Only

With extensive manufacturing experience, NOBLE provides the optimal solutions for all rapid prototyping and low-volume manufacturing requirements. We streamline the innovation cycle into four simple but effective steps.

Upload Your Design

Just simply upload your CAD files and submit RFQs with clear information online.

↓

Receive Design Analysis

We’ll send you a design for manufacturability analysis and transparent pricing.

↓

Start Manufacturing

Our experts will produce your parts with the required technologies and materials.

↓

Receive Your Parts

Your parts will be delivered to your door directly with stringent deadlines.

FAQ

What is the main difference between CNC milling and CNC turning?

The core difference is motion. In milling, the cutting tool moves around a stationary workpiece. In turning, the workpiece spins while the tool shapes it. This affects how you make precise parts in your factory.

Can I use both CNC milling and CNC turning for one part?

For one part needing both round features and complex details, you absolutely use both. The typical order is turning first to create the base cylindrical form, then milling to add slots, holes, or angled faces. A hybrid machine does this without moving the part, ensuring perfect alignment and saving time.

Which process works better for complex shapes?

Complex shapes belong to milling. The tool’s ability to move in multiple directions allows for pockets, intricate contours, and detailed 3D features. It’s the method for tough, non-round designs.

Is CNC turning faster than CNC milling?

Speed depends on the shape. For purely round parts, turning is almost always faster due to the rapid spinning. For high-volume cylindrical components, it’s the most efficient choice.

What materials can I use in CNC machining?

Material choice is broad. Both processes work with common metals like aluminum, steel, and titanium, as well as many plastics and composites. The application—like medical implants needing titanium—often dictates the material, not the other way around.

How do I choose the right CNC machining process?

Choosing the right process is a practical decision. Examine the part’s dominant shape. Is it round or cylindrical? Use turning. Does it have flat surfaces, pockets, or complex contours? Use milling. Also consider your material and order volume. Your factory’s needs help you decide.

Does CNC machining improve quality in my factory?

Yes, it drastically improves quality. Computer control removes human error from the cutting process. This leads to consistent parts, tight tolerances, and reliable fits. Your output becomes more predictable and trustworthy.

Can CNC machining aid in small-batch production?

And yes, it’s excellent for small batches. The setup is digital. Changing a design for a custom, small-batch job means loading a new program, not building new tooling. This allows for high-quality, low-volume production and keeps your operation adaptable.