What is Waterjet Cutting?

Water jet cutting is a cold working technology that uses ultra-high-pressure water flow for cutting. Ordinary water is pressurized to ultra-high pressure and forms high-speed jets through fine nozzles, which impact the surface of the material to achieve cutting. For hard materials such as metal and stone, abrasives are often added to the water to enhance the cutting force.

How Does Waterjet Cutting Work?

Pressurization

A high-power hydraulic pump or booster pressurizes ordinary tap water to an extremely high pressure, typically ranging from 3,000 to 6,000 bar, which is several times the pressure at the deepest trenches in the ocean. Such high pressure endows water with tremendous potential energy, laying a solid foundation for the subsequent formation of high-speed jets.

Water Acceleration

High-pressure water is conveyed through piping to the cutting head, where it is forced through an extremely small artificial sapphire or diamond nozzle. According to Bernoulli’s principle, as the high-pressure water is forced through this tiny orifice, its pressure energy is converted into kinetic energy, forming a high-speed jet travelling at approximately 900 metres per second. This extremely fine, high-velocity water stream serves as the ‘cutting edge’ for pure waterjet cutting.

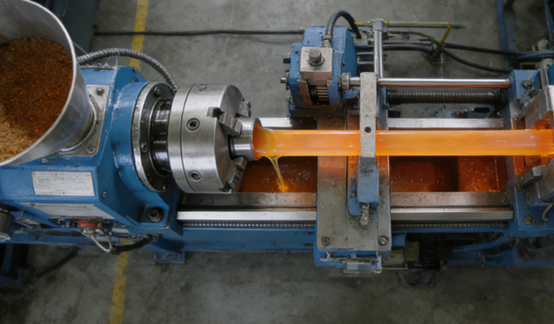

Abrasive Mixing

When cutting hard materials such as metal or stone, the abrasive mixing system is activated. Within the cutting head, a high-velocity water stream passes through a mixing chamber where the Venturi effect creates a vacuum, automatically drawing in fine abrasive particles.

These particles are accelerated to high velocities within the water stream, acquiring substantial kinetic energy. This transforms the pure impact force of the water jet into highly efficient micro-abrasive action, enabling the cutting of hard, thick materials.

Material Erosion & Cutting

The mixed abrasive or pure water jet strikes a tiny point on the material at extremely high energy density. Its kinetic energy instantly erodes the surface, washing away microscopic particles. By moving the cutting head precisely via the CNC system, this erosion point travels along the programmed path, producing a continuous, smooth cut. Throughout the process, the material remains free from thermal effects, avoiding any heat-affected zone or distortion.

CNC Motion & Drainage

The computer precisely controls the movement trajectory of the cutting head according to the path on the design drawing, thereby cutting out any complex shape. After cutting, the waterjet removes material particles and any residual abrasive flow into the water tank below, where their energy is dissipated. The water is then drained or treated, and abrasives can be separated and recycled.

Materials Used in Waterjet Cutting

Metal

- Steel: Water jet is an ideal method for cutting steel, especially suitable for heat-sensitive tool steel, alloy steel, or quenched steel. It will not create a heat-affected zone, can maintain the original hardness and structure of the material, and the cut will not harden or deform.

- Aluminium: Whether it is thin plates or thick aluminum blocks, water jets can cut quickly and cleanly without generating slag or altering material properties due to high heat, as in thermal cutting. The edge quality after cutting is excellent.

- Titanium: Titanium is highly prone to chemical reactions and property changes at high temperatures. The cold cutting characteristics of water jets perfectly avoid these problems and are one of the preferred methods for cutting aerospace-grade titanium alloys. The cut is clean, and there is no risk of thermal embrittlement.

- Brass: Copper has excellent thermal conductivity, making it very difficult to cut with heat and causing significant deformation. A water jet can cut easily without thermal stress, will not change the electrical conductivity and mechanical properties of the material, and the cut seam is fine.

Stone and Ceramics

- Marble: Water jets can cut out extremely complex and fine patterns and shapes, with smooth edges that do not require secondary polishing and do not produce dust or cause stone cracking. They are commonly used tools in stone art and decoration.

- Granite: As an extremely hard natural stone, water jet is the only practical method that can perform complex and irregular cutting on it. It avoids the problems of tool wear and edge chipping in traditional mechanical cutting and has high cutting accuracy.

- Tile: Whether it is ceramic tiles or vitrified tiles, water jets can achieve seamless curves, hollowed-out and inlaid cuts, with neat and smooth cuts and no cracking, greatly enhancing the possibilities of decorative design.

- Composite stone: This material, composed of stone chips and resin, does not cause delamination or edge chipping when cut by water jet, and can perfectly maintain its composite structure. The quality of the cut is superior to that of sawing.

Glass

Water jets can cut ordinary glass, laminated glass and tempered glass. Pure water or fine abrasive cutting can produce smooth edges with almost no micro-cracks, avoiding overall glass breakage caused by thermal stress.

Composites

- Acrylic and plexiglass: Cold cutting of acrylic and plexiglass using pure water jets results in crystal-clear edges without melting, fogging or thermal stress cracking, and no toxic gases are produced during the cutting process.

- Polycarbonate: Polycarbonate, as a tough engineering plastic, will melt and produce poor edges when heat-cut. Water jet cold cutting can achieve clean and burr-free cuts without introducing internal stress into the material.

- Glass fiber: Water jet cutting does not produce a large amount of harmful dust like sawing, nor does it melt the resin matrix like thermal cutting. It can effectively reduce delamination and edge wear, and the cut is clean.

- Carbon fiber: Water jet is the gold standard for cutting carbon fiber composite materials. It is cut through mechanical erosion, avoiding thermal damage and delamination, perfectly preserving the strength and structural integrity of the fibers, and there is no stringing at the cut.

Rubber

Low-pressure pure water jets can easily cut rubber, just like “cutting butter with a water knife”, without deforming, sticking or generating unpleasant odors due to heat generated by friction. The cut is smooth, and the dimensions are precise.

Wood

Water jets can cut wood and are especially suitable for inlaying techniques that create complex patterns. It can reduce the tearing and burrs of wood fibers, and there are no carbonization or burning marks. It is a clean cutting method.

Types of Waterjet Cutting

Pure Water Jet Cutting

Pure water jet cutting uses only ultra-high-pressure water, without abrasives. Ordinary tap water is pressurized to several hundred megapascals and forced through a fine gemstone nozzle, forming a high-energy water jet traveling at several times the speed of sound. This high-speed jet cuts by eroding the material surface through intense impact and washing away the micro-fragments.

Pure water jet is mainly suitable for cutting relatively soft materials, such as food, foam, rubber, cork, paper, plastic film, and some soft plastics.

Pros:

- Exceptionally high cutting precision

- No heat-affected zones or material deformation

- Relatively low operating costs and environmentally friendly

- Extremely rapid cutting speeds for soft materials

Abrasive Water Jet Cutting

The high-pressure water pump generates a pure water jet. This water jet creates a vacuum in the mixing chamber of the cutting head through the Venturi effect, automatically drawing in and accelerating abrasive particles to form an abrasive water jet.

Abrasive particles undertake the main cutting work, eroding the material through microscopic grinding and impact. This method greatly expands the cutting capacity and can efficiently cut various high-hardness and high-strength materials, including all types of metals, stones, glass, ceramics, composite materials, and thick plastics.

Abrasive water jet cutting retains all the cold working advantages of pure water cutting, but has a stronger cutting capacity and an extremely wide range of applications. The cost is that the cutting cost increases due to the consumption of abrasives, and the wear of the cutting head parts is also faster.

Pros:

- Exceptional material versatility

- Impressive cutting depth

- High-quality and flexible cutting

Benefits of Waterjet Cutting

Cold Cutting Process

Water jet cutting separates material through mechanical erosion by a high-speed water stream, not heat. As a result, the work area experiences no significant temperature rise. This completely avoids issues like heat-affected zones, changes in metallurgical structure, hardening, thermal deformation, or residual stress. The method is thus uniquely valuable for machining heat-sensitive, explosive, or previously heat-treated materials.

Material Versatility

From soft materials like rubber, foam, and food to hard ones such as stone, glass, and ceramics, water jets can cut almost all types of materials. Its “universal” feature stems from the fact that its cutting mechanism is physical erosion rather than relying on the material’s electrical conductivity or specific melting point, which makes it an ideal solution for cross-industry and multi-material machining environments.

High Flexibility and Precision

Water jets can easily start cutting from any point inside the sheet without the need for pre-made starting holes. Combined with an advanced numerical control system, it can precisely cut out extremely complex two-dimensional geometric shapes, acute angles, and fine contours. After cutting, the workpiece usually undergoes minimal deformation. In many cases, it can be used directly or only requires a small amount of subsequent machining, which greatly enhances production flexibility and design freedom.

Environmental and Safety Excellence

Water jet cutting does not use toxic chemicals. During the cutting process, no toxic gases, smoke, or dust are produced, and the working environment is clean and safe. Unlike plasma or flame cutting, it does not produce harmful radiation or cause the material to burn.

The main by-product is a mixture of water, abrasives, and material debris, which is easy to be centrally treated and recycled, meeting the requirements of modern green manufacturing.

Superior Cutting Quality

The cut quality of water jet cutting is excellent, with a smooth surface and usually no burrs. By controlling the process parameters, the cutting slope can be effectively reduced or controlled.

Water jet cutting can not only be used for contour cutting of the final product, but also for hole opening, slotting, and even surface cleaning or rust removal operations, achieving multiple uses with one machine and improving the comprehensive utilization rate of the equipment.

Water Jet Cutting Considerations

Initial Investment and Operational Cost

The upfront cost for a complete waterjet system is significant, typically higher than many traditional cutting tools. Operational costs include electricity, water, abrasives, and routine maintenance of high-wear components like intensifier seals, nozzles, and mixing tubes.

Material Thickness and Cutting Speed

Although waterjets can cut very thick materials, cutting speed decreases dramatically as thickness increases. For very thick, dense materials, the process can become slow compared to other methods. Production timelines must account for this inverse relationship between thickness and speed.

Kerf Taper and Cutting Accuracy

A natural characteristic of waterjet cutting is a slight taper, known as the “kerf taper.” For precision parts, this must be compensated for through nozzle tilt or in the CAD design.

Noise and Maintenance

The system generates considerable noise, primarily from the high-pressure pump and the cutting stream impacting the water in the catcher tank, requiring hearing protection and potentially sound enclosures in a shop environment. Maintenance demands are higher than for simpler machines, focusing on the high-pressure system to prevent failures and ensure consistent pressure.

Material-Specific Limitations

It is not ideal for cutting tempered glass or certain hardened ceramics, as the initial puncture can cause uncontrolled cracking. For laminated materials, water intrusion into the layers must be considered.

Waterjet Cutting vs Other Cutting Methods

| Cutting Method | Key Advantages | Key Limitations |

| Waterjet Cutting | True cold cutting. Can cut virtually any material. High flexibility for complex shapes. Good accuracy and surface finish. Environmentally friendly process. | Slower than laser/plasma for thin metals. Higher operational cost. Natural kerf taper requires compensation. Initial investment is high. |

| Laser Cutting | Very high speed and precision on thin to medium sheets. Excellent edge quality and minimal kerf. Low operating cost for sheet metal. Highly automated. | Creates a heat-affected zone (HAZ). Limited to reflective materials and non-metals. Lower efficiency on very thick materials. Higher initial cost for high-power systems. |

| Plasma Cutting | Very fast on medium to thick conductive metals. Lower equipment and operational costs than waterjet/laser. Portable systems are available. | Significant HAZ and thermal distortion. Wider kerf, lower accuracy, and edge quality. Limited to conductive metals. Produces fumes and noise. |

Applications of Waterjet Cutting

Aerospace

This industry extensively employs titanium alloys, high-strength aluminum alloys, nickel-based superalloys, as well as carbon fiber and aramid fiber composites that are extremely sensitive to heat.

The cold cutting characteristics of water jets perfectly avoid thermal stress, microcracks, and material delamination, and can precisely cut the fuselage wing ribs, honeycomb structures, and insulating materials, ensuring the structural integrity and fatigue strength of core components.

Automotive Industry

Water jet cutting technology is applied in the automotive industry, ranging from prototype vehicle development to component production. This process can be used to cut interior materials, composite panels, aluminum alloy body panels, transmission gaskets, and heavy truck frame beams. Its advantages lie in its ability to precisely cut soft materials without burrs, process high-strength steel without thermal deformation, and support lightweight design and multi-material mixed machining.

Architectural Decoration

A water jet is a revolutionary tool in the architectural decoration industry. It can cut any complex patterns, hollowed-out window lattices, kitchen countertop openings, and bathroom accessories on marble, granite, artificial quartz stone, and tiles in a numerically controlled manner. The cutting edge is smooth and does not require secondary polishing, and it will not cause the natural stone to crack, greatly enhancing the design freedom and artistic expressiveness.

Industrial Manufacturing

Water jets can cut various gears, mechanical bases, seals, bearing housings, etc. It is particularly suitable for machining high-hardness die steel that has undergone heat treatment, as it will not damage its quenched hardness. It is also used for cutting thick steel plates for equipment maintenance or single-piece and small-batch production, without the need to make molds, and is flexible and efficient.

Glass Industry

Water jet is the preferred method for cutting carbon fiber reinforced plastic (CFRP) and glass fiber reinforced plastic (GFRP), with no dust, no delamination, and less fiber drawing, perfectly maintaining the interlayer strength of composite materials. In the glass industry, water jet cutting is used to cut laminated safety glass, laminated glass, art glass, and display glass substrates. It features high cutting accuracy, smooth edges, and can effectively control microcracks.

Food Machining Industry

Pure water jets can cut various types of food, such as cakes, frozen meats, seafood, etc. The cutting process is hygienic, pollution-free, and free of debris. It will not change the texture and taste of food, and can achieve automated and uniformly shaped fine slitting. It is suitable for large-scale food production lines and high-end catering decoration.

NOBLE’s Waterjet Cutting Service

NOBLE is your trusted one-stop custom manufacturing solution, from prototype design to manufacturing, with huge manufacturing resources, suitable technology, streamlined process, expert guidance, and a perfect quality inspection process to turn your ideas into reality.

From design to prototyping to production, we are ready to turn your ideas into reality with advanced manufacturing solutions tailored to your product. Choosing us for custom sheet metal waterjet cutting means working with a team that values precision, reliability, and innovation. Here are the reasons why we are the ideal choice for your cutting needs:

- Rapid Prototyping Capabilities

- Expertise and Experience

- Precision and Accuracy

- Fast Turnaround Times

FAQ

What materials can a waterjet cut?

A waterjet cutter can handle an exceptionally wide range of materials. This includes metals (steel, aluminum, titanium), stone and tile, glass, composites, rubber, plastics, foam, and even food products.

How thick a material can a waterjet cut?

Waterjets are capable of cutting very thick materials. While it varies by material hardness, a high-powered abrasive waterjet can typically cut metals up to 8-10 inches (200-250 mm) thick and softer materials like foam or rubber up to several feet thick.

Is waterjet cutting accurate?

Yes, modern waterjet cutters are highly accurate. Typical positional accuracy is around ±0.003 inches (±0.076 mm), with repeatability of ±0.001 inches (±0.025 mm). The kerf (width of the cut) is small and consistent, allowing for intricate shapes and detailed parts.

How fast is waterjet cutting?

Cutting speed depends on material type and thickness. It can range from very high speeds for thin, soft materials to slower, deliberate speeds for thick, hard metals. The focus is on precision and quality rather than raw speed for thick materials.

Is waterjet cutting expensive?

The cost varies based on part complexity, material, and thickness. While the initial machine investment and abrasive cost are factors, waterjet cutting often proves cost-effective by eliminating secondary machining, minimizing material waste through nesting, and reducing tooling costs for custom one-off parts.