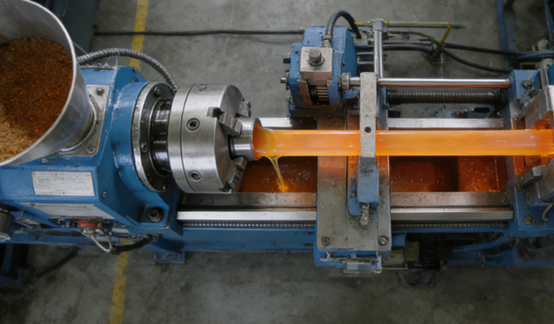

What is High Volume CNC Machining?

High-volume CNC machining refers to the automated, high-precision, and highly efficient cutting and forming of materials such as metals and plastics using computer numerical control (CNC) machine tools, producing identical components at mass production scales.

High-volume CNC machining relies heavily on automated equipment, optimised machining programmes, specialised tooling fixtures, and systematic production management to achieve the lowest unit cost, fastest production speed, and most stable quality.

Material Selection for High Volume CNC-Machined Parts

Aluminium

Aluminium alloy ranks among the most commonly used materials for high-volume machining, particularly grades such as 6061 and 7075. It offers a favourable combination of light weight and moderate strength, coupled with excellent machinability. This translates to high cutting speeds and reduced tool wear, significantly enhancing production efficiency while lowering unit costs.

Stainless steel

304 and 316 austenitic stainless steels are selected for their outstanding corrosion resistance, strength, and durability. Although their machining difficulty exceeds that of aluminium, demanding stricter requirements for cutting tools and machining parameters, they remain indispensable in industries requiring corrosion resistance and hygienic conditions, such as medical devices, food processing equipment, and chemical plant components.

Carbon steel

Carbon steels such as 1018 and 1045, with their high strength, good toughness, and lower cost, are the preferred choice for mass-produced structural components.

Carbon steel is readily machinable and can be further hardened through heat treatment. It is commonly used in the manufacture of gears, shafts, bolts, and various mechanical frames, with extensive applications in the automotive and industrial equipment sectors.

Brass

Brass alloys (such as C360) are renowned for their exceptional machinability, earning them the designation ‘free-cutting brass’. During machining, they exhibit excellent chip breaking properties, enabling very high surface finish and dimensional accuracy whilst offering extended tool life.

Brass is frequently employed in components requiring precision, electrical conductivity, corrosion resistance, and low friction, such as valves, pipe fittings, electronic connectors, and locks.

Plastic

Plastics such as nylon, POM (acetal), and ABS. These materials are insulating, lightweight, chemically resistant, and require no coolant during machining, making them exceptionally clean.

Engineering plastics are readily machinable at high speeds, making them suitable for producing lightly loaded structural components, insulating parts, bearings, and various housings. They are widely used in high-volume consumer electronics and automotive interior components.

Titanium

Titanium alloys such as Ti-6Al-4V, whilst commanding high material costs and presenting significant machining challenges, remain irreplaceable due to their exceptionally high strength-to-weight ratio, outstanding corrosion resistance, and biocompatibility.

The high volume machining of titanium alloys necessitates specialised equipment and processes, primarily serving high-end applications including aerospace engine components, high-performance racing parts, and surgical implants.

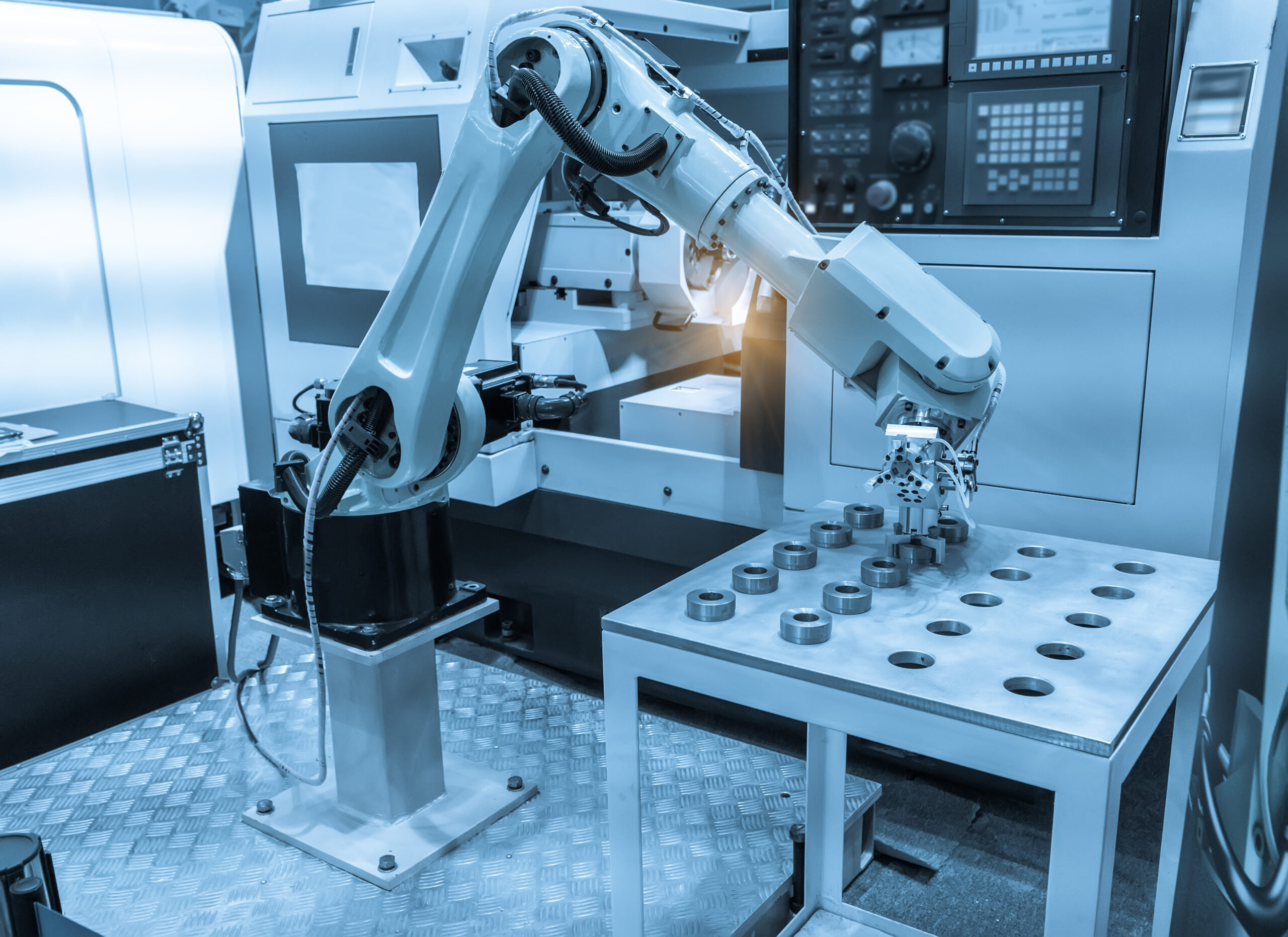

The Impact of Multi-Axis CNC Machining on High Volume Production Efficiency

Reduce Fixturing Steps

Machining complex components on conventional 3-axis machines often requires multiple re-clamping operations to process different sides, whereas multi-axis machines can complete virtually all machining operations except the base surface in a single setup. For high-volume production, such time savings are substantially amplified, directly enhancing overall production line throughput.

Optimizing Cutting Conditions

Multi-axis machining utilizes a rotary head or rotary table to position the cutting tool at the optimal angle relative to the workpiece, enabling the machining of deep cavities, inclined surfaces, and complex curved surfaces—areas that are impossible to machine on three-axis machine tools or require specialized tools.

Multi-axis interpolation can use the side of the tool instead of the cutting edge for cutting, or always maintain the optimal angle between the tool axis and the machined surface. This effectively increases the cutting contact area and improves the material removal rate.

In mass production, reduced tool changes and more stable tooling costs directly translate into higher overall equipment efficiency and more controllable production costs.

Improve Surface Finish

Multi-axis machining enables the tip of the ball-end mill to avoid the lowest point of its linear speed within the machining zone through continuous tool angle adjustment. This achieves a more uniform and higher-quality surface finish across the entire curved surface. Consequently, many components meet specifications upon completion in the machining centre, eliminating the need for subsequent manual polishing or specialised grinding operations.

Simplify Fixture Design

As the workpiece requires only a single clamping operation, fixture design can be greatly simplified, typically necessitating only a base plate or a simple vice. This not only reduces the tooling costs per production batch but also streamlines the operator’s clamping process, minimising downtime caused by complex fixture adjustments.

Comparing High Volume CNC Machining to Low Volume Prototyping

| Aspect | High-Volume CNC Machining | Low-Volume Prototyping |

| Cost Focus | Low per-unit cost via economies of scale | Acceptable higher per-unit cost for speed and flexibility |

| Production Quantity | Thousands to millions of identical parts | A few to hundreds of parts, often varying |

| Process Optimization | Highly optimized, fixed processes for maximum speed and minimum waste | Flexible, adaptable processes for iterative changes |

| Tooling & Setup | Significant upfront investment in dedicated tooling and automation | Minimal setup, often using standard tooling and quick-change fixtures |

| Lead Time | Longer initial setup, but very fast cycle time per part once running | Very short initial lead time, but slower cycle time per part |

Process and Equipment

- Small-batch prototyping: Processes are flexible, typically employing versatile equipment. Operations may be simplified, sacrificing some optimisation for speed. Material selection may utilise readily machinable alternatives.

- High-volume production: Processes are highly optimised and fixed, utilising specialised, automated equipment and customised tooling. Operations are meticulously designed to reduce cycle times by seconds per unit, potentially integrating multiple processes. Material selection is strictly defined and fixed.

Cost Structure

- Small-batch prototyping: Costs are primarily dominated by one-off engineering expenses, including programming, process preparation, and set-up time. Per-unit machining costs are high, yet total expenditure remains low due to low volume. A premium is paid for speed.

- High-volume production: Costs are dominated by marginal expenses – the materials, labour hours, tooling, and energy consumed per part. Substantial initial investment is required for tooling and process development, but economies of scale spread these costs across thousands of parts, driving unit costs down to minimal levels.

Quality Control Methods

- Small-batch prototyping: Quality control is comprehensive and manual. Full-dimension inspection is typically performed on the first article or each piece to ensure conformity with design intent, with a focus on ‘getting it right’.

- High-volume production: Quality control is statistical and automated. It relies on strict process control (SPC), ensuring consistency across entire production batches through regular sampling and automated in-line inspection, with a focus on ‘doing it the same every time’.

Supply Chain

- Small-batch prototyping: supply chain relationships are flexible, typically involving direct collaboration between design engineers and agile prototyping workshops or integrated machining facilities, prioritising rapid response.

- High-volume production: Supply chain relationships are rigorous and long-term, encompassing stringent supplier audits, contract manufacturing, long-term agreements, and complex logistics planning, prioritising stability and reliability.

Design for Manufacturability Tips for High Volume CNC Projects

Design Optimization

Designers must collaborate closely with process engineers to ensure part designs are as machinable as possible while meeting functional requirements. This entails: avoiding features such as deep cavities and minute internal angles that are difficult for cutting tools to access; designing reference surfaces and structures that facilitate easy clamping. A design optimised for manufacturing directly reduces machining cycles, minimises tool wear, and decreases scrap rates.

Tight Tolerance Control

Designers should rigorously analyse functional requirements, applying necessary tolerances only to mating surfaces, sealing surfaces, or critical assembly surfaces.

Non-critical dimensions should employ generous standard tolerances. More generous tolerances permit the use of more aggressive cutting parameters, reduce tool wear, minimise inspection time, and enhance yield rates, thereby accumulating substantial cost savings across all stages of production.

Material Selection

Beyond the material’s intrinsic cost, one must also consider its machinability, tool wear rate, heat treatment requirements, and subsequent surface treatment expenses.

For structural components, for instance, readily machinable aluminium alloys or specific pre-hardened steels may prove more cost-effective overall than high-hardness materials requiring post-processing heat treatment. Material consistency, supply reliability, and traceability are equally critical considerations for high-volume projects.

Process Integration Consideration

Effective design minimizes the need for secondary machining. For example, designers should aim to avoid manual deburring, integrate milling, drilling, tapping, and partial inspection into one CNC operation, and plan mounting points and conductivity requirements for surface treatments like anodizing or powder coating. A more advanced optimization is to consolidate multiple parts into a single unit, which eliminates assembly costs and reduces part inventory.

Quality Control Planning

During design, consideration must be given to whether component dimensions permit efficient and accurate inspection. Features that are difficult to measure internally or complex surface contours should be avoided.

Establish clear inspection benchmarks and access spaces for critical dimensions, considering the potential use of go/no-go gauges or automated visual inspection. A design that facilitates straightforward inspection forms the foundation for ensuring consistent quality in high-volume production.

Fixture Strategy Evaluation

The clamping arrangement should be conceived during the design phase. An ideal design should provide a large, flat reference surface with sufficient clamping areas or pre-set process screw holes. Consider employing standardised fixtures or designing dedicated, efficient multi-part fixtures to achieve machining of multiple components in a single setup. This represents one of the core methods for enhancing efficiency in high-volume production.

Common Challenges and Solutions in High Volume CNC Manufacturing

Machine Maintenance and Investment

The purchase of high-performance, stable CNC machines and automation systems requires significant upfront investment. Meanwhile, to ensure uninterrupted mass production, proactive predictive maintenance programs must be adopted. Neglecting maintenance causes unplanned downtime, the costs of which are greatly amplified in high-volume manufacturing and can offset all efficiency benefits.

Suitable Use Cases

High-volume CNC machining is not ideal for every component. Suitability depends on balancing annual production volume with part complexity. It is best suited for metal or plastic parts with high annual demand, complex geometries, and tight precision requirements, including automotive engine parts, medical device housings, and high-end electronics enclosures.

For simpler parts or those with low production volume, traditional methods like stamping or casting are often more cost-effective. Therefore, a thorough technical and economic analysis should be conducted before project launch.

Supply Chain and Production Coordination

Any shortage of raw materials or auxiliary supplies will result in the entire production line ceasing operations. The challenge lies in ensuring a continuous and stable supply of the substantial quantities of metal bar stock, coolant, and other materials required for high-volume production.

Strategic partnerships must be established with reliable suppliers, and models such as supplier-managed inventory must be implemented to mitigate market fluctuations.

Quality Assurance in Batch Production

Establishing a systematic quality assurance framework based on statistical process control. This entails setting up regular sampling inspection points at critical process stages, alongside integrating automated in-line measurement equipment for real-time feedback and compensation.

Quality Control in High Volume CNC Machining

Implement Statistical Process Control

Rather than relying solely on 100% inspection, regular and systematic sampling measurements of critical dimensions are conducted during production. Measurement data is plotted on control charts to monitor real-time trends in mean and range variations.

Should data points exhibit abnormal fluctuations or exceed control limits, the system immediately triggers alerts, indicating potential systematic process deviations. This enables intervention before significant non-conforming output accumulates, thereby achieving preventive quality control.

Automated Inspection

Before machining, the probe automatically detects workpiece position and performs origin offset compensation; during or after machining, it automatically samples critical dimensions.

Measurement data is automatically fed back to the CNC system, where comparison with theoretical values enables real-time, automatic adjustment of tool compensation values, ensuring dimensions remain centred within tolerance bands.

First Article Inspection

Before mass production or after tooling modifications, a full-dimension first-article inspection is required. This step validates not only part conformity but also verifies the machining program, process parameters, and fixture setup. High-precision equipment, such as a coordinate measuring machine, is typically used to produce detailed data reports. Batch production may proceed only after accuracy is confirmed.

Production Traceability

Assign a unique identifier to each production batch or individual part. Link this identifier via the manufacturing execution system to comprehensive production data, such as raw material batches, equipment used, operators, machining times, and inspection results. If quality issues arise, this system enables rapid and precise root cause analysis, identifying whether the problem originates from materials, equipment, or process deviations.

Manage Tool Lifecycle Strictly

Tool condition is a direct factor influencing machining dimensional stability. A tool management system must be employed to document the entire lifecycle of each tool, from procurement and presetting through usage to disposal.

Expected service life should be determined based on cutting materials and parameter settings, with replacement alerts issued before reaching the threshold. Concurrently, regular wear inspections must be conducted to prevent sudden quality deterioration caused by tool chipping or excessive wear, thereby ensuring stable machining conditions.

NOBLE’s High Volume CNC Machining

At NOBLE, we specialize in delivering precision, efficiency, and reliability through our advanced high-volume CNC machining services. We transform your design into thousands or even millions of identical and high-quality parts, ensuring consistency and cost-effectiveness at every stage of production.

Our Capabilities:

- Advanced Manufacturing Technology

- Design for Manufacturing (DFM) Partnership

- Integrated Quality Assurance

- Scalable Production & Supply Chain Management

FAQ

How does high-volume CNC machining reduce the cost per part?

High-volume machining achieves lower per-part cost through economies of scale. The significant upfront investment in optimized programming, custom fixtures, and specialized tooling is amortized over a vast number of units.

What are the main benefits of using multi-axis CNC machines for high-volume production?

A 5-axis CNC machine can access almost all sides of a part in a single setup. This eliminates errors from repositioning, ensures higher dimensional accuracy and complex geometry capability, and drastically reduces non-cutting time. For high volumes, this translates to faster overall throughput, consistent quality, and the ability to design more complex, consolidated parts that reduce assembly needs.

When is CNC machining the right choice over casting or stamping for high volumes?

CNC machining is ideal for high volumes when parts have complex geometries, tight tolerances, or require superior material properties from solid stock. For very simple shapes at extreme volumes, stamping or casting becomes more cost-effective due to even faster cycle times.

What are the biggest challenges in high-volume CNC projects?

Key challenges include maintaining consistent quality over the entire run, managing tool wear and scheduling preventive maintenance to avoid unplanned downtime, optimizing every second of the cycle time, and ensuring a reliable supply chain for materials and consumables.

What materials are most common for high-volume CNC machining?

Aluminum alloys are the top choices due to their light weight and good strength. Various steels are selected for strength and durability. Engineering plastics are used for electrical and lightweight components.