What is CNC Machining for Polycarbonate?

Polycarbonate is a high-performance thermoplastic, renowned for its outstanding toughness and transparency. Its most prominent feature is its extremely strong impact resistance. At the same time, it has high light transmittance, similar to glass, but is lighter in weight.

Polycarbonate is widely used in fields that require safe, transparent, and lightweight components, such as automotive lampshades, spectacle lenses, electronic device casings, medical devices, and common greenhouse polycarbonate sheets.

Understanding Polycarbonate Material Properties

Polycarbonate is a thermoplastic engineering plastic with outstanding properties, its core characteristics being summarised as ‘tough, transparent and lightweight’.

- Exceptional toughness. It possesses outstanding impact resistance, hundreds of times greater than ordinary glass, making it highly resistant to breakage and offering superior safety.

- High transparency: Light transmittance approaches that of glass, delivering excellent optical performance.

- Lightweight: Density is approximately half that of glass.

- Good heat resistance: Withstands elevated temperatures, making it suitable for applications requiring sterilization or high-temperature environments.

- Excellent electrical insulation: Serves as a superior electrical insulating material.

- Dimensional Stability: Resists deformation, enabling high machining

How Does CNC Machining Polycarbonate Work?

Material Pre-treatment

Due to the strong hygroscopicity of polycarbonate, it must be thoroughly dried before machining. It usually needs to be dried in a forced convection oven at 120°C for 4 to 6 hours to reduce the moisture content to below 0.02%.

Materials that have not been fully dried will develop silver streaks, bubbles, and surface defects during machining, seriously affecting the strength and transparency of the products. This is the primary prerequisite for ensuring machining quality.

Tool Selection

When machining polycarbonate, CNC machine tools with good rigidity and high precision should be selected, and hard alloy or diamond-coated tools should be given priority. The tool design should adopt sharp cutting edges and large chip removal grooves, and the rake Angle should be large to reduce cutting resistance.

Special plastic fixtures should be prepared to prevent surface damage or internal stress concentration of the material due to excessive clamping force.

Setting Machining Parameters

The rotational speed of machines machining polycarbonate is usually controlled within a medium range, and the feed rate should be kept uniform and continuous. The cutting depth should be shallow, and multiple tool passes should be adopted. The key to parameter setting is to avoid overheating, as polycarbonate will stick to the knife when overheated.

Performing Machining Operations

During the machining of polycarbonate, it is necessary to ensure continuous chip removal to avoid secondary friction and heat generation caused by chip accumulation.

For complex parts, a layer-by-layer cutting strategy should be adopted. First, rough machining should be carried out to leave an allowance, and then fine machining should be performed. When drilling, special attention should be paid to the speed of tool retraction to prevent cracking at the hole opening. The entire machining procedure requires real-time monitoring of the cutting status and timely adjustment of parameters.

Post-processing

After the parts are machined, they need to undergo annealing treatment to eliminate internal stress. Usually, the parts are placed in an environment of 120-130°C and held for 1-2 hours, and then cooled slowly. Afterwards, polishing, coating, hardening, or UV stabilization treatment can be carried out as needed. For transparent products, optical-grade polishing is also required to restore surface transparency, and finally, strict quality inspection is carried out

Different Methods of CNC Machining Polycarbonate

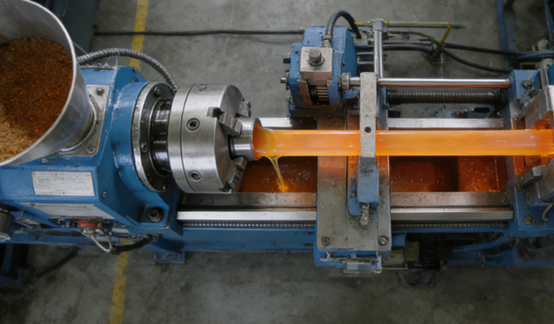

Plastic injection

Injection molding is the most commonly used method for large-scale production of polycarbonate parts. After drying, the polycarbonate particles are heated and melted, then injected under high pressure into a sealed metal mold cavity. After cooling and solidification, the mold is removed to obtain complex-shaped and precisely sized products.

Injection molding has extremely high efficiency and is suitable for manufacturing a large number of standard parts, such as mobile phone casings, car lampshades, and connectors, but the initial mold cost is high.

CNC milling

CNC milling is a process that uses a rotating multi-edge tool to cut a fixed polycarbonate billet. The cutting tool moves in multiple axial directions and removes material by cutting, scraping, or planing.

CNC turning

CNC turning is the process of rotating polycarbonate bar or tube billets while cutting them with a fixed tool. It is mainly used for machining parts with rotary symmetry characteristics.

CNC drilling

CNC drilling is the process of machining round holes in polycarbonate workpieces using a rotating drill bit. It can be used as an independent process or is often integrated into the milling or turning process.

Thermal Forming

Polycarbonate sheets are heated above their glass transition temperature to soften them, then pressed against a mould surface using vacuum, pneumatic pressure, or mechanical force before cooling to form the final shape.

Thermoforming can be formed under relatively low pressure, and the mold cost is lower than that of injection molding, but usually the scraps need to be trimmed later.

3D Printing

3D printing mainly uses fused deposition modeling technology to heat and extrude polycarbonate filaments and stack them layer by layer to create three-dimensional objects. This method offers unparalleled design freedom in complex prototypes, custom tools, and small-batch production, and is particularly suitable for trial production parts with complex structures.

The layered structure of 3D printing leads to anisotropy, with its strength usually lower than that of injection-molded parts and a poorer surface finish. It is mostly used in the design and verification stages.

Blow molding

Blow molding involves placing a heated and softened polycarbonate tube blank in a mold, blowing compressed air into the tube to cause it to expand and adhere to the inner wall of the mold. After cooling, a hollow product is formed.

Blow molding is the main process for manufacturing hollow products such as polycarbonate water bottles, containers, and automotive air ducts. It can form seamless hollow structures, but is usually limited to symmetrical or simple-shaped products.

Common Challenges When Machining Polycarbonate

Material Moisture Defects

Polycarbonate is highly prone to absorbing moisture from the air. If it is not fully dried before machining, the internal moisture will vaporize at high temperatures, forming silver streaks, bubbles, or cloud-like defects on the surface of the product, which seriously affects its transparency and mechanical strength.

Cutting Heat Adhesion

Polycarbonate has poor thermal conductivity and is sensitive to temperature. The heat accumulated during cutting can easily soften and melt the material, adhering to the cutting edge of the tool to form a built-up edge. This will lead to an increase in cutting resistance, deterioration of surface finish, and even cause material degradation and yellowing.

Elastic Recovery Accuracy

Polycarbonate has strong elasticity. During machining, the compressed area will partially rebound after the tool leaves, resulting in a deviation between the actual machining size and the designed size. This is particularly evident when drilling and milling inner cavities, where tool path compensation or reserved machining allowance needs to be carried out in advance based on material properties.

Residual Stress Cracking

Mechanical machining can disrupt the internal stress balance of polycarbonate, creating local stress concentrations around the edges and holes. These residual stresses may induce crack propagation during subsequent installation, use, or exposure to chemical solvents.

Low Hardness Scratching

The Mohs hardness of polycarbonate is only about 3M, and it is very easy to be scratched by hard objects during handling, clamping and machining. Even if special plastic fixtures are used, indentations may still occur at the clamping points. During machining, it is often necessary to retain a protective film or use chemical polishing in the final process to restore the surface condition.

Key Advantages of Polycarbonate for CNC Projects

Machining Stability

Polycarbonate demonstrates excellent dimensional stability during CNC machining. Its low shrinkage rate and low coefficient of thermal expansion ensure minimal deformation during cutting. Even under machining conditions of high rotational speed or large feed rate, the material can still maintain shape consistency. In addition, its uniform material structure allows for long-term continuous machining without local warping.

High Toughness

The impact strength of polycarbonate is more than ten times that of acrylic. This toughness directly translates into a process advantage in CNC machining: when performing thin-walled milling, deep hole drilling, or complex contour cutting, the material is less likely to experience edge chipping, microcracks, or brittle fracture.

For instance, when machining transparent partitions with a thickness of less than 1mm, polycarbonate can withstand the radial force of the cutting tool, while acrylic is prone to cracking.

Good Surface Finish

The surface of polycarbonate after machining has a relatively high natural smoothness and a small loss of transparency. Only slight polishing is needed to meet the optical grade requirements. This feature significantly reduces the time of post-processing procedures and is particularly suitable for light guide parts or observation Windows that require light transmission.

Heat Resistance

The heat distortion temperature of polycarbonate reaches 130-140°C, and it can withstand the instantaneous high temperature generated during CNC machining without softening or deforming. Compared with engineering plastics such as ABS, it allows for higher spindle speeds, thereby enhancing machining efficiency. Meanwhile, its own non-conductive property also avoids the problem of electrostatic adsorption of chips during machining.

Strength for Complex Structures

The mechanical strength of polycarbonate enables it to process parts with suspended structures, deep cavities, or fine ribs without structural collapse due to tool pressure. For instance, when machining the shock-absorbing frame of the unmanned aerial vehicle’s pan-tilt, its strength can ensure that the 0.5mm thick reinforcing ribs remain intact during the milling process.

Post-Processing and Finishing Options for Polycarbonate Parts

Annealing Treatment

Annealing is a key step in eliminating internal stress in polycarbonate, especially for parts that have undergone mechanical machining or complex forming. Annealing can significantly reduce the risk of stress cracking in parts during subsequent use or contact with chemical solvents, and enhance the long-term dimensional stability.

Mechanical Polishing and Grinding

Polishing polycarbonate parts with sandpaper can remove the tool marks or minor scratches from CNC machining and restore optical transparency. For parts with high transparency requirements, diamond gypsum is often used for precise polishing. This method can achieve a light transmission effect close to that of glass.

Chemical Polishing

Immerse the parts in a solvent mixture of a specific formula for several seconds to several minutes to achieve rapid leveling by slightly dissolving the surface layer and obtain a high gloss. This method is highly efficient and capable of handling complex geometries, but it requires strict control over time, concentration, and temperature.

Coating Treatment

- Hard Coatings: Surface spraying or dip coating with UV-curable or thermosetting transparent coatings significantly enhances surface hardness and scratch resistance, suitable for frequently touched dashboard panels and spectacle lenses.

- UV-Protective Coatings: Coatings incorporating UV absorbers effectively block ultraviolet radiation, preventing yellowing and brittleness caused by prolonged outdoor exposure, thereby extending component lifespan.

- Decorative Coating: Achieves metallic finishes, colour effects, or reflective properties through spraying, electroplating, or vacuum deposition. Commonly used on consumer electronics casings and automotive trim components.

Printing and Marking

Screen printing, pad printing, or inkjet printing can be used to add permanent marks, scales, or decorative patterns to polycarbonate parts.

Laser marking forms high-contrast permanent marks on the surface through precise energy, and it is non-contact and chemically consumption-free. It is particularly suitable for the traceability requirements of medical and aviation components.

Comparing Polycarbonate to Acrylic and Other Plastics

| Property | Polycarbonate | Acrylic (PMMA) | ABS |

| Transparency | High | Extremely High | Opaque |

| Impact Resistance | Extremely High | Low | Medium |

| Heat Resistance | High (~135°C) | Medium (~90°C) | Medium (~100°C) |

| Surface Hardness | Low (easily scratched) | High (more scratch-resistant) | Medium |

| Chemical Resistance | Fair (sensitive to strong bases) | Fair (sensitive to solvents) | Poor (sensitive to solvents) |

| Machinability | Medium (prevent gumming) | Easy (but brittle) | Easy |

Design Tips for CNC Machining Polycarbonate

Thin Wall Optimization

Although polycarbonate has good toughness, its overly thin wall thickness is prone to vibration and deformation during machining. It is recommended that the minimum wall thickness be no less than 1.5 millimeters. For large-area structures, grid-like reinforcing ribs should be added, with the height of the ribs not exceeding three times the wall thickness, to enhance rigidity and reduce material usage.

Stress Relief Design

All inner right angles and outer sharp corners of the parts should be changed to arc transitions, and the minimum fillet radius is recommended to be ≥0.5 millimeters. This can disperse the stress during machining and use, significantly reduce the risk of corner cracking, and at the same time extend the service life of the milling cutter.

Hole Slot Design

The drilling position should be at least 1.5 times the diameter of the hole from the edge to prevent edge cracking. It is recommended that deep holes adopt a stepped design. The width of the long groove is preferably greater than or equal to 1.2 times the material thickness, and a tool withdrawal fillet should be reserved at one end.

Cavity Simplification

Avoid closed cavities where the design depth of the parts exceeds five times the diameter of the cutting tool; otherwise, chip removal will be difficult, and overheating is likely to occur. For the necessary deep cavities, they can be designed for split assembly or with process bevels added to the side walls to facilitate machining.

NOBLE’s CNC Machining Polycarbonate Service

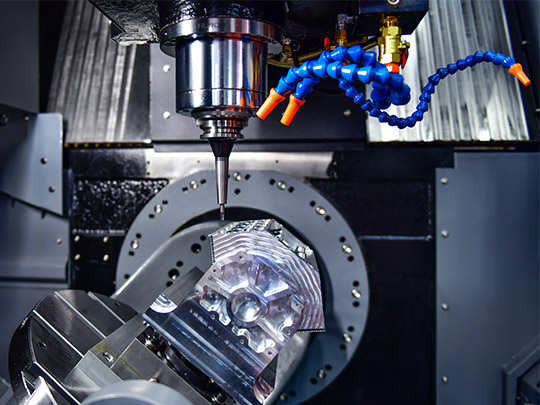

NOBLE’s CNC machining service for polycarbonate is engineered to deliver exceptional precision, durability, and optical clarity for your custom parts. NOBLE leverages state-of-the-art equipment and deep material expertise to transform raw polycarbonate sheet or block stock into high-performance components.

NOBLE utilizes advanced multi-axis CNC mills and lathes operated by experienced machinists. The key to our success lies in our optimized machining parameters. NOBLE employs sharp, polished carbide tooling with specialized geometries to cleanly shear the material. NOBLE runs our spindles at high speeds with precisely calculated feed rates.

FAQs of CNC Machining Polycarbonate

What are the main benefits of using Polycarbonate for CNC machining?

Polycarbonate offers several key benefits for CNC machining. Its most notable property is exceptional impact resistance. The material has good dimensional stability under heat and features inherent flame retardancy in many grades.

What are the biggest challenges when machining Polycarbonate, and how do you solve them?

The primary challenges are heat-related gumming or melting, moisture absorption, and internal stress. To prevent gumming, use very sharp, polished carbide tools with high RPM and a consistent feed rate to create chips, not dust.

How do you prevent Polycarbonate from melting or getting a poor finish during CNC machining?

Preventing melting is all about heat management. Ensure a strong air blast is directed at the cutting edge to cool the tool and immediately evacuate chips, preventing them from being re-cut and damaging the surface.

Can you hold tight tolerances with CNC-machined Polycarbonate parts?

Yes, Polycarbonate is excellent for holding tight tolerances, typically within +/- 0.005 inches or better, due to its stability. Achieving this requires starting with properly dried and stress-relieved material, using a rigid machine setup, and employing sharp tooling with optimized feeds and speeds.

What are typical applications for CNC-machined Polycarbonate parts?

CNC-machined Polycarbonate is used in many high-performance applications. These include protective machine guards, safety glasses and lenses, electrical insulators and non-conductive fixtures, and lightweight aerospace and automotive prototypes. These medical device components require sterilization, and durable covers for electronic equipment and LED light guides.