What is the Polishing Process in CNC Machining?

Polishing process in CNC machining is a final machining method for the surface of workpieces, aiming to remove microscopic surface unevenness through mechanical, chemical, or electrochemical means to improve the surface finish, gloss, or achieve a mirror-like effect of the workpiece.

Polishing processes are typically used to eliminate tool marks, burrs, or minor defects left by previous processes such as milling and turning, while enhancing the corrosion resistance, aesthetic appeal, or functionality of the workpiece.

Polishing can be classified into mechanical polishing (such as using sandpaper and polishing wheels), chemical polishing (corroding the surface with chemical reagents), and electrolytic polishing (smoothing the surface through electrochemical dissolution), among other methods. Polishing processes are widely used in the manufacturing of precision parts, molds, medical devices, and decorative components. The appropriate method should be selected based on the material properties and precision requirements.

How Does the Polishing Process Work?

Deburring

Deburring is the first step in polishing, with the main purpose of removing obvious tool marks, flash, burrs, and large surface defects remaining on the workpiece surface after machining.

Rough polishing usually employs coarse-grained hard polishing wheels or abrasive belts, in combination with abrasives with strong cutting force, such as silicon carbide or coarse-grained diamond grinding paste.

The core of rough polishing is to quickly and effectively achieve the leveling of the basic shape, laying the foundation for subsequent fine machining. Therefore, it sacrifices the fine surface quality in exchange for a higher material removal efficiency.

Semi-Finish Polishing

Based on rough polishing, semi-fine polishing aims to eliminate new scratches and wear marks produced during the rough polishing process, making the surface smoother.

When performing semi-fine polishing operations, a finer polishing wheel and grinding medium will be used instead, such as medium-grained diamond gypsum or polishing liquid. This process is a transitional stage. It gradually reduces the surface roughness, replacing the originally deeper scratches with finer and denser shallow ones, preparing for the final gloss and serving as a key foundation for achieving a mirror-like effect.

Fine Polishing

Fine polishing is the core step to achieving high gloss or mirror-like effects. At this stage, very soft polishing wheels, such as those made of velvet or fine fibers, will be used, along with extremely fine-grained polishing pastes, such as micron-sized diamond gypsum or cerium oxide.

The goal of fine polishing is no longer to remove obvious scratches, but to fill and eliminate the tiny flaws left by semi-fine polishing through extremely fine grinding and plastic flow, minimizing the height difference between the surface’s microscopic peaks and valleys, thereby generating a high degree of gloss and reflection clarity.

Cleaning and Inspection

After all the polishing steps are completed, the workpiece must be thoroughly cleaned to remove all polishing paste, abrasive particles, and metal debris adhering to the surface and crevices. Usually, an ultrasonic cleaner in combination with a dedicated cleaning agent is needed to achieve the desired effect.

Following cleaning, the workpiece must undergo rigorous inspection under ample lighting using a magnifying glass or a professional surface roughness gauge. This ensures its finish, flatness, and appearance meet design specifications, constituting an indispensable step in guaranteeing the final product’s quality.

Common Polishing Methods for CNC Metal Parts

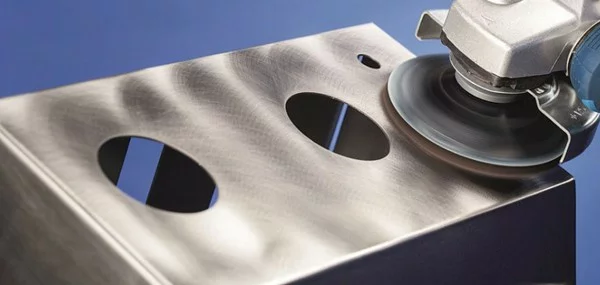

Mechanical Polishing

Mechanical polishing is currently the most widely used polishing technique. It involves using a rotating soft polishing wheel or abrasive belt, in combination with polishing paste containing fine abrasive particles, to perform cutting and plastic machining on the surface of the workpiece through physical friction.

The high-speed rotating polishing wheel presses the polishing paste onto the surface of the workpiece. By using abrasives like micro-tools, the microscopic protrusions and scratches on the material surface are gradually removed, continuously reducing the roughness, and ultimately achieving a smooth or mirror-like effect. This method is highly dependent on the skills and experience of the operators.

Pros:

- High surface quality

- Broad Material Applicability

- Flexible Process Control

Cons:

- Skill-Dependent Results

- Low Efficiency, High Cost

- Potential Surface Defects

Chemical Polishing

Chemical polishing immerses a workpiece in a specific chemical solution to smooth the surface through selective chemical dissolution, without using external electrical energy. Microscopic surface protrusions, having a larger surface area and higher chemical activity, dissolve faster than concave areas. Thus, in the continuous reaction, the surface undulations are gradually eliminated, forming a relatively smooth and bright surface.

Chemical polishing is suitable for machining workpieces with complex shapes and is highly efficient. However, it has limitations such as great difficulty in process control, easy generation of waste liquid, and the surface finish is usually not as good as that of electrolytic polishing.

Pros:

- Superior for Complex Geometries

- High Efficiency, No Specialized Equipment

- No Mechanical Stress

Cons:

- Relatively Lower Surface Quality

- Challenging Process Control

- Limited Material Applicability

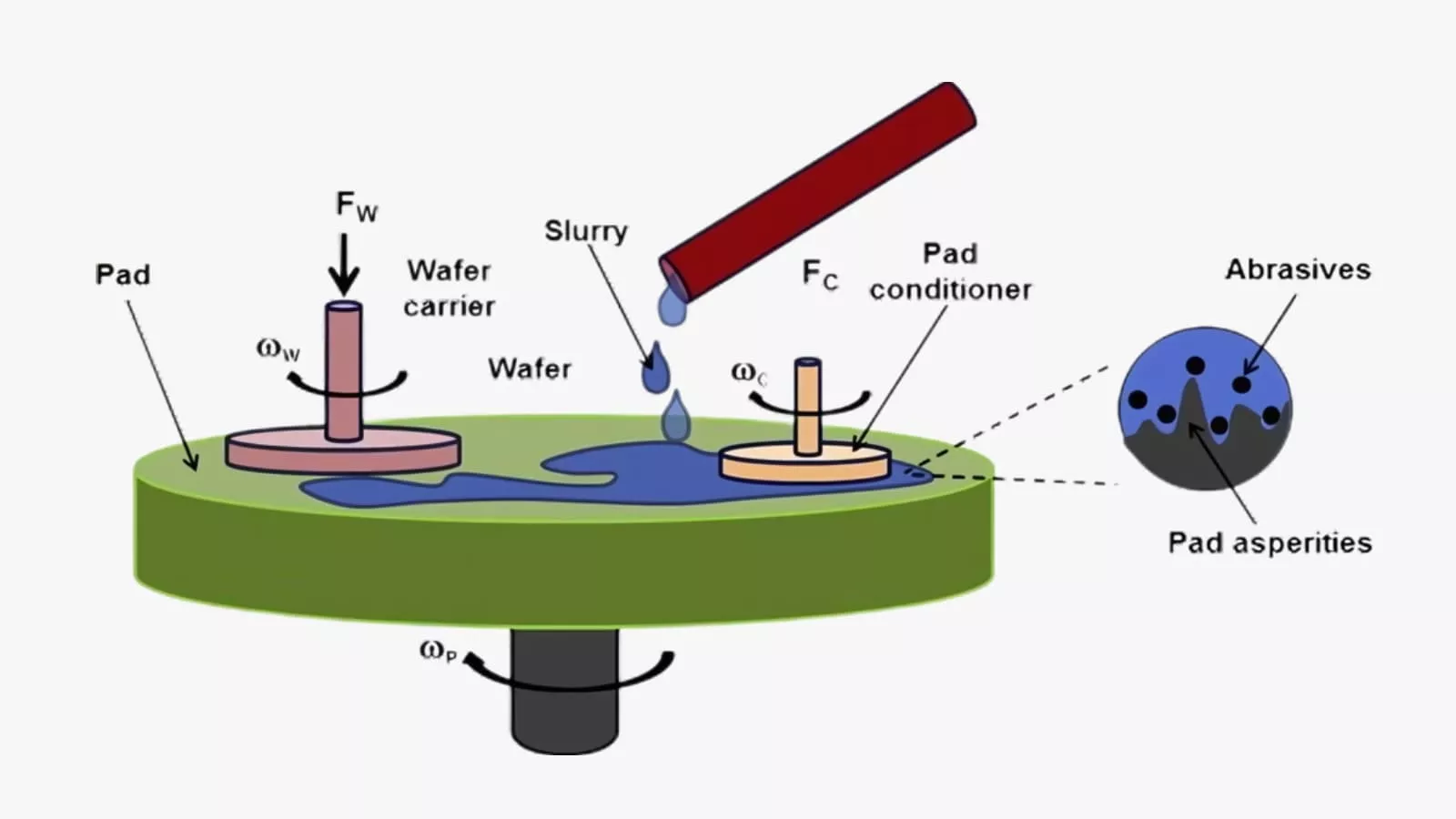

Electropolishing

Electrolytic polishing is an electrochemical process in which the workpiece serves as the anode and an electric current is applied in a specific electrolyte. Atoms on the metal surface ionize to form a viscous mucosa. This film is thin at microscopic protrusions, has a high current density, and dissolves quickly. The concave areas are thicker and dissolve more slowly.

Through this selective dissolution, the surface of the workpiece is rapidly leveled, achieving high gloss and strong corrosion resistance, especially suitable for complex structural parts of hard metals such as stainless steel.

Pros:

- Exceptional Comprehensive Performance

- High Efficiency and Superior Consistency

- No Physical Damage or Burrs

Cons:

- High Initial Investment and Cost

- Complex Process Control

- Limited Applicability

Advantages and Disadvantages of the Polishing Process

Advantages

1. Improved Surface Quality

Polishing can effectively remove microscopic unevenness, scratches, burrs, and oxide layers on the surface of products, making the surface smooth, flat, and even, achieving a mirror-like effect.

The smooth surface not only greatly enhances the appearance, beauty, and texture of the product but also reduces the friction coefficient and wear of the surface. For precision parts with high sliding or rolling contact requirements, such as bearings and molds, it can effectively extend their service life and improve the smoothness of operation.

2. Enhanced Corrosion Resistance

Workpieces subjected to polishing, particularly those treated with electrolytic polishing, exhibit eliminated micro-pits and ridges, thereby reducing surface area. This makes it difficult for contaminants, moisture, and corrosive substances to adhere and accumulate. Concurrently, the polishing process itself removes numerous potential sources of surface contamination.

For medical devices, food machining equipment, and chemical components, this smooth and dense surface is easier to clean and disinfect, and can significantly enhance their corrosion resistance, ensuring the hygiene safety and environmental durability of the products.

3. Reliable Function and Safety

Polishing can remove microscopic cracks and burrs on the surface of materials, which may become the origin of fatigue cracks under stress. By eliminating these potential risks, polishing can enhance the fatigue strength and overall reliability of parts.

For the surfaces of joints that require high sealing performance, the reflective surfaces of optical components, and semiconductor wafers that demand extremely high cleanliness, the polishing process is an indispensable step to achieve their functionality.

Disadvantages

1. Cost and Efficiency Concerns

Polishing, particularly high-precision mechanical polishing, is typically a labour-intensive process heavily reliant on the technical skill and experience of skilled workers, resulting in high labour costs. Concurrently, the polishing process itself is time-consuming, especially when involving multiple stages from coarse to fine finishing, leading to overall low production efficiency.

Specialised polishing equipment, consumables, and the maintenance of bath solutions required for electrolytic and chemical polishing collectively constitute the majority of production costs.

2. Potential Dimensional Inaccuracy

Polishing is a material removal process. Although the amount removed each time is small, when pursuing high smoothness, the accumulated amount removed may affect the dimensional tolerance of high-precision parts, leading to dimensional out-of-tolerance.

More importantly, for soft materials or complex surfaces, if the operation is improper or the pressure is uneven, the polishing force can easily cause the edges and corners to become rounded, the plane to collapse, or the geometric contour to distort, which instead destroys the original design accuracy of the workpiece.

3. Environmental and Safety Challenges

Chemical polishing and electrolytic polishing will produce waste liquid and waste gas containing heavy metal ions and chemical reagents, which must undergo strict and costly environmental protection treatment. Mechanical polishing will generate dust and noise pollution.

The consistency of polishing effects is hard to guarantee. There may be differences in different batches or even different parts of the same workpiece. The instability of manual operation is the main reason. Achieving fully automated intelligent polishing remains a technical challenge for complex parts.

How Polishing Improves Surface Finish in CNC Machining

Physical Cutting Action

When polishing tools and fine abrasives rub against the surface of the workpiece at high speed, these abrasive particles, which are much harder than the workpiece, act like countless tiny cutting tools.

Through shearing and scratching, they preferentially remove the microscopic protrusions on the surface contour. Through continuous machining, these protrusions are gradually removed, and the height difference between the surface peaks and troughs is effectively reduced. Macroscopically, the surface becomes smoother.

Surface Plastic Flow

During the polishing process, local high temperatures and pressures are generated due to friction, which causes the surface material of the workpiece to enter a slightly melted or highly plastic state. In this state, the material is not merely removed but undergoes plastic deformation and flow, being squeezed from the protruding area and filled into the adjacent microscopic pits.

This “peak shaving and valley filling” effect physically reduces the unevenness of the surface, thereby enhancing the smoothness and laying a smooth foundation for further fine polishing.

Selective Dissolution Leveling

Selective dissolution leveling is the main principle of chemical polishing and electrolytic polishing. It takes advantage of the characteristic that the microscopic protrusions on the surface have higher chemical activity and a larger surface area.

In chemical polishing, the raised parts come into more thorough contact with the solution and react more quickly. In electrolytic polishing, the current density at the protruding parts is higher. Both of these situations cause the metal atoms at the protruding parts to dissolve into the solution or electrolyte preferentially and more quickly. Through this differentiated and selective dissolution, a surface that is ultimately flatter and smoother as a whole is formed.

Comprehensive Finishing

Advanced polishing methods, such as ultrasonic polishing and abrasive flow polishing, perform all-around uniform micro-grinding on the surface of the workpiece through high-frequency micro-impact or flowing abrasives.

The grinding process can not only eliminate microscopic unevenness and burrs, but also round out sharp grain boundaries and microcracks, making the surface texture more uniform and smooth. In this way, the surface morphology is optimized at the microscopic level, which not only improves the smoothness but also enhances the fatigue resistance and corrosion resistance of the parts.

Tips for Polishing Process in CNC Machining

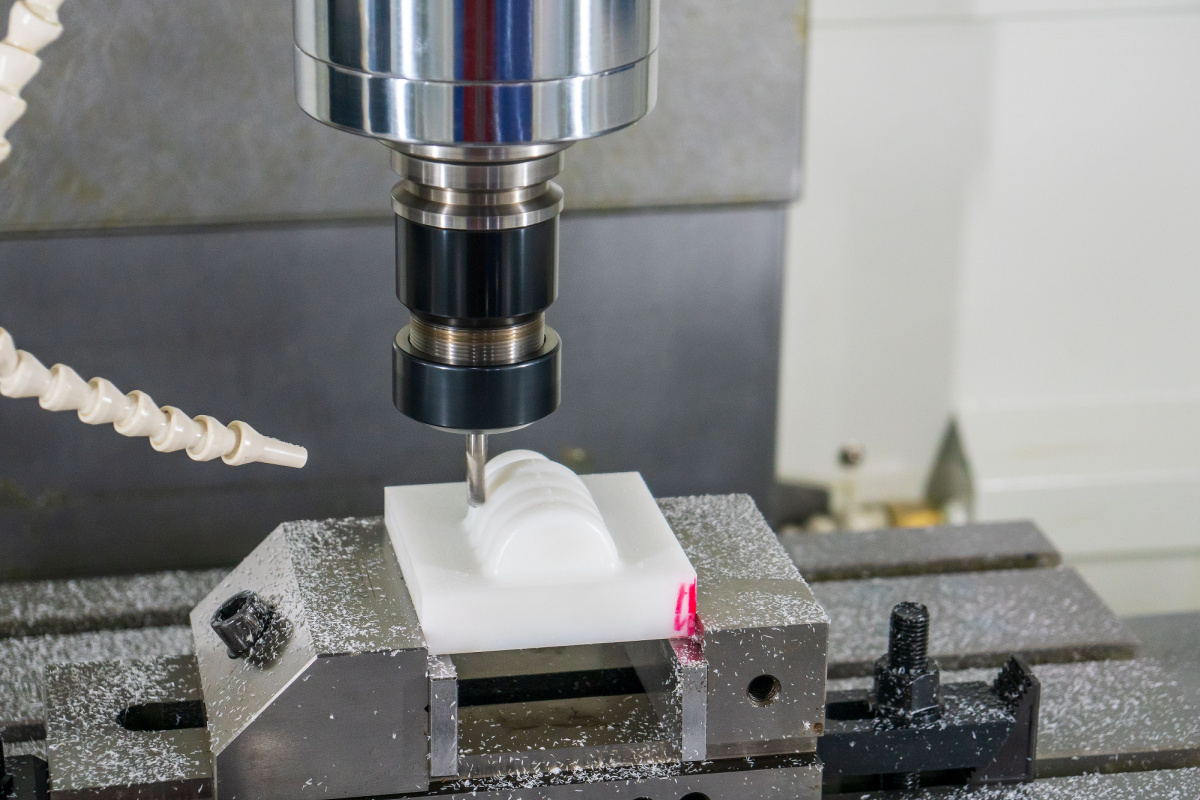

Programmed Mechanical Polishing

Programmed mechanical polishing refers to the use of soft tools on CNC machines and the writing of specific programs for polishing. By precisely controlling the pressure, path, and speed of the polishing tool through the CNC path, uniform and repetitive polishing of complex curved surfaces can be achieved.

Programmed mechanical polishing can effectively reduce the corner collapse problem caused by manual polishing, significantly improve consistency, and lower the reliance on senior technicians. It is a balanced choice between high-quality surfaces and high-efficiency production.

Magnetic Abrasive Finishing

Magnetic grinding uses a magnetic field to control the magnetic grinding needle to brush the surface of the workpiece. It is particularly suitable for cleaning micro-burrs and white layers produced after CNC milling or electrical discharge machining.

Abrasive Flow Polishing

The abrasive flow forces the semi-fluid abrasive to squeeze through the inner cavity of the workpiece and the flow channel, which can evenly polish all the contact surfaces. This method can efficiently handle cross-holes and complex flow channels that are difficult to reach by hand. While removing microscopic unevenness, it hardly changes the dimensional accuracy of the workpiece.

Vibratory and Barrel Polishing

The workpiece, along with abrasives and additives, is placed in a vibration tank or drum. Through continuous and slow rolling and friction, uniform and micro-grinding of all outer surfaces of the parts is achieved. This method can efficiently handle tens of thousands of tiny parts and achieve a consistent polishing effect. However, it is necessary to pay attention to controlling the time and abrasive ratio to prevent new scratches caused by mutual collisions between parts.

Tooling Design

Enhance the electrolytic polishing effect by optimizing the tooling design and current distribution. For complex CNC parts, special fixtures should be designed to ensure uniform current density, and auxiliary electrodes should be added to deep holes, narrow slits, and other areas to prevent uneven polishing due to the “shielding effect”.

By precisely controlling the electrolytic parameters, the surface can be quickly leveled without generating mechanical stress, and a corrosion-resistant passivation film can be formed.

Path Planning

Despite the increasing degree of automation, the final fine polishing of high-end products still often relies on experience.

The operator needs to plan a cross-polishing path at a certain Angle to the tool path texture left by the CNC machine, based on it, in order to effectively cover up the original traces.

At the same time, it is necessary to master the control of force and temperature by hand to avoid the occurrence of “orange peel” defects or overburning. This is a crucial step to elevate the surface from “good” to “excellent”, highly dependent on the inheritance of experience.

Sequential Application of Hybrid Processes

The most efficient technique does not rely on a single method, but on a scientific combination. For instance, first, programmed mechanical polishing is used to quickly remove most of the tool marks, then magnetic grinding is employed to clean up burrs, and finally, a short period of vibration polishing or electrolytic polishing is supplemented to achieve a uniform matte or mirror-like effect. This combination can fully leverage each other’s strengths, maximizing overall efficiency while ensuring quality.

How to Maintain the Surface of Polished Parts

Thorough Cleaning

Following polishing, components must be thoroughly cleaned immediately using a neutral detergent and deionised water or high-purity organic solvent to remove all traces of polishing compound, abrasive particles, and grease residues.

Components should be dried promptly with a lint-free cloth or compressed air to prevent any water marks or secondary contamination, which is fundamental to avoiding subsequent spot corrosion and staining.

Application of Protective Coatings

Applying a protective coating to cleaned surfaces is one of the most effective methods, according to application requirements.

- Passivation treatment: For metals such as stainless steel, passivation solutions form a chromium-rich oxide film on the surface, significantly enhancing corrosion resistance.

- Application of rust-preventative oil/agent: Before short-term storage or transport, applying a thin, uniform layer of rust-preventative oil or anti-fingerprint agent effectively isolates the surface from air and moisture.

- Deposition of functional coatings: For high-specification components, methods such as Physical Vapour Deposition (PVD) or Chemical Vapour Deposition (CVD) may be employed to apply ultra-hard, wear-resistant films (e.g., diamond-like carbon coatings) while preserving the surface appearance.

Segregated Storage

It is strictly prohibited to store polished parts alongside unpolished parts or components made of different metallic materials. Each workpiece must be individually isolated using dividers, foam, bubble wrap, or lint-free paper to prevent contact with hard objects and mutual scratching.

Use of Dedicated Tools

When handling and installing polished components, operators must wear clean white cotton gloves or nitrile gloves. Direct bare-handed contact may leave sweat marks and fingerprints, leading to localised corrosion. Specialised clamps or non-metallic tools should be used to avoid direct metal-to-metal contact.

Regular Inspection and Maintenance

Establish a regular inspection regime to promptly identify and address early-stage corrosion points, wear, or minor scratches. For components with protective coatings, re-coating or re-passivation should be performed according to their lifecycle to maintain long-term protection.

Applications of Polishing Process in CNC Machining

Mold Making Industry

The mold industry is the field where polishing processes are most widely applied and have the highest requirements. Whether it is a plastic injection mold or a die-casting mold, the smoothness of the cavity surface directly determines the appearance quality and demolding ability of the product. High-level polishing can significantly reduce molding resistance and prevent defects such as scratches and sticking to the mold on the product. It is a core link to ensure the service life of the mold and production efficiency.

Medical Device Manufacturing

Medical devices have extremely strict requirements for surface quality. For instance, components of surgical robots, orthopedic implants, and endoscope parts must undergo perfect polishing treatment. This is not only to reduce frictional resistance, but also to eliminate microscopic defects and bacterial hiding spots, ensure biocompatibility, resistance to body fluid corrosion, and facilitate strict cleaning and disinfection.

Automotive Industry

In the automotive and aerospace fields, polishing combines functionality and safety. After polishing, the core components of the engine, fuel system parts, and hydraulic system can significantly reduce flow resistance, improve sealing performance, and eliminate stress concentration points, thereby enhancing efficiency and reliability. More importantly, a high-quality surface can significantly extend the fatigue life of key components under high pressure and high cyclic loads.

![]()

Semiconductor and Electronics

At the microscopic scale, polishing is the foundation for achieving circuit manufacturing. For chip substrates, lead frames, RF devices, and connectors, etc., an ultra-smooth surface is a prerequisite for ensuring circuit integrity, signal transmission quality, and device reliability. Any microscopic unevenness may cause a short circuit in the circuit or signal attenuation.

Packaging Machinery Industry

All surfaces of equipment that come into direct or indirect contact with food must undergo high-standard polishing treatment. The smooth and seamless surface can effectively prevent material residue and bacterial growth, meeting strict food hygiene and safety regulations. At the same time, it is convenient for thorough cleaning, ensuring food safety.

NOBLE’s Polishing Process in CNC Machining

NOBLE specializes in advanced polishing surface treatment, offering a comprehensive range of techniques, including mechanical polishing, electropolishing, and abrasive flow machining, to meet diverse industrial requirements.

We meticulously follow a multi-stage process—from rough deburring and semi-finishing to fine polishing and final cleaning—ensuring the complete removal of imperfections and the achievement of a superior surface finish. This rigorous approach significantly enhances the aesthetic appeal, corrosion resistance, and overall functionality of the components.

By leveraging our expertise and state-of-the-art equipment, we deliver consistently high-quality, reliable results that extend product lifespan and performance, making us the trusted partner for your most demanding precision manufacturing needs.

FAQs

What are the main types of polishing used for CNC-machined parts?

The most common types are Mechanical Polishing (using abrasive wheels or pastes for a glossy finish), Electropolishing (an electrochemical process ideal for stainless steel, removing material evenly for a deburred, corrosion-resistant surface), and Abrasive Flow Machining (for polishing complex internal passages and geometries). The choice depends on material, part geometry, and the required final surface quality.

Can polishing affect the dimensional accuracy of a CNC-machined part?

Yes, it can. Polishing is a material removal process. While the amount is minimal (often mere microns), it must be carefully accounted for in the design and machining stages, especially for parts with tight tolerances. A skilled manufacturer will plan the pre-polish dimensions to ensure the final polished part meets all specified dimensional and geometric tolerances.

Which materials are best suited for electropolishing?

Electropolishing is most effective for conductive metals, with austenitic stainless steels (like 304 and 316) being the most common and achieving excellent results. It is also successfully used on aluminum, titanium, copper alloys, and some tool steels. It is not suitable for non-conductive materials like plastics or composites.

What is the difference between a matte, satin, and mirror polish finish?

These terms describe the level of reflectivity. A matte finish has low reflectivity with a uniform, non-directional texture. A satin (or brushed) finish has a soft sheen with a fine, directional grain. A mirror polish is the highest gloss, producing a clear, undistorted reflection. The finish is achieved by progressing through successively finer abrasives during the polishing process.

Is polishing a manual or automated process?

Both methods are used. Manual polishing relies on skilled technicians for complex geometries or low-volume, high-mix production. Automated polishing (using robotic arms or dedicated machines) is preferred for high-volume production of consistent parts, offering better repeatability, lower cost per part, and reduced human variability. Many shops use a hybrid approach.