What is Custom Sand Casting?

Sand casting is a common metal casting method. The main process is to use a sand mold as mold to form metal parts. First, make a model according to the shape of the part, place the model in the sandbox, fill it with molding sand, and compact it tightly, then take out the model to form a cavity. Next, pour the molten metal liquid into the cavity of the sand mold. After the metal cools and solidifies, break the sand mold and remove the casting.

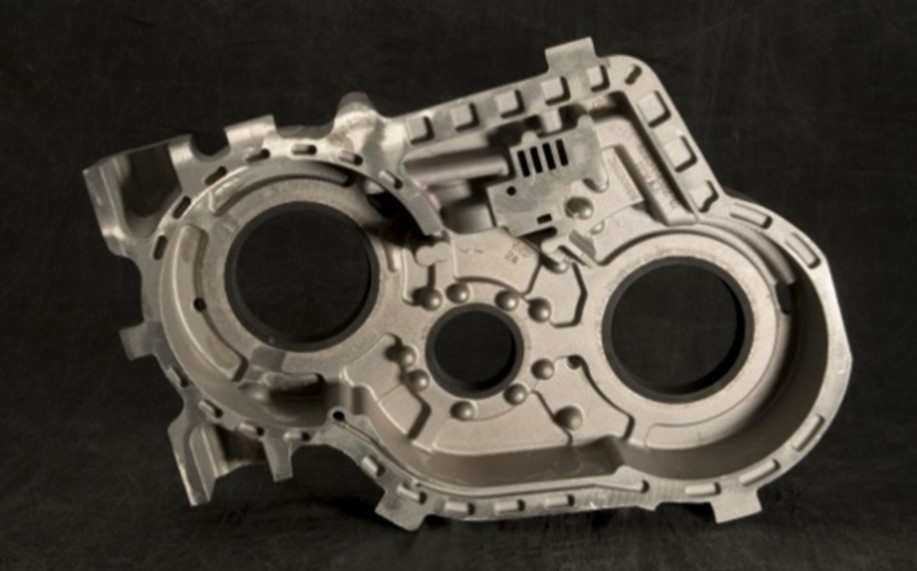

Sand casting is suitable for various metal materials and can produce complex-shaped and large parts at a relatively low cost. However, its surface roughness and precision are relatively poor. It is often used to manufacture industrial components such as engine blocks and pipe fittings.

How Does Custom Sand Casting Work?

Model Making

Sand casting begins with creating a precise pattern of the final part, typically made from wood, metal, or plastic. The pattern incorporates a draft angle for easy removal from the mold and accounts for metal shrinkage during solidification.

For castings with internal cavities, corresponding core molds must also be produced. The pattern’s accuracy directly determines the final casting’s dimensional and structural quality..

Molding

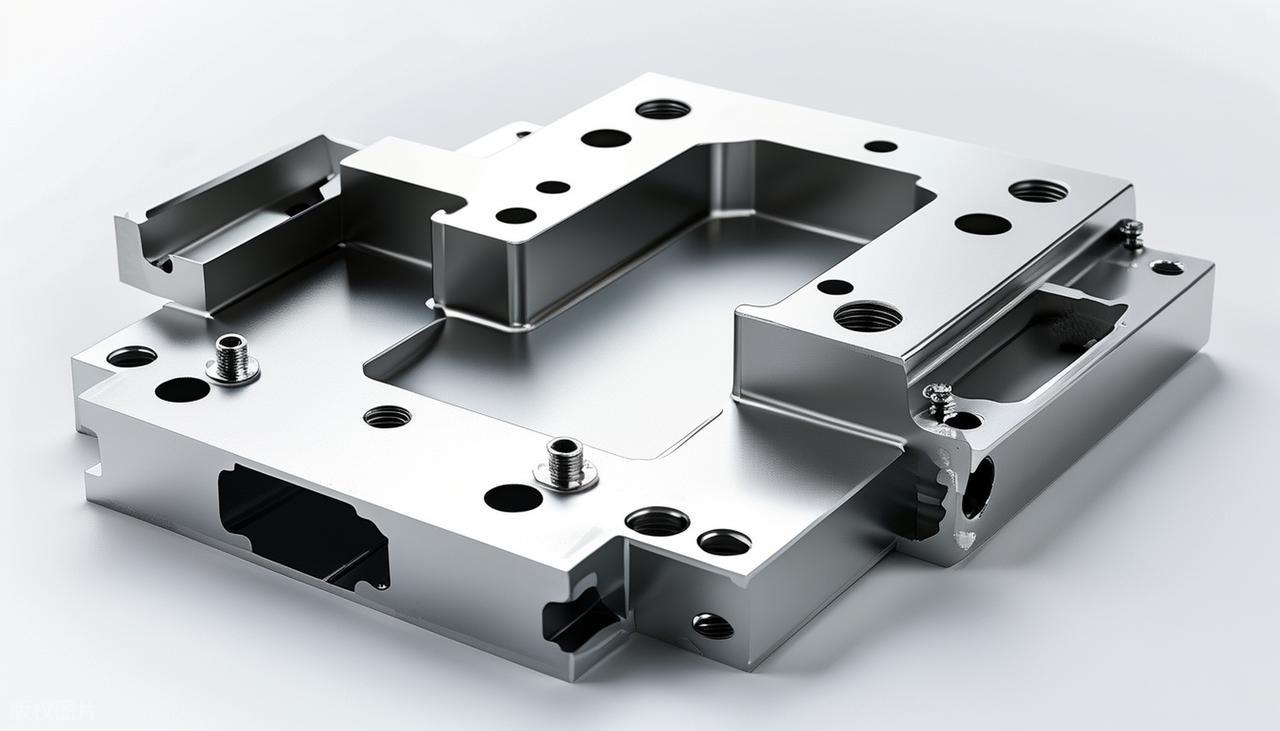

Molding creates a cavity in sand using a pattern. The pattern is fixed on a base plate, enclosed in a flask, and filled with molding sand—a blend of silica sand and binder that provides strength and permeability when compacted. The sand is uniformly rammed by hand or machine. After removing the pattern, the resulting cavity matches its shape and will contain the molten metal.

Core Making

Sand cores are individually produced in core boxes to form complex internal casting cavities. These cores undergo baking or hardening treatments to achieve greater strength than the main sand mold, ensuring they withstand molten metal erosion without failure. Finally, the hardened cores are precisely positioned within the sand mold cavity.

Box Assembly

Box assembly involves combining the upper and lower sand molds with cores to form a complete casting mold. Precise alignment of the sand boxes prevents misalignment, while secure core positioning ensures accurate internal structures.

Once closed, the mold creates a unified cavity containing both the external shape and internal features of the casting. The final step involves firmly fastening the sand boxes together to prevent molten metal leakage or mold separation during pouring due to metallostatic pressure.

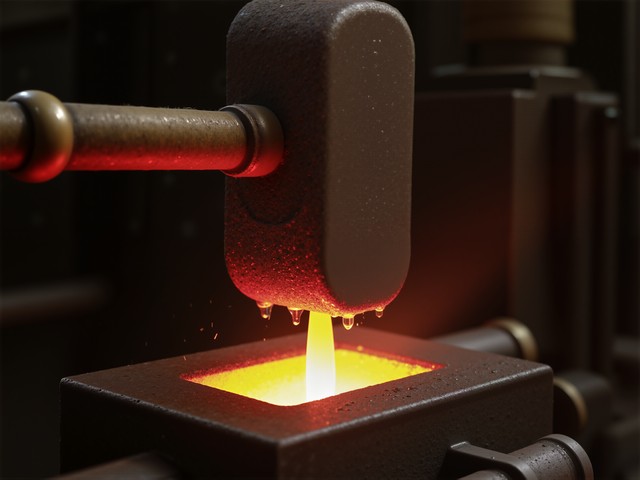

Melting and Pouring

Smelting is the process of heating solid metal raw materials in a furnace above their melting point to melt them into a liquid with good fluidity. During the smelting process, necessary treatments need to be carried out on the molten metal, such as slag removal and adjustment of chemical composition, to ensure its quality.

When the molten metal reaches the required temperature and composition, use a pouring ladle to smoothly and continuously inject it into the closed mold gate cup until the molten metal fills the entire cavity and overflows from the vent hole. The temperature and speed of pouring are crucial to the quality of the casting.

Shakeout and Cleaning

After pouring, the mold must fully cool to solidify the metal. Once near room temperature, shakeout occurs through vibration, knocking, or flushing to break the sintered sand mold and remove the casting. The casting is then cleaned by removing surface sand, grinding excess metal from the gating system, and extracting internal sand cores to obtain the final blank.

Material Used in Custom Sand Casting

Cast Iron

Cast iron is the most widely used type of material in sand casting processes, among which gray cast iron is particularly common. This type of material features excellent casting fluidity, a low shrinkage rate, as well as outstanding wear resistance and shock absorption.

- Pros:

Defect Resistance

Low Cost

Easy Molten Formability

- Applications: Engine block, brake disc, machine tool base

Cast Steel

Cast steel provides sand castings with higher strength and toughness, enabling them to withstand greater loads and impacts. Its melting point is higher than that of cast iron, and the requirements for casting processes are also stricter.

Cast steel parts have a relatively large shrinkage rate and are more prone to shrinkage cavities and internal stress, which need to be compensated for through reasonable design and process.

- Applications: Engine blocks, brake discs, machine tool bases, and shells of large pressure vessels

Aluminum Alloy

Aluminum alloy is highly favored in sand casting due to its low density, high specific strength, and good corrosion resistance. They have good fluidity in the molten state and can produce lightweight castings with complex shapes and thin wall thicknesses. Aluminum alloy castings also have good mechanical processing performance and thermal conductivity.

- Pros: Good corrosion resistance, high specific strength, and good fluidity

- Applications: The pistons and cylinder heads of automotive engines, structural components of aircraft, heat dissipation shells of various electronic devices, and hardware parts in daily life

Copper Alloy

Copper alloys, mainly including bronze and brass, are mainly used in sand casting to manufacture parts that require wear resistance, corrosion resistance, or good electrical and thermal conductivity. Bronze has excellent wear resistance and chemical stability, and is often used to manufacture gears, bearings, Marine screw pumps, and valve components.

- Pros: Good mechanical properties, electrical conductivity, and beautiful color

- Applications: Casting water pipe fittings, Musical Instruments, decorative artworks, and various electrical connectors

Types of Sand Casting Process

Green Sand Casting

Green sand casting is the most common and cost-effective sand casting method. Its characteristic is to be directly poured using a damp, unbaked sand mold. The main binder of molding sand is bentonite, and its viscosity is activated by moisture.

- Pros: It features high production efficiency and is suitable for mechanized assembly line operations

- Cons: Wet sand molds have relatively low strength, and moisture can easily cause defects such as porosity in castings

Lost Foam Casting

Lost foam casting is a relatively advanced sand casting process, and its model is made of foam plastic. When molding, embed the foam model into dry sand without a binder, and then directly pour high-temperature molten metal into the model. The foam model vaporizes and vanishes instantly upon encountering the molten metal, and the molten metal takes its place to fill the model area, eventually forming a casting.

- Pros: No mold lifting is required, there is no parting surface, and castings with extremely complex shapes can be manufactured

- Cons: Foam models have a relatively high production cost

Self-Hardening Sand Casting

The sand mold cast by self-hardening sand does not need to be baked after molding and can harden by itself through chemical reactions at room temperature to reach the required strength.

Common materials include sodium silicate, sand, and resin self-hardening sand. Self-hardening sand molds have superior precision and strength compared to wet molding sand, making them more suitable for single-piece or small-batch production of medium and large-sized castings.

Advantages of Custom Sand Casting

Low Material Cost

The main raw material required for making sand molds is silica sand, which is extremely abundant in nature and inexpensive. Adhesives such as clay and resin also have relatively low costs.

The mold production cost of sand casting is much lower than that of other casting methods that require the use of metal or special ceramic molds. It is particularly suitable for the single-piece or small-batch production of large castings and will not lose its economic efficiency due to the high cost of the mold itself.

Highly Flexible Production Process

Sand casting is not strictly restricted by the size, weight, and complexity of the castings. It can not only produce small parts weighing only a few grams, but also manufacture large machine tool bases or giant Marine propellers weighing hundreds of tons.

After pouring, the sand mold is damaged, and castings with deep cavities, depressions, and other features that are difficult to form by other methods can be removed from the complex sand mold. This flexibility is unmatched by many permanent mold casting methods.

Broad Metal Compatibility

Sand casting has almost no restrictions on the types of metals to be poured. From low-melting-point aluminum alloys and copper alloys to high-melting-point cast iron, cast steel, and even high-temperature alloys such as nickel-based and cobalt-based ones, all can be formed by sand casting.

Molding sand itself has an extremely high refractoriness and can withstand the high temperatures of the vast majority of metal melts without melting, which provides a universal platform for the production of metal components with different properties and uses.

Rapid Mold Manufacturing

Sand casting is very fast for the processing and manufacturing of wooden or plastic molds. When the design needs to be modified, sand casting only requires the modification of the model, without the time-consuming and laborious mechanical processing as in metal molds.

The manufacturing of molds significantly shortens the cycle from product design to successful trial production, reduces the costs and risks during the development stage, and is highly economical and efficient for trial production or small-batch production.

Unlimited Size Range

The wide range of casting sizes is a very prominent advantage of sand casting. Sand molds are made in blocks and assembled. In theory, parts of any size can be cast by making sandboxes large enough.

In the actual industry, the largest and heaviest castings, such as large engine blocks and large machine tool beds, are almost all produced by sand casting. It is very difficult for other casting methods to achieve such huge dimensions.

Disadvantages of Custom Sand Casting

Poor Dimensional Accuracy

Sand molds are formed by bonding granular sand grains together. Their inner walls are not as smooth as those of metal molds by nature, which leads to a relatively rough surface of the castings. Usually, subsequent mechanical processing is required to improve this.

During operations such as demolding and box closing, the sand mold is prone to minor deformation or damage. Coupled with the scouring of high-temperature molten metal, it may cause dimensional deviations in the castings and surface defects such as burrs.

Harsh Work Environment

A large amount of dust is generated during the sand casting production process, especially in the sand mixing, molding, and shakeout stages. At the same time, smelting metals, hot casting molds, and the decomposition of binders all produce harmful gases and smoke.

Dust and harmful gases pose a threat to the health of workers in workshops, and enterprises need to invest a large amount of costs in ventilation, dust removal, and waste gas treatment to comply with strict environmental protection regulations.

Complex and Skill-Dependent

Sand casting involves numerous processes, from mold making, molding, smelting, to pouring and cleaning. The parameter control in each link will affect the quality of the final casting.

The sand casting process is highly dependent on the experience and judgment of skilled workers, such as the selection of pouring temperature and speed. Fluctuations in human factors can easily lead to unstable product quality, and the demand for skilled workers also increases management costs.

Precision Sand Casting Services: Power the Project You Need

Welcome to NOBLE, your trusted partner for high-quality sand casting solutions. We specialize in transforming your designs into durable, complex metal components through our advanced sand casting capabilities. From prototyping to high-volume production, we provide the reliability, expertise, and capacity to meet your most stringent requirements.

Why Partner With Us?

- Proven Quality & Reliability: Our rigorous quality control systems, from raw material inspection to final dimensional checks, guarantee that every casting meets your specifications.

- Technical Collaboration: Our engineering team works closely with you to optimize designs for manufacturability, enhance performance, and reduce total cost.

- Competitive Lead Times: We leverage efficient production planning and robust processes to deliver your components on time, every time.

Let us be the foundation of your next project. Contact us today to discuss your requirements and receive a comprehensive quote.

FAQs

What is sand casting, and how does it work?

Sand casting is a versatile metal casting process where molten metal is poured into a disposable sand mold to create a part. The process involves creating a sand mold from a pattern (a replica of the part), filling it with molten metal, allowing it to cool and solidify, and then breaking away the sand mold to retrieve the finished casting.

What materials can be used in sand casting?

Sand casting services support an extensive range of ferrous and non-ferrous metals. Common choices include gray iron, ductile iron, carbon steel, stainless steel, aluminum alloys, and copper alloys (like bronze and brass). The selection depends on the required mechanical properties, such as strength, wear resistance, or corrosion resistance.

What is the typical size and weight range for sand castings?

Sand casting is uniquely capable of producing parts across an enormous size spectrum. Components can range from a few ounces (100+ grams) to over 100 tons, making it ideal for everything from small enclosures to massive machine bases, pump housings, and industrial equipment.

What are the limitations of the sand casting process?

While highly versatile, sand casting has some limitations. The resulting parts typically have a rougher surface finish than those from investment casting or die casting and generally have lower dimensional accuracy.

What are the advantages of choosing sand casting services?

The primary advantages of sand casting include its low tooling cost compared to other methods, the ability to produce very large and heavy components, and exceptional design flexibility for complex geometries.