What is the Sheet Metal Bending Process?

Sheet metal bending is a metal machining technique that mainly uses a bending machine to apply pressure to metal sheets, causing them to undergo plastic deformation at specific positions, thereby obtaining parts with predetermined angles and shapes.

The process of sheet metal bending usually involves molds, including an upper die (punch) and a lower die (V-shaped groove), where the sheet metal is forced into the opening of the lower die by pressure to form a bend. Bending technology is widely used in the manufacture of various metal structural components such as boxes, brackets, and cabinets. It features high efficiency, high precision, and strong adaptability, and is a key step in sheet metal machining.

How Does the Sheet Metal Bending Process Work?

The core of the sheet metal bending process is to apply external force to cause plastic deformation of metal sheets at a predetermined position, thereby forming specific angles and shapes. This process mainly relies on bending machines and dedicated molds.

Metal Materials Used in Sheet Metal Bending

Cold-rolled Steel Plate

Cold-rolled steel plates are carbon steel plates that are rolled at room temperature. Cold-rolled steel plates have excellent strength and machinability, and thus are highly suitable for precise bending, stamping, and welding.

Cold-rolled steel plates usually do not require pre-treatment such as rust removal and can be directly electroplated or painted.

Stainless Steel

Stainless steel is renowned for its outstanding corrosion resistance because the chromium element it contains can form a dense layer of chromium oxide passivation film on its surface.

304 stainless steel has excellent comprehensive performance and is suitable for various environments. 316 stainless steel, due to the addition of molybdenum, has a stronger resistance to chloride corrosion.

| 304L | Suitable for welding; Good anti-corrosion performance |

| 321 | Contains titanium; Good anti-corrosion performance |

| 301 | Relatively high hardness; Good strength |

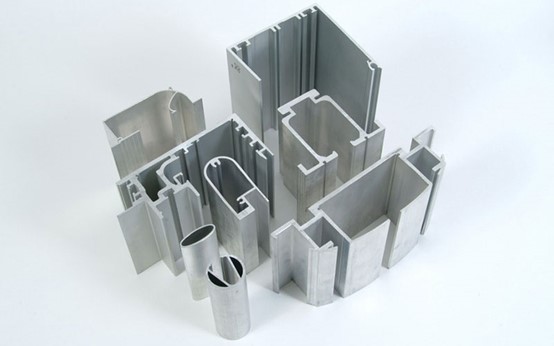

Aluminum

Aluminum is a lightweight metal with a density approximately one-third that of steel, which is crucial in applications where weight reduction is required.

Aluminum materials also have good corrosion resistance and excellent thermal and electrical conductivity. In addition, aluminium has excellent plasticity and is easy to bend and stretch into shape.

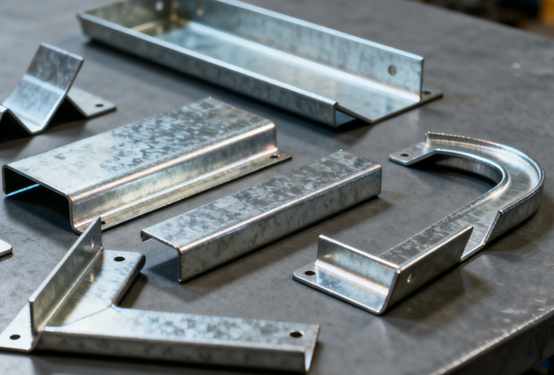

Galvanized Steel Sheet

Galvanized steel sheets are made by coating a layer of zinc on the surface of cold-rolled or hot-rolled steel sheets, aiming to provide protection for the internal steel through the zinc layer and effectively prevent the steel sheets from rusting.

- Electro-galvanized Steel: The surface is fine and uniform, making it more suitable for spraying.

- Hot-dip galvanized Steel: The zinc coating is relatively thick and has strong corrosion resistance, but there are zinc flowers on the surface.

Brass

Brass is a copper-zinc alloy. It has a very beautiful golden yellow appearance and is often used for decorative components. In addition to its aesthetic appeal, brass also features excellent electrical conductivity, thermal conductivity, and outstanding antibacterial properties.

In terms of machining, brass is soft and has excellent ductility, making it highly suitable for complex stamping and forging operations.

Hot-rolled Steel Plate

Hot-rolled steel plates are carbon steel plates that are rolled at high temperatures. Compared with cold-rolled plates, its surface will have a layer of oxide scale, be relatively rough, and its dimensional accuracy is also slightly worse.

The advantage of hot-rolled steel plates lies in their relatively low price, and they can provide thicker sheet materials and higher structural strength.

Types of Sheet Metal Bending Processes

Folding Bending

Folding bending is achieved by folding the beam up or down along the edge of the workpiece, and is often used for box-type and shell-type parts.

Pros:

- No-mold mark bending: Does not damage the surface coating or decorative layer.

- High precision and good repeatability.

- Suitable for large-sized plates: Especially aluminum plates, thin stainless steel plates, etc.

Cons:

- Low efficiency: Suitable for medium and small batch production.

- Complex structure: The maintenance cost of folding mechanisms is high.

- Not suitable for thick plate machining.

Roll Bending

Roll bending is a process that uses a three-roll or multi-roll plate bending machine to gradually bend sheet metal into arc-shaped, cylindrical or conical parts through multiple bends.

Pros:

- Suitable for large curvature bending: It can continuously form large radius or fully circular parts.

- Uniform deformation: Avoid stress concentration caused by one-time bending.

- It can machine thick plates and large-sized parts.

Cons:

- The Angle control is difficult: The roller distance needs to be adjusted multiple times.

- Small curvatures or acute angles are not easy to achieve.

- High equipment investment cost.

Coining

The punch presses the sheet metal into the lower die at extremely high pressure, causing the material to undergo thorough plastic deformation. The Angle is almost completely determined by the die.

Pros:

- Extremely high dimensional and angular accuracy: Almost no rebound.

- Sharp corners or characteristic edges: Suitable for precision parts processing.

- Good forming consistency: The Angle is completely controlled by the mold.

Cons:

- High equipment requirements: High-tonnage presses are needed.

- Severe wear of the mold: High pressure, high requirements for mold materials, and heat treatment.

- High cost: The cost of mold manufacturing and maintenance is high.

Air Bending

The workpiece bent by air only comes into contact with the tip of the upper die and both sides of the V-groove of the lower die. When the punch presses downward, the metal undergoes elastic-plastic deformation at the contact points, forming the required Angle.

The Angle is controlled by the depth of the punch stroke.

Pros:

- Strong Angle adjustability: The bending Angle can be changed by controlling the stroke of the punch, offering high flexibility.

- Low mold wear: Due to the small contact area between the upper and lower molds, the mold has a longer service life.

- Good adaptability: The same set of molds can process parts with different angles and plate thicknesses.

Cons:

- Low-angle accuracy: It is greatly affected by rebound and requires empirical correction.

- Greater bending force: Compared with other methods, it has higher requirements for the tonnage of the equipment.

Bottoming

The punch presses the sheet into the bottom of the V-groove of the lower die, making the sheet fully adhere to the die for shaping. Obvious plastic flow or even imprinting occurs in the deformation zone.

Pros:

- High Angle accuracy: almost no rebound, and stable bending Angle.

- Good repeatability: Suitable for mass production of parts with high consistency requirements.

- Excellent surface quality: Clear creases and neat edges.

Cons:

- Mold wear: Large contact area, obvious friction, and stress concentration.

- Frequent mold changes: Molds need to be replaced for different plate thicknesses or angles.

- High energy consumption: A Greater pressing force is required.

The Machining Steps of the Sheet Metal Bending Process

Process Analysis

Before bending, carefully analyze the part drawing to confirm the bending Angle, bending radius, unfolding size and direction, and check whether the bending sequence is reasonable.

The purpose of analyzing part drawings is to avoid dimensional errors or workpiece interference problems caused by improper design.

Select Material

Calculate the unfolding size based on the bending Angle and plate thickness, consider the bending compensation coefficient, and then prepare the materials. This process is carried out to ensure the dimensional accuracy of the raw materials and provide a foundation for subsequent bending.

Mold Preparation

Select the appropriate upper die, lower die, and tonnage of the bending machine according to the shape, Angle, and thickness of the bent part, and carry out installation and commissioning.

The selection of molds directly affects the bending accuracy and surface quality. Different plate thicknesses require different V-groove sizes to be matched.

Positioning

The operator places the workpiece on the worktable of the bending machine and ensures its correct position through the stopper and positioning device, aligning it with the bending line. This step has a significant impact on the consistency of the bending Angle and size, and positioning accuracy must be maintained.

Bending Operation

Start the bending machine. The punch presses down to press the sheet metal into the lower die to form the required Angle. The operator needs to control the depth of the downward pressure or the stroke to prevent overturning or excessive rebound.

During the bending process, attention should be paid to the direction of force on the material and the control of the indentation.

Dimension Inspection

After the bending of the parts is completed, a protractor, vernier caliper or three-coordinate measuring equipment is used for measurement to confirm whether the Angle, side length, and flatness meet the design requirements.

If deviations are found in the product after inspection, they can be corrected by fine-tuning the stroke or the mold clearance.

Secondary & Compound Bending

For complex parts, multiple bends or bending in different directions are required. Before performing secondary bending, it is necessary to check whether the bending Angle of the previous step is correct and pay attention to preventing the formed part from interfering with the mold.

Deburring

After the workpiece is bent, burrs need to be removed, chamfered, and surface-treated to prevent sharp edges from affecting assembly or use. If welding, powder coating or anodizing is required subsequently, the deburring step is particularly important to ensure the appearance quality.

Final Inspection

Ultimately, a full or random inspection of the dimensions, angles, flatness, and appearance of the workpiece is required. Only after confirming that they meet the requirements of the drawings can protective packaging be carried out.

Ensure that the bent parts are not damaged during transportation and assembly, and guarantee the quality of the finished products delivered.

Advantages of the Sheet Metal Bending Process

Sheet metal bending, as one of the most widely used forming processes in sheet metal machining, has multiple advantages. It can not only ensure structural strength but also take into account production efficiency and cost control.

High Precision

Modern CNC bending equipment can precisely control the bending Angle, position, and pressure. The bending error is usually controlled within ±0.5°, ensuring the consistency of the size and shape of the parts and meeting the requirements of precision assembly.

High Production Efficiency

The sheet metal bending process is easy to operate and has a short cycle. Especially when using CNC bending machines, multiple continuous bending processes can be achieved through programmed operation, greatly improving production efficiency. It is suitable for both batch and small-batch production.

Flexibility

Sheet metal bending can machine parts of different shapes, angles, and plate thicknesses by changing the die or adjusting the stroke parameters. The same equipment can adapt to multiple products and is suitable for the customized production mode of multiple varieties and small batches.

High Material Utilization Rate

Bending mainly achieves shape changes through plastic deformation, does not generate a large amount of cutting waste, has a high material utilization rate, saves raw material costs, and conforms to the concept of green manufacturing.

High Surface Quality

During the bending process, there is no obvious damage to the material surface, maintaining a good smoothness. It can directly enter the subsequent spraying, anodizing or welding processes, reducing rework steps.

Wide Range of Applications

Bending technology applies to all kinds of metal plates, such as carbon steel, stainless steel, aluminum, copper, etc., and is widely used in industries such as electronics, electrical appliances, automobiles, mechanical equipment, and construction.

Disadvantages of the Sheet Metal Bending Process

Material Property Limitations

The ductility, strength, and resilience of different metals vary greatly, which can easily affect the bending Angle and dimensional accuracy.

For instance, high-strength steel or hard aluminum is prone to cracking when bent, while soft metals may experience excessive deformation or uneven creases.

Springback Effect

There is an elastic recovery phenomenon in metals after bending, which leads to the actual Angle being either too large or too small.

Especially when it comes to high-strength materials and large bending radii, the difficulty of springback control is even higher, and it needs to be corrected through experience or compensation processes.

Complex Bending

When the thickness of the sheet is large, or the bending Angle is complex, the demand for forming force increases significantly, the tonnage of the die and equipment is required to be high, and problems such as bending line deviation, cracking, or indentation are prone to occur, making the forming process more difficult.

High Skill Requirement

The control of bending angles, mold selection, and sequence arrangement all require the operator to have rich experience; otherwise, problems such as uneven deformation, Angle deviation or workpiece interference are likely to occur.

Applications of the Sheet Metal Bending Process

Electronics Industry

Sheet metal is widely used in the manufacture of products such as chassis, server casings, and distribution boxes. This type of product has high requirements for dimensional accuracy and heat dissipation performance. The sheet metal structure can effectively protect the internal electronic components and is convenient for maintenance and installation.

- Network cabinet

- Industrial computer casing

- Distribution box

- Shielding cover

Communication Equipment

Sheet metal machining can be used to manufacture 5G communication base station casings, network racks, router casings, etc.

The sheet metal structure has excellent electromagnetic shielding performance and can meet the requirements of communication equipment for dust-proofing, moisture-proofing and anti-interference.

Automotive Industry

Sheet metal is used to manufacture body panels, chassis brackets, as well as the shells of motorcycles and electric vehicles etc. Through sheet metal bending and welding processes, high-strength and lightweight structural designs can be achieved.

- Car doors, hood, trunk lid

- Frame and chassis parts

- Battery tray

Home Appliances

Sheet metal manufacturing is widely used in the shells and internal brackets of products such as refrigerators, washing machines and air conditioners.

Sheet metal parts can achieve a precise appearance and high assembly accuracy, while also having excellent heat dissipation and protective properties.

- Side panel of the refrigerator

- Washing machine casing

- The outer casing of the air conditioner’s outdoor unit

NOBLE: Your Trusted Sheet Metal Manufacturing Service Provider

Provide custom sheet metal bending services that exceed customer expectations at competitive prices. From prototype design to sheet metal bending manufacturing, we rely on our experienced team and advanced production equipment to ensure that you receive sheet metal bending parts with high precision and stable performance. Get a quote in minutes and sheet metal bending parts within days!

ISO 9001:2015 and ISO13485-2016 Certificated, NOBLE ensures providing our customers with quality prototypes and production parts. Mature and advanced supporting metal-bending machines and skilled technicians provide accurate and high-quality metal-bending services for rapid prototyping and production.

FAQs

How is springback controlled in sheet metal bending?

Springback can be minimized by increasing bending force, using bottoming or coining methods, adjusting die angles, or compensating through CNC programming. Material selection also plays a key role in springback behavior.

What are the common challenges in sheet metal bending?

Typical issues include springback, cracking at bend lines, tool wear, and dimensional inaccuracies in multi-stage bending. Proper tooling, material preparation, and angle compensation can help avoid these problems.

What industries commonly use sheet metal bending?

This process is widely applied in automotive, electronics, home appliances, telecommunications, aerospace, and industrial machinery, mainly for enclosures, brackets, housings, and structural components.

How to bend sheet metal easily?

To bend sheet metal easily, mark the bend line, clamp it firmly, and apply steady pressure using a bending brake or vice. For thicker or precise parts, use a CNC press brake for accurate angle and radius control.

What are the main types of sheet metal bending methods?

The most common types include air bending, bottoming, coining, folding, and roll bending. Each method differs in tooling setup, bending accuracy, and force requirements, allowing manufacturers to choose based on material thickness and design complexity.