What is Sheet Metal Cutting?

Sheet metal cutting technology is a commonly used technique for separating and machining metal sheets. It mainly cuts the entire sheet into parts of the required shape and size through mechanical, thermal, or special means. Common traditional methods include shearing and punching, while modern processes widely adopt high-precision technologies such as laser cutting, plasma cutting, and water jet cutting, which can efficiently handle metals of different thicknesses and materials.

The core of sheet metal cutting technology lies in choosing the appropriate method based on material properties and production requirements. For instance, laser cutting is suitable for complex profiles and smooth cut surfaces, plasma cutting is appropriate for thicker plates, and water jet cutting can avoid thermal effects. It directly serves the first process of sheet metal manufacturing, providing precise blanks for subsequent bending, welding, and other links, and is widely used in fields such as mechanical equipment, automotive manufacturing, and aerospace.

History of Sheet Metal Cutting

The history of sheet metal cutting began with traditional manual and mechanical methods. Early artisans relied on tools such as scissors and chisels for manual cutting. After the Industrial Revolution, mechanical shearing machines and punch presses emerged, which achieved cutting through physical molds and pressure. This greatly improved efficiency, but their flexibility and precision were limited.

The revolution of modern cutting technology began in the mid-20th century. The emergence of oxygen cutting and plasma cutting technologies has solved the problem of cutting thick metal plates. Subsequently, laser cutting technology has become mainstream due to its high precision and flexibility, while water jet cutting offers a cold cutting solution without thermal effects.

How Does Sheet Metal Cutting Work?

Drawing Analysis

Engineers need to carefully analyze the part drawings, accurately understand their geometric shapes, dimensional tolerances, technical requirements, and subsequent machining needs. On this basis, plan the cutting path, select the most suitable cutting process, determine the layout scheme of the sheet to maximize the material utilization rate, and compile a detailed machining program.

Material Preparation

According to the drawing requirements, select the appropriate metal sheet and check whether its material, thickness and surface condition meet the standards. Subsequently, accurately place the sheet on the workbench and firmly fix it using fixtures, magnetic suction cups or vacuum adsorption tables and other devices.

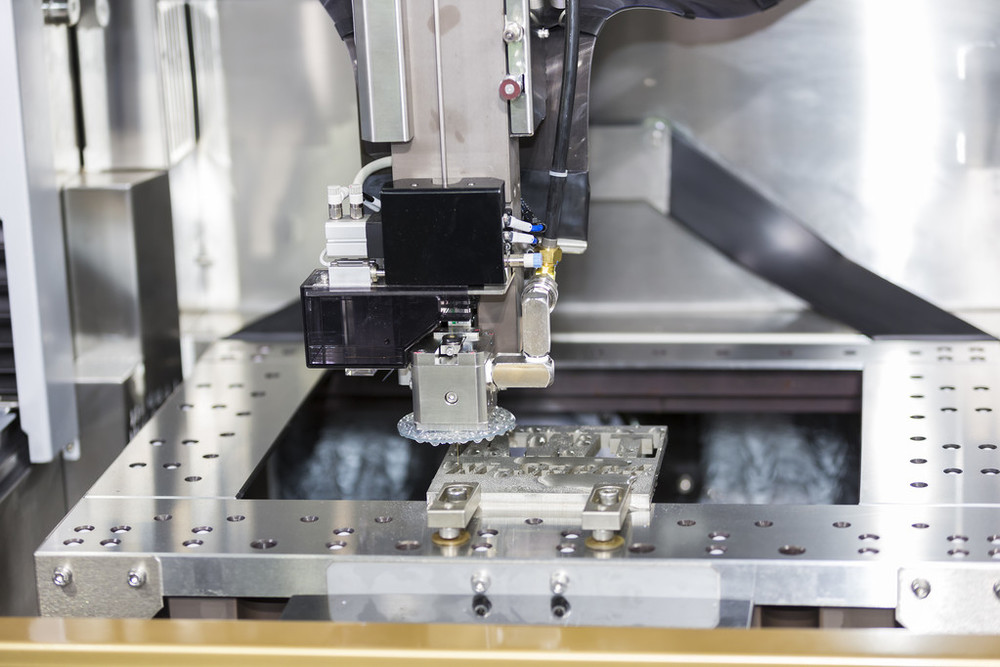

Equipment Setup

Before the formal cutting, the cutting equipment must be finely debugged. This includes installing and calibrating the appropriate cutting head, checking whether the auxiliary gas pressure meets the standard, and setting the optimal core parameters such as power, speed, and frequency according to the material type and thickness.

For laser cutting, the focus position also needs to be calibrated. For plasma cutting, it is necessary to determine the appropriate current and the height of the cutting nozzle.

Cutting Execution

After the materials and equipment are ready, start the equipment and execute the preset machining program. During this process, the operator needs to closely monitor the cutting status, observe the shape of the sparks and whether the slag ejection is normal, and listen for any abnormal sounds during the operation of the equipment.

Modern automated equipment is usually equipped with real-time monitoring systems that can automatically detect whether the perforation is successful, whether there is a risk of collision, and fine-tune the cutting parameters according to the situation.

Post-Processing

After the cutting is completed, the workpiece is moved to the subsequent machining area. First, burrs, slag, and other substances on the workpiece need to be removed. If necessary, grinding should be carried out to make the edges smooth and flat. Then, using tools such as calipers, projectors, or three-coordinate measuring machines, the key dimensions, contour accuracy and surface quality of the workpiece are strictly inspected to ensure that they fully comply with the requirements of the drawing.

Only qualified parts that pass the inspection can flow into the next manufacturing process, such as bending and welding, which is an important checkpoint to ensure the quality of the final product.

Metal Materials Used in Sheet Metal Cutting

Stainless Steel

Stainless steel is one of the most popular materials for sheet metal cutting due to its excellent corrosion resistance, durability, and attractive surface finish.

Applications:

Used in medical equipment, kitchen appliances, automotive trim, and architectural panels.

Mild Steel

Carbon steel is known for its strength, hardness, and cost-effectiveness. It’s easy to process and suitable for structural parts.

Applications:

Widely used in machinery, automotive frames, construction, and industrial equipment.

Aluminum

Aluminum is lightweight, corrosion-resistant, and has excellent thermal and electrical conductivity. However, it is reflective and requires specific laser wavelengths for precise cutting.

Applications:

Used in aerospace components, electronic housings, automotive panels, and consumer electronics.

Copper

Copper provides superior electrical and thermal conductivity, making it essential for electrical components. It’s reflective and can be challenging to laser-cut.

Applications:

Used in electrical connectors, busbars, heat exchangers, and decorative panels.

Brass

Brass is an alloy of copper and zinc, offering good machinability, corrosion resistance, and an attractive golden appearance.

Applications:

Ideal for decorative parts, nameplates, instruments, and architectural hardware.

Galvanized Steel

Galvanized steel has a zinc coating that protects against rust and corrosion. It combines durability with a relatively low cost.

Applications:

Common in HVAC ducts, automotive parts, and household appliances.

Titanium

Titanium offers an exceptional strength-to-weight ratio, high corrosion resistance, and excellent biocompatibility. It’s more expensive but ideal for critical applications.

Applications:

Used in aerospace, medical implants, and high-performance machinery.

| Material | Main Cutting Methods | Key Advantages |

| Stainless Steel | Laser, Waterjet | Corrosion resistance, strength |

| Carbon Steel | Laser, Plasma | Strong, affordable |

| Aluminum | Laser, Waterjet | Lightweight, conductive |

| Copper | Waterjet, Fiber laser | Conductive, durable |

| Brass | Laser, Waterjet | Aesthetic, machinable |

| Galvanized Steel | Laser, Plasma | Anti-rust, low cost |

| Titanium | Waterjet, Laser | High strength, biocompatible |

Types of Sheet Metal Cutting Processes

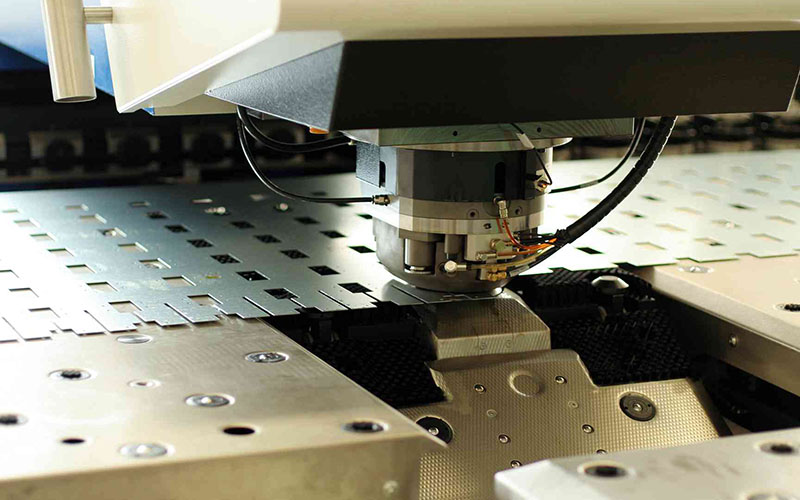

Sheet Metal Laser Cutting

Laser cutting uses a high-energy-density focused laser beam as a heat source to achieve cutting by melting, vaporizing, or igniting the material. This is a non-contact machining method with high precision and flexibility, which is particularly suitable for machining complex contours and fine parts. Its cutting speed is fast, the heat-affected zone is small, and the cross-sectional quality is usually very smooth.

According to the type of laser, it can mainly be divided into fiber laser cutting and CO2 laser cutting. Laser cutting applies to almost all metal plates, especially excelling in the field of medium and thin plates.

Sheet Metal Plasma Cutting

Plasma cutting melts the material through a compressed plasma arc and uses a high-speed gas flow to blow away the molten metal, forming a cut. The main advantage of plasma cutting lies in its ability to efficiently cut medium and thick plates as well as highly conductive metals, with an extremely fast cutting speed. However, its cutting accuracy and cross-sectional smoothness are usually not as good as those of laser cutting, and the heat-affected zone is also larger.

Plasma cutting technology is widely applied in heavy machinery, shipbuilding, steel structures, and other fields, and it is an economical and efficient solution for machining thick plates.

Sheet Metal Waterjet Cutting

Waterjet cutting is a cold-state cutting process. It uses ultra-high-pressure water flow or water flow mixed with abrasives to erode materials to achieve cutting. Its greatest advantage is that no heat is generated during the cutting process, so there is no heat-affected zone, thermal deformation, or metallographic change of the material at all.

Water jet cutting can cut any material, from metal and stone to glass and composite materials, and the starting point is arbitrary, with extremely high flexibility. The disadvantages are that the cutting speed is relatively slow and the operating cost of the equipment is high. It is often used for machining heat-sensitive or composite materials with different textures.

Sheet Metal Punching

Punching is a traditional mechanical machining method that uses a die installed on a press to shear, punch, or blank sheet metal through strong mechanical pressure. It is suitable for the production of large quantities of parts with relatively standardized shapes. Its machining speed is extremely fast, and it can be formed in a single stamping. The cost of molds is relatively high, but the machining cost per piece is very low.

For parts that require a large number of standard holes or simple shapes, such as chassis cabinets and electrical components, stamping remains the most efficient and economical choice.

Advantages of Sheet Metal Cutting

High Precision

Modern sheet metal cutting techniques, especially laser cutting, can achieve extremely high dimensional accuracy, with tolerances easily controlled within ±0.1 millimeters or even smaller. This means that the processed parts have precise dimensions and strong interchangeability.

Excellent Repeatability

Due to the adoption of digital programming control, once the program is set up, the same parts can be produced the same number of times, ensuring the stability and consistency of quality in large-scale production and laying a solid foundation for subsequent automated assembly.

Superior Flexibility

Sheet metal cutting, especially non-contact machining methods such as laser and water jet, offers unparalleled flexibility. There is no need to make expensive physical molds. Just by modifying computer drawings and programs, it is possible to quickly switch and process parts of different shapes and sizes, which is very suitable for small-batch, multi-variety production and rapid prototyping.

In addition, these processes can handle a wide range of metal materials from carbon steel, stainless steel, aluminum, copper, to titanium alloys, and even non-metal materials. Water jet cutting can deal with almost any material, meeting the material requirements of all industries.

High Efficiency

Compared with traditional manual or mechanical machining, automated cutting is extremely fast, especially when laser cutting thin plates; it can significantly shorten the production cycle.

Material Utilization

Sheet metal cutting can be carried out through a computer-optimized intelligent layout system to arrange parts in the most compact and reasonable way on the sheet metal, minimizing the waste at the corners and significantly improving the utilization rate of the sheet metal. This directly reduces raw material costs, and the effect of such savings is particularly astonishing in large-scale production.

High Quality Cut

Many advanced cutting techniques can directly achieve very smooth and vertical cutting surfaces. The cross-sectional smoothness of laser cutting is very high, while water jet cutting can maintain the original properties of the material.

After cutting, parts often do not require or only need very few secondary grinding and finishing processes, and can directly enter the bending, welding or assembly stage. This not only saves time and labor costs but also avoids dimensional deviations or surface damage that may be caused by secondary machining, achieving higher overall manufacturing efficiency and quality.

Challenges in Sheet Metal Cutting

Material Challenges

Different materials require specific cutting methods due to their unique properties. For example, reflective metals like aluminum and copper absorb very little laser energy. This makes them hard to cut. They can also reflect light and damage the laser equipment. On the other hand, hard materials like special alloy steel and titanium alloys reduce cutting speed. They also wear down blades and consumables more quickly.

Surface conditions matter too. Coatings, rust, or oil stains can disrupt cutting. This often leads to uneven edges or leftover slag. Setting the right cutting parameters for each material remains a key challenge.

Thermal Distortion Issues

Thermal cutting processes, such as laser and plasma cutting, inevitably input a large amount of heat into the material. If the parameters are not properly controlled, heat will accumulate excessively and spread to the material outside the cutting area, causing local stress and thermal deformation, resulting in dimensional deviations and shape warping of the parts. This is particularly prominent in thin plate machining.

To control the heat-affected zone and minimize deformation, it is necessary to precisely balance parameters such as power, speed, and air pressure, and adopt a reasonable cutting path design to disperse heat. This places high demands on the operator’s experience and the stability of the equipment.

Thickness vs. Precision

All cutting methods have a limit. Cutting thick materials means lower precision. For example, laser cutting is very precise on thin sheets. But with thicker plates, the cut becomes wider and rougher. Plasma cutting works well on thick plates, but the cut quality is poor.

Slowing down improves quality but hurts efficiency. Speeding up may leave an incomplete cut or create slag. Finding the right method for each thickness and balancing speed, precision, and quality is the key challenge.

Cost-Efficiency Balance

The cost structure of sheet metal cutting is complex, covering equipment, energy, gases, part replacement, and labor. Laser cutting, for instance, offers high precision but involves high investment, maintenance, and continuous gas costs.

Therefore, profitability depends on meticulous optimization. This includes improving material use through better nesting, extending part life with optimal parameters, and increasing equipment efficiency via smart production scheduling. Such measures are essential for enhancing overall profitability.

Cost Factors in Sheet Metal Cutting — What Affects the Price?

Material Cost

The cost of raw material procurement forms the basis of the total cost. The prices of metal plates of different materials and specifications vary greatly. More importantly, it is the material utilization rate, that is, how to arrange the parts on a single sheet.

Optimizing the layout, cutting out as many useful parts as possible, and reducing the waste at the edges and corners can directly lower the material cost allocated to each part. This is the most effective way to control costs.

Process Selection

The operating cost composition of different cutting processes varies greatly. Laser cutting relies on vulnerable parts such as electricity, auxiliary gas, and lenses. Plasma cutting consumes electrodes and nozzles; Water jet cutting wears out high-pressure seals and cutting heads.

The choice of process directly affects energy consumption, gas consumption, and the frequency of replacement of vulnerable parts.

Labor & Operational Efficiency

Machining time is directly related to labor and machine costs. Its length depends on the degree of optimization of the cutting path, the introduction and cutting speed, as well as the no-load operation time of the equipment. The skill level of the operators is also of vital importance.

Experienced operators can program, clamp materials, and handle unexpected malfunctions more quickly, thereby enhancing the overall efficiency of the equipment, reducing downtime, and indirectly lowering the labor cost per unit of product.

Post-Processing

The costs incurred after the cutting is completed should not be ignored either. If the cutting quality is high, the cross-section is smooth, and there is no slag hanging, the manpower and time for secondary machining, such as grinding and finishing, can be saved or reduced.

Sheet Metal Cutting Tolerances and Accuracy Standards

To ensure part maneuverability and precision of fabricated prototypes and parts, our custom sheet metal cutting services standards are as follows:

| Dimension Detail | Tolerance |

| Edge to Edge, Single Surface | +/- 0.010″ |

| Edge to Hole, Single Surface | +/- 0.010″ |

| Hole to Hole, Single Surface | +/- 0.010″ |

| Hole Diameter, Single Surface | +/- 0.010″ |

| Edge to Feature, Multiple Surface | +/- 0.030″ |

| Overformed Part, Multiple Surfaces | +/- 0.030″ |

| Bend Angle | +/- 1 deg |

Tips for Sheet Metal Cutting

Wear PPE

When performing sheet metal cutting operations, it is essential to wear a full set of protective equipment throughout the process and in a standardized manner.

High-quality goggles or protective face shields can effectively block high-speed flying metal debris and sparks. Sturdy and durable labor protection gloves can protect hands from cuts caused by the sharp edges of the sheet and burns from high temperatures during machining.

As many cutting devices generate extremely high levels of noise during operation, it is crucial to wear professional hearing protection devices to prevent permanent hearing damage.

Ensure Ventilation

The cutting process, especially laser cutting, plasma cutting, or flame cutting, generates a large amount of toxic metal fumes, harmful gases, and suspended particulate matter. Therefore, operations must be carried out in workshops equipped with powerful exhaust and dust removal systems to ensure air circulation and promptly expel harmful smoke outdoors.

Maintain Tools

Whether it is manual tools or consumables in automated equipment, maintaining the sharpness of their cutting edges is the cornerstone for ensuring efficiency and safety.

Blunt cutting tools will significantly increase cutting resistance, not only requiring greater force to be applied and causing fatigue, but also making them more prone to slippage, rebound, and other out-of-control situations, which can easily lead to serious accidents. In addition, worn cutting tools will produce poor cutting surfaces, increasing the difficulty of subsequent machining.

Secure Materials

Before the cutting begins, tools such as bench pliers, C-shaped pliers, special fixtures, or magnetic chucks must be used to stably fix the metal sheet on the working platform. This step can completely prevent the sheet from shifting, vibrating or flipping when subjected to cutting force, thereby ensuring the accuracy of the cutting dimensions.

More importantly, stable clamping can effectively prevent dangers such as tool path deviation and workpiece ejection caused by sudden movement of the sheet, fundamentally eliminating many potential mechanical injury risks.

Operate Equipment Properly

A high degree of vigilance must be maintained towards all power tools and CNC equipment. Before starting any device, check whether its power cord, switch, and protective cover are intact. During the operation, one must be highly concentrated and strictly follow the operating procedures.

Hands should be kept away from moving parts and the cutting head. Before completing the assignment or making any adjustments or cleaning, make sure that the equipment has been completely shut down and is not running.

Why Choose NOBLE’s Sheet Metal Cutting Service?

With many years of rich sheet metal cutting experience, NOBLE provides customers with unparalleled high-precision sheet metal cutting parts. Get a quote in minutes and parts in days.

NOBLE’s sheet metal cutting services can cut almost any material using laser and waterjet capabilities. NOBLE provides a one-stop solution for any project, providing instant quotes, a variety of materials, and a variety of sheet metal cutting process options.

NOBLE is your trusted one-stop custom manufacturing solution, from prototype design to manufacturing, with huge manufacturing resources, suitable technology, streamlined process, expert guidance, and a perfect quality inspection process to turn your ideas into reality.

FAQs

What is the most precise sheet metal cutting method?

Laser cutting, particularly fiber laser cutting, is widely regarded as the most precise method for sheet metal. It can achieve tolerances as tight as ±0.1 mm and produces extremely clean, burr-free edges with a minimal heat-affected zone. This makes it ideal for complex contours and intricate designs where high accuracy is critical.

How thick a metal sheet can a laser cutter cut?

The maximum thickness depends on the laser’s power and the material type. A typical high-power industrial fiber laser can cut through mild steel up to about 25 mm, stainless steel up to 20 mm, and aluminum up to 12 mm. However, for optimal speed and cut quality on thinner materials (under 15-20 mm), lasers are significantly more effective than plasma or flame cutting.

Is laser cutting more expensive than plasma cutting?

It depends on the application. Laser cutting has a higher initial equipment cost and can be more expensive to operate per hour due to gas and maintenance. However, for thin to medium thickness materials, its superior speed, precision, and reduced need for secondary finishing can make it more cost-effective overall. Plasma is generally a better budget option for cutting thick structural steel where extreme precision is not the primary concern.

Can you cut aluminum with a waterjet?

Absolutely. Waterjet cutting is an excellent choice for cutting aluminum. As a cold-cutting process, it introduces no heat, which means there is no heat-affected zone that could alter the material’s properties or cause warping, especially in heat-sensitive aluminum alloys. It can cleanly cut through any thickness of aluminum that is commercially available.

What is the maximum thickness a laser cutter can handle?

The maximum thickness depends on the laser’s power and the material. A high-power industrial fiber laser can typically cut:

- Mild Steel: Up to 25-30 mm

- Stainless Steel: Up to 20-25 mm

- Aluminum: Up to 12-15 mm

For thicknesses beyond these, plasma or waterjet cutting is often more efficient and effective.