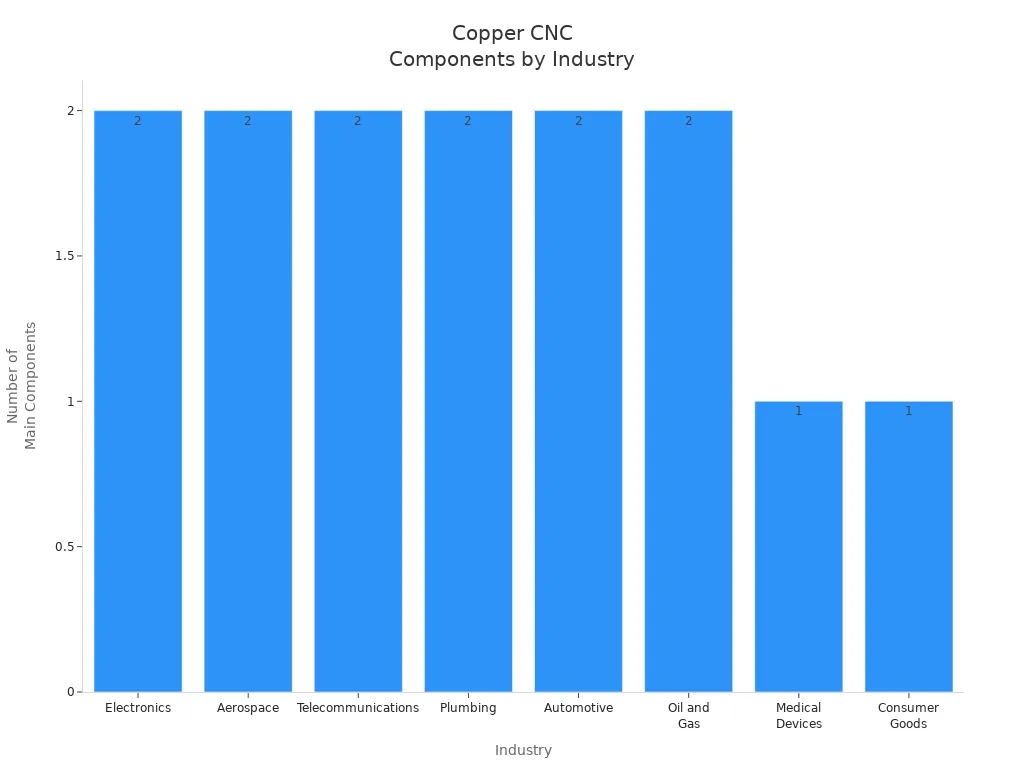

You use copper CNC machining to make very accurate parts. These parts are so important to so many big industries, aren’t they? You know, copper is pretty amazing! It’s great at conducting electricity and heat. And the best part is, it doesn’t rust easily. It is also simple to shape and cut. Copper is great for making heat sinks, connectors, valves, and electrodes, and that’s all thanks to its properties. The table below shows how different industries use copper parts:

| Industry | Main Components Produced |

| Electronics | Heat sinks, connectors |

| Aerospace | Heat sinks, waveguides |

| Telecommunications | Connectors, terminals |

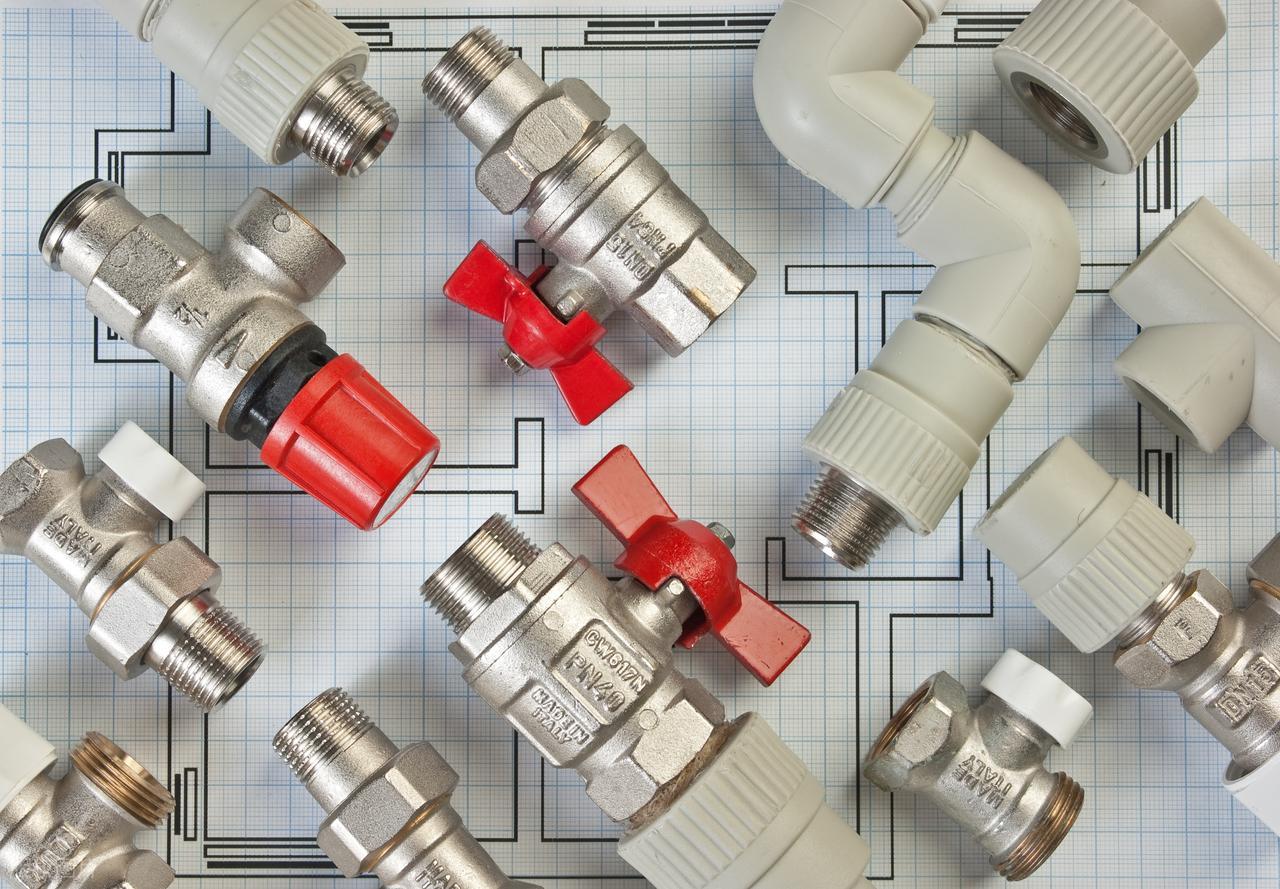

| Plumbing | Pipe fittings, elbows |

| Automotive | Bushings, bearings |

| Oil and Gas | Valves, fittings |

| Medical Devices | Electrodes |

| Consumer Goods | Magnetrons |

Why Copper for CNC Machining

Electrical and Thermal Conductivity

People pick copper for CNC machining because it works well with electricity and heat. Copper is used all over the world for electrical wiring. It lets electricity flow better than most metals. This is why it is used for connectors, circuit boards, and terminals. Copper also conducts heat very well. Its thermal conductivity is about 400 W/mK. This means copper can get rid of heat quickly. Therefore, you can find copper in radiators, heat exchangers, and cooling plates.

The following table explains exactly why copper is so successful in these areas:

| Property | Description |

| Excellent Electrical Conductivity | Copper is the international standard for electrical wiring and components– it’s pretty much essential in the electronics field. |

| Superior Thermal Conductivity | Copper’s high thermal conductivity makes it the go-to choice for applications such as heat exchangers and heat sinks. |

| Corrosion Resistance | Copper naturally resists corrosion, developing a green patina over time that enhances its durability. |

| Antimicrobial Properties | Copper surfaces are great at killing bacteria and viruses. In healthcare settings, this is really useful for high-touch areas. |

Tip: If you want very accurate copper parts for electronics or heat control, copper CNC machining is the best choice.

Corrosion Resistance and Strength

Copper does not rust easily. Copper is great for use in harsh environments because it lasts for ages. Over time, a protective green oxide layer—known as verdigris—forms on its surface. This layer keeps the metal safe and robust. So, it’s no surprise that copper components are often used in marine, industrial, and outdoor settings.

Copper alloys are also strong. You can look at the tensile strength numbers for copper alloys in the table below:

| Copper Alloy | Ultimate Tensile Strength (ksi) | Yield Tensile Strength (ksi) |

| C14500 | 32-56 | 10-51 |

| C16200 | 35-100 | 7-69 |

| C17500 | 45-115 | 25-110 |

| C18200 | 34-86 | 14-77 |

You get strong and long-lasting parts when you pick copper for hard jobs. This is why many industries use copper machining for important parts.

Copper CNC Machining Processes

Copper CNC machining uses different advanced methods to make parts. Each method has its own good points. You must pick the best one for your part’s shape and size. Of course, the surface finish required for your parts also demands attention. Copper’s soft texture and excellent thermal conductivity make it easier to cut (compared to many metals). However, achieving the desired results still requires selecting the right tools and adjusting the parameters appropriately.

CNC Milling for Copper

CNC milling is a common way to shape copper. The rotary tool is a total game-changer! It can cut copper to create flat surfaces and slots, and even produce intricate shapes! Copper is easy to machine, so you can get very close fits. With CNC milling, you can reach tight tolerances as low as 0.01 mm. This is really important for parts like connectors and heat sinks.

| CNC Process | Standard Tolerance (mm) | Standard Tolerance (inch) |

| Milling (3-axis) | ±0.13 | ±0.005 |

To get good results, use sharp carbide tools. These tools are polished and have sharp edges. They help keep the copper surface clean. Just a heads-up: because copper is pretty soft, tools can wear out pretty quickly. Our NOBLE engineers recommend that you take a look at your tools every now and then to make sure they’re in good shape. When you’re using this, it’s a good idea to try and cut quickly and lightly to help you use less material. This helps avoid marks on the copper.

Tip: Always use sharp, polished carbide tools for copper CNC machining. This helps extend the tool life on CNC milling machines and keeps surfaces smooth.

CNC Turning for Copper

CNC turning is best for making round copper parts. In simple terms, it involves rotating a copper rod and shaping it using tools. Tolerances can reach ±0.13 millimeters—meeting the requirements of most industries.

| Parameter | Recommendation |

| Cutting Speed (SFM) | 200-300 |

| Tool Material | Carbide or diamond-coated |

| Chip Removal | Effective with coolant |

| Vibration Minimization | Stable fixtures required |

| Coolant Quality | High-quality lubricants |

When turning copper, use carbide or diamond-coated cutting tools. These tools last longer and keep the copper parts looking good. Just make sure you use secure clamping fixtures to stop the workpiece from vibrating. Just make sure you use secure clamping fixtures to stop the workpiece from vibrating. It helps get rid of chips and keeps the workpiece cool, so you don’t end up with any damage, and the copper parts stay looking good.

CNC Grinding for Copper

CNC grinding gives copper parts a very smooth finish. A grinding wheel takes off tiny bits of copper. This is perfect for parts that need a shiny finish or are tight-fitting.

- CNC grinding can make surfaces as smooth as Ra 0.4 μm to Ra 1.6 μm.

- Milling or turning cannot get to Ra 0.8 μm without extra work.

- Grinding, lapping, and polishing are needed for very precise copper parts.

If you’re in need of copper parts for electronics or medical tools, grinding is usually the final step. It makes sure your parts meet strict rules.

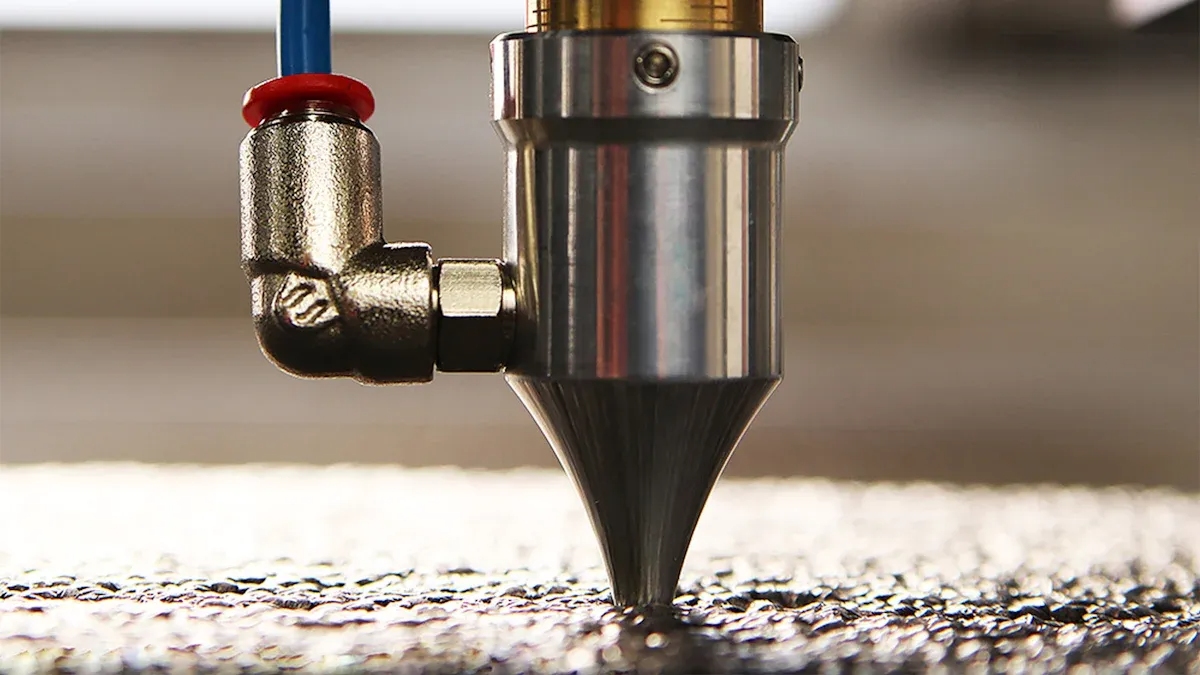

EDM and Specialized Techniques

Electrical Discharge Machining (EDM) is a special way to machine copper. EDM uses sparks to shape copper without touching it. This is good for making tiny or complex shapes. You can get accuracy up to 5 μm. So it’s great for high-tech stuff like aviation and healthcare.

New EDM uses copper and chromium powder electrodes. These last longer and resist wear. Sinker EDM uses a 2D electrode to make detailed 3D shapes. This method makes it easy to produce molds and dies with deep holes and sharp angles.

Note: Just so you know, EDM is great for machining hard and delicate copper parts without putting too much pressure on them. It is the best way for tiny designs and micro-features.

Copper CNC machining gives you many ways to make good parts. If you pick the right method and tools, you’ll get the finish and accuracy you need.

Types of Copper and Alloys

When you pick copper for CNC machining, you should know about pure copper grades and copper alloys. It’s not just copper—every material’s got its own unique properties. These characteristics change how you use and process them. Knowing the differences between them will help you pick the best material for the job.

Pure Copper Grades (C101, C110)

Pure copper grades like C101 and C110 are used a lot in copper CNC machining. A lot of industries are into these grades because they can handle electricity really well and are easy to use. Here is what you should know:

- C110 copper is easier to machine than C101.

- C110 is good for making exact parts in electronics.

- C101 is best if you need strong parts and top electrical conductivity. You see it in wires and airplane parts.

You can look at the table below to compare C101 and C110:

| Property | Copper 110 | Copper 101 |

| Hardness (HB) | 45-60 | 70-90 |

| Strength (MPa) | 150-220 | 250-350 |

| Ductility | Good | Limited |

| Machinability | Good | Excellent |

| Machining Stability | Good | Excellent |

Pick C101 for the best electrical performance. Pick C110 if you want easier machining and good conductivity.

Common Copper Alloys

As well as the models I mentioned, copper alloys give you more options for strength, resistance to corrosion, and how easy they are to machine. You can pick from many alloys made for special jobs. Here are some common copper alloys you might use:

| Copper Alloy | Composition | Typical Applications |

| C90700 | 89% Cu, 11% Sn | Worm wheels, gears, bearings for heavy loads and low speeds |

| Alloy 230 | 85% Cu, 15% Zn | Musical instrument parts (like French horns) due to corrosion resistance |

Adding tin or zinc to copper changes its features:

- Alloying elements can make copper stronger or weaker.

- Tin makes copper stronger and helps stop it from rusting.

- Zinc makes copper easier to shape and work with.

- If an alloy has more than 15% zinc, it might need to be heat-treated to stop stress corrosion.

- Tin-brasses use tin to make copper stronger and better against rust. This also makes it easier to machine.

- Tin makes copper stronger than zinc, but tin costs more.

- Zinc isn’t as good at lowering electrical and thermal conductivity as tin.

Tip: For strong gears or bearings, go for C90700. Use Alloy 230 for musical instruments or parts that get wet.

Application Suitability

It is best to select the appropriate copper grade or alloy based on your project requirements. So, using what I’ve learned in the past, here are the main points I want to share with you:

| Criteria | Description |

| Mechanical Properties | Just check the strength, hardness and ductility. |

| Thermal Properties | Check out how well it can handle heat and how much it grows when it’s hot. |

| Chemical Properties | Just make sure it doesn’t rust and that it fits your chemical needs. |

| Machinability | Just think about how easy it is to machine and how long the tools last. |

| Cost and Availability | Just look at the price and how easy it is to get. |

| Application Needs | Make sure you match the material to the work and final product. |

Copper CNC machining can be used to make parts for electronics, airplanes, and big machines. If you need high conductivity, go for pure copper grades like C101 or C110. If you need something stronger or more rust-resistant, try using copper alloys like C90700 or Alloy 230. Make sure you know what your project needs before you pick.

Remember: Picking the right copper grade or alloy will help your parts work well, last longer,er and save you money.

Copper CNC Machining Applications

Electrical Components and Connectors

Copper CNC machining is used to make many electrical parts. We use copper for processing because it’s really good at conducting electricity. Here are some common applications where copper is vital:

- Electrical connectors are things like terminals, plugs and sockets that are used to connect to power.

- Switchgear parts that are important for safety, like contacts and terminals.

- Transformer parts that help with heat and electricity.

- Parts for motors and generators that help machines work well

Robots need connectors and terminals that always work. Copper CNC machining produces parts that are perfect for the small spaces inside robotic arms. If robots are fitted with the right parts, they can work safely and do their jobs well.

3Heat Sinks and Thermal Parts

Copper CNC machining is used to make heat sinks for electronics. Copper conducts heat very well, which means that heat dissipates rapidly from components it touches. Copper heat sinks stop computers, servers, and power tools from getting too hot, so they work properly. If mishandled, they could even cause fires. Copper heat sinks are also used in car computers and airplane electronics.

| Property | Description |

| Thermal Conductivity | Copper moves heat fast, so things stay cool. |

| Malleability | You can shape copper into many heat sink forms. |

| Corrosion Resistance | Copper lasts long, even in hard places. |

Automotive and Aerospace Parts

Copper CNC machining is used in cars and airplanes. NOBLE’s copper bushings and bearings are used in cars to stop parts from wearing out too quickly. This means engines and transmissions last longer.

When we fly, copper waveguides and connectors in aircraft make sure that signals can be sent without any interruptions. This is important for keeping air transport safe. Copper CNC machining technology is also used to make parts for electric vehicles, like battery connectors and heat sinks.

Medical and Consumer Products

Medical tools need to be safe and clean. Have you heard that copper can kill bacteria? It’s truly remarkable! Because of this, it’s also great for use with electrodes and surgical instruments. If you open the case of medical equipment, you might see them inside. Copper is used in many household products, such as microwave ovens and electrical wiring, because it can conduct heat very well.

Copper CNC machining ensures that your parts meet the necessary standards. This helps you make products that last and work well.

Challenges in Copper CNC Machining

Tool Wear and Material Softness

When you machine copper, you face unique challenges. Copper’s high thermal conductivity and ductility make it tricky to work with. The material often smears and sticks to your cutting tools. Clearly, this will make the tools wear out more quickly, meaning that the equipment will have to be replaced sooner. If you use high-speed cutting, wear and deformation may become even more severe. Softer copper grades can also smear, so you need to choose the right cutting tool edge angles. You should also know that pure copper is harder to machine than copper alloys. We only use pure copper when customers ask us to.

- Copper generates more heat when it is being machined. This makes tools wear out faster.

- Smearing is common, so you need sharp tools and the right angles.

- If you cut too fast, you can damage both the tool and the part.

Burrs and Surface Finish

Burrs are small, unwanted pieces of metal that form on the edges of your copper parts. Copper often sticks and changes shape when it is cut. If there are any burrs on the surface of the part, it will look bad and the part might not fit properly or work properly.

However, it’s hard to get a smooth finish on copper surfaces because it’s soft and sticky. When you try to cut it, you often get scratches or rough spots left behind. Here are some methods that NOBLE engineers have come up with to reduce burrs and improve surface finish:

| Technique | Description |

| Optimize cutting tool geometry | Use tools with higher rake angles for neater cuts and fewer burrs. |

| Optimize cutting depth | Just make the cuts shallow so you keep the edges smooth and you won’t have to do as much extra work. |

| Vibration-assisted deburring | Get rid of those pesky burrs while making sure your part stays strong. |

You can also use special tool paths to avoid cutting out at the part’s edge. Tailored coatings and lubricants help control burrs and keep your parts smooth.

Solutions and Best Practices

You can overcome these challenges by following some best practices. First, let’s select the appropriate cutting tool for this job. High-speed steel (HSS) tools are ideal for machining copper. They excel at handling soft materials, even sticky ones, so you can use them with confidence.

A reminder: To maintain stable, vibration-free machining, we recommend securing the workpiece firmly with a robust clamping method. This effectively maintains machining stability and ensures a smooth process. Don’t worry—we can easily control heat generation by adjusting the cutting speed and feed rate, thereby effectively preventing surface roughness.

| Best Practice | Description |

| Tool Selection | Why not try different speeds, feeds and depths to see what works best for your copper material? |

| Workholding Considerations | Hey, just a friendly reminder to use stable setups to stop vibration and keep your part in place. |

| Surface Finish Enhancement | If you want to achieve a high-quality finish, why not try polishing or grinding? |

| Addressing Material Challenges | Just a friendly reminder to use those coatings and lubricants! They stop copper from sticking to your tools. |

Tip: Remember to keep an eye on your tools at all times! This helps you get the best results from copper CNC machining.

Design and Material Considerations

Selecting Copper Grades

Picking the right copper grade is very important. You need to match the material to what your part will do. You’ve got to think about the environment where the components will be used – will it be really hot? Underwater? In direct sunlight? Some copper alloys are easier to machine, while others are stronger or better at conducting electricity.

Design requirements are equally important—when selecting materials, make sure the chosen copper alloy fits the component’s dimensions and shape. It should also work for how your part will perform. When the machine is running, choose a feed rate that gives you a smooth surface finish – this also makes the tool last longer. Pick the right tool material for your copper grade. If you want to get the best results when working with certain types of copper, it’s best to pick the right tool for the job.

Here’s what you need to do:

- Check if you need high conductivity. Use high-purity copper like C101 for this.

- Have you thought about how easy it is to machine? Free-machining grades make work easier.

- Take a look at how strong and durable it is. Bronze and brass alloys are great for strong parts.

- Make sure the grade matches your job. Just think about things like heat, moisture and wear and tear.

Design Tips for Machinability

A good design makes copper CNC machining easier and cheaper. You can help machinability by using these tips. Make your part design simple. Try not to add unnecessary elements wherever you can. Just break down complex components into a few simpler parts. When not essential, using swept surfaces alone will make your work easier. Try to design features that can be machined from one side. If you can reduce the number of steps in the installation process, you can make significant cost savings. Be mindful of high walls and tight corners—they can cause tools to bend or wobble.

Cost and Supply Factors

Copper prices can go up and down fast. This might mean changes to the budget for the project. NOBLE suggests the following to help sort out the situation and keep costs and supply under control:

- Select copper alloys with better cost-performance ratios.

- Important tip: Simplify designs to reduce machining time!

- Demand tight tolerances boldly—but only when truly necessary. Stricter tolerances are a quality investment; though more costly, they deliver value for money.

- Bulk purchasing materials is an excellent way to save expenses.

- Pre-planning tool paths and cutting sequences saves time and material.

- Good news: Robots and machinery effectively reduce labor costs!

- Maintain tools meticulously to keep them in peak condition!

- Optimize part layout planning!

- Collaborate with suppliers to explore cost-saving opportunities.

- Top tip: Implement energy-saving practices in the workshop!

Thorough planning is the key to achieving the best possible results for every single project! And if you need a helping hand, our NOBLE team of super-talented engineers is always ready and waiting to lend a hand!

Choose NOBLE for Copper CNC Machining

If you need copper parts made, you want a company you can trust. NOBLE is a top machining company in China. We know a lot about copper CNC machining. NOBLE has many years of experience making copper parts. Whatever you need, whether it’s a small test part or a big order, we’ve got you covered! You can trust them with any size project.

The NOBLE team uses modern equipment and skilled workers to make sure that your copper components are of the highest quality. Our team is very good at working on complicated designs and making sure things fit perfectly. NOBLE can make one piece or lots of pieces quickly and correctly.

Here are some things that make NOBLE special:

| Capability | Description |

| Wire EDM | Makes wire sizes from 0.006″ to 0.012″ and does 4-axis Wire EDM cutting for copper. |

| CNC Milling & Turning | Uses new machines for milling, turning, drilling, and reaming copper parts. |

NOBLE checks every copper part carefully. All parts meet world standards. You get the same good results every time, no matter how many you order.

NOBLE’s engineers are pros at fixing hard machining problems. We’ll help you pick the best copper grade and design for the job. It’ll save you time and money.

NOBLE makes copper parts for loads of different fields. You see their work in electronics, cars, planes, and medical tools. Their team uses real facts and the right tools to make your project a success.

If you’re after a reliable partner for your copper CNC machining, look no further than NOBLE. What you’ll get: fast quotes, clear responses, and on-time delivery. Try NOBLE for your next copper CNC machining job and see how their skill helps you.

You get lots of benefits when you pick copper CNC machining:

- High electrical and thermal conductivity

- Strong and can take a lot of bending without breaking

- Able to last a long time in tough conditions

- Can be shaped to meet the most important requirements

FAQ

Why do most people choose CNC machining when machining copper?

Copper is great at conducting electricity and heat quickly. This helps make parts for electronics and heat control. Copper is easy to cut and shape.

How do you avoid tool wear when machining copper parts?

NOBLE engineers use sharp carbide or diamond-coated cutting tools. It is essential to always select the appropriate coolant.

Regularly inspecting tool wear is a good practice, ensuring copper machining remains in optimal condition.

Can NOBLE machine complex shapes with copper?

Of course, you can make tricky shapes with copper. CNC milling, turning, and EDM help you do this.

Which industries use copper machining services the most?

Copper machining is used in electronics, cars, planes, and medical tools. I totally get it, these fields need copper for connectors, heat sinks, electrodes, and special parts.