What is Blow Molding

If you had a piece of material and wanted to make something thin-walled and hollow (like a bottle), how would you go about it? You could carve it straight from the material, but that’s a bit of a pain. It’s wasteful and slow. You could try sticking two pieces together, but that’d leave a seam. That’s where the blow molding process comes in.

Blow molding is basically like blowing up a balloon inside a bottle. So, engineers melt plastic into a soft tube in a mold, and then they inject air into it. The plastic expands really quickly and fits snugly into the mold. Now, just a matter of waiting for it to cool down and taking out the part. This process produces a hollow, thin-walled component.

The Blow Molding Process: How It Works

Types of Blow Molding Processes

Blow molding is primarily categorized into three types: Extrusion Blow Molding Process, Injection Blow Molding Process, and Stretch Blow Molding Process. I will now provide a brief overview of each.

| Type | How It Works | Best For |

| Extrusion | Squeeze out a tube → clamp it → blow it up. | Large & complex containers (jugs, drums). |

| Injection | Make a preform with a perfect neck → blow it up. | Small, precise containers (pill bottles). |

| Stretch | Make a preform → stretch it → blow it up. | Strong, clear bottles (soda, water bottles). |

Step-by-Step Overview of the Blow Molding Process

So, how does the blow molding process work? Essentially, the blow molding process is used to create hollow plastic items, such as soda bottles, shampoo bottles, or even large gas tanks. The main idea is simple: you take a hot, soft blob of plastic (called a “parison”), put it inside a mold, and then blow air into it like a balloon. The plastic expands to fit the mold, cools down, and you get your finished product.

The most common type is called the extrusion blow molding process. Here’s how it works, step by step:

Step 1: Melting and Squeezing out the Plastic

- Feed it: They pour small plastic pellets into a machine.

- Melt it: The machine heats up and melts those pellets until they’re gooey.

- Shape the blob: The melted plastic is then squeezed out through a round hole, forming a hot, droopy, hollow tube. This tube is the “parison.”

This paragraph is the starting point. Its quality decides how good the final product will be.

Step 2: Catching the Plastic in a Mold

- Mold opens: The two halves of the mold are open and waiting.

- Blob drops down: When the hot plastic tube is long enough, it’s cut free.

- Mold closes: The two halves of the mold quickly snap shut, trapping the soft plastic tube inside. It pinches and seals the top (which becomes the bottle neck) and the bottom, trimming off any extra plastic.

Step 3: The “Blow” Part

- Air pipe goes in: A thin metal pipe (called a “blow pin”) moves down into the sealed bottle neck.

- Pump in air: High-pressure air is blown through this pipe into the trapped, soft plastic.

- It balloons out: The plastic inflates like a balloon, pushing out against the cold walls of the mold. It takes the exact shape of the mold, including any details or text.

Step 4: Cooling and Setting

- Hold and cool: The air pressure is kept for a few moments while the mold (which has cool water running through it) chills the plastic, making it hard.

- Let the air out: Once the plastic is solid, the air is released.

This cooling step is often the slowest part of the entire process. Making it faster means you can make more bottles per hour.

Step 5: Opening the Mold and Getting the Product

Mold opens: The two halves of the mold split apart.

Product pops out: The now-finished bottle is pushed out.

A little clean-up: The bottle might need some final touches, like:

- Trimming: Cutting off the excess plastic bits from the top and bottom.

- Decorating: Adding labels or printing on it.

- Quality check: Making sure it looks good and doesn’t have any holes or thin spots.

Then, the mold closes again, and the whole process repeats!

A Quick Look at Other Types

There are a couple of other common methods:

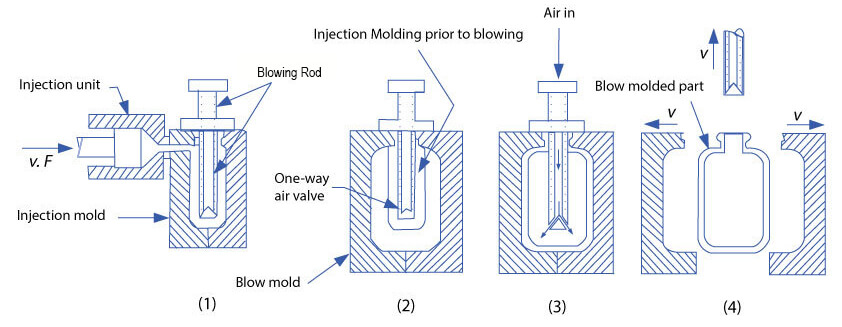

Injection Blow Molding

Good for: Super precise, small things like medicine bottles. The neck (opening) is very neat, and there’s no seam line.

How it’s different: First, a precise test-tube-like piece with the bottle neck already formed is made by injection. Then, while it’s still hot, it’s moved to another station where it’s blown into its final shape.

Stretch Blow Molding

Good for: Water and soda bottles (usually made from PET). It makes the plastic stronger and clearer.

How it’s different: Before they blow the air in, they stretch the plastic blob both up and down and outwards. This “stretching” makes the plastic a lot tougher.

The Main Idea in a Nutshell

You can think of it like this: Make a soft tube → Trap it in a mold → Inflate it like a balloon → Let it cool and harden → Take out your new bottle. Different methods just change how they make the first soft tube, or if they stretch it first.

Materials Used in the Blow Molding Process

Common materials

| Raw Material | Key Characteristics | Common Applications |

| PET | High clarity, strong gas barrier, high rigidity & toughness, recyclable. | Beverage bottles, food containers, and pharmaceutical packaging. |

| HDPE | Excellent chemical resistance, waxy surface, high impact strength, opaque, and recyclable. | Household chemical bottles (bleach, detergents), industrial containers, and medical fluid vessels. |

| PP | Good heat resistance, fatigue resistance (e.g., for living hinges), and chemical resistance. | Automotive coolant tanks, food containers, hinged caps, and medical disposables. |

| PVC | Inherent rigidity, good clarity, and versatile flexibility with additives. | Note: Use is declining and specialized, but includes blister packs and some plumbing conduits. |

| LDPE | High flexibility, tough & impact resistant, transparent in film form. | Squeeze bottles (e.g., for honey), tubing, and flexible packaging. |

So how do you choose? The application dictates everything. It’s a puzzle we solve with our clients daily.

Let me give you a concrete example from the medical field. Imagine a custom irrigation bottle used during surgical procedures. It can’t interact with the sensitive fluids it holds. For this, HDPE is often the champion. Its superb chemical resistance ensures product purity, a critical factor. The material is also relatively flexible, allowing a nurse to squeeze the bottle with control.

Advantages of the Blow Molding Process

Frankly, when developing components, we constantly have to balance numerous factors. We want them to be both robust and durable, yet lightweight and portable; cost-effective without compromising design integrity. This is the most challenging phase of the design process.

Yet it is precisely here that blow molding technology reveals its full potential. At NOBLE, our engineers witness its advantages daily. For hollow structural components, it effectively addresses a unique set of challenges that injection molding or CNC machining struggle to overcome.

Cost-Effective Manufacturing

Blow molding is a surprisingly cost-effective path for manufacturing. Creating a single prototype can be one thing, but when you need thousands, or even millions, of units, the economics shift dramatically. The per-part cost plummets.

The molds themselves, while a precision tool, often represent a lower initial investment compared to other high-volume methods. This allows our clients to allocate their budget more strategically across the entire project.

Design Flexibility

The design flexibility is, in a word, exceptional. Think of intricate contours, undercuts, and integrated handles—all formed in one go. This capacity for custom machining of hollow shapes is its core strength.

From a practical standpoint, you no longer have to worry about whether complex parts can be manufactured. Whether you are designing ergonomic handles for medical fluid containers or developing intricate air ducts for the automotive industry, you no longer have to assemble multiple components. It’s all one part.

Lightweight and Durable Products

You get products that are both incredibly lightweight and remarkably durable.

In the automotive sector, every gram saved translates to better fuel efficiency. A blow-molded fluid reservoir or air duct is tough enough to handle engine heat and vibration but weighs a fraction of a metal equivalent. We apply the same principle to our precision manufacturing work. The resulting parts resist impact and corrosion, offering a longevity that belies their light weight.

Environmentally Friendly Options

The most common materials in the blow molding process, like HDPE and PET, are highly recyclable. This creates a circular life cycle for the products. This is great news for companies that are serious about sustainable professional machining, as these energy-saving practices are really impressive. It lets you meet production targets while also being eco-friendly.

Challenges in the Blow Molding Process

For all its fantastic benefits, the blow molding process has its own set of headaches. I’ve seen brilliantly designed parts fail in production because we underestimated these challenges. Understanding them isn’t about pointing out flaws; it’s about engineering a robust solution from the start.

Mold Design and Maintenance

The initial mold design demands an almost artistic foresight. Not just carving a cavity; you’re predicting how molten plastic will flow, stretch, and cool under pressure. A slight miscalculation in the draft angle, and the part won’t eject.

Wear issues are also a big problem. Even the hardest steel molds will wear down after thousands of cycles. In the end, this wear subtly changes part dimensions, which leads to nonconformity. This is a really important thing to think about when it comes to precision manufacturing, and we can’t afford to ignore it.

Material Wastage and Environmental Impact

Material waste remains an area where NOBLE must continue to improve, as it impacts both customer costs and environmental protection. Blow molding itself is highly efficient, but it is not without its flaws.

You may notice a “tail end” or “spike” forming at the mold seam of the blank. This portion is a residue directly formed during the blow molding process. Our approach is twofold.

First, we optimize the parison programming to use the absolute minimum material required for each section of the part. Second, we have robust systems in place to collect and regrind that scrap directly on the production line, feeding a percentage back into the process.

Technical and Production Challenges

Inconsistent wall thickness is probably the most common fight we have. When you blow mold plastic parts, gravity can make the upper sections thicker and the lower sections thinner, which needs to be fixed.

Additionally, the blow molding process may introduce bubbles or inclusions. These defects typically stem from material contamination or moisture ingress at some stage. For instance, resin exposed to humid environments can suffer severe degradation, leading to bubble formation that compromises the strength of your final parts. We integrate our CNC machining expertise here, using it to create and maintain the perfect mold tooling that gives the plastic a flawless path to follow.

Key Considerations When Choosing the Blow Molding Process

Production Volume and Lead Time

The most important things to think about are how much we can produce and how long it’ll take to get things to you. Blow molding only really shows how good it is when you’re making at least a few thousand of something. The first stages, which are designing and machining the molds, require a lot of investment, including both time and money.

So, if your part quantities are relatively low, I’d suggest looking into other methods (like CNC machining of solid blocks). After all, it’s more cost-effective this way, isn’t it? We help our clients model this break-even point.

Cost Considerations

The initial investment is a reality you can’t avoid. High-quality mold tooling is expensive. But you must view this as a capital expense that gets amortized over every single unit you produce. That initial outlay is what buys you the long-term savings. Part number 10,000 will cost a fraction of part number one. This economy of scale is the fundamental financial engine of blow molding.

Material Selection

We talked a bit about materials earlier. Choosing the right materials is about more than just whether they’re suitable; it’s also about how well blow-molded parts work throughout their lifetime. For example, medical device housings have to be biocompatible and able to withstand repeated sterilisation cycles. An automotive duct needs to resist under-hood heat and oil vapors. Materials determine a product’s durability, tactile feel, and even its core functionality.

NOBLE routinely conducts material compatibility testing for custom manufacturing clients, as discovering that a certain chemical causes stress cracking after producing fifty thousand units would be a disaster.

Quality Control in the Blow Molding Process

Never, ever underestimate the importance of quality control. Consistency is the name of the blow molding process. If you ask me, “How do you ensure the 50,000th part is identical to the first one?”—the key lies in the mold.

We’ve got to make sure you do regular maintenance and inspection to stop flash or dimensional drift. When we’re on the production line, we’re always keeping an eye on the key things like parison temperature and blow pressure. We do this using something called statistical process control. We also perform destructive testing on a sampling of parts—cutting them open to physically measure wall thickness with calipers.

Blow Molding Process vs. Rotational Molding Process

NOBLE clients sometimes ask me, “Why should I choose the blow molding process over rotational molding or other processes?” That’s a great question. The truth is, it’s not about which process is better; it’s about finding the one that best fits your needs. Picking the wrong tool is like using a hammer to tighten a screw – it’ll get the job done, but it’s not the best way to do it. Let me explain.

Overview of Rotational Molding

Imagine placing plastic powder into a hollow mold. Then, that mold is heated and rotated slowly along two axes, tumbling through a giant oven. The powder melts and gradually coats the inside of the mold cavity, layer by layer, until it forms a solid part.

Key Differences Between Blow Molding Process and Rotational Molding

-

Process Comparison

The core process mechanics are worlds apart. Blow molding is like inflating a balloon inside a bottle. We start with a molten tube of plastic (the parison), clamp a mold around it, and then inject high-pressure air to push the material out against the mold walls. It’s fast and oriented towards high-volume production. Rotational molding, by contrast, involves the material being sintered and built up from the inside out. This fundamental difference dictates everything that follows.

-

Cost and Efficiency

In terms of cost and efficiency, they differ significantly. Blow molding is specifically designed for high-speed, high-volume production. Once the mold is loaded into the machine, production cycles are measured in minutes, sometimes even seconds. This makes the process extremely cost-effective for mass production.

Rotational molding, however, is slower. After all, its economic advantage does not stem from speed, but rather from extremely low mold costs. The molds for rotational molding are often much cheaper to produce than the hardened steel molds required for blow molding.

-

Design Flexibility and Complexity

It’s when things get really interesting that you start to see the benefits of design flexibility. Blow molding is great for complex projects. But it can be a bit tricky to get the wall thickness right.

Rotational molding is the best way to get consistent walls. The slow, tumbling action makes the thickness of the part uniform, which is a big plus for large, structural items like chemical tanks or marine buoys.

-

Material Suitability

Another factor NOBLE must consider is material suitability. Blow molding commonly employs materials that can be extruded into strong, resilient molten parisons, with our primary raw materials being PET, HDPE, and PP. Rotational molding, however, primarily utilizes powdered polyethylene, particularly LDPE and MDPE. The range is a bit more limited. If your application needs the specific chemical or clarity properties of PET, then the blow molding process may be your only option.

When to Choose the Blow Molding Process vs. the Rotational Molding

So, when do you choose one over the other? The decision tree is actually quite clear once you know the questions to ask.

- Choose the blow molding process when: You can choose the blow molding process when you need to produce large quantities, use complex shapes, and common thermoplastics like HDPE or PET. This could be anything from making car parts to medical bottles or packaging for products. This approach strikes a balance between efficiency and complexity in large-scale production. NOBLE has produced millions of parts, and their facilities are really good at this because they put a lot of money into molds.

- Choose rotational molding when: You need a very large, simple, hollow part with critical uniform wall thickness, but your production volume is low to medium. Think things like agricultural water tanks, kayaks, or large industrial containers. It’s perfect for making sure things are the same size and shape, even when you don’t have much money for expensive tools.

Types of Blow-Molded Products

Once you get your head around the blow molding process, you start seeing its influence everywhere. The blow molding process is so versatile, it’s a cornerstone of modern manufacturing. Here at NOBLE, we don’t just see raw plastic; we see the potential for a huge range of essential items.

| Product Category | Examples | Considerations |

| Plastic Bottles & Containers | Beverage bottles, detergent jugs, food containers. | Requires precision manufacturing for consistent thread quality and wall thickness. |

| Automotive Parts | Air ducts, dashboards, fluid reservoirs, bumpers. | Weight reduction is critical. Often involves custom machining for part consolidation. |

| Medical Devices & Packaging | Saline bottles, medicine vials, diagnostic fluid containers. | Demands material purity and biocompatibility; strict regulatory compliance; production in controlled environments. |

| Consumer Goods & Toys | Shampoo bottles, cosmetic packaging, hollow toys (e.g., rocking horses). | Durable and safe for end-users; leverages professional machining for aesthetic details. |

We Can Help with the Blow Molding Process

Here at NOBLE, we’re not just any old Chinese manufacturer; we’re a team that’s in it for the long haul, working closely with you every step of the way to bring your ideas to life and bring them to market.

Our Expertise in the Blow Molding Process

NOBLE has got you covered from start to finish. We’ve got a pretty straightforward approach to what we do: we make it easy to go from prototype to production. We offer a range of services, including CNC machining, which is great for quickly producing small batches of prototypes. We make the molds for production at our factory, and we’ve got really strict quality control measures in place at every stage. NOBLE handles the whole ecosystem for you, so you don’t have to deal with loads of different suppliers.

How We Can Improve Your Blow Molding Process Projects

First, we immerse ourselves in your project during the consultation and design phase. Our engineers will meet up with your team – online or face-to-face-to take a close look at your design and see if it’s actually possible. We can spot the little issues that customers might have missed, like thin-walled areas or chamfer defects that could stop parts from working. This helps avoid expensive mold changes down the line.

Why Choose Us for Your Blow Molding Needs

The answer lies in a commitment that goes beyond a simple transaction.

We safeguard your blow molding projects with unwavering quality, practical innovation, and sustained value. NOBLE’s production processes strictly adhere to ISO 9001:2015 standards, ensuring every injection-molded part leaves our facility with consistent, reliable quality.

We understand that products lacking fair pricing hinder customer choice. As an experienced manufacturer, we optimize production costs through efficient operations, passing savings directly to clients without compromising standards.

Every action we take is designed to ensure your complete satisfaction. Each order receives unwavering focus, treated as if it were our first collaboration. This means clear communication, transparent pricing, and truly responsive after-sales service from the NOBLE team. When you choose NOBLE as your partner for custom machining and blow molding projects, you choose a team as committed to your success as you are. Let’s start the conversation and create something extraordinary together.

FAQs of Blow Molding

How does the blow molding process outperform other processes?

The blow molding process is highly efficient for the mass production of hollow components, and it offers significant flexibility in the design of complex shapes.

What is the difference between the extrusion blow molding process and the injection blow molding process?

The extrusion blow molding process forms a hollow tube (parison) and then inflates it, ideal for irregular shapes like containers. Injection blow molding injects plastic into a mold to form a precise preform first.

Can the blow molding process be used to manufacture complex or custom-shaped products?

Absolutely. The blow molding process is ideal for producing complex custom geometries, such as integrated handles, chamfers, and double-walled structures. This technique allows for the creation of seamless, one-piece components in a single operation, eliminating the need for costly separate parts and assembly processes.

What materials can be used in the blow molding process?

You can choose from HDPE, PET, PP, and PVC—select the option that best meets your requirements.

How does NOBLE determine the cost of blow-molded products?

Cost is primarily driven by the initial mold investment and the raw material usage per part.

Is the blow molding process environmentally sustainable?

It can be, as the most common materials like HDPE and PET are highly recyclable. Additionally, NOBLE reduces waste by systematically regrinding and reusing production scraps, thereby lowering overall environmental pollution.

How long does the blow molding process usually take?

Designing and machining molds can take a long time and a lot of effort, and it can take several weeks to get them done, depending on what you need. But once the mold is finished and has passed inspection, we can crank out more batches really quickly. This means we can deliver loads of products in no time at all.

If I’m on a tight budget, how can I make the most of the blow molding process to boost efficiency?

We usually get this right by keeping a close eye on how the molds are being used to make sure the walls are the right thickness and that we’re not using too much material. We also have a strict programme to look after the molds. If that doesn’t work, our engineers will have a chat with you to find the best solution for your needs.