What is Custom 3D Printing Service?

3D printing is a rapid prototyping technology that manufactures three-dimensional objects by layering materials. 3D printing is based on digital model files and uses powdery metals, plastics, and other bondable materials. Through the print head, the materials are stacked layer by layer to eventually form solid objects.

The idea of 3D printing can be traced back to the late 1970s and early 1980s, and its core concept is light curing.

Since the 2010s, 3D printing technology has continued to develop and is now capable of printing metals, ceramics, biomaterials, and even food. Its applications have also expanded from rapid prototyping manufacturing to the production of final components in aerospace, medical implants, customized product manufacturing, and other fields.

Material Used in Custom 3D Printing Service

PLA

PLA is a very popular 3D printing material. PLA is derived from renewable resources such as corn starch or sugarcane, so it has a milder odor and is environmentally friendly when printed.

PLA plastic prints at a low temperature. It is easy to use and does not warp easily. You can also find it in many bright colors and cool styles, like glow-in-the-dark or color-changing types. But PLA is not very strong and has low heat resistance. So, if it gets too hot or sits in the sun, it can soften, bend, and lose its shape.

Note:

- Low-temperature printing: About 180-220°C

- Take precautions against moisture: Store in a dry place

- Limited strength: Avoid load-bearing or high-temperature environments

ABS

ABS is a kind of engineering plastic with high strength and durability, renowned for its excellent toughness and impact resistance. Many plastic products in our daily life, such as Lego bricks, are made of it.

Compared with PLA, ABS requires a higher nozzle temperature and a heated base plate during printing to prevent interlayer cracking caused by cooling shrinkage during the printing process. ABS is often used to manufacture functional parts and housings that need to withstand external forces or heat.

Note:

- Must be insulated: Close the printer housing when printing

- Ventilation is required: Operate in a well-ventilated environment or one equipped with a filtration system

- Good heat resistance: The finished product can withstand high temperatures and impacts

Liquid resins

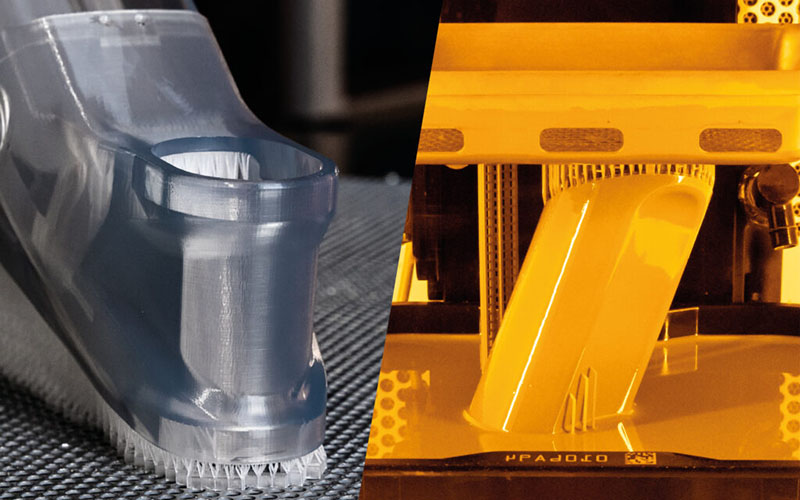

Photosensitive resin is a liquid material. It is used in SLA and DLP 3D printers, which use UV light to harden it. The liquid resin quickly turns solid when a specific UV light shines on it.

This material can create models with very high detail and a smooth surface. The level of detail is much better than what you usually get from standard plastic printers. Models printed with photosensitive resin are usually brittle in texture and need to undergo secondary ultraviolet curing to achieve the final strength.

- Standard resin

- High-toughness resin

- Resin for casting

- Medical resin

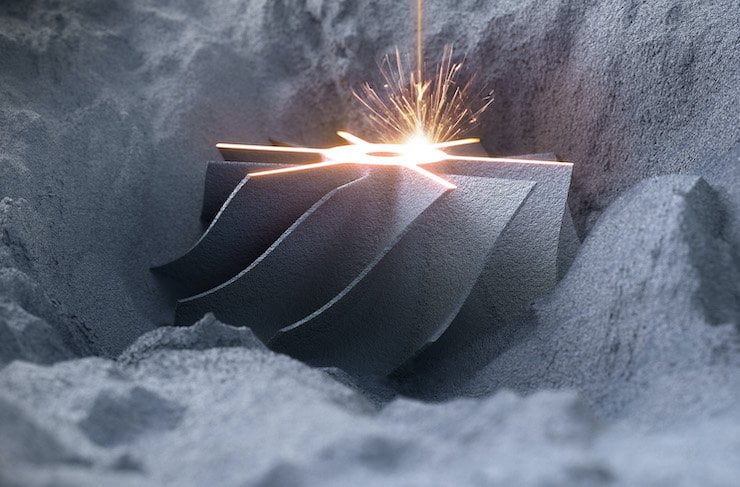

Metal Powders

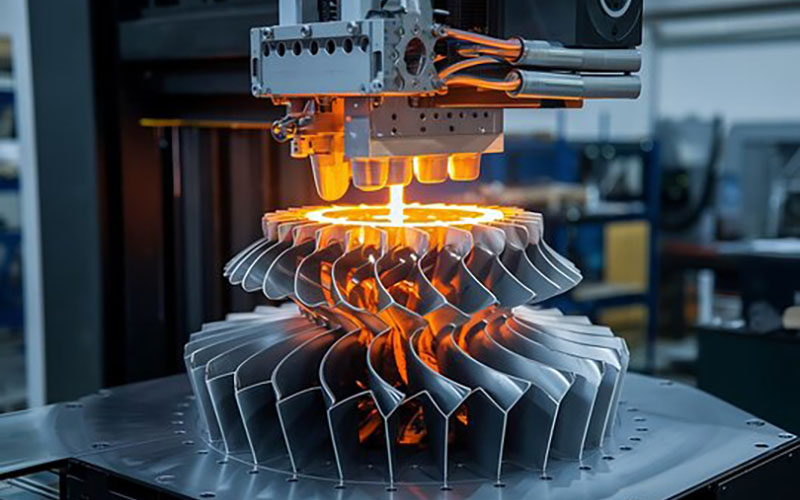

Metal 3D printing belongs to industrial-level applications and usually employs selective laser melting or electron beam melting technology. The printing materials are extremely fine metal powders, including stainless steel, titanium alloy, aluminum alloy, etc.

In metal 3D printing, a high-power laser or electron beam melts metal powder in a specific area. Then, the melted powder fuses together and cools down to form a solid, dense metal part.

These printed metal parts are very strong and hard. Their performance can match or even beat parts made by traditional forging. 3D printing also allows for the creation of very complex internal structures, like cooling channels.

Note:

Professional equipment: Dedicated industrial-grade metal 3D printers such as SLM and SLS

Strict protection: Protective equipment must be worn throughout the operation

Nylon

Nylon is an engineering plastic with outstanding performance and can be 3D printed through selective laser sintering technology.

Nylon is renowned for its outstanding strength, toughness, and wear resistance. The printed components have good flexibility and fatigue resistance, and can be repeatedly bent like hinges without breaking.

Nylon material also has certain chemical resistance and biocompatibility. The surface of its printed products usually has a sandy granular texture, but it is very strong and practical.

Composite Material

Composite materials mix small pieces of carbon or glass fiber into plastics like PLA, ABS, or nylon. This is done to make the printed parts stronger, stiffer, and less likely to shrink or bend.

Components printed from composite materials are light in weight but very strong and hard, and their mechanical properties are close to those of some metals.

However, the fibers can wear down a standard brass nozzle quickly. So, it is better to use a more durable, hardened steel nozzle for printing.

Composite materials are specifically designed for applications with strict requirements for strength and weight, such as drone frames and high-performance automotive parts.

Types of Custom 3D Printing Service

FDM 3D Printing

FDM heats and melts thermoplastic material filaments, such as PLA or ABS, into a semi-fluid state through a heating nozzle.

The nozzle moves along the preset path, extruding the molten material layer by layer and depositing it on the construction platform. The material cools and solidifies rapidly and adheres firmly to the previous layer. This process is repeated and stacked until the entire object is manufactured.

Pros:

- Low cost, diverse materials, and simple operation;

- Suitable for prototyping and teaching.

Cons:

- Relatively Low Surface Accuracy and Noticeable Layer Texture

- Relatively Slow Printing Speed

- Pronounced Anisotropy in Mechanical Properties

SLA 3D Printing

SLA is the earliest commercialized 3D printing technology. It uses liquid resin sensitive to ultraviolet rays. By scanning the liquid surface layer by layer with ultraviolet lasers, the resin undergoes photopolymerization reactions to solidify and form. After each layer is completed, the construction platform moves in macro mode to cover the surface with new resin, and the laser scans the next layer. This cycle continues until the object is finished.

Pros:

-

- Smooth surface and high precision (up to 0.05mm);

- Suitable for complex and precise models.

Cons:

- High material prices.

- Printed parts are prone to aging and deformation.

- High Cost and not suitable for parts requiring high structural strength.

SLS 3D Printing

Selective laser sintering technology uses high-power lasers to scan and sinter plastic, metal, or ceramic powders layer by layer, causing them to fuse and form parts. After each layer is completed, the platform descends, and new powder is laid to continue sintering, and the unsintered powder naturally becomes the support.

Pros:

- No Support Structure Requirement

- Capability for Complex Geometry Printing

- Excellent Material Properties and High Structural Strength

- Suitability for Functional Testing and Small-Batch Production

Cons:

- High Production Cost

- Rough Surface Finish Requiring Post-Processing

- Complex Equipment Maintenance

SLM 3D Printing

SLM is a 3D printing technology that uses a high-energy laser beam to melt metal powder layer by layer and rapidly solidify it into shape. This process can directly manufacture metal parts with complex structures and high strength.

Pros:

- Direct Fabrication of High-Strength Metal Parts

- High Dimensional Accuracy

- Suitability for Aerospace, Medical, and High-End Mold Manufacturing

Cons:

- Expensive Equipment and Complex Operation

- Slow Printing Speed

- High Material Cost and Complicated Post-Processing

MJF(Multi Jet Fusion)

MJF is a 3D printing technology mainly using nylon powder as the material. It achieves rapid melting and shaping of the powder layer by spraying a melting agent and a refining agent in combination with high-temperature heating.

Pros:

- High Printing Speed and Dimensional Accuracy

- Uniform Mechanical Properties

- Capability for Small-Scale Batch Production

Cons:

- Limited Material Options

- High Equipment and Maintenance Costs

- Single Surface Color Appearance

Benefits of Custom 3D Printing Service

Design Flexibility

The core advantage of 3D printing lies in its almost unlimited design freedom. 3D printing can directly create extremely complex geometric shapes based on digital models, such as internal cavities and intricate grid structures.

Designers and engineers can quickly transform creative ideas into physical prototypes, significantly shortening the product development cycle.

Customization

3D printing is excellent for making single items or small batches. This is because creating personalized versions does not require much more money or a lot of extra time.

- Medical field: Based on the CT scan data of the patient, print out implants, surgical guides, or dentures that fully fit their bone structure

- Consumption field: Tailor-made, unique glasses, insoles, and jewelry for users

Streamlined Manufacturing Process

3D printing is an additive manufacturing process that turns digital files into physical parts in a single step, greatly simplifying the multiple procedures required in traditional manufacturing, such as mold design, mechanical machining, and assembly.

Efficient Material Utilization

Unlike traditional subtractive manufacturing (such as milling and turning), which removes excess parts from a single piece of material by cutting, 3D printing adds material layer by layer until the part is formed.

This “use only the required materials” approach significantly reduces the waste of raw materials, especially when machining expensive metals or special polymers, it can save a large amount of costs.

Surface Finishing of Custom 3D Printing Parts

Polishing

Remove layering, burrs, and surface roughness by mechanical or manual means to make the parts smoother. Both plastic and metal parts can be polished or ground.

Polishing can enhance the surface finish of parts and prepare them for subsequent spraying or electroplating, but it is time-consuming and labor-intensive, and is not suitable for large-scale production.

Painting and Coating

Painting is the process of applying paint or coating on the surface of parts, which can achieve a variety of colors and surface effects. Painting can improve the appearance of parts and enhance their protective performance.

Painting and Coating are commonly used for SLA and FDM parts, but the parts need to have good flatness at the bottom layer.

Electroplating

Electroplating is the process of depositing a layer of metal, such as nickel, copper, chromium, etc., on a conductive surface, and is often used to enhance strength or for decoration.

Electroplating can enhance surface hardness and wear resistance, improve electrical conductivity, and corrosion resistance. Some plastics require conductive base treatment.

Sandblasting

Sandblasting is a process that uses high-speed sand particles to clean or roughen the surface, removing powder residues and layering.

Sandblasting can improve the uniformity of the surface of parts and enhance the adhesion of subsequent coatings. Sandblasting is often used for SLS and MJF nylon parts.

Anodizing

Anodizing is a process that forms a dense oxide film on metal parts such as aluminum alloys through electrochemical methods. Anodizing can enhance the corrosion resistance, surface hardness, and decorative properties of parts, and can be achieved in a variety of colors.

Custom 3D Printing Service vs CNC Machining

Both 3D printing and CNC machining are important manufacturing technologies driven by digitalization. Both rely on computer-aided design models to guide equipment in machining, capable of efficiently and precisely manufacturing complex geometric shape prototypes and final parts.

However, 3D printing and CNC machining also have certain differences in some aspects.

| Comparison Item | 3D Printing | CNC Machining |

| Machining Principle | Builds parts layer by layer (additive process) | Removes excess material from a solid block (subtractive process) |

| Applicable Materials | Plastics, resins, nylon, metal powders, ceramics, etc. | Metals, plastics, composites, wood, etc. |

| Dimensional Accuracy | Typically ±0.1 mm (up to ±0.05 mm with high precision) | Very high accuracy, up to ±0.005 mm |

| Production Efficiency | Flexible for single parts, slower printing speed | High efficiency for batch production |

| Material Utilization | High — only the material needed for the part is used | Low — significant material waste from cutting |

Applications of Custom 3D Printing Service

Prototype Development

The most classic application of 3D printing is rapid prototyping manufacturing. Designers can transform concepts into physical models within a few hours or days, significantly shortening the product development cycle and facilitating design verification, functional testing, and assembly inspection.

Medical Care

3D printing can utilize a patient’s CT or MRI data to precisely print out organ models for surgical planning, implants that match the bone structure (such as skull repair plates), and surgical guides. In the field of dentistry, 3D printing can also be used to make models of dental crowns, dental Bridges, and invisible braces.

Aerospace and Automotive

The aviation industry has fully leveraged the advantages of 3D printing in terms of lightweight, integrated manufacturing, and rapid iteration.

3D printing can manufacture complex metal components such as turbine blades and lightweight brackets. These components usually require multiple parts to be assembled through traditional methods, but 3D printing can be formed in one piece, reducing weight and enhancing performance.

Construction Industry

In architecture, 3D printing can quickly make accurate scale models. This helps architects and clients see and evaluate a design easily.

Also, large-scale 3D printing can now create actual building parts, or even whole houses. This process typically uses special concrete or composite materials.

Consumer Goods

3D printing enables mass personalization. For example, it can create insoles shaped to your feet, custom-fit glasses, and unique fashion items or lamps.

In the cultural sector, this technology can restore damaged artifacts and replicate rare archaeological finds. 3D printing is also widely used to make detailed movie props and anime figures.

NOBLE’s Custom 3D Printing Service

NOBLE is a Chinese 3D printing manufacturer known for manufacturing high-quality and competitively priced parts. We offer a range of 3D printing technologies, including SLA, SLS, FDM, MJF, PolyJet, DMLS, EBM, etc. You can get an online quote for your part within a few days, or communicate with production experts to get solutions covering your entire product lifecycle.

NOBLE is your trusted one-stop custom manufacturing solution, from prototype design to manufacturing, with huge manufacturing resources, suitable technology, streamlined process, expert guidance, and a perfect quality inspection process to turn your ideas into reality.

FAQs of 3D Printing

Is 3D printing expensive?

The cost of 3D printing depends on the material, machine, part size, and required detail. So, a single piece can be expensive. But this method saves money because it does not need special molds or tools. It also lets you go from idea to finished part faster. This makes it very cost-effective for small batches or custom items.

Do 3D printed parts need post-processing?

Yes. Most printed parts require surface finishing such as sanding, polishing, coating, or painting to improve appearance, strength, or functionality. Metal parts may also require heat treatment or machining.

What’s the difference between 3D printing and CNC machining?

3D printing is an additive process ideal for complex geometries and prototypes, while CNC machining is a subtractive process suited for high-precision and mass production parts. Each has unique strengths depending on design goals.

How fast is 3D printing compared to traditional manufacturing?

3D printing can produce prototypes in a short period of time, while traditional manufacturing, such as CNC machining or injection molding, usually takes several days or weeks to complete the tools and setup. However, for large-scale production, traditional methods are still faster and more economical.

Can 3D printing be used for mass production?

While 3D printing is mainly used for prototyping and low-volume manufacturing, advancements like MJF and SLM are making small-batch production increasingly feasible. For large-scale production, hybrid manufacturing that combines 3D printing and traditional methods is often used.