When you need parts that fit very well, look smooth, and are always good quality, gravity die casting is better than other ways to make parts. You should choose this method if you need strong and exact parts for cars, planes, or big machines. Here is where gravity die casting works best:

| Industry | Common Applications |

| Automotive | Engine blocks, cylinder heads, wheel rims |

| Aerospace | Aircraft engine parts, landing gear parts |

| Industrial Equipment | Pump housings, valve bodies, heavy machinery parts |

| Defense | Missile components, armor plates |

| Consumer Goods | Cookware, lighting fixtures |

With NOBLE, you get more than a factory. You get a partner who helps you make things just right. Our team gives quick prices, smart help, and results you can trust every time.

Gravity Die Casting Process

You want parts that fit well and last long. Gravity die casting helps make this happen. NOBLE makes the process simple for you. You can order one part or many for your factory. Let’s see how it works and why it is a great choice for making exact parts.

How It Works

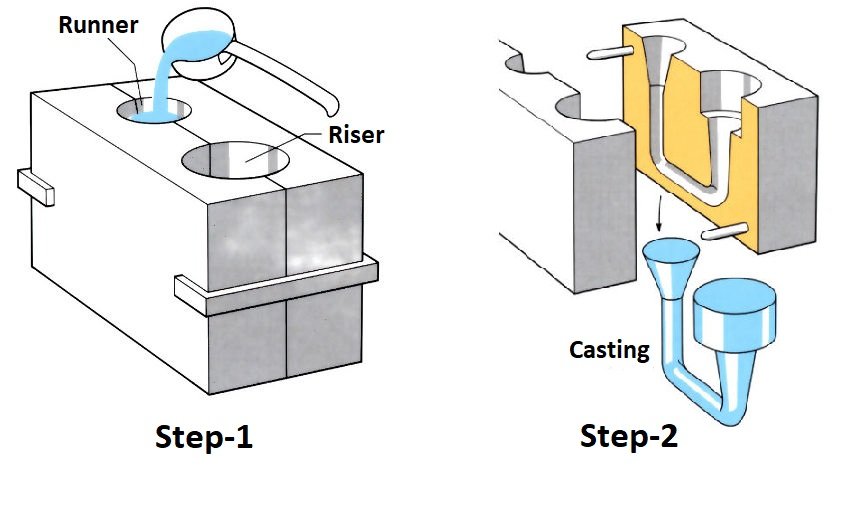

Gravity die casting uses a metal mold. Molten metal flows in by gravity. You do not need high pressure. This way, you get strong and smooth parts. NOBLE starts when you upload your CAD files. You get a quick quote. Our team checks your design. We help you pick the best options for your needs.

Here are the main steps:

| Step | Description |

| Mold Preparation | We get the mold ready so your parts come out right and fast. |

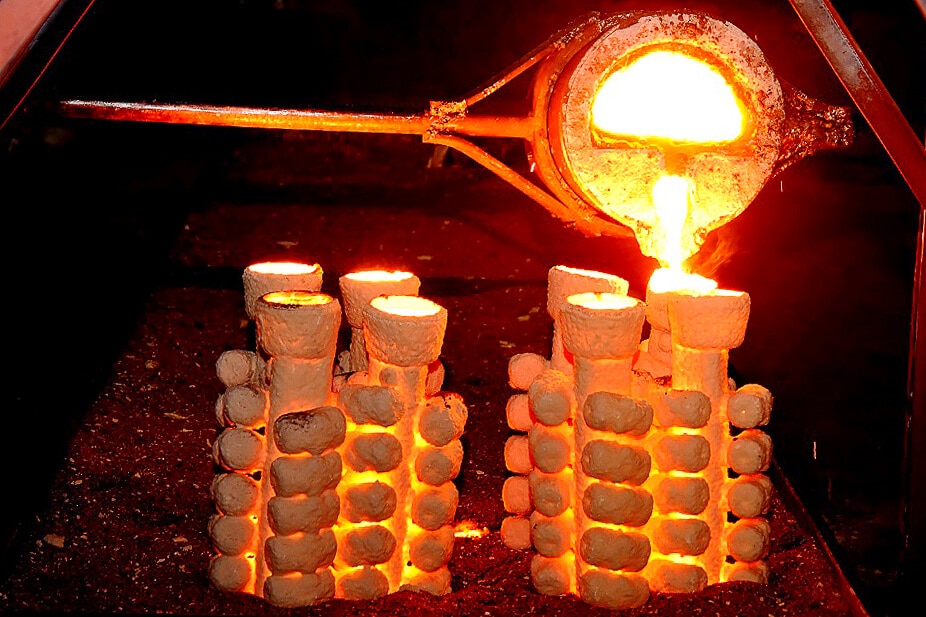

| Pouring Molten Metal | Our team pours the metal carefully to fill every detail and stop mistakes. |

| Cooling and Solidification | The part cools and gets hard. This step gives your part the right shape and strength. |

| Part Ejection | We take out the part gently so it stays perfect. |

| Machining if Necessary | If you need tighter fits or special surfaces, we can machine the part after casting. |

Mold Materials

You get molds made from strong steel or iron. These materials can handle heat and last a long time. NOBLE’s molds are made for exact work. You get the same results every time.

Filling Method

We use gravity to fill the mold. No pumps or pressure are needed. This simple way means fewer mistakes and better control. You get parts with smooth surfaces and strong insides.

Materials Used

NOBLE offers many metals for gravity die casting. You can pick what works best for your project. Here is a quick guide:

| Material | Key Properties | Primary Applications |

| Aluminum | High strength-to-weight ratio, corrosion resistance | Automotive, Aerospace, Medical Devices |

| Zinc | Dimensional stability, low melting point | Electronics, Industrial Machinery |

| Magnesium | Lightweight, high-strength | Automotive, Aerospace |

| Copper | Good conductivity, durability | Electrical, Specialized Components |

You can ask for special alloys or finishes. Our custom process lets you get what you need for medical tools, car parts, or electronics.

Applications

Gravity die casting is best for parts that need tight fits and smooth surfaces. NOBLE works with many industries. We are experts in the automotive and medical fields. You may need engine blocks, cylinder heads, or battery housings for cars. You might want brackets or housings for medical devices. Our factory can make small or large orders.

| Application Area | Description | Market Share (%) |

| Automotive | Engine blocks, cylinder heads, battery housings, wheel rims | 40.25 |

| Aerospace | Turbine blades, housings, and brackets | N/A |

| Industrial Machinery | Pumps, compressors, valves | N/A |

| Electrical and Electronics | Housings, connectors, heat sinks | N/A |

| Medical Devices | Surgical tools, device housings, and implant components | N/A |

Tip: If you need parts fast, NOBLE can deliver gravity die casting parts in just seven days. Our team checks every part, so you get quality you can trust.

NOBLE is China’s top manufacturing partner. You get expert help, fast service, and results you can count on. If you need exact parts for a new car or custom parts for medical tools, our factory is ready to help.

Gravity Die Casting vs Sand Casting Process

When you look at how gravity die casting and sand casting work, you notice some big differences. You use a permanent metal mold in gravity die casting. This mold gets preheated and coated before you pour in the metal. The molten metal flows into the mold by gravity, filling every detail. You always get the same shape.

Sand casting uses a different approach. You pack sand around a pattern to make the mold. Each time you want a new part, you build a new sand mold. You pour molten metal into the sand mold, but the process does not use pressure. The sand mold gets broken after each use.

Here’s a quick table to help you see the main differences:

| Aspect | Gravity Die Casting | Sand Casting |

| Mold Preparation | Permanent metal mold, preheated and coated | Mold made from sand, packed around a pattern |

| Metal Pouring | Molten metal poured by gravity | Molten metal poured into sand mold |

Tip: If you want repeatable results and less mess, gravity die casting is the way to go. NOBLE’s factory uses advanced molds for precision manufacturing and customized processing.

Cost

You might wonder about the cost difference. Sand casting usually costs less at the start. The sand molds are cheap to make, and you do not need special equipment. This makes sand casting a good choice for small runs or prototypes.

Gravity die casting has a higher upfront cost. You pay more for the permanent metal mold. But if you need many parts, the cost per part drops fast. The metal mold lasts a long time and gives you more parts before it wears out. For large orders, gravity die casting saves you money in the long run.

- Sand casting: Lower setup cost, higher cost per part for big orders.

- Gravity die casting: Higher setup cost, lower cost per part for big orders.

NOBLE helps you decide which method fits your budget and project size. Our team supports both prototyping and mass production, so you get the best value.

Quality

Quality matters when you need parts that fit well and look good. Gravity die casting gives you high precision and smooth surfaces. The permanent metal mold shapes each part exactly the same. You get tight tolerances and a clean finish. Most parts need little or no extra work.

Sand casting gives you less precision. The sand mold can shift or break, so the parts may not match your design perfectly. The surface feels rough and often needs grinding or sandblasting to look better.

Here’s a table to show the difference:

| Feature | Gravity Die Casting | Sand Casting |

| Dimensional Tolerances | High precision, accurately shaped parts | Thicker walls, less precision |

| Surface Finish | Smooth finish, no extra processes | Rough finish, needs more finishing |

If you want parts that meet strict standards, gravity die casting is the better choice. NOBLE’s factory checks every part for quality. You get reliable, repeatable results with our precision manufacturing and customized processing.

Note: NOBLE stands out as China’s premier manufacturing partner. We deliver top-quality parts fast, whether you need a single prototype or a full production run.

Speed

You want your parts fast. Speed matters, especially when you need to meet tight deadlines or keep your project moving. Gravity die casting gives you a real advantage here. With this method, you can get up to 200 parts per hour. That means your factory can keep up with big orders and tight schedules. Sand casting works more slowly. Each sand mold takes time to build and break apart. You wait longer for each part. If you need a lot of parts quickly, gravity die casting is the better choice.

- Gravity die casting: Up to 200 parts per hour

- Sand casting: Slower, because you must make a new mold for every part

NOBLE’s factory uses advanced tools and smart workflows. You get your parts on time, whether you need a few or a few thousand. Our team focuses on precision manufacturing and customized processing, so you never have to worry about delays.

Tip: Fast turnaround means you can test, build, and ship your products sooner. NOBLE helps you stay ahead.

Materials

Choosing the right material is key to your project. Both gravity die casting and sand casting work with many metals, but each method has its favorites. Gravity die casting shines with aluminum, copper, and zinc alloys. These metals flow well and fill the permanent mold with ease. Sand casting can handle more types of metals, even those that melt at higher temperatures.

Here’s a quick look at some common alloys you can use with gravity die casting:

Material Type

| Examples of Alloys Used in Gravity Die Casting | |

| Aluminum Alloys | A356, A380, ADC12 |

| Copper Alloys | C83600 (Red Brass), C95400 (Aluminum Bronze) |

| Zinc Alloys | Various zinc alloys with high fluidity |

You can ask NOBLE for help picking the best alloy for your part. Our team knows how to match your needs with the right material. We support both prototyping and mass production, so you always get the best results from our factory.

Note: NOBLE’s customized processing lets you choose special alloys or finishes for your unique project.

Design Flexibility

Design flexibility means you can make parts in almost any shape you want. Sand casting is great for this. You can create parts with complex shapes, deep undercuts, and lots of details. If you need a one-of-a-kind part or want to try out a new design, sand casting gives you more freedom.

Gravity die casting works best for simpler shapes. The permanent metal mold must open and close easily, so you can’t have deep undercuts or super complex features. Still, you get strong, precise parts with smooth surfaces. If your design fits the process, gravity die casting is a smart choice.

NOBLE’s engineers help you get the most out of your design. We guide you on how to adjust your part for the best results with gravity die casting. Our precision manufacturing and customized machining make sure your parts look and work just right.

Pro Tip: If you want to move from prototype to mass production, NOBLE’s factory can help you refine your gravity design die casting. You get expert advice every step of the way.

Gravity Die Casting vs Pressure Die Casting

Process

Gravity die casting and pressure die casting are two different ways to make metal parts. In gravity die casting, you pour molten metal into a metal mold. Gravity pulls the metal down and fills the mold. No extra force is used. This makes strong parts with a smooth finish. You get good results when you need many parts.

Pressure die casting works another way. Molten metal is pushed into a cold metal mold using high pressure. The metal moves fast and fills every tiny space. This lets you make parts with sharp details and tight fits. You can create complex shapes that look very exact. The pressure helps fill even small spaces, so parts are very accurate.

| Casting Process | Pressure Application |

| Gravity Die Casting | Relies on gravity to fill the mold |

| Pressure Die Casting | Uses high pressure to inject metal into the mold |

NOBLE’s factory has advanced machines for both methods. You get help picking the best way for your project. Our team supports you from start to finish and checks your parts.

Cost

Cost matters when you pick a casting method. Both gravity die casting and pressure die casting use metal molds. These molds cost a lot to make. But if you make many parts, the cost per part goes down.

- Gravity die casting costs a lot at first, but each part gets cheaper as you make more. This is good for making many parts.

- Pressure die casting molds cost even more. They must be strong for high pressure. But if you need thousands or millions of parts, this method saves money because it is fast and uses machines.

- Gravity die casting often uses less energy and produces less waste. Pressure die casting can make more scrap, which can cost more.

NOBLE helps you choose the best way for your budget and needs. Our team makes sure you get good value, whether you need a few parts or many.

Quality

You want parts that look nice and work well. Both gravity die casting and pressure die casting make good parts, but there are some differences.

Gravity die casting makes strong parts with good properties. The surface is smooth and the results are steady. For example, gravity-cast AlSi7MgMn samples stretch about 8.8%, have a yield strength of 236.6 MPa, and a top strength of 296.0 MPa. This means your parts are tough and last long.

Pressure die casting can make even finer details and tighter fits. The high pressure makes fewer tiny holes inside the metal. Some alloys can stretch up to 11.5% because the grains are smaller and there are fewer holes. You get parts that are strong and can bend more.

NOBLE’s factory checks every part for quality. Our team uses special tools to make sure your parts are right. You can trust us for both ways of casting.

Tip: If you need parts with very tight fits and complex shapes, pressure die casting may be best. For strong, steady parts with a smooth finish, gravity die casting is a good choice. NOBLE helps you pick what works for your project.

Speed

When you need parts quickly, your casting choice matters a lot. Gravity die casting makes parts at a steady pace. Pressure die casting is much faster than gravity die casting. The numbers show how much quicker pressure die casting can be.

| Casting Method | Average Cycle Time (parts/hr) |

| Gravity Die Casting | 30-50 |

| Pressure Die Casting | 200+ |

Gravity die casting makes 30 to 50 parts each hour. This works well for medium or big orders. It also helps keep the quality high. Pressure die casting can make more than 200 parts every hour. This is great if you need thousands of parts fast.

NOBLE’s factory uses smart machines and good planning. Your orders move quickly, no matter the size. You get fast service and high quality. Our team uses careful manufacturing and custom processing.

Tip: Gravity die casting is a good choice if you want strong parts and decent speed. NOBLE helps you pick the best method for your deadline.

Materials

Picking the right metal is important for your project. Both gravity die casting and pressure die casting use aluminum alloys. Each method works best with certain metals. Gravity die casting often uses aluminum and zinc. These metals make strong parts with fewer tiny holes. Your parts last longer and stay tough.

Pressure die casting works best with aluminum and magnesium. This method makes thin parts with smooth surfaces. You can create shapes that look sharp and need little extra work.

Here’s a table to show the differences:

Gravity Die Casting

| Casting Method | Common Alloys Used | Reasons for Preference |

| Aluminum, Zinc | Less porous, higher strength, suitable for larger parts | |

| Pressure Die Casting | Aluminum, Magnesium | Precise, complex shapes, dimensionally accurate, smooth finish |

- Gravity die casting gives you strong parts with fewer holes.

- Pressure die casting makes thinner, smoother parts with less finishing.

NOBLE’s team helps you pick the best metal for your needs. Our factory supports small and large orders. You always get the right material for your project. We use careful manufacturing and custom processing for every job.

Design Flexibility

You want your parts to work well and look good. Design flexibility is important. Pressure die casting lets you make very complex shapes. You can add thin walls, sharp corners, and small details. This method is great for parts with many features or tight spaces.

Gravity die casting works best for simple shapes. The mold must open and close easily. You cannot have deep undercuts or tricky angles. You still get strong, smooth parts. If your design fits, gravity die casting is a smart choice for quality.

NOBLE’s engineers help you with every step. We guide you to adjust your design for the best results. Our factory uses advanced tools for careful manufacturing and custom processing. You get expert help for prototypes or big orders.

Pro Tip: NOBLE’s team can help you turn your idea into real parts. We support you from start to finish, whether you choose gravity die casting or pressure die casting.

Gravity Die Casting vs Investment Casting

Process

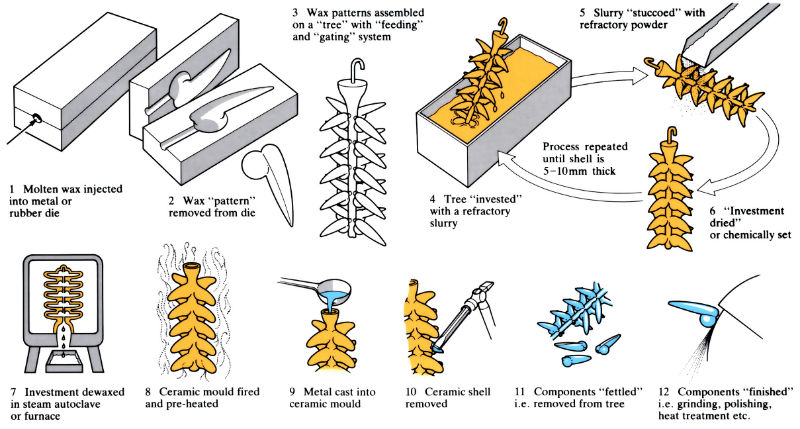

Gravity die casting and investment casting make metal parts in different ways. In gravity die casting, you pour hot metal into a metal mold. Gravity helps the metal fill every space in the mold. When the metal cools, the mold opens, and you get your part. This method works well for making many parts at once. You get the same results each time.

Investment casting starts with a wax model of your part. The wax model gets dipped in ceramic to make a hard shell. After the shell dries, the wax is melted out. Then, hot metal is poured into the empty shell. The ceramic shell breaks away, leaving your finished part. This way, you can make parts with lots of small details.

NOBLE’s factory uses smart machines for both methods. You get help picking the best way for your project. Our team helps you whether you need a simple part or a complex one.

Cost

Cost is important when you choose how to make parts.

- Investment casting costs less to start. You do not need expensive molds.

- Gravity die casting costs more at first because you need a strong mold. This is better if you make lots of parts.

- Investment casting is good for small or medium batches. You save money if you only need a few parts or want to test a new idea.

- Gravity die casting gets cheaper as you make more parts. The price per part drops when you make many.

If you need hundreds or thousands of parts, gravity die casting saves you money. NOBLE’s team helps you pick the best way for your budget and schedule.

Quality

You want parts that look good and fit well. Both methods make high-quality parts, but they are a bit different. Here is a table to show you:

| Casting Type | Surface Finish | Dimensional Accuracy |

| Gravity Die Casting | Smooth and refined | Precise dimensions and tight tolerances |

| Investment Casting | Superior smoothness | High precision and intricate designs |

Gravity die casting makes strong parts with smooth surfaces. You get parts that fit well and work for cars or planes. Investment casting makes parts with even smoother surfaces. You can make parts with tiny details, which is good for medical tools or special pieces.

NOBLE is a top factory in China. We check every part for quality. Our team uses smart machines and custom steps to make sure your parts are just right, no matter what you need.

Speed

You want your parts fast. Speed is important for your project. Gravity die casting and investment casting work at different speeds. Investment casting is quicker for small batches or prototypes. The molds for investment casting take 1 to 3 weeks to make. Simple parts are ready in about 5 to 6 weeks. Average parts need 6 to 8 weeks. Critical parts can take up to 10 weeks.

Gravity die casting takes longer to set up. Metal molds need 9 to 12 weeks to build. After the mold is done, you can make many parts quickly. Simple parts take 8 to 10 weeks. Average parts need 10 to 12 weeks. Critical parts take 12 to 14 weeks. Gravity die casting is best for making lots of parts fast. NOBLE’s factory uses smart steps to help deliver on time.

| Casting Type | Simple Components | Average Components | Critical Components |

| Gravity Die Casting | 8 to 10 weeks | 10 to 12 weeks | 12 to 14 weeks |

| Investment Casting | 5 to 6 weeks | 6 to 8 weeks | 8 to 10 weeks |

Tip: If you need hundreds or thousands of parts, gravity die casting makes them faster after the mold is built. NOBLE’s team helps you meet tight deadlines with careful manufacturing and custom processing.

Materials

Picking the right material is important for your project. Gravity die casting works best with aluminum, copper, and zinc. These metals make strong parts with smooth surfaces. You get good results and save money. Investment casting uses many alloys, both ferrous and non-ferrous. You can use steel, stainless steel, nickel, and more. This method lets you make complex shapes with a great surface finish.

| Casting Method | Suitable Materials | Unique Advantages |

| Gravity Die Casting | Aluminum, Copper, Zinc | Saves money, smooth surfaces, accurate sizes |

| Investment Casting | Ferrous and non-ferrous alloys | Makes complex shapes, very accurate sizes |

- Gravity die casting gives you strong parts for cars, planes, and medical devices.

- Investment casting lets you use more metals for detailed designs.

NOBLE’s factory helps with both methods. You get expert advice on picking the right metal. Our team matches your needs with the best alloy, whether you want a light part or one that handles lots of stress.

Design Flexibility

Design flexibility means you can make your ideas real. Investment casting is great for complex shapes. You can make parts with thin walls, deep cuts, and tiny details. This is perfect for medical tools or electronics.

Gravity die casting works best for simple shapes. The mold must open and close easily, so you avoid deep cuts. You still get strong, smooth parts. If your design fits, gravity die casting is a smart choice for quality and repeatability.

- Investment casting: Best for detailed, complex designs.

- Gravity die casting: Good for simple, strong shapes with tight fits.

NOBLE’s engineers help you every step of the way. You get help making your design work for the casting method you pick. Our careful manufacturing and custom processing make sure your parts look and work great. Whether you need a sample or lots of parts, NOBLE’s factory gives you results you can trust.

Pro Tip: NOBLE can make custom molds for special designs. You get the freedom to create and the support to make your ideas real.

Advantages of Gravity Die Casting

Quality

You want every part to meet your standards. With gravity die casting, you get reliable quality every time. NOBLE’s factory uses precision manufacturing and customized processing to make sure your parts fit and work as they should. Our team checks each part at every step. You can count on these quality control measures:

- CNC Machining: We use advanced machines to shape your parts exactly. This step removes any extra material and makes sure every piece matches your design.

- Surface Treatments: We polish, sandblast, or coat your parts. This keeps them smooth, clean, and protected from wear.

- Inspection: Our experts look at every part before it leaves the factory. You get parts that pass strict checks for size, shape, and finish.

NOBLE’s commitment to quality means you get fewer mistakes and less scrap. You save time and money because you do not need to fix or replace parts.

Surface Finish

You want your parts to look good and feel smooth. Gravity die casting gives you a better surface finish than other casting methods. The permanent metal molds help create parts with fewer bumps and a more even look. This is important if you need parts for cars, planes, or medical devices.

Compared to sand casting or investment casting, gravity die casting stands out. You get a smoother finish and more accurate shapes. Industries that need detailed designs and strong parts choose this method for a reason. You do not have to spend extra time or money on finishing steps. Your parts come out of the mold looking ready to use.

Tip: If you want your products to impress customers, a smooth surface finish makes a big difference. NOBLE’s factory delivers parts that look and perform better right from the start.

Volume Flexibility

You may need just a few parts for a prototype, or you might need thousands for mass production. Gravity die casting works well for both. NOBLE’s factory can handle small orders and big runs with the same care. This method is most cost-effective when you need anywhere from a few thousand to several hundred thousand parts each year. Our operation can produce up to 200 tons of parts annually, depending on what you need.

- You can start with a small batch to test your design.

- When you are ready, you can scale up to full production without changing your process.

- NOBLE supports you at every stage, from the first sample to the last shipment.

With NOBLE, you get a partner who adapts to your needs. Our precision manufacturing and customized processing make sure you always get the right amount of parts, on time.

Material Options

You want to pick from many metals. Gravity die casting lets you choose from lots of alloys. You can use aluminum if you want parts that are light and strong. Magnesium is even lighter than aluminum. Brass and bronze are good if you need parts that last a long time. Stainless steel and carbon steel are strong choices for tough parts. This means you can always find the right metal for your part.

Here’s a table that shows how gravity die casting compares to other ways:

| Casting Method | Alloys Processed | Characteristics |

| Gravity Die Casting | Aluminum, Magnesium, Brass, Bronze, Stainless Steel, Carbon Steel | Uses metal molds again and again, lets gravity fill the mold, makes small or medium parts, gives a smooth finish. |

| Sand Casting | Many metals, even big parts | Good for making one big part, not as exact as gravity die casting. |

| Die Casting | Makes lots of small parts, mostly with aluminum | Best for making many parts fast, uses high pressure to fill the mold. |

You can also use special alloys like ZA12. These work well with permanent molds. All ZA alloys fit gravity die casting. You can use graphite molds too, because zinc does not hurt them much. This gives you even more choices for your project.

NOBLE’s factory helps you pick the best metal for your part. Our team gives you advice and makes sure your part is just right. You can order one part or many. NOBLE helps you find the best material for your design.

Tip: If you want a part that lasts and looks nice, ask NOBLE about custom alloys and finishes. Our team will help you match your needs.

Cost Efficiency

You want to save money on your parts. Gravity die casting helps you do this. The process uses metal molds that you can use many times. This means you spend less money as you make more parts. You get good parts with fewer mistakes. You do not have to fix or throw away many parts. The slow filling keeps the metal calm. Your parts come out strong and smooth.

You get less waste and do not need to redo parts. This saves you both money and time. NOBLE’s factory checks every part to make sure it is right. Our team helps you avoid mistakes and get the same results each time. You get good prices, fast service, and parts you can trust.

Here are some ways gravity die casting saves you money:

- Less waste means you save more.

- Fewer mistakes mean less fixing.

- Using molds again lowers costs for big orders.

- Fast production helps you finish on time.

NOBLE is a top partner in China. We help with small and big orders. You get the best deal, whether you need a few parts or thousands.

Note: When you pick NOBLE, you get a partner who cares about your money and your schedule. Our team helps you get the most from gravity die casting.

Limitations of Gravity Die Casting

Design Constraints

You want your parts to look just right, but gravity die casting has some rules you need to follow. The design of your part must fit the process. If you try to make shapes that are too complex, you might run into trouble. The mold needs draft angles so the part comes out easily. Thin walls can be tricky. You need to keep the wall thickness just right so your part stays strong and the mold fills well. Parting lines matter too. They help the mold open and close, but they can limit your design.

Here’s a quick look at the main design constraints:

| Design Constraint | Impact on Manufacturability |

| Draft Angles | Essential for mold filling and ejection, limits design flexibility |

| Wall Thickness | Must be optimized to ensure structural integrity and manufacturability |

| Parting Lines | Affects the ease of mold assembly and part removal |

- You must follow these rules to get the best results from gravity die casting.

- If your part is too complex, you might need to change the design.

The cooling rate in gravity die casting is slower than in other methods. This can change the inside structure of your part. Sometimes, you might not get the exact strength you want. NOBLE’s factory team helps you with design optimization. You get advice on how to adjust your part for precision manufacturing and customized processing. Our engineers make sure your design fits the process, so you get strong, reliable parts every time.

Tip: If you’re not sure about your design, NOBLE’s experts can review your CAD files and suggest changes. You get support from China’s premier manufacturing partner.

Tooling Cost

You want to keep costs low, but tooling for gravity die casting can be a big investment. The mold is made from steel or iron, and it lasts a long time. This means you pay more at the start, but you save money as you make more parts. Here’s how tooling costs compare:

| Casting Method | Tooling Cost Range | Production Volume |

| Sand Cast Tooling | $6,000 to $20,000 | Low-volume production |

| Permanent Mold Tooling | $10,000 to $90,000 | Moderate-volume production |

| Die Cast Tooling | $60,000 to $500,000 | High-volume production |

- Gravity die casting molds cost less than die casting molds.

- Sand casting is cheaper for small runs.

- Permanent molds work best for medium to large orders.

If you need just a few parts, sand casting might be better. If you want thousands of parts, gravity die casting saves you money over time. NOBLE’s factory helps you plan your project. You get smart quotes and advice on how to balance cost and production needs. Our precision manufacturing and customized processing make sure you get value for your investment.

Note: NOBLE’s team supports both prototyping and mass production. You get the right tooling for your budget and timeline.

Alloy Range

You want choices for your materials, but gravity die casting works best with certain alloys. Aluminum, magnesium, and copper are popular. These metals fill the mold well and make strong parts. If you need steel or other high-melting alloys, gravity die casting might not be the best fit. The process works best with metals that melt at lower temperatures.

- You get great results with aluminum, magnesium, and copper alloys.

- Some alloys need special care or might not work with gravity die casting.

NOBLE’s factory offers a wide range of materials for precision manufacturing. Our team helps you pick the right alloy for your part. You get customized processing and expert advice. If your project needs a special metal, just ask. NOBLE’s engineers will guide you to the best solution.

Pro Tip: Not sure which alloy to choose? NOBLE’s experts can help you match your design to the right material. You get support from China’s top manufacturing partner.

Choosing NOBLE for Superior Gravity Die Casting

Are you thinking about using gravity die casting for your next project? Let’s look at what makes it a good choice. You want parts that fit well, look nice, and last long. You also want to save time and money. Here’s how you can know if this method is right for you—and why NOBLE is the best partner.

When Should You Choose Gravity Die Casting?

Pick gravity die casting if you need:

- Parts that fit tightly and have smooth surfaces.

- Medium or large amounts of parts.

- The same quality from start to finish.

- Many material choices, like aluminum, magnesium, or copper alloys.

- Fast delivery and quick service.

If your part is simple or not too tricky, and you want to avoid rough sand casting or expensive pressure die casting, this is a smart pick. You get strong, exact parts without extra trouble.

Tip: Not sure about your design? Upload your CAD files to NOBLE’s website. Our engineers will check your project and give you advice.

Why NOBLE Is Your Best Choice

NOBLE is more than just a factory. You get a team of experts who help you from start to finish. Here’s why NOBLE stands out:

- Seamless Process:

You upload your CAD files. You get a fast quote. Our team checks your design and helps you pick the right materials. You always know what’s happening with your order. - Support for Every Stage:

Need one part or many? NOBLE can do both. We make small batches for testing and big runs for full production. You don’t have to change suppliers as your needs grow. - Precision Manufacturing:

Our factory uses advanced machines and strict checks. You get parts that match your drawings every time. We focus on accuracy, so you don’t waste time fixing mistakes. - Customized Processing:

Need a special finish or a unique alloy? NOBLE offers many finishes and can make custom molds. You get parts that look and work just how you want. - Industry Expertise:

NOBLE works with many industries, like automotive, aerospace, medical devices, and robotics. You can trust us to know what you need and deliver parts that meet standards.

| NOBLE Advantage | What You Get |

| Fast Quotes & Turnaround | Quick prices and delivery, even for big orders |

| Design Guidance | Expert help to make your part better for casting |

| Quality Control | Every part checked for size, shape, and finish |

| Flexible Volumes | From one part to mass production |

| Material Options | Aluminum, magnesium, copper alloys, and more |

Note: NOBLE’s team is always ready to help. You get clear updates and real support at every step.

How to Get Started with NOBLE

Getting started is simple. Just do these steps:

- Upload your CAD files to NOBLE’s website.

- Look at your instant quote and pick your options.

- Work with our engineers to finish your design and pick materials.

- Approve your order and let our factory do the rest.

- Get your finished parts—fast, accurate, and ready to use.

You don’t have to worry about hidden costs or delays. NOBLE’s process is clear and made for your success.

Ready to see the difference? Upload your files today and try China’s top manufacturing partner.

NOBLE uses precision manufacturing, customized processing, and a world-class factory to give you the results you want. Whether you need a prototype or lots of parts, you get a partner who cares about your project as much as you do.

You want parts that fit right, look great, and last. Gravity die casting gives you that edge, especially when you need precision manufacturing and customized processing. If you need strong parts fast, NOBLE’s factory stands ready. Not sure which casting method fits your project? Upload your CAD files to NOBLE. Our team will guide you with expert advice and fast quotes. Trust China’s premier manufacturing partner for your next job.

FAQs of Die Casting

What is gravity die casting best for?

Gravity die casting works great when you need strong parts. The parts come out smooth and fit exactly. This method is used for car, plane, and medical device parts. NOBLE’s factory can make one part or many. We use careful manufacturing and special steps for every order.

How fast can I get my parts from NOBLE?

You can get your gravity die casting parts in just seven days. NOBLE’s factory uses smart steps to work quickly. You always know what is happening with your order.

Can I use my own design for gravity die casting?

Yes, you can use your own design. Just upload your CAD files to NOBLE. Our engineers check your design and help you make it work. You get advice on careful manufacturing and special steps.

What materials can I choose for my parts?

You can choose aluminum, magnesium, copper alloys, and more. NOBLE’s factory has many materials for your project. We help you pick the best metal for your needs.

How does gravity die casting compare to sand casting?

Gravity die casting makes smoother parts than sand casting. The parts fit better and look nicer. You get less waste and better quality. NOBLE’s careful manufacturing makes sure every part is right.

Is gravity die casting good for small or large orders?

Gravity die casting works for small batches and big orders. NOBLE’s factory can make a few parts or thousands. We help you at every step.

Why should I choose NOBLE for gravity die casting?

NOBLE is a top factory in China. You get fast prices, expert help, and strict checks. Our factory uses careful manufacturing and special steps for every order.

What industries trust NOBLE’s gravity die casting service?

Many industries trust NOBLE, like cars, planes, medical devices, and robots. You get parts that meet tough standards. Our factory has lots of experience with many kinds of projects.