What is Acrylic CNC Machining

Acrylic CNC machining is a technology that uses computer numerical control (CNC) equipment to precisely cut, engrave, drill and form acrylic sheets.

Acrylic CNC machining uses computer programs to control machines, allowing automatic production of complex shapes and detailed designs.

During machining, it is important to carefully manage the tool speed and cooling method to keep edges smooth and prevent cracks.

Overview of Acrylic

Acrylic is a type of polymer called polymethyl methacrylate (PMMA) and is often called organic glass.

Acrylic has an extremely high transparency, with a light transmittance of over 92%, which is superior to ordinary glass. Moreover, it is lightweight, has good toughness, and strong weather resistance.

Acrylic material is easy to dye, process, and thermoform, and can be made into various shapes through processes such as cutting, engraving, and polishing. Meanwhile, it has strong impact resistance, several times that of ordinary glass, and is safer.

Properties of Acrylic

| Transparency | Acrylic offers excellent optical clarity, with light transmission of about 92%, making it a good alternative to glass. |

| Lightweight | Acrylic is much lighter than glass, which makes handling, transport, and installation easier. |

| Machinability | Acrylic is easy to cut, drill, and shape, making it versatile for CNC machining and fabrication. |

| Aesthetic Appearance | Acrylic can be polished to achieve a smooth and glossy surface, which is often used for displays and decorative items. |

| Impact Resistance | Acrylic is stronger and more impact-resistant than glass, reducing the risk of shattering. |

Types of PMMA Machining Materials

Extruded PMMA (Standard Grade)

Extruded PMMA is made by pushing melted PMMA through a mold to form sheets or rods. It costs less than cast PMMA but has slightly lower clarity and surface smoothness. It is often used in applications where keeping costs low is more important than having a perfect appearance.

Cast PMMA (High-Quality Grade)

Cast PMMA is known for its excellent clarity and smooth surface, making it perfect for high-end uses like optical lenses and displays. CNC machining can cut it precisely and produce high-quality finishes, and polishing is often done to achieve the best clarity.

Impact-Modified PMMA

Impact-modified PMMA enhances impact resistance while maintaining optical clarity. It’s suitable for outdoor signage and automotive parts. CNC machining is effective, but extra care is needed to avoid cracking, especially in high-stress areas, due to its inherent brittleness.

UV-Resistant PMMA

UV-resistant PMMA does not yellow or break down easily under long-term sun exposure, making it great for outdoor uses like signs. CNC machining works much like standard PMMA, but you must avoid overheating, as it can reduce the material’s UV protection.

Antistatic PMMA

Antistatic PMMA stops static electricity from building up, which is useful for electronics and cleanroom settings. CNC machining is simple, but extra care is needed to keep its static-dissipating properties, ensuring the parts stay clean and free from contamination.

What are the steps to CNC machining Acrylic?

CNC machining acrylic is a manufacturing process that takes a basic acrylic sheet or block and transforms it into a detailed, accurate, and functional component or finished product.

This process uses CNC technology, where computer-controlled machines carry out cutting, milling, drilling, or engraving with high accuracy.

Every step matters, from preparing the raw material, making digital designs, programming toolpaths, and choosing the right tools, to carefully controlling speed and temperature during machining. All of these steps together ensure a precise and high-quality final product.

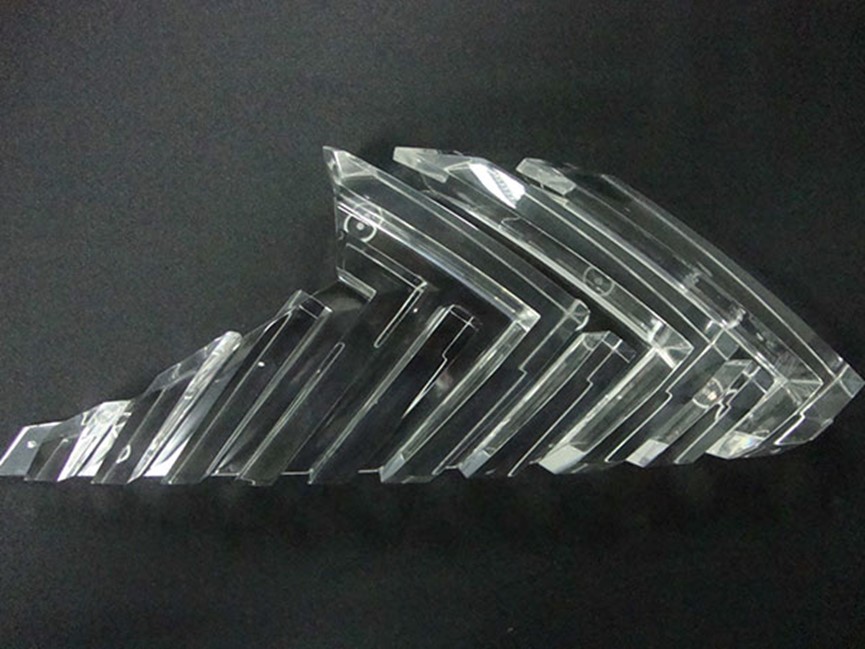

- Material Preparation: Choose the right acrylic sheet or block and secure it firmly on the CNC machine.

- CAD Design: Use CAD software to create a digital 2D or 3D model of the part you want to make.

- CAM Programming: Turn the CAD model into a CNC program, setting toolpaths, feed rates, and speeds that are safe for acrylic.

- Tool Selection: Pick the right cutting tools, like sharp end mills or router bits, to prevent cracking or melting.

- Machining Process: Carry out cutting, milling, drilling, or engraving while controlling speed and heat to keep the surface smooth.

- Finishing: Use polishing, flame treatment, or buffing to make the surface clear and smooth.

- Inspection: Check the size, surface quality, and clarity to make sure the final part meets all requirements.

Common CNC Processes for Acrylic

CNC Milling Acrylic

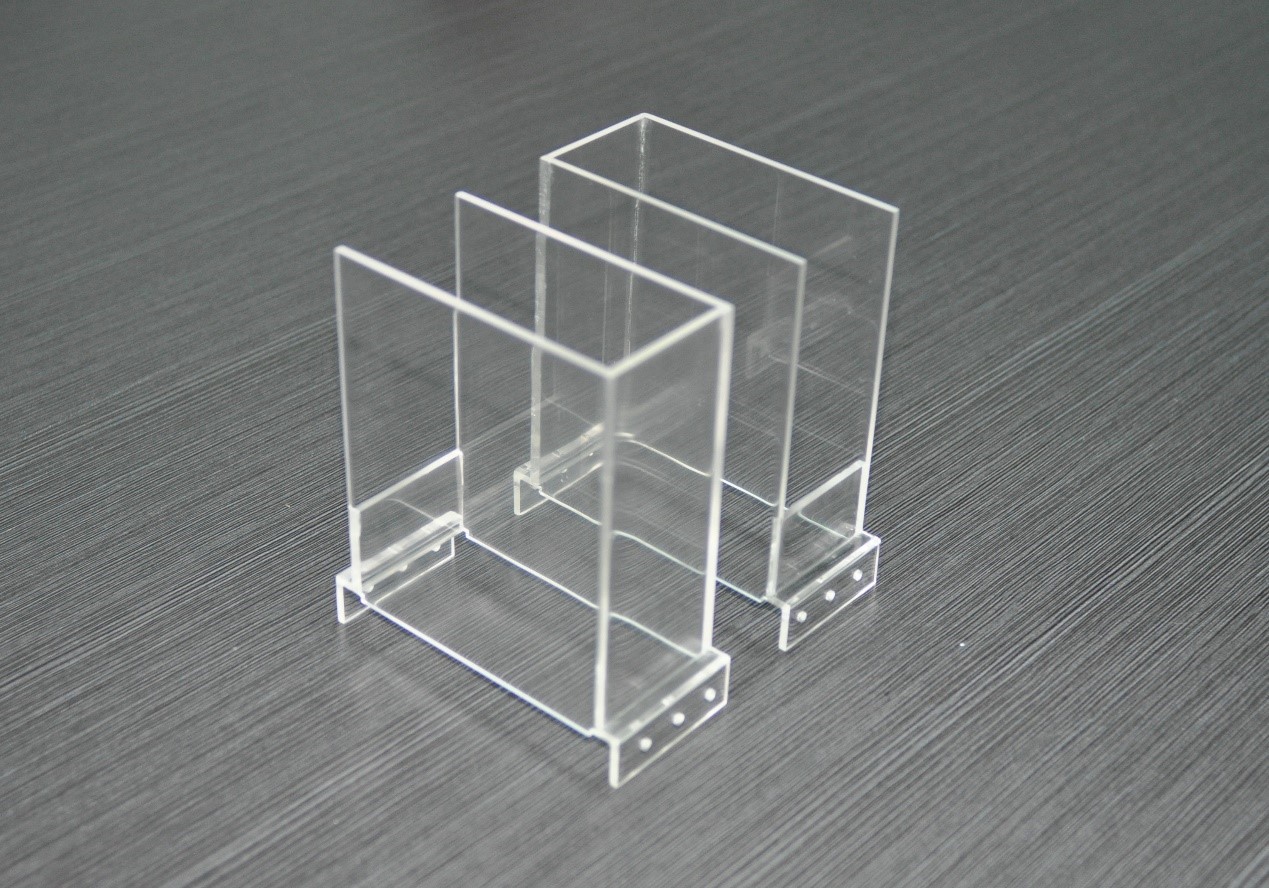

CNC milling is one of the most common methods used to process acrylic. In this process, rotating cutting tools move along multiple axes to remove material and shape the workpiece. It is highly versatile and allows for the creation of flat surfaces, grooves, pockets, and complex 3D geometries.

When milling acrylic, it is important to control the cutting speed and feed rate carefully to prevent melting, chipping, or burns on the surface. Using the right settings and sharp tools allows milling to create smooth and precise parts that can be polished to become clear like glass.

CNC Turning Acrylic

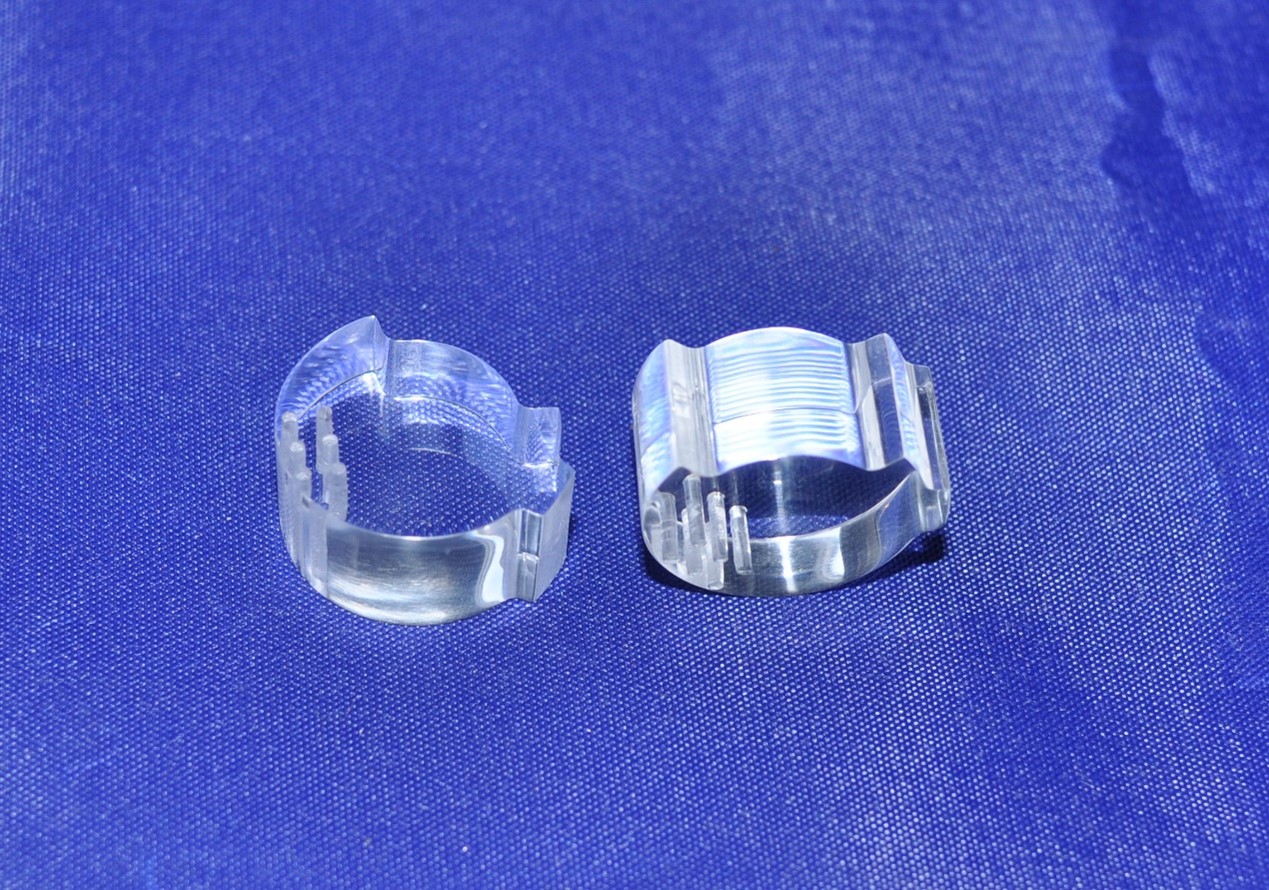

CNC turning is used to make round or cylindrical acrylic parts, like tubes, rods, or decorative pieces. In this process, the acrylic workpiece rotates on a spindle while a stationary cutting tool removes material along its surface.

CNC turning provides accurate diameters, smooth curves, and consistent shapes. For acrylic, low cutting forces and sharp tools are used to reduce heat and avoid cracks.

CNC Drilling Acrylic

CNC drilling is a specialized process for creating precise holes in acrylic sheets or blocks. Computer control ensures that the holes are the same size and in the same place on each piece.

When drilling acrylic, sharp drill bits and slower feed speeds are needed to avoid cracks and overheating. Using cool air or a small amount of lubricant can help make the surface smoother.

CNC Engraving Acrylic

CNC engraving acrylic is a precise method where computer-controlled tools or lasers carve designs, patterns, or text onto acrylic surfaces.

Unlike basic cutting or shaping, engraving makes detailed markings or shallow cuts that add decoration or function.

One big advantage of CNC engraving is that it can produce consistent and repeatable designs with high detail and accuracy.

The engraved areas can also be backlit or filled with color to improve visibility and look. This makes CNC engraving perfect for signs, displays, branding, and personalized products.

CNC Laser Cutting Acrylic

CNC laser cutting acrylic is a manufacturing process that uses a high-powered, computer-controlled laser beam to cut through acrylic sheets with precision.

The laser works by melting or vaporizing the material along a set path, creating sharp edges and smooth surfaces without touching the acrylic.

A major advantage of CNC laser cutting is that it produces very clean cuts, often without needing any extra finishing.

Advantages of Acrylic CNC Machining

High Precision

CNC machining provides very accurate dimensions and tight tolerances, which is perfect for complex acrylic parts that need to meet exact specifications.

Excellent Surface Finish

Using the right tools and cutting settings, acrylic parts can have smooth surfaces that can be polished to look almost like glass.

Design Flexibility

CNC machines can create detailed and intricate shapes, including both 2D and 3D designs, without losing quality.

Consistency and Repeatability

After setting the digital program, CNC machines can make identical acrylic parts in both large and small batches, keeping the quality consistent.

Compatibility with Various Processes

Acrylic can be milled, drilled, turned, routed, or engraved, giving manufacturers many ways to create different designs and functions.

Durability of Products

CNC machining puts less stress on the material than manual methods, which helps prevent cracks and makes the acrylic parts strong and reliable.

Wide Application Range

CNC machining of acrylic can be used in many industries, including signage, displays, automotive, lighting, medical devices, and consumer products, because acrylic is clear, strong, and versatile.

Why Choose CNC Machining Over Other Methods to Cut Acrylic?

CNC machining is very precise, so it can cut acrylic with just the right force without causing serious damage.

Acrylic can be cut using either CNC mills or CNC lathes. CNC lathes are mainly used for softer materials like wood, foam, plastic, and aluminum. In this method, the part rotates while the cutting tool stays still.

A CNC milling machine is very accurate because it uses a cutting tool with many points that can move in different directions.

CNC milling is especially good for harder materials, such as metals and strong plastics. Many engineers prefer using CNC milling to cut acrylic because it produces parts with the best strength and quality.

Available Surface Finishing for Machined Acrylic

As-Machined Finish

This is the natural finish left after CNC cutting or milling. As-Machined Finish may appear slightly rough or matte, with visible tool marks, but it is often sufficient for functional parts that do not require a polished look.

Polished Finish

Flame polishing is a finishing method where the edges of acrylic parts are exposed to a flame, which slightly melts the surface and creates a shiny, clear finish. It smooths out cut edges and makes the part look more attractive. This method is ideal for items like retail displays or decorative pieces that need a high-gloss appearance.

Engraved Finish

CNC engraving can produce textured or patterned surfaces on acrylic.

Transparent Finish

With precise machining and proper polishing, acrylic can become nearly as clear as glass. This high level of transparency is very useful for products such as lenses, protective covers, and premium displays.

Painted Finish

Acrylic surfaces can be painted, dyed, or coated after machining. This allows for adding specific colors or protective layers, giving more options for design and function.

Tips for High-Quality Parts in Acrylic CNC Machining

Choose the right tool

Dull tools can cause chipping, cracking, or melting of acrylic, so it is essential to choose the correct tool.

Optimize Cutting Parameters

Maintain moderate spindle speeds and feed rates to avoid excess heat buildup. If the speed is too high, the acrylic may melt. If it is too low, the acrylic may crack.

Control Heat Accumulation

Use air cooling or a small amount of coolant to keep the acrylic at a steady temperature. This prevents warping and surface damage.

Secure the Workpiece Properly

Firm clamping or vacuum fixtures help prevent vibrations, which could leave marks or make the part less accurate.

Plan Toolpaths Carefully

Create smooth cutting paths to lower stress on the acrylic. This helps avoid cracks inside the material and keeps the edges clean.

Polish After Machining

Polishing makes the surface clearer and smoother, improving the final appearance of the part.

Applications of CNC Acrylic Parts in Different Industries

Lighting Fixtures

Acrylic parts are often used for light diffusers, lamp covers, and decorative lighting elements. Their excellent light transmission and ability to be frosted or clear allow for creative lighting designs.

Automotive Industry

PMMA CNC machining is often used in the automotive industry to make parts such as headlamp lenses, dashboard covers, and window panels. Since PMMA is lightweight, resistant to UV light, and very clear, it helps cars look better, perform well, and stay lighter in weight.

Medical Equipment

Acrylic components can be applied to protective covers, casings, and transparent panels of medical equipment. Acrylic material itself is lightweight, durable, and easy to disinfect, making it suitable for healthcare environments.

Architectural Models

Architects often use CNC-machined acrylic to build scale models, structural pieces, and design prototypes. Because acrylic is clear, it makes it easy to see and present the inner parts of a structure.

Display and Signage Components

CNC-machined PMMA is commonly used to make lighted signs, displays, and advertising boards. It is strong, easy to shape, and lets light pass through very well. These features make it a great choice for both indoor and outdoor signs, helping them look attractive and easy to see.

Comparing Acrylic CNC Machining with Other Plastic Machining Techniques

Acrylic CNC machining and Injection Molding

Injection molding is very efficient for making large numbers of parts, but the molds are expensive to create. This makes it less suitable and more costly when producing only small batches or prototypes.

CNC machining does not need molds and is ideal for low- to medium-volume production with high customization.

Acrylic CNC machining and 3D Printing

3D printing makes it easy to create prototypes and complex designs quickly, but the surface is usually rough and needs extra finishing work.

CNC machining, however, can produce acrylic parts with much better accuracy, clearer transparency, and stronger durability compared to most 3D-printed acrylic options.

CNC Machining Acrylic Parts With NOBLE

NOBLE specializes in reliable CNC machining part prototyping and production, ranging from simple to complex projects.We combine manufacturing expertise with advanced technologies and adherence to quality requirements to bring your ideas to life. Regardless of, the end use of your PMMA parts, We can help you reach your unique goals.

We offer a full range of PMMA CNC machining services with in-house machining and a vast network of resources across China. Our solutions cater to various industries, ensuring high-quality, durable, and visually clear components for prototypes and production runs.

- Instant Online Quote

- Competitive Price 30% cost savings

- High Quality and Consistency

- Lead time As Fast As 3 Days

- 50+ Countries Shipped

- ISO 9001:2015 Certified 100% PMMA Part Inspection

FAQs of Acrylic CNC Machining

Can acrylic be CNC machined?

Yes, acrylic can be CNC machined. Acrylic is a versatile plastic material that can be cut, milled, drilled, and shaped with CNC machines. This makes it useful for creating parts with different designs and functions.

What type of acrylic is suitable for CNC?

Both cast and extruded acrylic can be machined with CNC, but cast acrylic is generally preferred for high-quality CNC parts. Cast acrylic offers better optical clarity, smoother edges, and higher resistance to cracking.

What is the difference between CNC and laser-cut acrylic?

CNC machining and laser cutting are both used to shape acrylic, but they work differently. CNC machining works by using spinning cutting tools to remove material. This makes it possible to create very accurate 2D and 3D shapes.

Laser cutting, on the other hand, uses a strong and focused laser beam to melt or burn away the acrylic along the cutting line. This method is fast and leaves the edges smooth and shiny.

What is the best method to cut acrylic?

The ideal technique varies based on the project. For detailed 2D patterns, logos, or thin sheets, laser cutting is typically the preferred option as it produces smooth, polished edges with little need for finishing. For thicker acrylic pieces, functional parts, or components that demand precise measurements and complex shapes, CNC machining is better suited because of its flexibility, precision, and capability to perform drilling, milling, engraving, and cutting.

What are common mistakes when cutting acrylic?

Common mistakes include using dull tools, which can cause chipping, cracking, or melting; applying excessive speed or feed rates, leading to heat buildup and poor edge quality; improper clamping, which can cause vibrations and dimensional inaccuracies