What is CNC Plastic Machining

CNC plastic machining is a subtractive manufacturing process that uses computer-controlled machines to precisely cut, drill, and shape plastic materials into finished parts.

Unlike molding or 3D printing, CNC machining removes material from a solid block of plastic, also known as a workpiece, to create components that meet exact design specifications.

CNC Plastic Machining is widely used for creating prototypes, functional testing parts, and end-use components. Common plastics used in CNC machining include ABS, acrylic, nylon, POM (Delrin), polycarbonate, and PTFE.

CNC plastic machining is valued for its speed, repeatability, and ability to work with a wide variety of plastic materials, making it an ideal choice for industries such as automotive, medical, electronics, and consumer products.

Can Plastics be CNC machined?

Yes, plastics can be CNC machined. In fact, CNC machining is one of the most effective methods for producing plastic parts with high precision and consistency. Unlike metals, plastics are softer and lighter, which allows them to be cut and shaped efficiently without excessive tool wear.

Many types of plastics can be CNC machined, including ABS, acrylic, nylon, POM (Delrin), polycarbonate, PTFE (Teflon), and HDPE. Each plastic material offers different properties such as strength, flexibility, impact resistance, and chemical resistance, making them suitable for a wide range of applications.

CNC plastic machining is widely used in industries like automotive, aerospace, medical devices, and electronics to produce prototypes, functional components, and custom parts.

Why Use Plastic for CNC Machining

Plastic is a popular material because it offers convenience, flexibility, durability, and cost-effectiveness when processed through CNC milling, turning, drilling, and similar methods.

In addition, plastic is relatively easy to machine. It allows for precise designs without causing excessive wear or damage to cutting tools, unlike certain metals. Plastic also resists corrosion and does not easily react to harsh environmental conditions, making it suitable for applications in the medical, food, and industrial fields.

Different types of plastics, such as ABS, acrylic, or nylon, can be used to achieve properties like strength, insulation, or transparency. In the following section, we will examine various types of plastics suitable for CNC machining.

The Types of Materials for CNC Plastic Machining

CNC machining features high precision and flexibility, thus enabling the machining of almost all types of engineering plastics and high-performance plastics. The following are some of the most common and important types:

ABS

ABS is a very versatile thermoplastic. It has excellent mechanical strength, impact resistance, wear resistance, and dimensional stability. It is easy to undergo CNC machining, bonding, and surface treatment (such as spraying, electroplating).

PC

PC is renowned for its extremely high impact strength and transparency, and is known as “bulletproof glass” plastic. It also has excellent heat resistance, dimensional stability, and flame retardancy.

PA

PA features outstanding wear resistance, high strength, and good toughness. Oil-resistant and chemically resistant. There are various models (such as PA6, PA66, PA12), among which MC nylon (cast nylon) is particularly suitable for CNC machining, as it has higher strength and more stable dimensions.

POM

POM is known as “racing steel” because it has strength, stiffness, and hardness close to that of metals. It features an extremely low coefficient of friction, excellent fatigue resistance, and outstanding dimensional stability.

PEEK

PEEK is a top-grade, high-performance, special thermoplastic. It features astonishing high-temperature resistance (with a continuous operating temperature of up to 250°C), extremely high mechanical strength, excellent chemical resistance, and radiation resistance.

PE

Polyethylene (PE) is a type of plastic that comes in two main forms: high-density (HDPE) and low-density (LDPE). HDPE is hard and can resist strong impacts, while LDPE is strong but very light. Both types handle high temperatures well and can get damaged by sunlight unless special chemicals are added.

PMMA

Acrylic, also called PMMA, is a lightweight plastic that can be used instead of glass and handles weather very well.

It is great for signs, lenses, and aquariums because it is clear, shatterproof, and can resist outdoor conditions. However, it can break if hit hard and scratches easily, so it is not the best choice if you need something very strong.

How to Pick the Right Plastic for Your CNC Project?

When choosing the appropriate plastic for your CNC machining project, it is necessary to make a decision based on different usage requirements and environmental conditions. The following points can be used as references:

- Hardness and strength: Plastics must have sufficient hardness and strength to withstand the weight and impact generated by parts during use.

- Chemical resistance: If the parts are to be used in chemical or harsh environments, plastic materials that are resistant to chemical corrosion must be selected.

- Moisture resistance: In high-humidity or outdoor environments, plastics need to have good moisture-proof performance to prevent water absorption, deformation, or damage.

- Appearance requirements:For parts that require an aesthetic or transparent effect, such as toys or shells, transparent or smooth-surfaced plastics should be chosen.

- Heat resistance:When used in high-temperature environments or electrical insulation conditions, plastics must have good heat resistance.

- Budget cost:The prices of plastics vary greatly. Common ones like polyethylene and nylon have relatively low costs, while high-strength composite plastics are more expensive. A reasonable choice should be made based on the project budget.

CNC Machining Techniques for Plastic Parts

CNC machines make plastic parts by cutting and shaping the material. They remove pieces of the material to create a specific shape that matches the design. Depending on how complicated the part is and what kind of plastic is used, different cutting methods can be used to get the final result.

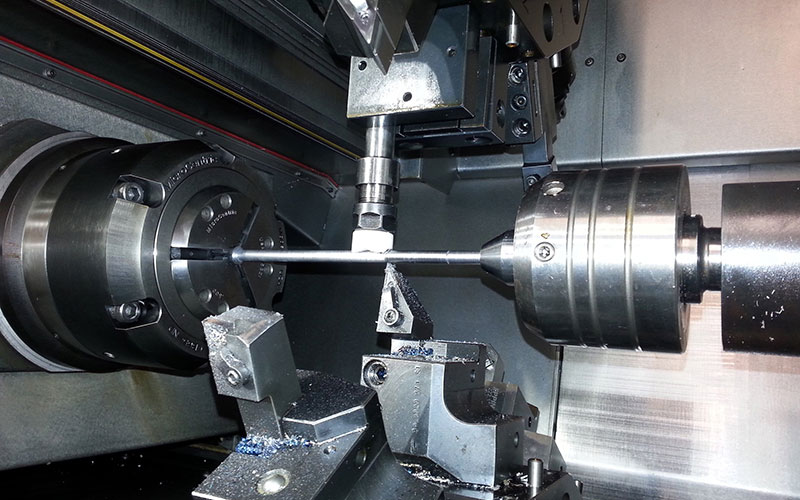

CNC Turning

This method works by spinning a cylindrical plastic piece while a cutting tool shapes it into the desired part. Usually, the cutting tool is set with a negative back rake angle to prevent rubbing against the material. The relief angles are also adjusted depending on the type of plastic.

To make the part smooth, it can be polished. During cutting, a slower feed rate is used: 0.015 inches per revolution for rough cutting and 0.005 inches per revolution for the final finish. Changing the tool angles carefully can make the part more accurate and smoother.

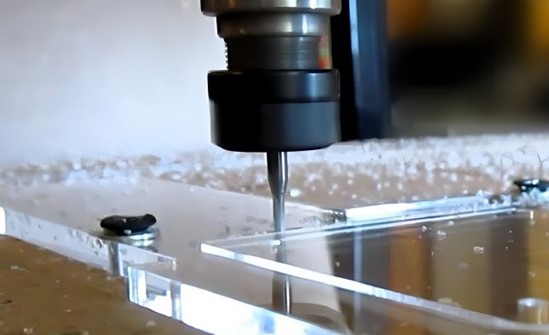

CNC Drilling

This CNC plastics machining process is used to drill holes in thermoplastic materials. Special drill bits are used at angles between 90 and 150 degrees. Cooling systems help remove heat from drilling and make it easier to clear the plastic chips. The drill should not go deeper than 3 to 4 times its diameter, and the feed rate should be slowed near the end to prevent damage.

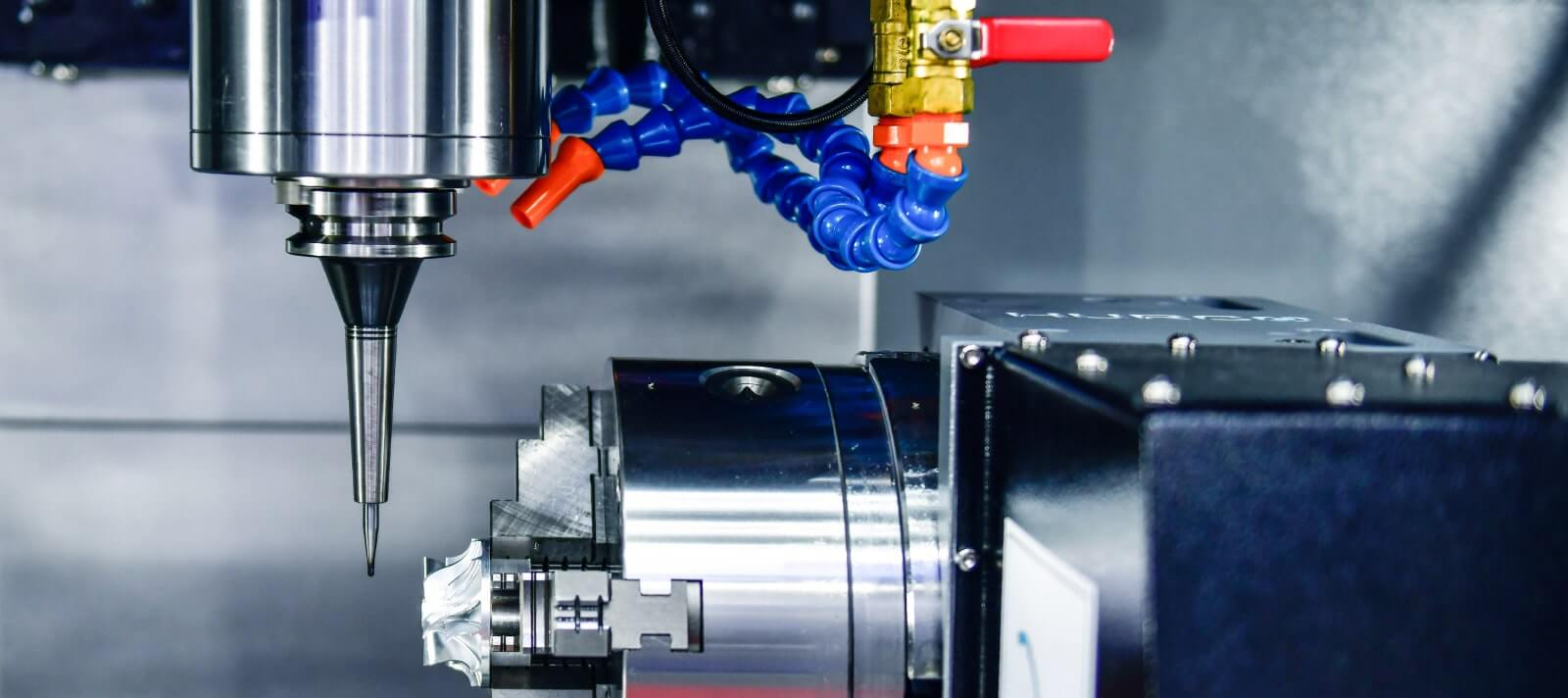

CNC Milling

Plastic milling makes complex parts by cutting a workpiece with rotating tools and removing material. Tools used on reinforced plastics often have rounded inner corners to get better results.

Using a high spindle speed and securing the workpiece properly makes the process faster and more efficient. A good cooling system is also important to keep the machine and spindles from overheating or bending.

Benefits of CNC Plastic Machining

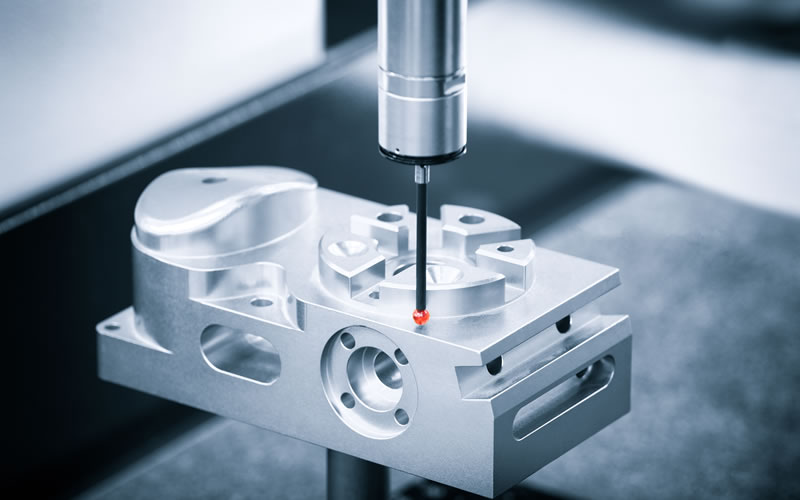

High-precision machining

CNC plastic processing uses computer-controlled machines and can precisely cut and shape plastic parts. Even complex shapes can maintain consistent dimensions, reduce errors, and improve product quality and consistency.

High machining efficiency

CNC machining can operate continuously, at high speed, and handle multiple parts simultaneously. Compared with traditional manual processing, the production cycle is shorter, suitable for mass production, and can improve overall production efficiency.

Strong flexibility

By modifying the program, CNC machines can process plastic parts of different shapes and sizes. Whether it is prototype making or small-batch customization, CNC machining can be quickly adjusted to meet diverse demands.

Reduce costs and risks

CNC machining has a high degree of automation, reducing the need for manual operation and lowering the labor intensity of workers. At the same time, it reduces the risk of operational errors and accidents, making the production process safer and more reliable.

CNC Machining Plastics Post-Finishing Options

Polishing treatment

Polishing can remove the tool marks and roughness on the surface of plastic parts, making them smoother and more transparent. It is especially suitable for materials such as acrylic. After polishing, it can present an effect close to that of glass, enhancing the appearance quality and visual effect.

Powder coat

Through painting or dyeing, plastic parts can be given different colors or surface textures. At the same time, it can also play a certain protective role, preventing surface aging and fading caused by ultraviolet rays or chemical environments.

Silk screen printing and laser engraving

Adding signs, words, or patterns to the surface of plastic is often used for brand identification or functional marking. Screen printing is suitable for large-scale printing, while laser engraving has higher precision, stronger durability, and is less prone to wear and tear.

Assembly and bonding

Some plastic parts need to be used in combination with other components. Post-treatment can be achieved through bonding, hot pressing or ultrasonic welding. This can ensure that the parts are firmly connected and meet the application requirements of function and structure.

Key Applications of CNC Plastic Machining

The automotive industry

CNC plastic processing can be used to produce interior parts of automobiles, such as dashboard panels, buttons, decorative parts, etc. These parts need to be lightweight, wear-resistant and of high precision. CNC machining can meet the dual requirements of appearance and functionality.

Aerospace

In aerospace, plastic parts such as lightweight brackets, internal partitions, and insulating components are often processed by CNC. Its advantages are light weight and high strength, which can effectively reduce the overall weight and ensure reliability.

Medical devices

The medical industry requires a large number of high-precision plastic parts, such as surgical instrument handles, catheter connectors, and transparent casings. CNC machining can provide smooth surfaces and strict dimensional control, ensuring product safety and hygiene.

Electronic products

CNC plastic machining is widely used in the manufacturing of electronic product casings, connectors, and functional components. It features high precision and strong adaptability, which can meet the assembly requirements of complex electronic components and enhance the appearance quality of products.

Household appliances

CNC machining can be used to manufacture parts for daily consumer goods and household appliances, such as transparent panels, knobs, and decorative pieces. Through high-precision processing, the parts not only have an attractive appearance but also possess excellent durability and consistency.

NOBLE: Your Trusted CNC Plastic Machining Service Provider

NOBLE offers professional CNC machining services for plastic materials and is capable of efficiently producing various precision parts according to customer requirements.

We are equipped with advanced CNC equipment and an experienced engineering team, capable of machining a variety of plastic materials, including ABS, acrylic, nylon, polyethylene, polycarbonate, etc.

Whether it’s prototype making, small-scale trial production, or large-scale customized production, we can ensure precise dimensions, smooth surfaces, and offer a variety of post-finishing techniques to meet both appearance and functional requirements.

Our services are widely applied in the automotive, medical, electronic, aerospace, and consumer goods sectors, helping clients quickly realize the implementation of their designs.

FAQs of CNC Plastic Machining

What is the most commonly used plastic for CNC machining?

Delrin is the most popular choice. It provides excellent strength, stiffness, and dimensional stability, making it ideal for precision parts in automotive, electronics, and machinery.

What is the strongest plastic for CNC machining?

Polyamideimide is considered the strongest plastic for CNC machining. It has a tensile strength of over 21,000 psi. Despite this high strength, it can still be machined easily with CNC equipment.

What is the easiest plastic to CNC machine?

ABS (Acrylonitrile Butadiene Styrene) is known as the easiest to machine. It is widely used in prototyping and manufacturing because it is simple to process while still being strong and durable.

What is the cheapest plastic for CNC machining?

Polyethylene (PE) is the most affordable option. It is widely used because of its low cost and good machining properties. Common applications include wear strips, gears, and consumer products.

What is the hardest plastic to CNC machine?

PEEK (Polyether Ether Ketone) is one of the toughest plastics to machine. Its resistance to heat and chemicals, along with its strength, makes it difficult to cut but very valuable in the aerospace and medical industries.