What Is Precision Machining?

Precision machining is a way of making parts by using computer-controlled machines to cut and remove material from a piece. It can manufacture parts with very precise tolerances, complex shapes, and smooth surfaces.

Precision automotive machining refers to a group of specialized machining techniques used in the automotive industry. Precision machining provides high accuracy and consistency, allowing manufacturers to produce auto parts with very tight tolerances.

Precision machining includes several technologies designed to make complex and highly accurate auto parts. CNC machining allows for automated cutting of metal and plastic parts with exact dimensions.

Parts like engine components, transmission pieces, and suspension elements rely on precision machining to meet performance and safety standards.

CNC Precision Machining Process

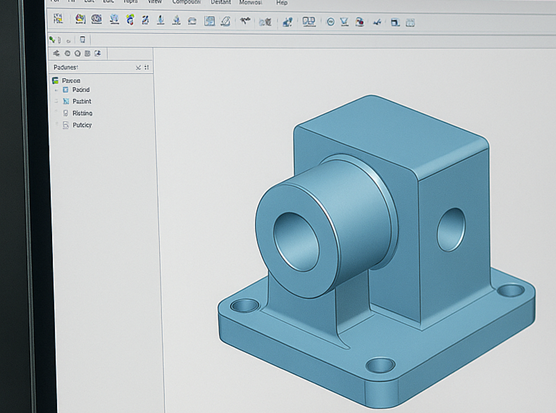

Design and CAD Modeling

Once the requirements are clear, engineers create a detailed 3D design with dimensions, tolerances, features, and scales. Software such as AutoCAD or SolidWorks is often used to build the CAD model of the part. At this stage, design for manufacturability (DFM) is also important. The model must be suitable for precision CNC machining methods.

CAM and CNC Programming

Next, CAM software creates the instructions for tool movement from the CAD model, known as G&M codes. This step is called CNC programming, and the codes are read directly by CNC machines. CAM can also simulate the best tool path for cutting, which helps reduce errors and improve accuracy.

Set up of the CNC Machine

Setting up a CNC machine requires two main steps: installing the tools and securing the workpiece. The operator mounts the tool in the collet or tool holder and places the workpiece on the machine bed or chuck. Some machines also use an Automatic Tool Changing (ATC) system.

At this stage, choosing the right tool—such as end mills, face cutters, or drill bits—and holding the tool and workpiece firmly is crucial for accuracy. Using the wrong tool or misaligning the tool and workpiece can cause serious defects in precision parts.

Machining the Part

The CNC machine connects to the control system to follow the operation instructions. This is the actual machining stage. The operator sets parameters like spindle speed, depth, and feed rate. Then, the machine moves the tools to cut the workpiece. Testing and adjusting these parameters ensures the parts meet precision requirements.

Post-Processing and Finishing

This is the final and important step in CNC precision machining. Machined parts may have tool marks, burrs, or chips, which can affect both accuracy and appearance.

Post-processing methods like grinding and deburring remove small amounts of material to achieve the correct dimensions.

Finishing techniques such as sandblasting, electroplating, or polishing improve surface quality and appearance. Some parts, like hydraulic rods or rotating components, also need finishing to ensure proper function and performance.

Precision Machining and the Automotive Industry

The automotive industry needs high accuracy, efficiency, and reliability to ensure safety, performance, and durability. Precision machining helps meet these needs by making complex parts with tight tolerances. From engine blocks to transmission systems, advanced machining makes sure every part works smoothly in modern vehicles.

Precision machining uses advanced CNC machines and special tools to produce parts with extreme accuracy. Unlike traditional machining, it focuses on fine details, small deviations, and high repeatability. This makes it essential for critical car parts that must meet strict safety and performance standards.

Materials Used in Precision Machining for Automotive Parts

Metals play a key role in making automotive parts, which is why they are widely used in the industry. The following are some common metal materials:

Steel

Steel remains the most widely used material in the automotive industry due to its high strength, good wear resistance, and relatively low cost.

- Carbon steel, such as 45 steel, is used to manufacture structural components with not particularly high strength requirements, such as shafts, gears, bolts, etc.

- Stainless steel, such as 304 and 316, has excellent corrosion resistance.

Aluminium alloy

Aluminum alloy is increasingly widely used due to its excellent lightweight (with a density about one-third that of steel), good thermal conductivity, and corrosion resistance.

Magnesium

Magnesium alloys are lighter than aluminum alloys and are the lightest metal structural materials in engineering applications, but they are more expensive and have poorer corrosion resistance. It is mainly used in fields with extremely high requirements for weight reduction, such as transmission cases, steering wheel frames, seat brackets, etc.

Cooper

Copper has good electrical conductivity, thermal conductivity, and corrosion resistance.

Plastic

Plastic materials have obvious advantages in terms of lightweight and corrosion resistance, and are increasingly replacing metal parts.

- POM: It features high rigidity, low friction coefficient, and excellent dimensional stability

- PA: High strength, heat resistance, and wear resistance, used for engine hood covers, cooling fans, door handles, etc.

- PEEK: High-performance special plastics, with excellent heat resistance and chemical stability

Key Precision Machining Techniques in Automotive Manufacturing

Electrical Discharge Machining (EDM)

Electrical Discharge Machining (EDM) is particularly well-suited for processing hard-to-machine metals and creating highly intricate designs that traditional machining methods often struggle to achieve.

In automotive manufacturing, EDM is important for making parts with complex shapes and fine details. It is widely used in the fabrication of fuel system parts, as well as in the production of molds and dies that are critical for forming various automotive components.

EDM provides great flexibility in making complex shapes. It improves production efficiency and helps ensure automotive parts meet strict quality and performance standards. This makes EDM a key technology for innovation and reliability in the automotive industry.

Laser Cutting

Laser cutting is a modern manufacturing method that uses a high-power laser to cut materials with great accuracy and clean edges.

In the automotive sector, laser cutting is widely used. It makes custom body panels, exhaust systems, and brackets, all requiring precise dimensions and smooth surfaces.

Laser cutting has many advantages. Its precision minimizes material waste and ensures consistent quality.

The advantages of laser cutting mainly include the following points:

- High precision and accuracy in cutting complex shapes.

- Fast cutting speed with high efficiency.

- Smooth and clean edges that often require little or no finishing.

- Ability to cut a wide range of materials, including metals, plastics, and wood.

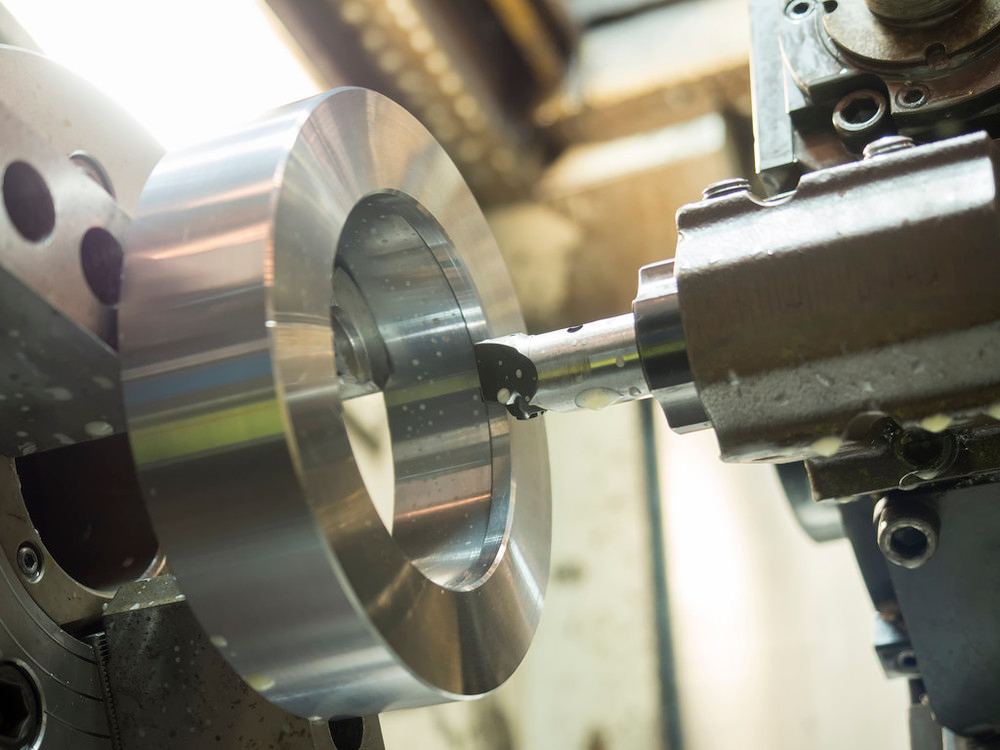

CNC Milling

CNC milling is one of the most widely used techniques. It can rotate the cutting tool to remove material from a fixed workpiece.

- Applications: Engine blocks, cylinder heads, transmission cases, and custom brackets.

- Benefits: High precision, repeatability, and ability to produce complex shapes.

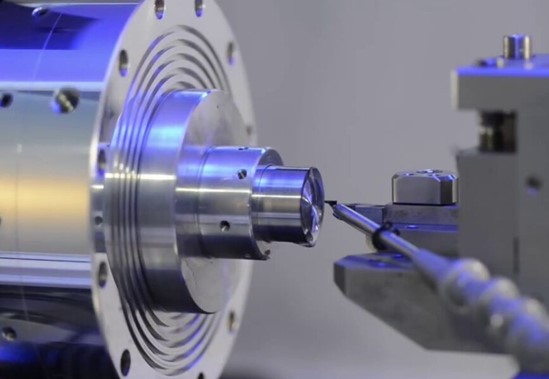

CNC Turning

CNC turning rotates the workpiece while a stationary cutting tool removes material. This is ideal for creating cylindrical parts.

- Applications: Axles, shafts, pulleys, and various bushings.

- Benefits: Excellent for producing rotationally symmetric parts with high dimensional accuracy.

CNC Grinding

Grinding uses an abrasive wheel to achieve ultra-fine surface finishes and extremely tight tolerances.

- Applications: Camshafts, crankshafts, and gear teeth where smooth operation is critical.

- Benefits: Creates a superior surface finish and precise dimensions.

The Application of Precision Machining in the Automotive Industry

Gears

Gears are essential automotive components that transfer the power produced by the engine to the wheels.

The manufacturing of gears must machine high-precision characteristics, including precise tooth profiles, appropriate clearances, and smooth surface finishes. Achieving this level of precision requires the use of precision machining techniques specifically designed for the automotive industry.

Chassis

The car chassis is the main structural frame that supports the vehicle. It holds key systems such as suspension, steering, and brakes. These parts need precision machining to ensure accurate fitting and alignment during assembly.

Engine Blocks

The engine block contains key parts such as pistons and cylinders. It relies on precision machining for proper performance. Cylinder bores must be made with high accuracy, keeping a perfectly round shape and the right surface finish to meet strict standards.

Cylinder Heads and Blocks

The cylinder head is a crucial automotive component positioned on top of the engine block along with the cylinder and other related parts.

Benefits of Precision Machining in Automotive Manufacturing

Precision and Repeatability

Precision machining can reach micrometer or even nanometer accuracy. It ensures that the size and position tolerances of key parts, such as engine blocks and transmission gears, are extremely precise. This consistency in precision machining ensures the fit of parts assembly, reduces friction and wear, and thereby enhances the reliability, lifespan, and performance of the entire vehicle.

Complex Structure

With advanced methods like five-axis machining and micro-hole machining, it is possible to make complex shapes such as integrated body structures and lightweight hollow parts, as well as optimized fluid channels like those in fuel injection systems.

Traditional methods cannot achieve these designs. This helps reduce part weight, lower fuel use and emissions, and improve structural strength and space efficiency.

Production Speed

Precision machining often uses numerical control automation with CAD/CAM systems. This greatly reduces manual work and processing errors. It also cuts raw material waste by optimizing cutting paths. At the same time, it supports fast mass production, shortens new product development cycles, and meets the automotive industry’s demand for large-scale, high-quality production.

Limitations of CNC Machining in the Automotive Industry

High Cost

CNC machining can be expensive for large production runs. The price of machines, tools, and programming is high. For simple parts or mass production, methods like injection molding are often cheaper. This makes CNC less suitable for low-cost automotive parts.

Material Limits

Some materials that are relatively hard are very difficult to process. Parts made of very tough metals will wear out tools. Some plastics may melt or deform under cutting heating. These material limits can affect which automotive components can be made with CNC.

Shape Complexity

Sometimes, CNC precision machining cannot machine very complex internal geometric shapes. Deep holes, depressions, or complex curves are difficult to machine accurately. If the wall thickness of the part is too thin, it may bend or crack. This limits the design freedom for some automotive parts.

Production Speed

CNC machining is slower for large quantities. Each part of the component must be cut separately, which takes time. This may lead to delays for large-scale car production. For mass-produced parts, faster methods such as stamping or forming are usually more popular.

Future Trends in Precision Machining for Automotive Parts

Precision machining of automotive parts is moving toward greater use of intelligence and digitalization. With smart factories that combine IoT and AI, it is possible to achieve adaptive machining across the whole process and enable predictive maintenance.

Additive manufacturing technology is used for the rapid prototyping of complex structural components.

Why Choose NOBLE as Your CNC Precision Machining Supplier

NOBLE offers high-precision CNC machining services designed to meet the most demanding industry standards. Equipped with advanced 3-axis, 4-axis, and 5-axis CNC machines, we are capable of producing complex parts with exceptional accuracy and consistency.

- Advanced CNC equipment capable of producing complex and precise parts.

- A skilled engineering team ensures strict quality control at every stage.

- Wide material selection to meet diverse industry requirements.

- Fast turnaround time with reliable and consistent performance.

NOBLE‘s skilled team works with a wide range of materials, including metals, plastics, and composites, to deliver components that meet your exact specifications.

From prototyping to small and large-scale production, NOBLE ensures fast turnaround times, strict quality control, and reliable performance, helping your projects move from concept to completion efficiently.

FAQs of CNC Precision Machining

-

Which automotive parts are commonly made with CNC machining?

CNC machining is widely used to produce engine blocks, cylinder heads, transmission housings, brake components, steering parts, and custom automotive prototypes. These parts require high accuracy and durability, making CNC machining the ideal choice.

-

Why is precision machining important in automotive manufacturing?

Precision machining is of vital importance in automotive manufacturing because the assembly of automobiles relies on precisely machined parts. Engine parts, transmission components, brake systems, and other critical elements require tight tolerances.

-

What are the advantages of automotive CNC milling?

Automotive CNC milling can produce complex shapes with excellent dimensional accuracy. It enhances the precision of large-scale production, reduces errors, and ensures the dimensions of key components such as gearboxes and engine parts.

-

What is the difference between precision machining and non-precision machining?

The key difference between precision machining and non-precision machining lies in the fact that precision machining is specifically designed to meet strict tolerance requirements. This processing method can produce parts with higher precision, better repeatability, and fewer defects.

-

What materials are used in precision machining for cars?

Automotive precision machining is capable of working with a wide range of materials, including steel, aluminum, titanium, and various engineering plastics.