Are you thinking about whether low-volume manufacturing is right for your business? You get things done faster, save money, and have more choices. You also get good quality. NOBLE’s skilled team and modern factory help with rapid prototyping, custom machining, and prototype machining for industries that need things made exactly and delivered fast.

Low Volume Manufacturing Overview

What It Means

Low-volume manufacturing lets you make small groups of products. You do not have to buy thousands at once. You can order only what you need. This way, you can try new ideas and launch products quickly. It also helps you keep costs low. If you work in medical or automotive fields, you need things made fast and exactly right. NOBLE is a top low-volume production company in China. You get rapid prototyping, prototype machining, and custom machining in a modern factory. These services help you make good parts for testing, market trials, or small releases.

Key Differences

There are some big differences between low-volume manufacturing and mass production. With low-volume manufacturing, you get:

- Parts are made faster. NOBLE’s factory can finish parts in a few days.

- Easy design changes. You can change your prototype machining or custom machining without spending a lot.

- Less money is needed at the start. You do not need costly tools for rapid prototyping.

- Very accurate parts. NOBLE uses CNC machining and injection molding to meet tough rules like ISO 9001 and ISO 13485.

| Feature | Low Volume Manufacturing | Mass Production |

| Batch Size | 10–1,000 units | 10,000+ units |

| Design Flexibility | High | Low |

| Speed | Rapid | Slower |

| Cost per Unit | Moderate | Lowest |

| Risk | Lower | Higher |

You can see how low-volume manufacturing helps you be creative and get good quality. NOBLE’s skills in rapid prototyping and custom machining help you finish projects on time and meet strict needs, especially for medical and automotive work.

Advantages of Low Volume Manufacturing

Faster Market Entry

You want your product out before others. Low-volume manufacturing helps you do this fast. You go from design to finished part in days. NOBLE’s factory uses rapid prototyping and custom machining to speed things up. For example, a medical company needed a new surgical tool. NOBLE’s prototype machining gave them working samples in less than a week. This quick process let them test and improve the design fast. You can launch your product sooner and react to changes quickly.

Tip: NOBLE gives instant quotes and quick delivery. You can start your project right away.

Cost Savings

You do not need lots of money at first. Mass production needs expensive tools and big orders. Low-volume manufacturing lets you buy only what you need. NOBLE’s factory uses CNC machining, injection molding, and other ways to save money. You can save up to 30% compared to regular production. In the automotive field, a startup used NOBLE’s custom machining for a new car part. They skipped high tooling costs and kept their budget safe. You can spend your money on things like marketing or research.

| Cost Factor | Mass Production | Low Volume Manufacturing |

| Tooling Cost | High | Low |

| Minimum Order Size | Large | Small |

| Per Unit Cost | Lowest | Moderate |

| Design Change Cost | High | Low |

Design Flexibility

You can change your design anytime. Low-volume manufacturing lets you test and improve your product. NOBLE’s rapid prototyping and prototype machining make updates easy. If you work in robotics, you might need to fix a part after testing. NOBLE’s engineers help you make changes fast. You get help from a skilled team and a modern factory that fits your needs.

Note: Design flexibility helps you fix problems early. You avoid big mistakes later.

Lower Inventory Risk

You do not need to store lots of parts. Low-volume manufacturing lets you order small batches. You keep inventory low and waste less. If your product changes or demand drops, you do not lose money on unused parts. In the medical field, companies often need small runs for trials. NOBLE’s factory delivers just the right amount, so you do not tie up money in extra inventory. You stay ready for new chances.

Sustainability

You help the planet by using only what you need. Low-volume manufacturing makes less waste. NOBLE’s high-mix, low-volume ability means you can make many parts without extra waste. The factory uses smart processes like CNC machining and 3D printing to cut scrap. In the automotive field, companies use NOBLE’s services to test eco-friendly parts before making large quantities. You support sustainability and meet today’s standards.

Sustainability matters: Less waste, smarter production, and a cleaner future for all.

Main Types of Low Volume Manufacturing

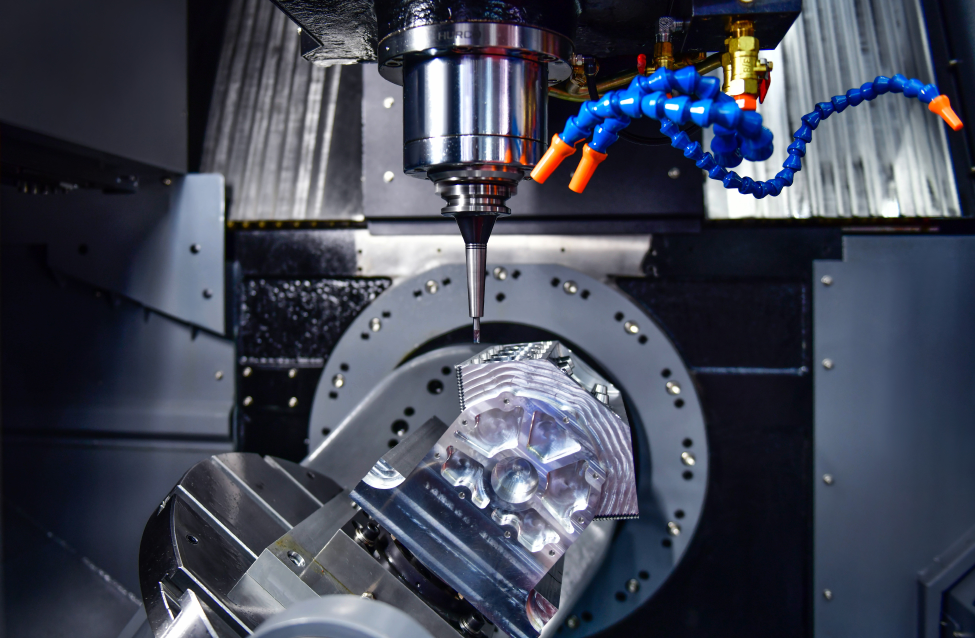

CNC Machining

Practice has proven that CNC machining is an efficient method for low-volume manufacturing and is also the one we use most frequently. This is primarily due to its high precision, versatility, and high speed in manufacturing complex parts. For certain low-volume manufacturing orders, CNC machines can fabricate custom parts or prototypes with exceptional accuracy without requiring the costly investment in molds or tools.

From a practical standpoint, CNC machining enables manufacturers to rapidly refine designs, shorten lead times, and utilize diverse materials while maintaining strict tolerances. With lower setup costs and reduced reliance on manual labor, the process becomes increasingly cost-effective for low-volume manufacturing.

3D Printing (Additive Manufacturing)

When it comes to low-volume manufacturing, we can’t overlook 3D printing, which, alongside CNC machining, handles the bulk of processing in low-volume manufacturing. This is a process that builds objects layer by layer by adding material. Using a computer and a 3D printer, parts transition from virtual designs into tangible objects.

It’s very well-suited for low-volume manufacturing because it eliminates the need for expensive molds or tools, enabling rapid and flexible production of custom parts, prototypes, or small production runs. You can even make them yourself at home.

Plastic Injection Molding

If your low-volume manufacturing order is urgent, injection molding is also a viable option. It enables rapid production of high-quality parts. But the mold manufacturing cost presents a challenge for your project, with upfront expenses potentially being high (primarily depending on part complexity). Once the mold is complete, however, you can rapidly produce numerous parts with minimal additional cost per unit.

That’s why injection molding is commonly used for limited production runs of custom parts, prototypes, small electronics, medical device testing, automotive components, and similar products.

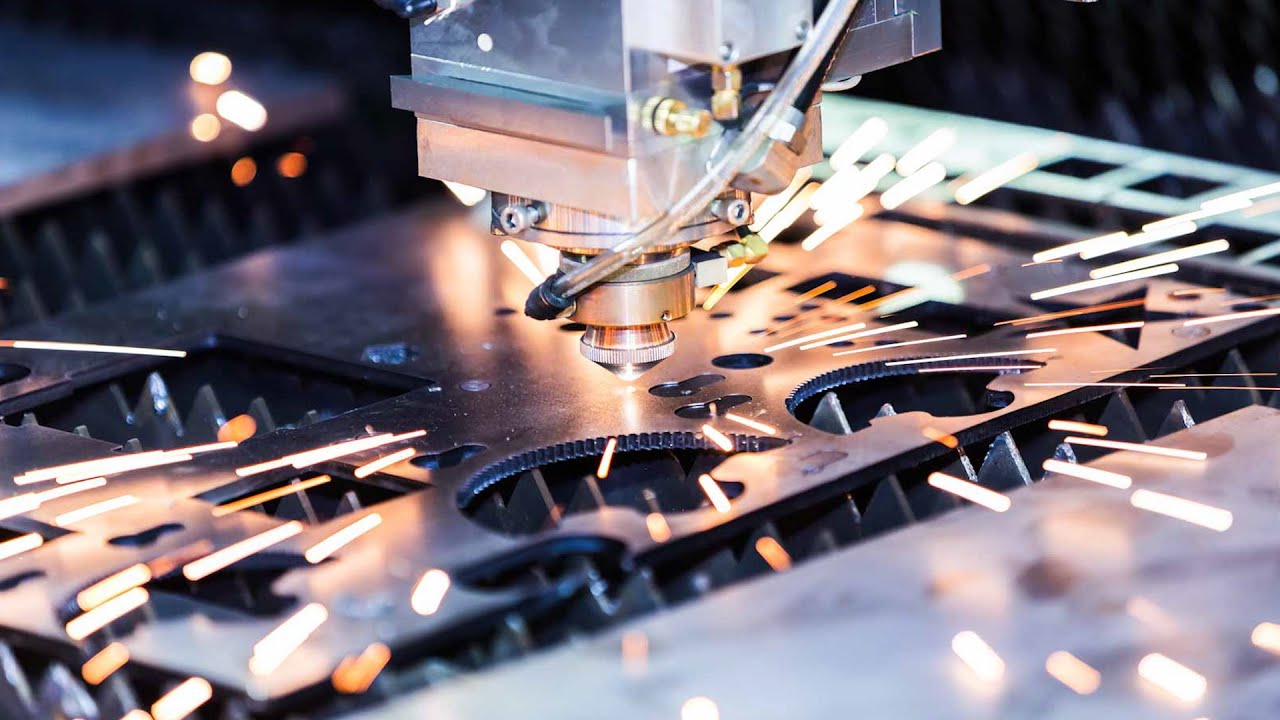

Sheet Metal Fabrication

Sheet metal fabrication involves cutting, bending, and shaping metal sheets—like steel, aluminum, or copper—into different product parts. It’s commonly used in low-volume manufacturing due to its ability to quickly create strong, precise, and cost-effective components without requiring expensive tooling.

For low-volume manufacturing, sheet metal fabrication usually includes processes like cutting (via laser, waterjet, or shears), bending (with press brakes), and assembly (using welding or riveting). These methods provide enough flexibility to produce a variety of parts, such as enclosures, brackets, panels, and structural elements, even in low-volume manufacturing.

Vacuum Casting

Vacuum casting is also a method suitable for low-volume manufacturing. Liquid material is injected into a silicone mold, then a vacuum is applied to eliminate air bubbles. This effectively ensures smooth part surfaces and precise dimensions. Vacuum casting is particularly well-suited for producing rapid, high-quality prototypes, custom parts, or low-volume manufacturing, especially for components requiring materials that simulate plastic or rubber properties.

Die Casting

Similar to vacuum casting, die casting involves injecting molten metal into steel molds under high pressure. This process is typically used for high-volume production, but it remains viable for low-volume manufacturing when robust, precision metal parts are required. The process is extremely fast, producing parts with mirror-like surfaces and impressive tolerances.

But, much like vacuum casting, the upfront cost of manufacturing die-casting molds is high. Therefore, if you plan to use die casting for low-volume manufacturing, ensure the unit cost remains within a manageable range.

Is Low Volume Manufacturing Right for You?

Ideal Scenarios

You may wonder when low-volume manufacturing is best. Many companies use it for different reasons. If you want to test a new idea, rapid prototyping helps you see how it works. You can change your design quickly with prototype machining. This is good for market testing. You can make a small batch, get feedback, and improve your product before making more.

Niche products often need custom machining. If you serve a special group, you do not want to make thousands of parts. You want more choices. Low-volume manufacturing lets you order only what you need. This keeps your costs down and lowers your risk.

Sometimes, you do not know how many people will buy your product. You can start with a small batch and watch what happens. If more people want it, you can make more. If not, you do not lose money on extra parts.

NOBLE helps many industries with these needs. In the medical field, companies need small runs for clinical trials or new devices. NOBLE’s factory uses CNC machining and injection molding to make exact parts fast. Automotive startups use rapid prototyping and custom machining to test new car parts. They avoid high tooling costs and get parts that meet strict rules. NOBLE is a top machining manufacturer in China. You get quality parts, fast delivery, and expert help.

Tip: If you want to move fast, test ideas, or serve a special group, low-volume manufacturing gives you what you need to win.

Potential Limitations

You should know when another way might be better. If you need very high numbers, mass production may save you more money per part. Big factories can make tens of thousands of units at the lowest price. This is best for products with steady, high demand.

Some products need the lowest cost for each part to compete. In these cases, the setup and tooling costs of mass production pay off over time. If your design will not change and you expect big orders, traditional manufacturing may be better.

Still, many companies like low-volume manufacturing for its speed and flexibility. NOBLE’s factory helps industries like aerospace, robotics, medical, and automotive. You get rapid prototyping, prototype machining, and custom machining. The team helps you meet tough industry rules, like ISO 9001 and ISO 13485. You can trust NOBLE’s experience to help you, whether you need a few parts or a few hundred.

| Scenario | Best Approach |

| Prototyping & Testing | Low Volume Manufacturing |

| Niche or Custom Products | Low Volume Manufacturing |

| Uncertain or Fluctuating Demand | Low Volume Manufacturing |

| Very High Volume, Stable Demand | Mass Production |

| Ultra-Low Per-Unit Cost Needed | Mass Production |

Note: NOBLE’s engineering team can help you choose. You get support and advice for your project, no matter the size.

Decision Factors

Product Stage

You should know your product’s stage. Are you testing or launching? Rapid prototyping helps you make samples fast. Prototype machining checks if parts fit and work. Medical companies use NOBLE’s factory for trial devices. Automotive startups order custom machining for early car parts. You can change designs quickly. This helps you avoid expensive mistakes.

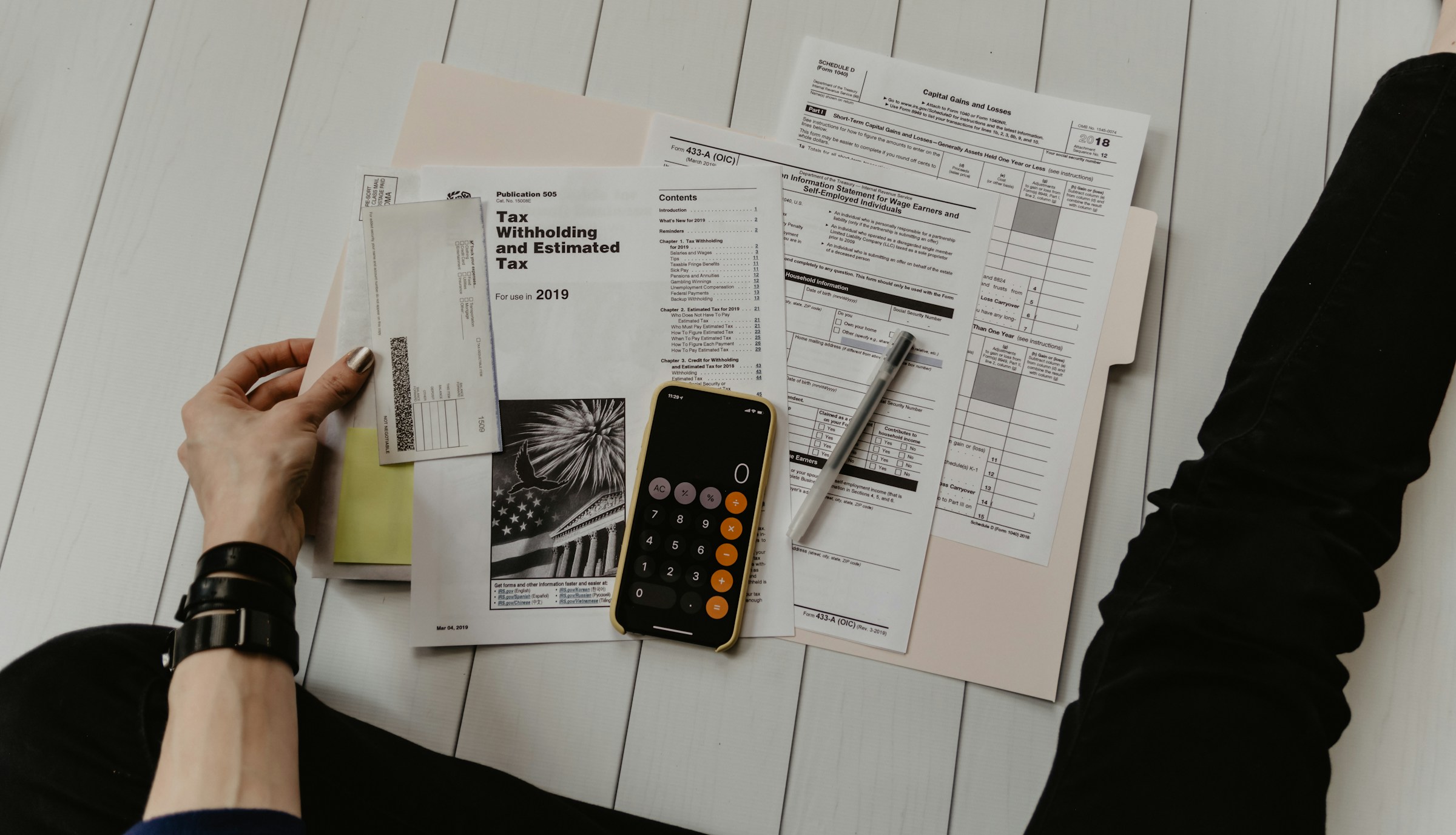

Budget

Money is important. You want to spend less. Low-volume manufacturing saves you from big upfront costs. NOBLE’s factory gives instant quotes and up to 30% savings. You spend less on tooling. You can use more money for marketing or research. If you need a few hundred units, rapid prototyping and prototype machining help you stay on budget.

Ask NOBLE’s engineers for help. We guide you on costs and the best process.

Demand Uncertainty

You might not know how many will buy your product. Low-volume manufacturing lets you order small batches. You can test the market and change plans fast. Medical device makers use this for new products. Automotive companies try custom machining for special parts. You avoid extra inventory and lower your risk.

Customization

You want your product to be unique. Custom machining lets you change shapes, sizes, and features. NOBLE’s factory supports high-mix, low-volume runs. You can offer special choices for customers. Rapid prototyping helps you test new ideas quickly.

Quality Needs

Quality matters a lot. You need parts that meet strict rules. NOBLE’s factory has ISO 9001 and ISO 13485 certifications. Prototype machining and custom machining make precise parts. Medical and automotive industries trust NOBLE for accuracy and reliability.

Note: NOBLE’s engineering support is always ready to help. You get expert advice for your needs.

- Low-volume manufacturing helps you launch products quickly. You also save money and can change your design easily.

- NOBLE’s factory makes medical and automotive parts fast. They use rapid prototyping, prototype machining, and custom machining.

Want to start now? Check out NOBLE’s Low-Volume Manufacturing Services. You will get expert help for your project.

Why Choose NOBLE for Low Volume Manufacturing Services?

NOBLE boasts over a decade of experience in small-batch manufacturing services and a robust supply chain. We can produce a wide range of parts for you, delivering high-quality small-batch manufacturing solutions. Our experienced team assists clients in optimizing designs, selecting appropriate processes, reducing costs, and achieving rapid mass production.

- Advanced Equipment & Cost-Effective Price

- 10+ Years of Low-Volume Manufacturing

- ISO 9001 & ISO13485 Certified Factory

- Get Instant Low-Volume Manufacturing Quotes

- Fast Cycle Time Reduced by 50%

- 24/7 Engineering Support

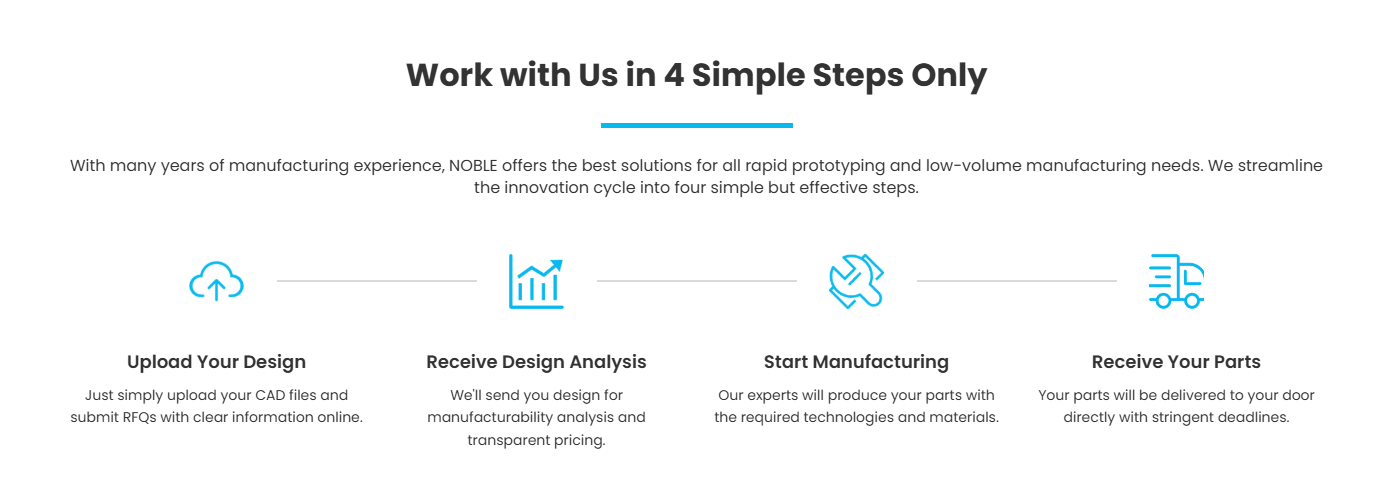

Work with Us in 4 Simple Steps Only

With years of manufacturing expertise, NOBLE delivers optimal solutions for all rapid prototyping and small-batch production needs. We streamline the innovation cycle into four simple yet effective steps.

Upload Your Design

Simply upload your CAD files and submit RFQs with clear information online.

↓

Receive Design Analysis

We’ll send you a design for manufacturability analysis and transparent pricing.

↓

Start Manufacturing

Our experts will produce your parts with the required technologies and materials.

↓

Receive Your Parts

Your parts will be delivered to your door directly with stringent deadlines.

FAQs

What is the minimum order size for low-volume manufacturing?

You can buy only 10 units if you want. NOBLE’s factory makes small batches for rapid prototyping, prototype machining, and custom machining.

How fast can I get my parts?

You get your parts in a few days. The factory uses rapid prototyping and prototype machining to make deliveries faster.

Can I change my design after production starts?

Yes, you can change your design anytime. The factory’s custom machining and rapid prototyping help you make changes quickly and easily.