What is Rapid CNC Prototyping

Rapid CNC Prototyping is a process that utilises computer numerical control (CNC) technology to swiftly create high-precision, functional physical prototypes from digital design files through automated subtractive manufacturing techniques.

The word “rapid” means a much faster turnaround than traditional manufacturing when making functional and precise prototypes. It is not always as fast as 3D printing for some parts. But it is important because it can produce parts from final production materials with better strength and accuracy.

Key features

- Speed and efficiency:CNC machining can make prototypes in just a few days.

- High precision: It produces parts with tight tolerances and smooth surfaces.

- Material versatility:It can use many real engineering materials. Common options include metals such as aluminum, stainless steel, and brass, and plastics such as ABS, Nylon, and PEEK. This makes prototypes match the strength and properties of the final product.

- Digital process: It works directly from a 3D CAD model. This makes design changes and updates easy before machining starts.

Rapid prototyping CNC machining is the best choice when you need a strong, precise, and accurate prototype made from real materials in a short time. It is often used for functional testing, design checks, or client presentations.

Why Use CNC Machining for Rapid Prototyping?

Prototypes machined by CNC can be used for functional testing, assembly inspection, and design evaluation.

The main advantage of CNC rapid prototyping is its fast update speed, which can help car manufacturers launch new models more quickly at a lower cost.

CNC technology relies on computer control to precisely manage tools. This level of fine control is not achievable with other prototyping methods.

CNC rapid prototyping provides high precision and smooth finishes, making the prototype close to the final product. CNC precision machining also allows easy design changes, so prototypes can be adjusted and tested quickly. It is reliable, repeatable, and suitable for both simple and complex parts. This makes it an effective choice for functional testing and design validation.

How does Prototype Machining Work?

The process of prototype machining starts with the creation of a 3D CAD model of the design. From this digital model, G-code is generated, which serves as the programming language that the CNC machine can interpret.

Before actual machining, the G-code is carefully reviewed to confirm that it is free of errors or potential issues. Once the program is verified and testing results are satisfactory, production of the part begins.

CNC prototype machining is classified as a subtractive manufacturing method. Guided by the instructions contained in the G-code, the machine shapes the workpiece using a variety of electronic tools and cutting instruments.

A wide selection of materials can be used during this stage, depending on project requirements. After machining is complete, the finished part is removed from the machine and subjected to any necessary secondary finishing processes to meet the specified standards or customer preferences.

Different CNC Prototyping Operations

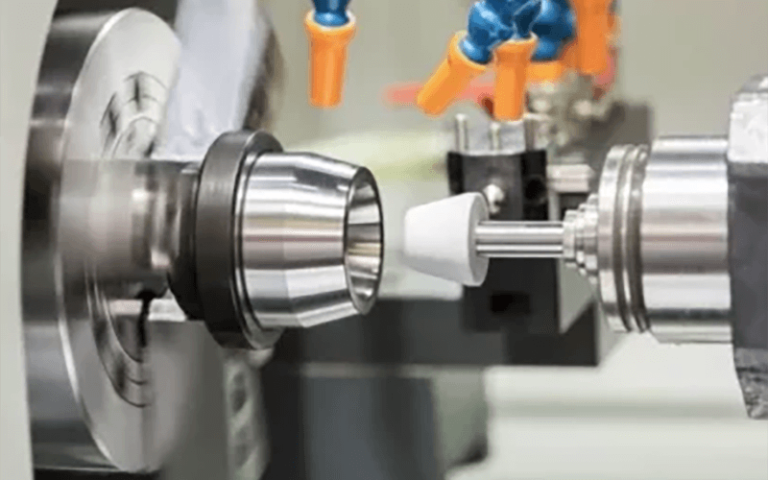

CNC Turning

Turning is mainly done on lathes. The workpiece is fixed on a spindle and spins at high speed. The cutting tool moves along the surface to shape the part into the desired form. This process is suitable for making round parts like cylinders, cones, or discs.

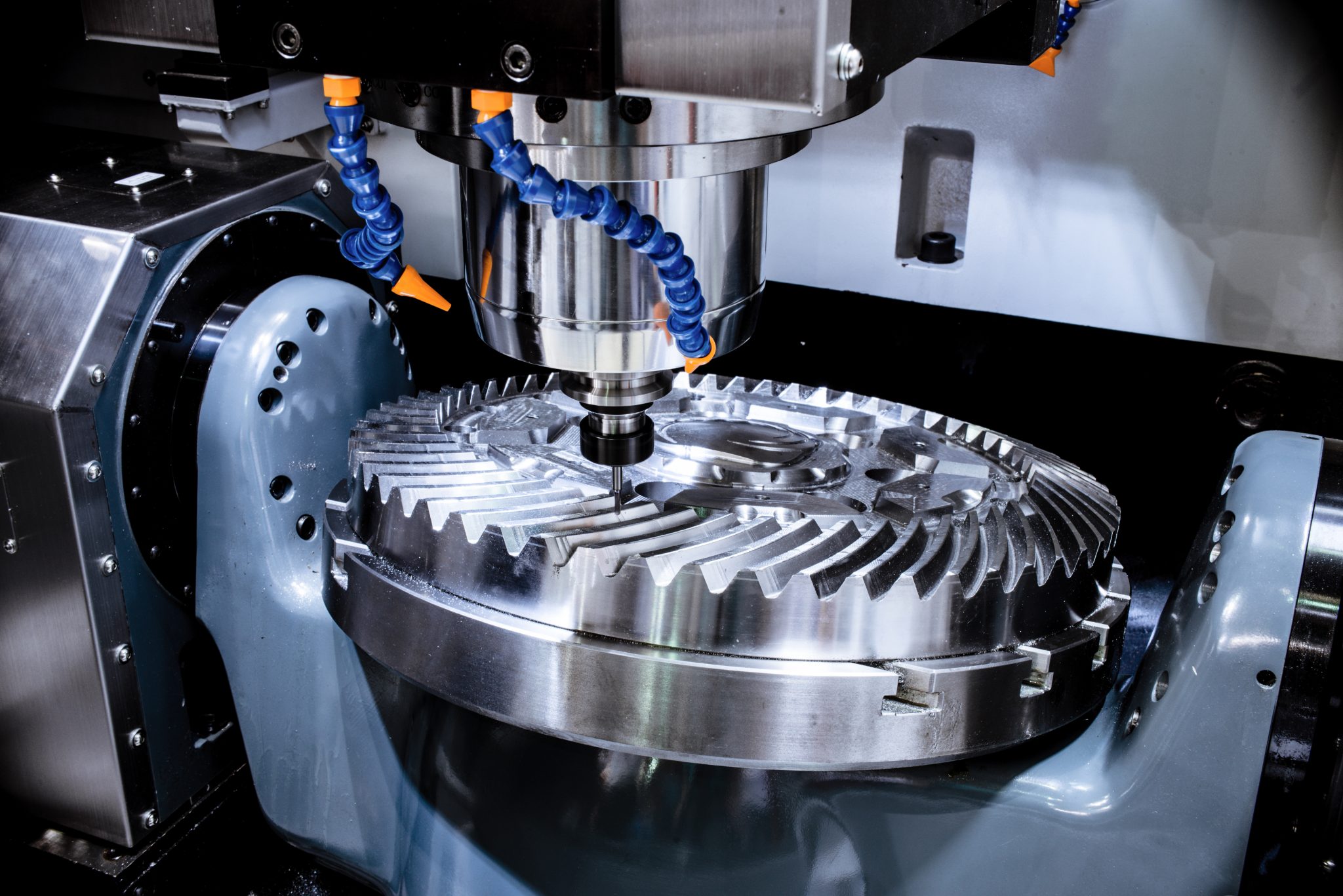

CNC Milling

CNC Milling is performed on a milling machine, employing a process opposite to turning: the workpiece is secured to the worktable, while the milling cutter rotates at high speed.

The worktable can be moved in multiple directions, enabling the tool to cut different surfaces of the workpiece and form diverse shape features.

Tolerances

| Feature / Parameter | Typical Tolerance Range |

| General machining tolerance | ±0.1 mm (±0.004 in) |

| Standard CNC milling tolerance | ±0.05 mm (±0.002 in) |

| High-precision milling | ±0.01 mm (±0.0004 in) |

| Hole diameter (drilled) | ±0.05 mm (±0.002 in) |

CNC Drilling

CNC drilling is a machining process used to create round holes in a workpiece.

CNC drilling can produce holes of different sizes and depths. It is commonly used for parts in industries like automotive, aerospace, and electronics. The method is fast, precise, and suitable for both metals and plastics.

CNC Grinding

Grinding constitutes a finishing process that employs a high-speed rotating abrasive wheel to perform minute material removal from the workpiece surface. Its fundamental principle involves utilising numerous hard abrasive grains as minute cutting edges to remove extremely thin layers of material.

Tolerance

| Type | Tolerance Range |

| External Grinding | ±0.002 ~ ±0.01 |

| Internal Grinding | ±0.002 ~ ±0.01 |

| Surface Grinding | ±0.002 ~ ±0.005 |

Surface Finishing of Rapid CNC Prototyping

CNC prototyping parts can undergo a variety of surface finishing processes to improve their appearance, performance, and durability. Common options include:

- Anodizing– Provides corrosion resistance, increased surface hardness, and different color options (commonly for aluminum parts).

- Powder Coating– Adds a durable, wear-resistant, and colorful coating.

- Polishing– Creates a smooth or mirror-like surface finish.

- Bead Blasting / Sandblasting– Produces a uniform matte or satin surface texture.

- Electroplating (Chrome, Nickel, Zinc, etc.)– Enhances corrosion resistance and surface appearance.

- Brushing– Leaves fine, consistent lines for a textured metallic look.

- Painting– Adds protective and decorative coatings in various colors.

- Heat Treatment (e.g., Black Oxide)– Improves strength, wear resistance, and adds surface protection.

- Passivation– Enhances corrosion resistance of stainless steel by removing surface contaminants.

Advantages of Rapid CNC Prototyping

Diverse Materials

CNC prototype machining can handle a variety of different materials. These materials include strong metals and alloys as well as wood and plastics, allowing the prototype to be made from the same material as the final product, which offers a significant advantage.

| Metal Material | Aluminum alloy 6061, 7075, 2024 |

| Stainless steel 303, 304, 316L | |

| Steel 45#, P20, H13 | |

| Plastic Material | ABS |

| PC | |

| POM | |

| Nylon PA6, PA66 |

In automotive development, prototypes are used to confirm the appearance and physical properties of the final product.

Time-Saving Process

A faster R&D cycle can enable car companies to maintain a leading position in the market. CNC rapid prototyping helps to quickly change designs.

The traditional mold casting method requires a relatively long mold preparation time. CNC machining is digital and requires no costly fixtures. Once the CAD design is finalized, programming and setup can be completed within hours.

If the prototype manufactured is unusable, the designer can immediately update the CAD model and write a new version. A new part can usually be machined within one or two days. Components such as battery boxes, motor housings, and charging ports on electric vehicles are frequently updated. The speed and flexibility of CNC machining help manufacturers launch new products more quickly.

High Precision

CNC machining offers very high precision, with tolerances as tight as ±0.01 mm (0.0004 inches). This accuracy is critical in industries where part performance and prototype quality matter.

Unlike 3D printing, which can leave flaws from its layer-by-layer process, CNC machining gives smooth surfaces and exact dimensions. This makes it especially important in aerospace, automotive, and medical device manufacturing.

Disadvantages of Rapid CNC Prototyping

High cost

The primary drawback of CNC rapid prototyping lies in its substantial equipment and operational costs.

The prices of CNC machine tools range from hundreds of thousands to millions of yuan, which imposes a heavy economic burden on small and medium-sized enterprises and start-ups. The cost of operating and maintaining these machines is also very high. CNC machining requires skilled operators for programming and processing, which will increase labor costs.

For very complex parts made in large numbers, CNC machining can cost more than methods like injection molding. The cost can also rise for very small parts or for parts that need special surface finishes.

Subtractive Process

CNC machining is a subtractive manufacturing process. It makes parts by removing material from metal or plastic blanks using methods like milling and turning. This process produces a lot of swarf and scrap.

For high-priced materials, the rapid machining of CNC prototypes will lead to a large amount of material waste. If the internal structure of the part is relatively complex, the removed material may be heavier than the finished product.

In contrast, additive manufacturing machining methods such as 3D printing produce almost no waste. With the rapid changes in design, CNC machining requires re-cutting, which further increases material loss.

Geometrical Restrictions

CNC machining also has limits when it comes to complex shapes. It cannot easily make very complex internal shapes or deep cavities. Sharp undercuts and intricate curves are hard to machine. Very small features may be too fine for the tool to reach. These limits depend on the tool size and machine capabilities.

The Challenges of CNC Machining for Prototypes

Several strong arguments have already been presented to explain why CNC machining is an excellent option for producing prototypes. However, it is important to recognize that the method does have certain limitations, which may make it less suitable for specific projects. Below are a few key considerations.

Higher Cost Compared to 3D Printing

Prototyping through CNC machining is generally more expensive than alternative methods such as 3D printing. The higher cost is largely due to the operational expenses of running large CNC machines and the need for skilled labor to manage the process.

For this reason, engineers and product designers are advised to conduct thorough cost evaluations before selecting CNC machining as their preferred prototyping solution.

Material Waste

CNC prototype machining operates as a subtractive machining process, meaning the final prototype is produced by systematically cutting away excess material from a solid block.

As a result, a considerable amount of scrap material is generated. This not only increases production costs but can also hurt the environment.

To mitigate these drawbacks, some machine shops implement recycling practices, allowing them to recover and reuse a portion of the discarded material, thereby reducing waste and offsetting costs to some extent.

Geometrical Constraints

Although modern CNC machines, including advanced 5-axis milling systems, are highly capable of producing complex shapes and intricate components, certain design features can still pose significant challenges.

Prototypes with intricate internal geometries, for instance, may be particularly difficult to machine because the cutting tools cannot always access such confined spaces.

Technical and Skilled Labor

The process of CNC prototyping requires a high level of technical knowledge and practical expertise. Developing accurate CAD and CAM files is not a straightforward task and demands strong design and programming skills.

Successful CNC prototyping relies not only on technical proficiency but also on experience and creative problem-solving. For this reason, skilled and well-trained operators are essential to ensure precision, efficiency, and consistent quality.

CNC Prototype Machining and Other Rapid Prototyping Technologies

Rapid CNC Prototyping and 3D Printing

Compared with 3D printing, CNC rapid prototyping has clear advantages. CNC rapid prototyping can make larger parts, achieve a smoother surface finish, and work with materials more accurately.

CNC rapid prototyping can also be used for a wide variety of surface treatments. This accelerates the R&D speed and prevents the increase in costs due to design revisions in the later stage.

Rapid Prototyping, CNC Machining, and Plastic Injection Molding

The main difference between rapid prototyping, CNC machining, and plastic injection molding is the principle each uses to make parts.

Rapid prototyping CNC machining is a subtractive process. It removes material from a solid block of metal or plastic using cutting, milling, and similar operations to create the desired part.

Plastic injection moulding, conversely, constitutes an additive process. It works by pressing molten plastic into a closed mold. Then the plastic cools and solidifies to form the final part.

Key Applications of Rapid Prototyping CNC Machining in the Automotive Industry

The automotive sector relies heavily on rapid prototyping and CNC machining for various stages of development and production:

Machining prototype parts

In automotive design and development, a key application of CNC rapid prototyping is the manufacture of high-precision body and interior/exterior trim prototypes.

Designers frequently require physical components based on CAD models for aerodynamic testing, assembly validation, and similar purposes. CNC machining enables the direct production of large-scale cover components such as bumpers, dashboards, and door panels in 1:1 scale from materials including ABS engineering plastics and aluminium alloys.

Low-Volume Production

CNC machining is suitable for small-batch production, such as custom parts or model testing before large-scale production. Since it doesn’t need costly molds, it is more efficient and cost-effective for small runs.CNC rapid prototyping plays a significant role in the manufacturing of small-batch custom parts. It serves specialised parts for high-end bespoke vehicles, racing cars, or concept cars. It serves rapid production lines by generating the necessary tooling fixtures and inspection gauges.

Design and Testing

CNC rapid prototyping is important for making functional prototypes and testing parts. In automotive research and development, performance and reliability are of vital importance. Before mass production, important components such as engines and chassis need to be tested.

CNC prototypes can be fitted directly on the engine for testing. CNC prototypes have the same mechanical, thermal, and dimensional characteristics as the final product, so they can withstand complex environments. This provides reliable test data for the R&D team.

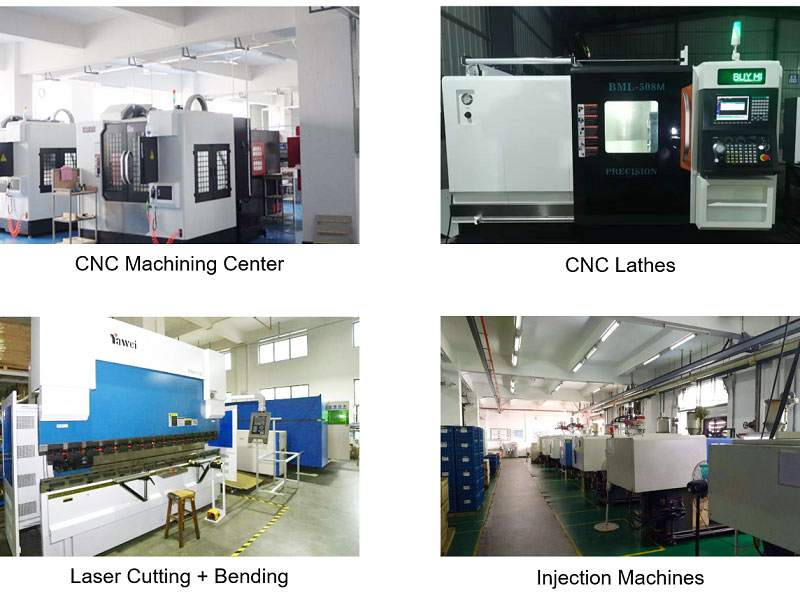

NOBLE: The Rapid Prototyping CNC Machining Service You Need

NOBLE machines’ extensive experience and specialised expertise in rapid prototyping and CNC machining enable the swift realisation of high-precision machining from drawings to physical components according to client design specifications.

NOBLE is equipped with advanced 5-axis and multi-axis CNC machines. They can process both metal and plastic materials with high efficiency. This enables each prototype to meet the customer’s requirements for precision, surface finish, and performance.

- Expertise and Experience: Early in the product development process, our thorough DFM methodology can assist in identifying and resolving possible design issues and suggest modifications to enhance the components’ manufacturability.

- Competitive Price: We’ll also help you optimize your material selection and production process for the best results, at the best price. Our experienced engineers will help you efficiently move your projects from prototype to production.

- Perfect Supply Chain: NOBLE focuses on prototype manufacturing and low- to mid-volume, highly customized parts, which is a perfect match for any company that is looking for ways to accelerate its rate of new product development.

- Strong Manufacturing Capabilities: NOBLE has advanced rapid prototyping manufacturing equipment and professional machinists, allowing our fast prototyping services to exceed competitors in the same industry far and meet your immediate prototyping needs.

NOBLE offers quality inspection, assembly testing, and functional prototype design. This helps customers speed up product development and validate their designs faster..

FAQs

Is there a better method than CNC prototyping?

The selection of prototype machining technology depends on the type of material, structural stability requirements, and other specific technical conditions.

What factors affect CNC prototyping cost?

The main factors influencing the cost of CNC rapid prototyping are the complexity of parts, tolerance requirements, and material selection. The type of CNC machine and the surface treatment process also have a big impact on the total cost.

What materials are commonly used for CNC prototyping?

CNC rapid prototyping can machine many metal materials, including aluminum, stainless steel, titanium, copper, brass, bronze, zinc, and magnesium. Plastics are also suitable, including acrylic, ABS, PP, nylon, PC, PTFE, HDPE, LDPE, and PVC.

Which has a lower cost, CNC machining prototypes or injection molding prototypes?

Injection molding is usually more expensive than CNC machining because it requires the making of molds. The mold cost can be spread across many products in mass production. However, for prototypes produced in small batches, the initial cost is difficult to cover. For this reason, injection molding is relatively costly at the prototype stage.

How long does it take to complete a rapid prototyping CNC machining project?

The time for processing prototypes depends on the complexity, size, and quantity of the parts.