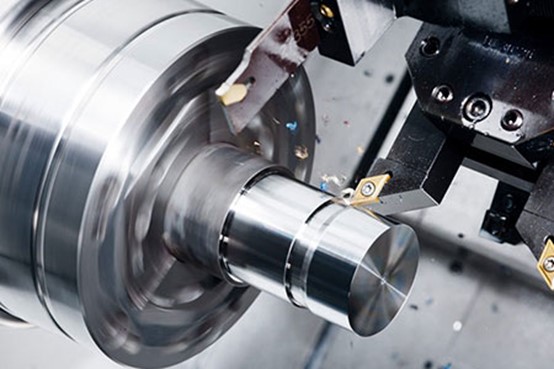

What is Stainless Steel Machining?

Stainless steel is an iron-based alloy mainly containing chromium, which endows it with anti-rust and corrosion-resistant properties. Its corrosion resistance stems from the fact that the chromium content is usually no less than 11%, which can form a passive film on the surface.

Stainless steel has excellent strength, corrosion resistance, and durability, and is one of the most widely used materials for producing prototypes and end-use parts.

By combining the outstanding material properties of stainless steel with advanced CNC machining services, manufacturers can achieve high-precision, consistent, and fully functional components.

Can Stainless Steel be Used for CNC Machining?

Stainless steel has become an ideal material for CNC machining due to its unique advantages. It has excellent corrosion resistance and oxidation resistance, ensuring the long-term stable use of parts in harsh environments. In addition, stainless steel also has excellent mechanical properties, including high toughness and wear resistance, making it suitable for applications such as structural components, precision fixtures, and medical devices.

In CNC machining, easily machinable stainless steel grades are often selected, such as austenitic stainless steel 304 and 316, or martensitic stainless steel 416. These materials achieve a good balance among strength, hardness, and corrosion resistance, and can meet the high requirements of industries such as aerospace, medical devices, the automotive industry, and food machinery.

Overall, as long as the material grade is reasonably selected and the processing parameters are optimized, stainless steel can fully achieve efficient and high-precision CNC machining, and the finished parts perform excellently in terms of dimensional stability and surface quality.

Types of Stainless Steel

Austenitic stainless steel

This is the most commonly used type, featuring excellent corrosion resistance, toughness, and weldability. However, due to its obvious tendency towards work hardening, it has relatively high requirements for cutting tools.

Types of austenitic stainless steel

304: The most common general-purpose stainless steel, it has good corrosion resistance and is suitable for industries such as food, chemical, and medical.

316: Compared with 304, it contains more molybdenum, significantly enhancing its resistance to chloride corrosion (such as seawater and salt water), and is also known as “Marine steel”.

303: It is the free-cutting version of 304. By adding sulfur or selenium, its cutting performance is improved, but a small amount of corrosion resistance is sacrificed. It is very suitable for high-speed automatic lathe processing.

321: The resistance to intergranular corrosion is enhanced by adding titanium, making it suitable for high-temperature environments.

| Buildings and structural components | Exterior wall coverings of buildings, stair railings, and door and window fittings |

| Food and medical equipment | Sinks, countertops, kitchenware, surgical instruments, sterile containers |

| Daily consumer goods and industrial products | High-end mobile phone frames, watch cases, and decorative strips |

The application of austenitic stainless steel

Martensitic stainless steel

This type of stainless steel can be strengthened through heat treatment, featuring high strength and hardness, but its corrosion resistance is relatively poorer than that of austenitic stainless steel.

Types of martensitic stainless steel

416: One of the most machinable stainless steels, it has a high sulfur content and excellent processing performance, and is often used to manufacture high-strength parts such as gears and shafts.

420: A martensitic stainless steel with high hardness and good wear resistance. After heat treatment, it can be used to manufacture cutting tools, surgical instruments and bearings, etc.

440C: A high-carbon and high-chromium martensitic stainless steel, it is one of the hardest types of all stainless steels and is extremely wear-resistant. It is often used to manufacture high-end cutting tools, bearings, and valve parts.

The application of martensitic stainless steel

| Cutting tool | Table knives, scissors, and surgical blades |

| Shafts and fasteners | Valve parts, screws, bolts, nuts |

| Automobiles and mechanical parts | Gears, turbines, bearing rings |

Ferritic stainless steel

430: The most commonly used ferritic stainless steel, with a chromium content of approximately 16-18%. It has excellent corrosion resistance (superior to austenitic steels other than 304) and formability, and is used in household appliances, decoration, kitchenware, etc.

434: Based on 430, molybdenum is added to enhance the pitting resistance and strength. It is often used in automotive trim and exterior parts.

409: Titanium stabilization treatment, resistant to high-temperature oxidation and corrosion, low cost, widely used in automotive exhaust systems.

410L: Low-carbon and low-nitrogen version, with improved weldability and formability, suitable for containers, etc.

Which Type of Stainless Steel is Difficult to machine by CNC?

304 Stainless Steel

Standard AISI 304 stainless steel is widely recognized as one of the most challenging stainless steel materials in the field of CNC machining due to its extremely severe work hardening, high toughness and viscosity, poor thermal conductivity, and high sensitivity to process parameters.

316 Stainless Steel

316 has slightly higher strength due to the addition of molybdenum, but its work hardening tendency is generally considered to be slightly lower than that of 304. Therefore, its workability is sometimes considered to be slightly better than or comparable to that of 304.

Martensitic steel (such as 420)

These steels can achieve very high hardness after heat treatment, and they cause significant wear on cutting tools during processing.

Duplex steel (such as 2205)

Duplex steel has extremely high strength, is very wear-resistant, and wears out cutting tools quickly.

Which Type of Stainless Steel is Easy to use for CNC Machining?

303 stainless steel is highly suitable for parts that require extensive cutting, machining, and have low corrosion resistance requirements (in mild environments), such as screws, nuts, gears and other components.

The main characteristics of 303 stainless steel:

Advantages

Excellent machinability: Its machinability rating is much higher than that of 304 and 316, and even superior to many other types of steel.

Good surface finish: It is easy to obtain a better surface quality for processing.

High machining efficiency: It allows for higher cutting speeds, reduces the frequency of tool changes, thereby significantly enhancing production efficiency and lowering overall costs.

Disadvantage

Slight decline in corrosion resistance: Due to the addition of sulfur, its resistance to pitting and intergranular corrosion is slightly inferior to that of 304. It is not recommended for use in severely corrosive environments (such as core components of chemical and Marine equipment).

Reduced toughness: Not suitable for critical structural components that require high impact toughness.

Not suitable for welding: Welding can cause pores and hot cracks, seriously affecting the quality of the weld seam.

The Advantages of Stainless Steel CNC Machining

Excellent corrosion resistance

This is the core advantage of stainless steel. The processed parts do not require additional electroplating or spraying and can resist the corrosion of various media such as the atmosphere, moisture, acids, and alkalis. They are suitable for harsh environments such as medical devices, the food industry, the chemical industry, and outdoors.

Good high-temperature performance

Some types of stainless steel (such as 316 and 310S) have excellent oxidation resistance and high-temperature strength, making them suitable for manufacturing components that need to operate in high-temperature environments.

High surface quality and aesthetics

Stainless steel is easy to undergo post-treatment such as polishing, sandblasting, and passivation, and can achieve various surfaces ranging from fine matte to high mirror finish, balancing functionality and aesthetics.

A wide range of material options

The stainless steel family is vast (such as free-cutting 303, general-purpose 304/316, high-strength 17-4PH, etc.), and materials can be flexibly selected based on different requirements such as strength, hardness, corrosion resistance, and processability.

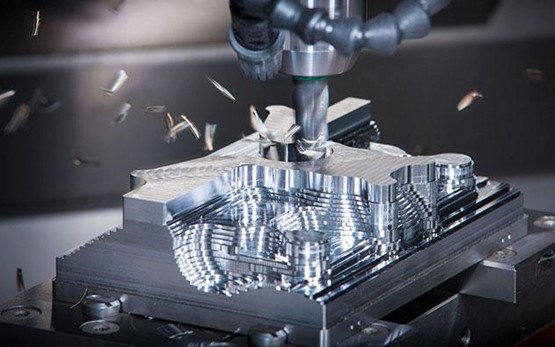

The Disadvantages of Stainless Steel CNC Machining

High cutting force and high power consumption

Stainless steel has high strength and good toughness. During cutting, it requires greater rigidity of the machine tool and driving power, which puts forward higher requirements for the performance of CNC machine tools.

Poor thermal conductivity

The thermal conductivity of stainless steel is relatively low. During the cutting process, the large amount of heat generated is difficult to be dissipated quickly but accumulates at the cutting edge of the tool, causing the tool temperature to be too high and accelerating tool wear and failure.

High tool cost

When machining stainless steel, it is usually necessary to select special tools with good wear resistance and high thermal hardness (such as coated hard alloy tools), and the tools wear out quickly, resulting in relatively high production costs.

The process requirements are strict

Experienced operators or process engineers are needed to optimize cutting parameters (such as rotational speed, feed rate, and depth of cut), select the appropriate coolant and injection method; otherwise, it is difficult to ensure processing quality and efficiency.

CNC Stainless Steel Machining Service Provider

NOBLE is a professional CNC stainless steel machining service provider, dedicated to offering customers high-precision and high-quality stainless steel parts customization services. With advanced, fully automatic CNC machining equipment and mature process technology, we are capable of handling various stainless steel materials (including 303, 304, 316, 17-4PH, etc.), meeting different demands from sample trial production to mass production.

NOBLE has rich experience in stainless steel machining, and our products are widely used in medical devices, food machinery, aerospace, automotive parts and high-end industrial equipment, and other fields. Whether you need structural parts, precision fixtures, appearance parts, or functional components, NOBLE can ensure that the parts meet high standards in terms of dimensional accuracy, surface quality, and corrosion resistance through optimized processing parameters and strict quality control.

Welcome to contact us for more technical solutions and quotation support. We will provide you with reliable stainless steel CNC machining solutions.

FAQs of Stainless Steel Machining

Is stainless steel good for CNC machining?

Yes, stainless steel is an excellent and widely used material in CNC machining, prized for its outstanding strength, superior corrosion resistance, and durability.

What is the best stainless steel for CNC machining?

The “best” grade depends heavily on the final part’s application requirements, balancing machinability, corrosion resistance, and strength.

Why is stainless steel difficult to machine?

Many stainless steels (especially 304 and 316) rapidly harden as they are cut. This can cause tools to rub instead of cut, leading to excessive tool wear and potential breakage.

Heat generated during cutting doesn’t dissipate quickly. Instead, it concentrates on the cutting tool’s edge, accelerating wear and reducing its lifespan.

What are the main applications of CNC-machined stainless steel parts?

It is mainly applied in industries such as medical care, aerospace, and automobiles. Including surgical instruments, implants, valve bodies, actuator components, fuel system components, etc.

How does the cost of machining stainless steel compare to aluminum?

Machining stainless steel is generally more expensive than machining aluminum. This is due to several factors: slower machining speeds (longer cycle times), higher tool wear (increased tooling costs), and the need for more powerful machinery. However, the superior strength, corrosion resistance, and durability of stainless steel often justify the higher cost for applications where aluminum would not perform adequately. The total cost of ownership, considering the part’s lifespan and performance, is a crucial deciding factor.