What is plastic injection molding?

Plastic injection molding is a widely used manufacturing process in industrial production. Its core principle involves injecting molten material into a pre-designed mold cavity, where the material cools and solidifies to form the desired shape of the part. This process has extremely high material adaptability, not only suitable for the most common thermoplastic plastics and thermosetting polymers but also applicable to the production of various materials such as metals (in which case the process is called die casting), glass, elastomers, and even candy. The entire process begins with feeding raw materials into a heated barrel, where they are uniformly melted through the mixing action of a screw auger. The molten material is then injected into the mold cavity under high pressure, and after cooling and solidification, the resulting product is identical to the mold cavity. In actual production, mold manufacturing is a critical step. Typically, professional mold manufacturers produce molds using metal materials such as steel or aluminum based on designs from industrial designers or engineers, ensuring the molds can precisely replicate the required part features. The application scope of injection molding technology is extremely broad, enabling efficient production of everything from miniature electronic components to large automotive body panels. In recent years, with the advancement of 3D printing technology, new types of photopolymer materials have been utilized in the production of simple injection molds. These materials exhibit special low-temperature thermoplastic properties, which prevent them from melting during the injection molding process, thereby providing new technical solutions for rapid prototyping and small-batch production.

How does plastic injection molding work?

Step 1: Raw Material Preparation and Heating/Melting

Plastic Injection molding is a highly efficient and precise plastic machining technique, with its complete workflow involving the seamless coordination of multiple critical stages. The entire production process begins with the pre-treatment of raw materials, where plastic pellets or powders must first undergo rigorous drying to remove any moisture present in the material. This step is crucial because residual moisture can vaporize at high temperatures, leading to bubbles or surface defects in the final product. The dried raw materials are fed into the hopper of the injection molding machine and enter the heated barrel under the influence of gravity. The barrel is equipped with a specially designed rotating screw, which not only conveys the material but also generates strong shear forces and mixing effects through its unique geometric structure. The heating system precisely controls the barrel temperature within the melting temperature range of the plastic, typically divided into multiple temperature zones for gradient heating, ensuring uniform heating and gradual melting of the plastic. Under the rotational advancement of the screw, solid plastic pellets undergo a transformation from the glassy state to the high elastic state and ultimately to the viscous flow state, forming a melt with good flowability. This plasticization process requires precise control of parameters such as temperature, pressure, and screw speed.

Step 2: Feeding and Melting Thermoplastic Plastic

The plastic injection molding stage in the injection molding process is one of the most critical steps in the entire process, directly determining the final product’s molding quality and dimensional accuracy. After the plastic raw material is fully melted in the barrel, the injection molding machine enters the high-pressure injection stage. At this point, the hydraulic system drives the screw to advance at a precisely controlled speed and pressure, injecting the molten plastic stored at the front end of the screw through the nozzle into the closed mold cavity. This injection process must be performed under extremely high pressure, typically ranging from tens to hundreds of megapascals, to ensure that the viscous melt can quickly fill every corner of the mold. The mold’s system is carefully designed, including structures such as the main runner, runner, and gate, which collectively guide the flow of the melt and control the filling process. During the filling process, the temperature, pressure, and flow rate at the leading edge of the melt must be strictly monitored, as any fluctuations may result in defects such as short shots, flash, or weld lines.

Step 3: Holding Pressure

In the injection molding process, the holding pressure stage is a critical step in ensuring product quality, directly affecting the dimensional accuracy, mechanical properties, and surface quality of the final product. Once the molten plastic has filled the mold cavity, the system immediately transitions to the holding pressure phase. During this phase, the injection molding machine continues to apply a certain pressure to the plastic melt that has not yet fully solidified. The primary function of this phase is to compensate for the volume shrinkage that occurs during cooling, thereby preventing defects such as dimensional deviations, surface depressions, or internal voids caused by material shrinkage. The holding pressure process requires precise control of three key parameters: holding pressure, holding time, and holding pressure curve. Typically, the holding pressure is set to 30%-80% of the injection pressure, with specific values optimized based on material properties, product structure, and process requirements. Holding time depends on product wall thickness and cooling rate, generally continuing until the plastic at the gate is fully solidified.

Step 4: Holding and cooling time

In the injection molding process, the cooling stage is a critical factor in determining production efficiency and product quality. After the holding pressure stage ends, the molten plastic inside the mold enters a controlled cooling process, which continues until the part achieves sufficient structural strength and dimensional stability to be safely demolded. The cooling process is not simply natural heat dissipation but a precisely controlled heat exchange process. The mold is equipped with a complex cooling channel system that uses circulating cooling media (typically water or oil) to rapidly remove the heat released during plastic solidification. The cooling system design must be scientifically sound, ensuring both cooling efficiency and avoiding internal stress or deformation caused by localized overcooling. The duration of the cooling time depends on multiple factors, including the thermal properties of the plastic material, product wall thickness, mold temperature, and cooling system efficiency. For crystalline plastics such as PP and PE, the impact of crystallinity on product performance must also be considered, making control of cooling rates particularly critical.

Step 5: Ejection and finishing processes

The final critical stage of injection molding is the mold opening and part removal phase, which marks the completion of the entire injection molding cycle. Once the part has cooled sufficiently within the mold cavity and reached the desired hardness, the injection molding machine’s clamping system begins to operate. First, it transitions from high-pressure clamping mode to low-pressure protection mode, then the mold opens smoothly along the parting line according to the pre-set program. The mold opening sequence and speed must be precisely controlled, typically using a three-stage opening curve (slow-fast-slow) to ensure efficient mold opening while avoiding part damage or mold injury caused by sudden separation. After the mold is fully opened, the ejection system installed on the moving mold side begins operation. Ejection mechanisms such as ejector pins, ejector plates, or pneumatic valves move smoothly under hydraulic or mechanical drive to separate the molded part from the mold cavity. The ejection process requires particular attention to controlling ejection speed, stroke, and ejection frequency to ensure complete demolding of the product without defects such as ejection marks or deformation. For complex-structured products, special demolding methods such as sequential operation of multiple ejection mechanisms or rotational demolding may be required.

What are the applications of plastic injection molding?

1. Automotive Industry

Plastic Injection molding plays a pivotal role in the automotive manufacturing sector, encompassing the production of various components ranging from interior to exterior, and from functional to decorative parts. In the automotive interior systems sector, injection molding technology is widely used to manufacture one-piece instrument panels, door trim panels, center console panels, seat armrests, and various storage compartments. These components not only need to meet strict dimensional accuracy requirements but also require excellent tactile feel and aesthetically pleasing surface textures. Injection molding, combined with subsequent processes such as painting, skin coating, or IMD (in-mold decoration), can perfectly achieve these requirements. In the automotive exterior field, injection-molded components such as bumper systems, wheel arch trim strips, and grille assemblies not only feature complex three-dimensional shapes but also meet special performance requirements such as impact resistance and weather resistance.

2. Medical Devices

Plastic Injection molding technology plays an indispensable role in the manufacturing of medical devices, with its applications spanning a wide range of products from basic medical consumables to high-end precision instruments. In the field of disposable medical supplies, injection molding processes are used to mass-produce various sterile syringe components, IV connector fittings, vacuum blood collection tubes, viral sampling tubes, and other disposable medical devices. These products have stringent requirements for dimensional accuracy, surface finish, and sealing performance. In the field of in vitro diagnostics, precision injection-molded microfluidic chips, reagent kit housings, and test card substrates provide reliable technical support for modern molecular diagnostics and point-of-care testing (POCT). In the field of surgical instruments, injection molding technology is used to manufacture laparoscopic instrument handles, hemostat components, surgical suturing devices, and other products.

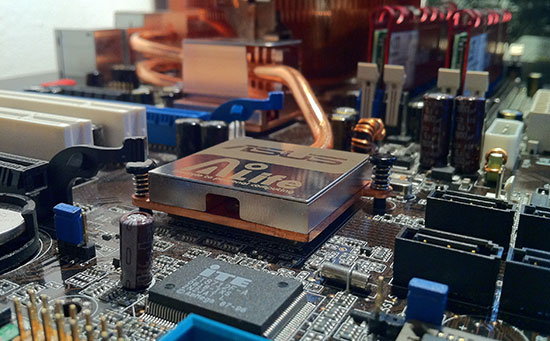

3. Electronics and Electrical Appliances

Plastic Injection molding technology plays a crucial role in the electronics and electrical appliance manufacturing industry, with its applications permeating virtually every stage of the supply chain for various electronic products. In the consumer electronics sector, injection molding processes are widely used in the production of smartphone casings, laptop structural components, smartwatch cases, and other products. These products not only require extremely high dimensional accuracy and surface finish quality but must also meet modern design demands for lightweight, slim profiles and one-piece construction. Electronic connectors are another important application area for injection molding, including precision components such as USB ports, Type-C connectors, and board-to-board connectors. These products have extremely stringent requirements for dimensional stability and insulation performance, with tolerances often controlled within ±0.02mm. In the field of home appliances, components such as air conditioner panels, washing machine control panels, and refrigerator door handles manufactured through injection molding must not only meet structural strength requirements but also possess excellent weather resistance and flame-retardant properties.

Advantages of plastic injection molding

1. High Forming Efficiency

Plastic injection molding stands out in manufacturing for its exceptional production efficiency. This process uses a fully automated production flow, enabling continuous, uninterrupted operation from raw material input to finished product output. A typical injection molding cycle usually ranges from 15 to 120 seconds, depending on product size and complexity. Modern high-speed injection molding machines can achieve up to hundreds of molding cycles per minute, making them particularly suitable for the production of components requiring large-scale manufacturing. Compared to traditional machining or manual molding, injection molding can save over 90% of production time. Additionally, the application of multi-cavity mold technology enables the simultaneous molding of dozens of identical products in a single injection, further increasing output per unit of time. This highly efficient production method significantly reduces the manufacturing cost per unit, providing an ideal solution for large-scale industrial production.

2. High precision and good repeatability

The Plastic injection molding process has outstanding advantages in terms of dimensional accuracy and product consistency. Advanced injection molding equipment combined with precision-machined molds can achieve ultra-high dimensional tolerances of ±0.01mm, meeting the most stringent requirements for precision parts. This level of precision is critical for products such as electronic connectors and medical devices that are highly sensitive to dimensional accuracy. In terms of repeatability, injection-molded products exhibit minimal variation between batches, with CPK values typically exceeding 1.67, ensuring that each product in large-scale production has identical quality characteristics. Modern injection molding machines are equipped with closed-loop control systems that monitor and adjust process parameters in real time, further ensuring production stability.

3. Wide range of applicable materials

The plastic injection molding process exhibits exceptional material adaptability, capable of processing nearly all types of polymer materials. In terms of thermoplastic plastics, materials ranging from general-purpose plastics like PP and ABS to engineering plastics like PC and POM, as well as high-performance plastics like PEEK and PEI, can all be processed via injection molding. Thermosetting plastics like phenolic resin and epoxy resin are also suitable for specialized injection molding processes. Additionally, various elastomers (TPE, TPU), bio-based plastics, and biodegradable materials are increasingly being applied in injection molding. By adjusting material formulations, products with specific properties can be produced, such as flame-retardant grades, UV-resistant grades, conductive grades, or electromagnetic shielding grades.

Disadvantages of plastic injection molding

1. High mold costs

The plastic injection molding process has significant economic barriers in terms of mold investment. A set of moderately complex injection molds typically requires an investment of 50,000 to 500,000 yuan for production costs, while high-precision or multi-cavity molds can cost up to several million yuan. The mold manufacturing process involves multiple steps, such as precision mechanical processing, heat treatment, and surface treatment, with a production cycle of 4 to 12 weeks from design to delivery. This high upfront investment makes the economic viability of injection molding only fully realized in large-scale production (typically requiring 5,000 units or more). For prototype validation or small-scale trial production during the early stages of product development, alternative processes such as 3D printing or silicone molds may offer greater cost advantages. Additionally, mold maintenance and storage require ongoing investment, further increasing the total cost of ownership.

2. Inflexible design modifications

Plastic injection molding exhibits significant rigidity when it comes to product design changes. As precision tools made of steel, molds are difficult to modify significantly once they have been manufactured. Even simple dimensional adjustments may require re-machining the core or cavity, while structural design changes often necessitate scrapping the existing mold and creating a new one. Such modifications not only incur additional machining costs (typically 30%-70% of the original mold cost) but also result in production delays of 2-4 weeks. During product development iterations, this inflexibility forces companies to complete all design validation before mold manufacturing, increasing the risks and costs of early-stage development.

3. Product dimensions are limited by mold constraints

Plastic injection molding inherently has process constraints regarding product dimensions. From an equipment perspective, the maximum molding dimensions are limited by the clamping force and mold cavity space of the injection molding machine. Currently, the largest injection molding machines on the market can produce products approximately 4 meters in length; however, the investment and operational costs for such equipment are extremely high. Ultra-thin-walled products (e.g., those with thicknesses less than 0.5 mm) impose extremely high demands on mold precision and process control. These limitations necessitate the exploration of alternative processes for certain applications with special size requirements. For example, large products may be better suited for rotomolding or blow molding, while micro-precision parts may require micro-injection molding or stamping. Additionally, increasing product dimensions significantly prolongs cooling time, impacting overall production efficiency.

FAQs for Plastic Injection Molding

How long does it take to produce parts with plastic injection molding?

The time required to produce parts with plastic injection molding depends on several factors, including part size, design complexity, material type, and production volume.

What factors affect the quality of injection-molded parts?

The quality of injection molded parts is mainly affected by mold design, material selection, processing parameters, machine condition, and operator skill. Good design, proper materials, accurate settings, and well-maintained equipment help ensure consistent, defect-free parts.