What is Electrical Discharge Machining

Electrical Discharge Machining shapes metal with electrical sparks. Traditional machining uses tools to cut material. Both methods have their strengths. Electrical Discharge Machining works on very hard, conductive metals. It makes complex shapes with high precision and smooth surfaces. Traditional machining is faster and works on more types of materials. It can cut non-conductive materials too. But it may have trouble with hard metals and tiny details. Understanding the differences in accuracy, materials, cost, speed, and usage will help you complete your projects more efficiently and economically.

Key Takeaways

- Electrical Discharge Machining (EDM) shapes hard metals with sparks. It uses electricity and does not touch the metal. EDM is very exact and works only on metals that conduct electricity.

- Traditional machining uses sharp tools to cut many materials. It can shape plastics and metals. It is faster for simple shapes or big parts.

- EDM is great for making tricky shapes and tiny details. It also makes smooth surfaces. But EDM costs more money and takes more time than regular machining.

- Traditional machining can do many jobs and save money on big projects. But it has trouble with very hard metals and small details.

- You should choose a method based on the material, shape, and the level of accuracy required. Consider how many parts you need and your budget as well.

Key Differences

Comparison Table

| Aspect | Electrical Discharge Machining (EDM) | Traditional Machining |

| Contact Method | EDM does not touch the metal. It uses sparks. | Traditional machining touches the material with tools. |

| Material Compatibility | EDM works only on hard, conductive metals. | Traditional machining works on most materials. |

| Speed | EDM is slower, especially for hard shapes. | Traditional machining is faster for big, simple parts. |

| Cost | EDM costs more because it is slower. | Traditional machining costs less for easy shapes. |

| Precision | EDM is very precise and makes tiny details. | Traditional machining is good but less precise. |

| Complexity | EDM can make sharp corners and complex shapes. | Traditional machining has trouble with tiny parts. |

| Surface Finish | EDM makes smooth surfaces and needs no extra work. | Traditional machining may need more finishing steps. |

| Tool Wear | EDM tools last longer since there is no contact. | Traditional machining tools wear out faster. |

| Environmental Impact | EDM uses more energy and makes toxic gases. | Traditional machining uses less energy and is cleaner. |

| Operator Skill | EDM needs a skilled person to set up and run. | Traditional machining requires less skill with machines. |

Main Contrasts

Electrical Discharge Machining takes away metal with sparks, not force. This lets it cut hard metals like titanium. EDM can make deep holes and sharp corners. It also makes smooth surfaces, and the tool does not wear out fast. NOBLE specializes in precision EDM processes that handle complex geometries while maintaining superior surface finishes. But EDM only works on metals that conduct electricity. It also takes more time and energy to finish a part. EDM can make toxic gases, so waste must be handled carefully.

Traditional machining shapes things with cutting tools. It works on many metals and plastics, even if they do not conduct electricity. This method is faster and cheaper for big or simple parts. But it cannot cut very hard metals well. It also cannot make tiny shapes as easily as EDM. At NOBLE, we integrate both traditional and advanced machining to offer the best solution for each project’s unique demands. The tools wear out and sometimes need to be replaced. Extra steps may be needed to make the surface smooth. Machines can help make the work easier and require less skill.

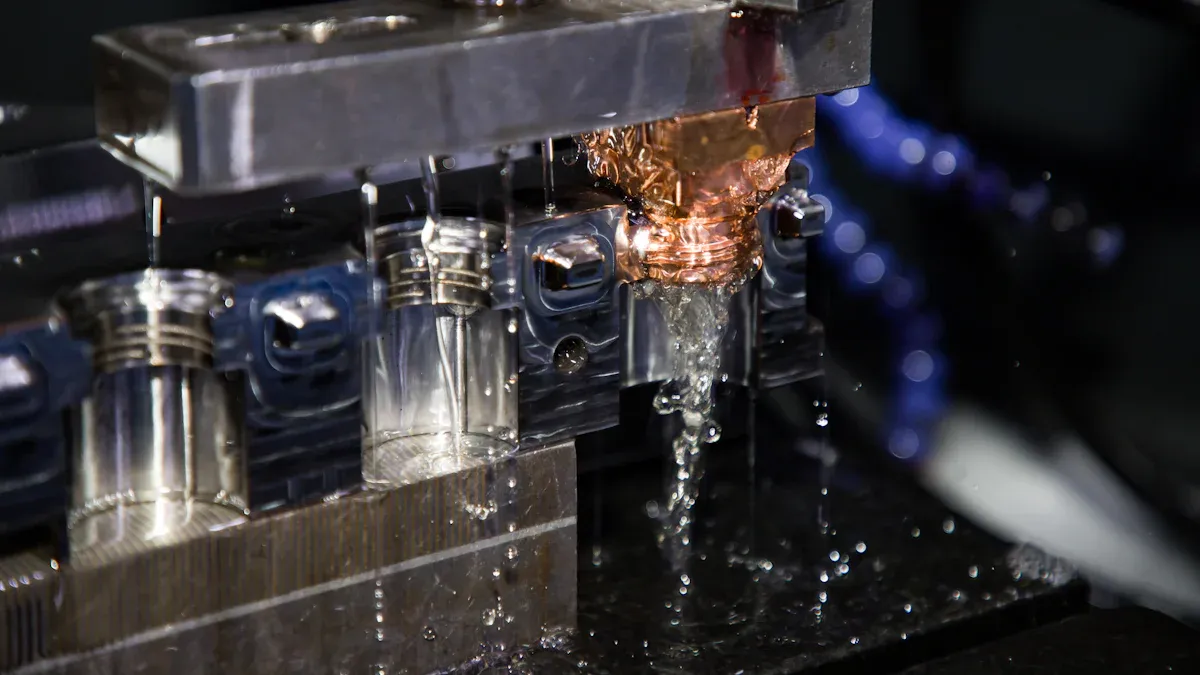

How Electrical Discharge Machining Works

Electrical Discharge Machining shapes metal using sparks. It only works on materials that let electricity flow. The tool and the metal part act like electrodes. When they get close, a spark jumps between them. This spark makes a lot of heat. The heat melts and turns small bits of metal into gas. The tool never touches the metal. The spark does all the work instead. Both the tool and the metal part stay in a special liquid called dielectric fluid. This fluid cools everything and washes away melted metal. Unlike traditional machining, there is no cutting or pushing. Electrical Discharge Machining removes metal without touching it. This way, it can make very exact shapes, sharp corners, and deep holes. It also works well on hard metals that are tough to cut with normal tools.

Note: Electrical Discharge Machining can make tricky parts without heating them up. This keeps the metal strong and steady.

Types of Electrical Discharge Machining

There are three main types of Electrical Discharge Machining. Each type uses a different way to shape metal and fits different jobs.

| EDM Type | How It Works | Common Uses | Key Features |

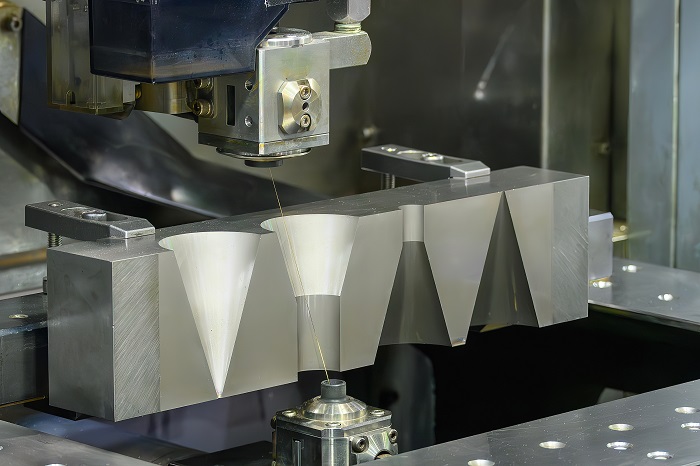

| Wire EDM | Uses a thin wire to cut metal with sparks. The wire moves along a path in water. | Cutting tricky shapes, making tools, medical devices, and airplane parts. | Very exact, no touching, works on hard metals. |

| Sinker (Conventional) EDM | Uses a shaped tool that sinks into the metal to make holes or shapes. The part and tool sit in a fluid. | Making molds, dies, and parts with deep or tricky shapes. | Good for 3D shapes, sharp corners, and smooth finish. |

| Hole Drilling EDM | Uses a hollow tube to drill small, deep holes with sparks. Fluid flows through the tube. | Drilling cooling holes in turbine blades, starting cuts for wire EDM, and medical parts. | Makes tiny, deep holes, works at any angle. |

Each type of EDM has its special uses. Wire EDM cuts detailed shapes. Sinker EDM makes deep holes and shapes. Hole Drilling EDM enables the creation of small, deep holes quickly. NOBLE offers all major EDM methods, delivering tailored solutions for aerospace, automotive, and medical industries with unmatched precision and reliability.

Traditional CNC Machining

Common Methods

Traditional machining uses many ways to shape materials. Each way uses a special tool and movement to take away material. The most common traditional machining methods are:

- CNC Milling: A spinning tool cuts away material from flat or shaped surfaces. Milling machines can make hard shapes for cars, planes, and machines.

- CNC Turning: The part spins while a still tool shapes it. Turning makes round things like rods and shafts.

- CNC Drilling: A spinning drill bit makes round holes in the material. Drilling is simple and is used a lot in machining.

- CNC Grinding: A rough wheel takes off small bits for a smooth finish. Grinding helps make parts look better and fit well.

- CNC Sawing: A blade with teeth or grit cuts the material into pieces. Sawing gets material ready for more work.

- CNC Boring: A tool makes holes bigger and more exact.

- CNC Broaching: A tool with teeth cuts shapes inside or outside in one go, like for gears.

- CNC Shaping: A tool moves back and forth to make flat, curved, or slotted surfaces.

How It Works

Traditional machining uses cutting to shape things. Machines and strong tools, often made from carbide steel or high-speed steel, cut away material from a part. The tool and the material move in a controlled way. The tool or the part can spin, move straight, or move back and forth.

Milling machines use a spinning cutter with sharp teeth. The cutter cuts away material as it moves over the part. Turning uses a lathe to spin the part while a tool shapes it along its side. CNC Drilling uses a spinning bit to make holes. CNC Grinding uses a rough wheel to take off tiny bits and make the part smooth. Sawing cuts material with a blade, and broaching takes away material in one pass with a toothed tool.

These ways use the idea of moving the tool and part in set paths. Material is taken away by cutting, rubbing, or scraping. This lets people control the final shape and size of the part. Traditional machining works on many materials, like metals and plastics, so it is good for many jobs.

NOBLE combines these versatile traditional machining techniques with modern expertise to deliver consistent accuracy, fast turnaround times, and outstanding service for projects of any scale.

EDM Pros and Cons

Advantages of EDM

Electrical Discharge Machining has many good points for making things today. Many companies pick this method because it has special features:

- The tool does not touch the part. This stops marks, burrs, and bending.

- EDM works well with thin or fragile parts. It can also shape hard metals without hurting them.

- The method makes very exact parts with smooth surfaces. Most parts do not need much polishing after.

- EDM can make shapes and inside details that cutting tools cannot do.

- Machines can run by themselves with things like auto wire threading. This helps the machine work longer and better.

- Computers watch the process and help save energy. They also help fix problems before they get big.

- EDM makes parts with no burrs. This saves time because you do not need extra steps.

- The process can shape very hard or rare metals with great accuracy. This is good for planes, medical tools, and making other tools.

- New ideas help EDM use less energy and safer fluids. Better ways to handle waste help the planet.

Note: EDM is great for making tiny or weak parts. It keeps them from bending and gives a smooth, exact finish.

Limitations of EDM

Even though Electrical Discharge Machining is strong, it has some problems. The table below shows the main problems, what they cause, and how to fix them:

| Limitation | Description | Impact on Adoption | Remedies / Mitigation Efforts |

| Processing Speed | EDM takes off metal slowly. | Not good for big jobs or making lots of parts. | Use better pulse makers, stronger electrodes, and more robots. |

| Electrode Wear | Electrodes get used up over time. | Costs more and makes parts less exact. | Pick tough materials and use auto fixes. |

| Surface Integrity | Parts can get tiny cracks or holes. | May need more work for some uses. | Change settings and use heat or polish after. |

| Processing Costs | Electrodes, fixing, and power cost a lot. | It can be too pricey for small shops. | Use cheaper stuff and save more energy. |

| Material Limitations | Only works on things that carry electricity. | Cannot shape plastics or ceramics. | Try new EDM types to work on more things. |

| Depth-to-Width Ratios | Deep, skinny shapes are hard to make. | Stops some tricky or deep part designs. | Use special electrodes and better cooling. |

| Environmental Impact | Some materials and fluids can hurt nature. | May not fit with green goals. | Use safer fluids and better waste care. |

| Equipment Costs | Fancy machines cost a lot at first. | Small shops may not have enough money. | Rent or buy used machines. |

EDM only works on things that let electricity pass through. This means it cannot shape plastics or ceramics. Electrodes wear out, and rough surfaces can make parts worse and cost more. EDM is slower than old methods, so it is not good for making lots of parts fast. Some parts need more work to fix the surface. EDM uses more power and can produce waste that needs safe handling. The machines cost a lot, which is hard for small shops. NOBLE helps clients weigh the trade-offs and benefits, offering expert guidance and advanced EDM capabilities for jobs that demand extreme accuracy and complex shapes. For jobs that need exact cuts or tricky shapes, EDM is still a great pick.

Traditional CNC Machining Pros and Cons

Advantages of Traditional CNC Machining

Traditional machining has many good points for makers. These ways include milling, turning, drilling, and grinding. They have helped factories for a long time.

- Versatility: Traditional machining works on many kinds of materials. People can cut metals, plastics, or even wood. This makes it helpful for lots of jobs.

- Speed for Simple Parts: Machines like lathes and mills shape easy parts fast. Big groups of simple pieces move through the shop quickly in these ways.

- Lower Initial Costs: Many shops already have these machines. Starting a new job costs less because no new tools are needed.

- Ease of Setup: Workers can get machines ready fast for easy jobs. Small design changes only need a few fixes.

- Availability of Skilled Workers: Many workers know how to use these machines. Teaching new people is faster since the tools are common.

- Good for Prototyping: Shops can make one part or a test piece quickly. This helps engineers try ideas before making lots of parts.

- No Need for Conductive Materials: Unlike EDM, traditional machining does not need the material to carry electricity. This gives more choices for what to use.

Limitations of Traditional CNC Machining

Traditional machining also has some problems. These can change how much things cost, how fast work gets done, and how good the parts are.

| Limitation | Impact on Manufacturing Efficiency |

| Material Waste | Makes more scrap, which costs more and can hurt nature |

| Longer Lead Times | Slows down work, especially for hard shapes |

| Higher Costs for Small Batches | Makes small jobs cost more because of setup and tool changes |

Traditional machining cuts away material, so there is a lot of scrap. This waste costs more money and can be bad for the planet. Shops must pay for the extra material and to throw away the scraps.

People must control the machines by hand. Skilled workers set up and run the machines. This takes time and can lead to mistakes. People can make errors, so some parts may not be right. Different workers or shifts can make parts turn out differently.

Making hard shapes slows down the work. Workers must stop to change tools or move the part. Each step adds more time. Many steps make the job take longer, especially for tricky shapes.

Small jobs cost more money. Each new job may need special tools or holders. Setting up for just a few parts spreads the cost over fewer pieces. This makes each part cost more than if you made a lot.

Labor costs go up with traditional machining. Skilled workers get paid more. Setting up and fixing machines by hand takes more time. All these things make each part cost more.

Shops using traditional machining must think about speed, cost, and quality. For hard shapes or very exact work, other ways like EDM or CNC machining might work better.

NOBLE addresses these challenges by blending expert craftsmanship with modern technologies, offering optimized machining strategies that reduce waste, speed up production, and maintain high part consistency.

Application of EDM & traditional CNC machining

Application of EDM

Many companies use Electrical Discharge Machining for special jobs. This method is good for hard metals and tricky shapes. It can make parts that other tools cannot make. Some common uses are:

- Small hole drilling: Factories use EDM to make tiny holes in turbine blades and fuel systems. The holes stay straight, and the tool does not break.

- Mold and die making: EDM shapes deep holes and forms in molds and dies. This helps make plastic parts and metal stamps.

- Removing stuck parts: Workers use EDM to get out broken bolts or pins. It does not hurt the main part.

- Medical components: EDM makes smooth, burr-free parts for medical implants. These parts must be exact and safe.

- Aerospace components: EDM makes thin slots, sharp corners, and deep holes in airplane parts.

EDM can work on any metal that carries electricity, even very hard ones. The tool never touches the part, so it does not bend or shake. New controls and smart machines help EDM work faster and make better parts. NOBLE invests in cutting-edge EDM technology to deliver high-precision parts with complex geometries that meet the most stringent industry standards. Many of our customers will request EDM for jobs that require great precision or have specialized shapes.

Traditional CNC Machining of Application

Traditional machining shapes and finishes many kinds of materials. These ways include turning, milling, drilling, tapping, planing, knurling, sawing, and shaping. NOBLE often uses them to accomplish many of these jobs:

- Shaping and sizing: Machines cut and shape metal, plastic, and other stuff to the right size and form.

- Threaded parts: Tapping makes screws and bolts with threads.

- Flat surfaces: Planing and shaping make big, flat areas on metal parts.

- Grip and decoration: Knurling adds patterns for better grip or looks.

- Cutting large pieces: Sawing cuts big parts into smaller pieces.

- General material removal: Turning, milling, and drilling take away extra material to get the final shape.

These ways are important for making cars, planes, electronics, and metal parts. NOBLE also has excellent CNC machining capabilities, combining precision CNC systems with specialized machining technology to produce high-quality parts for critical industries.

Material Compatibility

EDM Materials

Electrical Discharge Machining works only with materials that carry electricity. It uses sparks to wear away the metal. The part must let electricity pass through it. Metals like hardened tool steels, high-speed steels, titanium, and nickel-based superalloys are often used. Copper, aluminum, and their mixes also work well. Some graphite and a few ceramics can be used if they conduct electricity. These materials are very hard and can withstand a lot of heat. This makes them hard to cut with normal tools. Aerospace, car, and medical companies use EDM for parts with tricky shapes or tiny details. Non-conductive things, like most plastics and some ceramics, do not work with wire EDM. Sparks cannot form in these materials.

Traditional CNC Machining Materials

Traditional machining can shape many kinds of materials. It works on metals, plastics, and some ceramics. Many shops use plastics like HDPE and PVC. These plastics bend easily, do not get hurt by chemicals, and are simple to machine. Picking the right tool is important. High-speed steel tools are good for soft plastics. Carbide or diamond-tipped tools are better for tough plastics. Shops must watch heat and stress so parts do not bend or crack. High Efficiency Milling helps keep things cool and makes parts look better. Hard metals, like steels over 45 HRc, can be cut with hard turning and special tools like ceramic or CBN. NOBLE brings expert processing capabilities to these applications, ensuring precision and material integrity even in the most demanding projects. Diamond and CBN tools also help with composites and some ceramics. These ways let shops remove lots of material fast and make smooth parts.

- Traditional machining can work with:

- Metals (steel, aluminum, brass, copper)

- Plastics (HDPE, PVC, acrylic)

- Some ceramics and composites

- Wood and other soft stuff

Precision and Surface Finish in EDM

Tolerances

Precision is important in every machining job. Each method gives a different level of accuracy. The table below shows how well each method can hold tight sizes:

| Machining Method | Typical Tolerance Achievable | Notes |

| Wire EDM | ±0.005 mm | Uses a thin wire electrode; creates fine details and intricate parts; non-contact process reduces material stress; can cut inside corners with radii as small as 0.003 inches. |

| Sinker EDM | ±0.001 mm | Uses shaped graphite or metallic electrode; effective for complex geometries; achieves exceptional precision. |

| Traditional CNC Machining | Limited accuracy compared to EDM | Accuracy and material types are more restricted; less suitable for extremely tight tolerances or complex conductive materials. |

Electrical Discharge Machining is great for making very exact parts. Sinker EDM can make parts with sizes as close as ±0.001 mm. Wire EDM is also very accurate. It is good for parts with tiny details. NOBLE’s advanced EDM capabilities consistently achieve ultra-tight tolerances and fine features that traditional machining often cannot match. Traditional machining, like CNC milling or turning, is not as exact as EDM. It has trouble with hard or tricky shapes. NOBLE’s advanced EDM capabilities consistently achieve ultra-tight tolerances and fine features that traditional machining often cannot match, backed by excellent service and a focus on quality.

Surface Quality

How smooth a part is matters for how it looks and works. Each way of machining leaves its own mark on the part.

- Wire EDM makes a recast layer when it cuts rough shapes. This layer forms because sparks make a lot of heat.

- Doing more finishing passes with Wire EDM makes the recast layer thinner and the surface smoother.

- Sometimes, the recast layer can cause problems. This can make Wire EDM not the best choice for some parts.

- More finishing passes in EDM help make the surface better and fix problems.

- EDM melts and turns metal into gas to remove it. This leaves a new layer of metal on the part.

- The recast layer can have bits from the tool and the fluid. These can change how the part works.

- How rough the surface is in EDM depends on the settings and how many times it goes over the part.

- Traditional machining does not make a recast layer. It usually leaves a cleaner surface, but can have trouble with hard or tricky shapes.

- EDM is good for hard or tricky metals but needs careful settings to get the best finish.

Cost and Speed

Setup and Operation

Cost and speed are important when picking between Electrical Discharge Machining and traditional machining. The money needed to start and run each method can be very different. The table below shows how they compare:

| Cost Aspect | Electrical Discharge Machining (EDM) | Traditional Machining Methods |

| Setup Costs | High initial equipment cost ($100,000 to $500,000+ for Wire EDM machines); tooling costs also higher | Generally lower initial setup costs; tooling is less expensive initially |

| Operational Costs (Hourly) | $60 to $200+ per hour, including machine depreciation, electricity, wire consumption, labor, and maintenance | Typically lower hourly operational costs, but can increase with complex tooling and materials |

| Material Handling | Efficient for hardened materials; no need for pre/post heat treatment | May require additional processing for hardened materials (heat treatment) |

| Machining Complexity | Cost-effective for intricate geometries and fine surface finishes; reduces secondary operations | Less efficient for complex shapes; may require multiple setups and secondary finishing |

| Additional Benefits | Burr-free edges, no cutting forces, reduced scrap and rework, fine surface finish, reducing polishing/grinding | May produce burrs; cutting forces can cause distortion; additional finishing is often needed |

| Outsourcing Options | Professional EDM services reduce initial investment and operational costs | Outsourcing traditional machining is also possible, but less specialized for complex parts |

EDM machines cost a lot to buy and set up. They use more power and special supplies, so they cost more each hour. EDM is good for hard metals and tricky shapes. It can save money because you do not need as many extra steps. Traditional machining is cheaper to start and run, especially for easy jobs.

Production Rate

How fast a shop can make parts is important. EDM is usually slower than traditional machining. This is true when taking off a lot of material or working with thick pieces. EDM speed depends on things like how long the spark lasts, how strong it is, the space between the tool and part, and how fast things cool. Making EDM faster can wear out tools and make rougher parts. Shops must pick the right settings to get good results. With deep technical knowledge and efficient processing strategies, NOBLE helps clients balance speed and precision in EDM projects.

Traditional machining takes away material quickly. It is best for making lots of parts or rough shapes. This makes it a good choice for big jobs. EDM is better for making tricky shapes, small details, or working with hard metals. EDM trades speed for better detail and quality.

- Traditional machining is faster and costs less to make many parts.

- EDM is better for small batches, test parts, or tricky shapes.

- EDM makes less waste and needs less work for special parts, but costs more for big jobs.

- EDM uses more power and takes longer, so it is not as good for making lots of parts.

Choosing the Right Method

Decision Factors

Picking the best way to machine a part depends on many things. Every project is different and needs its own plan. The table below shows how EDM and traditional machining compare:

| Decision Factor | EDM | Traditional Machining |

| Part Complexity | Best for intricate, tight-tolerance parts | Better for simple, large parts |

| Material Type | Works with hard, conductive metals | Handles many materials, including plastics |

| Production Volume | Good for low to medium quantities | Best for high-volume runs |

| Tolerance and Precision | Very high precision | Less precise, risk of heat deformation |

| Initial Investment | Higher equipment cost | Lower cost, easier for small shops |

| Size of Workpiece | Small to medium, complex parts | Large workpieces |

| Industry Applications | Aerospace, medical, electronics | Automotive, oil and gas |

| Machining Efficiency | Slower, but smooth finish | Faster, cost-effective for simple parts |

| Material Properties | Needs electrical conductivity | Less dependent on material properties |

| Compatibility | Needs dielectric fluid | No fluid requirement |

The kind of material is important when picking a method. EDM only works with metals that let electricity pass through. These metals must also be able to handle heat and not wear out fast. This makes EDM good for hard metals that are hard to cut with normal tools. If you’re not sure what process is best for your project, our dedicated team of engineers may have the answer.

Practical Scenarios

Here are some real-life examples to help you know when to use each way:

- Aerospace: Engineers use EDM to make turbine blades with tiny holes. These parts need to be very exact and use hard metals. EDM gives the right size and smooth finish.

- Medical Devices: EDM makes small holes and slots in implants. The process does not put stress on the parts, so they stay safe.

- Automotive: Factories use traditional machining for engine blocks and big parts. This way is fast and works with many materials.

- Mold Making: EDM shapes hard steel molds with deep, tricky features. Even though EDM costs more and uses more energy, it can do jobs that other tools cannot.

- Electronics: EDM drills tiny holes in connectors. It makes very small sizes and smooth surfaces.

EDM is best for small groups of parts, tricky shapes, and hard metals. Traditional machining is better for big, simple parts and making lots of them. Both ways have good points. The best choice depends on project needs, materials, and funding.NOBLE will help you choose the right approach by evaluating each project’s goals, materials, and budget to provide the most effective manufacturing solution.

Whether you choose EDM or conventional machining depends on your project needs, and NOBLE’s experts say EDM is great for making precise, tricky parts with hard materials and a smooth surface. But it takes more time and costs more. To choose the best method, NOBLE recommends you take the following steps:

- Decide what you want to make and what materials you need.

- Think about how hard the shape is and how exact it must be.

- Make sure you have clear drawings that show all the details.

- Talk and work with people who know a lot about machining.

Why choose NOBLE as your trusted EDM supplier

NOBLE was chosen as the manufacturer because of its unmatched ability to deliver both Electrical Discharge Machining (EDM) and traditional machining services with exceptional precision, flexibility, and reliability. The strengths of each machining method come with trade-offs, but NOBLE bridges that gap by offering the best of both worlds—integrating advanced EDM technology with proven traditional machining techniques to provide custom solutions tailored to the unique requirements of each project.

NOBLE stands out for several reasons:

- Expertise in Complex EDM Projects: NOBLE specializes in high-precision EDM work, including Wire, Sinker, and Hole Drilling EDM, which are essential for industries that demand intricate geometries, such as aerospace, medical, and electronics. Our skilled technicians routinely produce tight-tolerance parts that conventional methods simply can’t match.

- Dual Capability Approach: Unlike many shops that focus solely on either EDM or conventional machining, NOBLE uses both. This allows us to recommend the most efficient, cost-effective process—or a combination of both—to meet your design, material, and volume needs.

- Advanced Technology and Equipment: NOBLE invests in the latest EDM systems and CNC machines, ensuring consistent performance, high repeatability, and the ability to machine difficult materials like hardened steels and exotic alloys with minimal finishing required.

- Application-Driven Decision Making: Our engineering team evaluates every project to determine whether EDM, traditional machining, or a hybrid strategy will produce the best results. This consultative approach ensures clients receive the right process for their part, not just the one that’s most convenient for us to run.

- Proven Industry Results: NOBLE has a track record of delivering parts to demanding specifications in industries where failure is not an option. From turbine blades to medical implants, clients choose NOBLE because we understand the importance of precision, safety, and reliability.

- Scalable Solutions: Whether you need a one-off prototype, a short run of precision parts, or a high-volume production of machined components, NOBLE is equipped to scale its operations while maintaining quality and speed.

NOBLE wasn’t just a machining vendor—it was the clear choice for a partner capable of navigating the complex balance between precision, speed, cost, and material compatibility. When your project requires expertise, accuracy, and innovation, NOBLE delivers.

FAQ of Electrical Discharge Machining

What materials can Electrical Discharge Machining cut?

EDM only works on things that let electricity pass through. This means it can cut steel, titanium, copper, and some special mixes. EDM does not work on plastics or most ceramics.

Note: EDM cannot cut wood or most plastics.

Is EDM safer than traditional machining?

EDM does not make sharp chips or edges that can fly off. It uses a liquid to keep parts cool. But EDM can make bad fumes. Workers need to wear the right safety gear.

Why do some parts need EDM instead of traditional machining?

Some parts have very small holes or sharp corners. EDM can make these shapes very accurately. Traditional machining cannot always make such tiny details.

Which method is faster for making many parts?

Traditional machining is faster for making lots of simple parts. EDM takes longer, especially for thick or tricky shapes.

- EDM: Good for small groups or detailed jobs.

- Traditional: Good for making many simple parts.