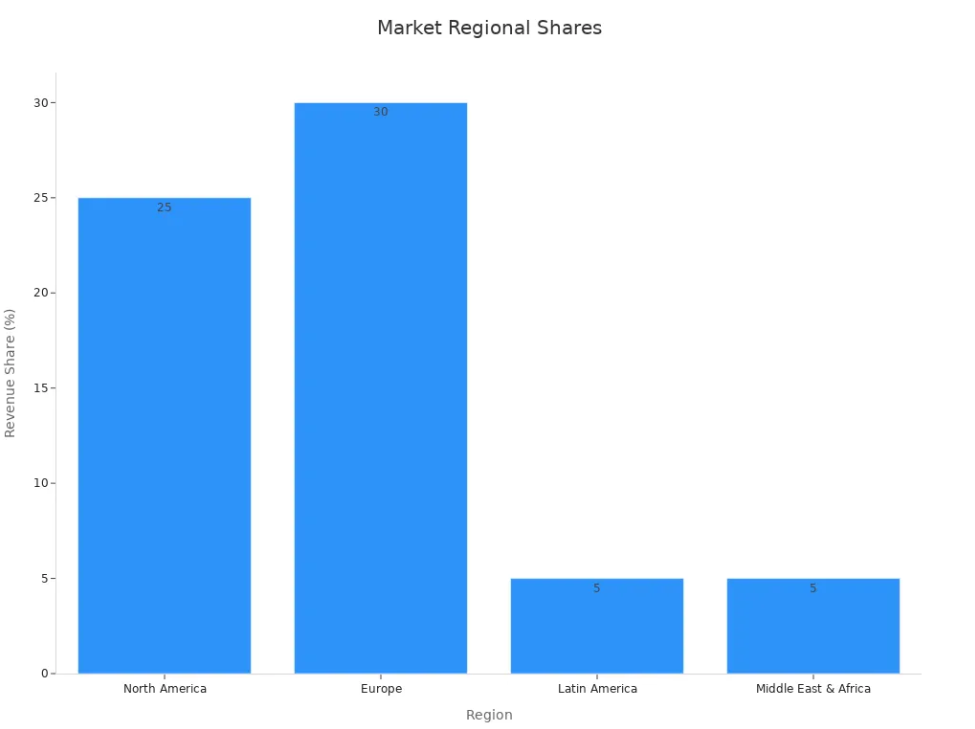

If you want your metal stuff to look cooler and hold up better, chrome plating is the way to go. It gives parts a shiny, almost mirror-like surface and keeps rust and scratches at bay. The process takes a few steps—starting with cleaning and ending with layers of metal—to get that classic chrome shine. The chrome plating market is growing, and by 2032, global chrome plating will be worth more than $26 billion. See how different regions compare:

Chrome Plating Overview

What Is Chrome Plating

Ever notice how some metal parts are super shiny and seem tough as nails? That’s chrome plating at work. Chrome plating is a special process that covers metal objects with a thin layer of chromium. This layer gives parts a bright, mirror-like finish and helps protect them from rust and scratches. You see chrome plating on car bumpers, tools, and even kitchen faucets. The process uses electricity to move chromium onto the surface, making it stick tightly and last longer.

Tip: Chrome plating isn’t just for looks—it makes stuff tougher and helps protect it from water, air, and everyday damage.

Chrome Plating Types

Decorative Chrome

You see decorative chrome on stuff like car trim, bathroom taps, and bike parts. It’s a thin layer of chromium usually put on top of nickel. It makes things shiny and gives some protection, but mostly, it’s all about making things look cool and clean.

Hard Chrome (Industrial Chrome)

Hard chrome, sometimes called industrial chrome, is way thicker than the decorative stuff. You’ll find it in machine parts, engines, and tools. It makes those parts tougher and helps them wear out less fast. Factories use it to keep everything running without a hitch.

Thin Dense Chrome (TDC)

Thin Dense Chrome (TDC) takes hard chrome to the next level with a thinner, tighter layer that’s tough and smooth. It’s perfect for precision tools and parts that must glide effortlessly without sticking. If you want durability with finesse, TDC is the choice.

Chrome Plating Process

Chrome plating looks easy, but there are a bunch of important steps. Each one helps make sure the finish is shiny and tough. Let’s check out how NOBLE gets the job done, start to finish.

Preparation

Before plating, proper surface prep is key. If this step is missed or rushed, the chrome won’t stick, causing peeling, dull areas, or rust down the line.

Cleaning

Start by cleaning the metal parts. This step removes dirt, oil, and old coatings. The following usually happens:

- Hand washing can be used to remove loose dirt and grime.

- Emulsion cleaning, alkaline cleaning, or solvent cleaning helps remove oil and organic matter.

- Electrolytic cleaning uses electricity to remove stubborn stains and oxides.

- Multiple rinses of the part are required to wash away residual chemicals.

- Sometimes, an acidic or alkaline activation solution is used to make the surface ready for plating.

- Different metals require different cleaning solutions for best results.

- Good cleaning helps the chrome layer adhere and keeps the surface flat.

If not cleaned or rushed, problems such as uneven coating, flaking, or rusting may occur. The surface of cleaned parts is strong and smooth.

Polishing

Once the parts are clean, we start polishing. Polishing gets rid of scratches and little dents. We want the surface smooth and shiny before plating.

- It helps the chrome layer look bright and even.

- It makes it easier to spot any dents or flaws before we move on.

- Polishing with a soft cloth or chrome polish brings out the shine.

If the plating looks dull or rough in spots, chances are the part didn’t get polished well enough beforehand.

Plating Steps

Now we’re ready for the main event. Chrome plating uses several layers to build up that tough, shiny finish.

Acid Dip

Next, dip the part in an acid bath to get rid of leftover rust or oxidation. It also helps the next layers stick better. Just make sure to rinse it off afterward!

Zinc and Copper Layers

Some parts get a thin layer of zinc or copper first. It helps protect the metal underneath and makes the surface smoother. Copper’s especially good at filling little pits and scratches. Not all parts need this, but it helps with rough or stubborn surfaces.

Nickel Layer

Next up, we add the nickel layer. That’s where most of the shine comes from, and it helps stop rust too. It also makes the surface nice and smooth, so the chrome looks great. For decorative parts, we usually lay down a thick base of nickel first.

Chromium Layer

Finally, we add the chrome layer. That’s what gives the part its shiny, mirror-like look. The thickness of this layer depends on what you need:

| Plating Type | Decorative Chromium | Hard Chrome Plating |

| Thickness Range | 0.5 to 2 micrometers | 12.7 to 254 micrometers (0.0005 to 0.01 inches) |

| Cathodic Current Density Range | 10 to 20 A/dm² | 20 to 50 A/dm² |

| Temperature Range (°C) | 25 to 45 | 54 to 60 |

| Cathode Efficiency (%) | 8 to 25 | 10 to 26 |

| Hardness (HV) | N/A | 800 to 1200 |

| Micro-cracking (cracks/inch) | N/A | 0 to 5000 |

| Brightness | Varies | Semi-bright to Very Bright |

How long plating takes depends on how thick you want it. Thin chrome? Just a few minutes. Thicker stuff for machines? That can take hours or even days. Thin dense chrome takes longer to build, but it ends up super strong and tough.

Tip: If you want a part that looks great but doesn’t need to be super hard, use a thin plating. If you need a part that will last under heavy use, use a thicker plating.

Post-Treatment

Just because the chrome’s on doesn’t mean we’re done. Post-processing helps your parts look great and hold up over time—because lasting quality is part of the deal.

Inspection

We don’t ship until we’re sure it’s right. Here’s what we check:

- Chrome thickness—spot on to your specs.

- Strong adhesion—no peeling.

- Hardness—resists wear.

- Corrosion resistance—built to last.

- Toughness—tested against scratches and scrapes.

If needed, we use special machines to inspect chrome-plated surfaces. These machines can find tiny defects that people might miss.

| Inspection Type | Method/Standard Used |

| Visual Inspection | Look for pitting, cloudiness, peeling |

| Thickness Measurement | X-ray fluorescence or magnetic induction |

| Adhesion Testing | Thermal shock or bend tests |

| Hardness Testing | Vickers or Knoop testers |

| Corrosion Testing | Salt spray testing (ASTM B117) |

Buffing

We polish the parts to make them nice and shiny. Polishing gets rid of little marks from plating and helps us spot any tiny problems that need fixing.

- Use a soft cloth or special chrome polish.

- Buffing makes the surface smooth and bright.

Custom Finishes

Sometimes, parts get extra treatments to change how they look or feel. Maybe you want a matte finish, a brushed style, or even a colored tint. Custom finishes let you make the part just right for you.

Advantages of Chrome Plating

Durability

Chrome plating gives your metal parts a serious upgrade. By adding chromium, the surface gets way harder than plain metal, so parts can take knocks, scrapes, and everyday wear without breaking. You see this a lot in cars and planes. The automotive sector uses chrome plating on 43% of its parts, showing just how much people trust it for durability. North America’s got the biggest slice of the pie, with 37% of the market, thanks to its focus on tough, long-lasting parts.

Hard chrome plating is booming, especially where parts need to take a beating. Experts predict a 4.49% yearly growth from 2024 to 2032, showing how much companies trust chrome plating to keep gear running strong. With chrome plating, you get surfaces that fight friction, stay smooth, and survive tough environments.

Corrosion Resistance

Rust and corrosion can wreck metal parts fast, but chrome plating acts like a shield. It keeps water, chemicals, and salty air from reaching the metal underneath. The chromium layer stops oxygen and moisture from causing damage, so your parts stay looking good and working right—even if they’re outside or wet.

We test our chrome parts with salt spray and humidity chambers to see how well they resist rust. Tests can vary, but the industry knows chrome plating works. You’ll find it on airplane parts, car bumpers, and heavy machinery—places where fighting corrosion matters. Both hard chrome and nickel-chrome coatings do a great job protecting parts for the long haul.

Appearance

Chrome-plated parts catch your eye with their shiny, mirror-like finish that makes anything look fancy. Whether it’s your car or kitchen faucet, chrome plating gives you that smooth, polished shine.

- It covers up little scratches and flaws.

- Makes old parts look fresh again.

- You can pick different looks—bright, matte, or brushed—to match your style.

A nice finish isn’t just about looks—it can make your stuff worth more and easier to clean. Chrome plating gives you both style and strength.

Maintenance

Good news—keeping chrome-plated items in top shape is easier than you might think. The smooth, shiny surface acts like a shield, so dirt and grime have a hard time sticking. You can usually keep things clean with just a soft cloth and a little soapy water. No need for harsh chemicals or fancy cleaners.

Here’s a simple routine you can follow:

- Wipe the surface with a damp, soft cloth to remove dust and fingerprints.

- Use mild soap and water for tougher spots. Rinse with clean water.

- Dry the part right away with a microfiber towel to avoid water spots.

- For extra shine, use a chrome-safe polish every few months.

Wondering if chrome-plated parts need special care in rough spots like outdoors or factory floors? Nope. Chrome’s tough—it can take on rain, salt, and even harsh chemicals. That’s why you see it on cars, tools, and heavy equipment.

It stops rust and cuts down on wear, which means fewer repairs and part swaps. Sure, chrome plating costs more at first, but it can make parts last 2 to 10 times longer. In factories, that saves a ton—machines run longer without breaking, and some companies even use planning tools to get the most out of every part.

Applications of Chrome Plating

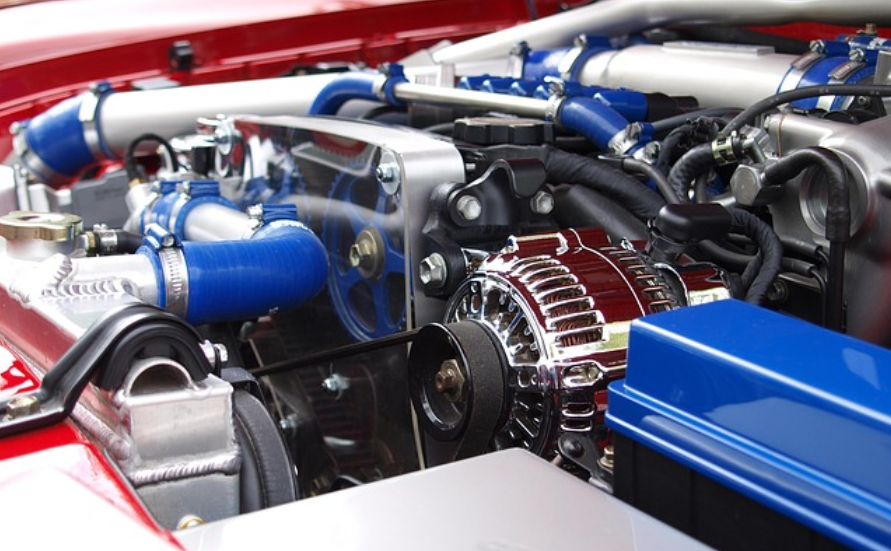

Automotive

You see chrome all over cars and trucks—on bumpers, grilles, wheels, and door handles. Sure, it looks shiny and cool, but it’s also tough. Chrome plating protects parts from rain, dirt, and salt, helping them last longer. That glossy finish isn’t just for show—it helps stop rust too. Drivers love Chrome because it gives their ride both good looks and real durability.

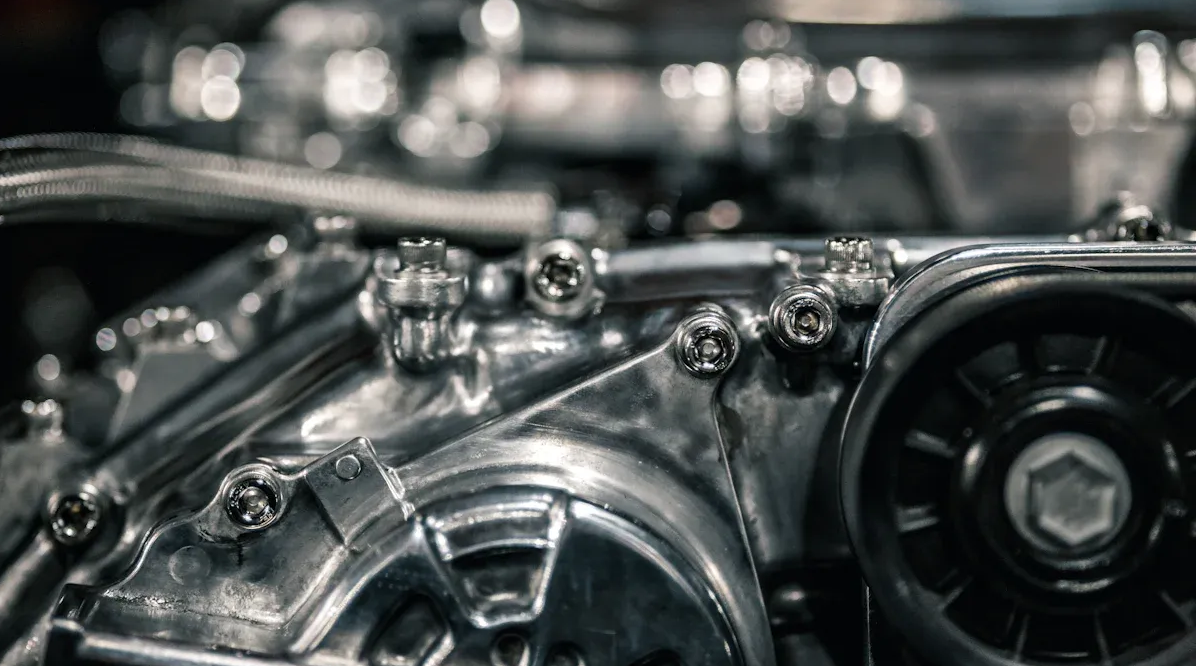

Industrial

When you’re dealing with big machines and heavy work, you need parts that can hold up. That’s where Chrome comes in. You’ll see it on shafts, hydraulic parts, and tools that get used nonstop. Chrome’s tough—it stands up to heat, scratches, and even chemicals. Depending on use, it can last 5 to 20 years. Pros check for flaws before and after plating, so parts come out smooth and ready. If you’re in a tough environment, chrome plating helps you avoid breakdowns—and expensive repairs.

Fixtures

If you want your kitchen or bathroom to look great and hold up over time, chrome’s got you covered. New research shows that advanced chrome coatings—like oxygen-doped PVD chrome—can make fixtures up to 55% harder and over 10 times more rust-resistant. That means your faucets, showerheads, and handles won’t just look shiny—they’ll stay that way. These coatings help block rust, resist scratches, and even make cleaning easier. So you get good looks, less upkeep, and gear that lasts, even with daily splashes and use

Custom Uses

You may think chrome finishes are just for cars or faucets. But people use them in many fun and creative ways. The shiny, tough look is not only for machines or tools. Chrome can help you show off your style or fix a problem.

Check out these cool ways people use chrome finishes:

- Home Decor: Use chrome on lamp stands, picture frames, or furniture legs. The shine makes rooms look bright and modern.

- Bikes and Scooters: Riders pick chrome for handlebars, wheels, and frames. It keeps bikes looking cool and protects them from rain and mud.

- Musical Instruments: Drummers and guitarists like chrome on drum hardware and guitar parts. The finish can handle sweaty hands and bright stage lights.

- Sports Gear: Some fishing reels, golf clubs, and skateboards use chrome for extra strength and a pro look.

- Jewelry and Fashion: Designers use chrome finishes on bracelets, watches, and belt buckles. You get a bold, mirror-like shine that stands out.

- Art and Sculpture: Artists use chrome to make sculptures and art that grab attention. The shiny surface gives a cool, futuristic feel.

Innovations

New Technologies of Surface Finishing

Metal finishing got a tech glow-up. Thanks to some sci-fi-level tools like nanotech, surfaces are smoother, shinier, and stronger than ever—and the planet’s happy about it too. Nanotechnology works at a teeny-tiny scale to perfect each coating. Pulse electroplating steps in to make sure every layer is even and just thick enough. So now your parts look amazing and play by the rules.

Look at these numbers from recent studies:

| Quality Metric | Specification / Description |

| Chromium Coating Thickness | 8–250 microns, layered over nickel for strength |

| Surface Hardness | 800–1000 HV, great for wear resistance |

| Surface Roughness (Ra) | 0.2 microns or less for a smooth feel |

| Corrosion Resistance | Salt spray test ratings 7–10 (ISO 4540) |

| Cohesion | No cracks after thermal shock testing |

| Environmental Standards | Meets ISO, ASTM, and local safety rules |

Industry Trends

The industry is changing quickly. Companies want better results and safer ways to work. Here are some big trends you should know:

- Switching to safer trivalent chromium to meet regulations.

- Automation is making plating cleaner and more reliable.

- Nano-coatings make parts tougher and stop rust.

- 3D printing is helping create custom parts for tricky jobs.

- AI is catching issues early and helping plan repairs.

- Companies join together to share new ideas and grow.

- The U.S. and Canada are offering rewards for going green.

More businesses are choosing energy-saving, low-chemical systems. People want finishes that last—and are better for the planet.

NOBLE Innovative Chrome Plating Technology

NOBLE uses the newest plating technology. We use nanotechnology for smooth, tough coatings. Their pulse electroplating gives even, shiny layers every time. These systems save energy and produce less waste. This saves money and helps the environment.

Here is what makes NOBLE special:

- Nanotechnology for smooth, strong coatings

- Pulse electroplating for perfect shine and thickness

- Energy-saving systems that cut costs and pollution

- Coatings that are harder and stop rust better

- Smart methods to let you pick the finish you want

NOBLE’s new ideas mean your parts last longer and look better. They meet strict safety rules. You can trust NOBLE to give you quality and care for the planet.

Choose a superior chrome plating service

How to select plating type based on function (decorative vs functional).

When you pick a chrome finish, you need to think about what the part will do. Do you want it to look shiny and new, or does it need to handle heavy use? Decorative chrome is best for things like car trim, faucets, and furniture. It gives a bright, mirror-like look and protects against rust. This type works well for most home and car parts that do not face much wear.

If you need something tougher, go for functional chrome. This type is thicker and built for strength. You find it on machine parts, tools, and equipment that face lots of friction or heat. Functional chrome stands up to scratches and lasts longer in rough spots.

Recent studies show that decorative trivalent chrome can match hexavalent chrome in both appearance and corrosion resistance. In tough winter conditions, chloride-based trivalent chrome even keeps its color better and resists peeling. For functional uses, the thickness and grain size of the coating matter most. Thicker coatings with larger grains last longer and resist wear better. If you want a part to look good, choose decorative. If you need it to work hard, pick functional.

Quality indicators: layer thickness, adhesion testing, surface hardness.

To check quality, look at three main things: thickness, adhesion, and hardness.

- Thickness: Good shops measure thickness by checking the part before and after plating. The difference tells you how much chrome is on the surface. For decorative parts, the layer is thin. For functional parts, it is much thicker.

- Adhesion: The chrome must stick well. Experts use microscopes to look for cracks or peeling. If the layer is smooth and unbroken, it means good adhesion.

- Hardness: Hardness tests show how well the chrome will resist scratches. Shops adjust the plating process to get a hard, bright finish.

NOBLE’s Outstanding Surface Treatment Services

When you want the best results, you need a service that stands out. NOBLE gives you more than just a shiny finish. You get a team that cares about every detail, from the first call to the final inspection. You can trust their experience. They have worked with all kinds of parts, from car trim to heavy machinery.

You might wonder what makes NOBLE different. Here are some reasons customers choose them again and again:

- Expertise: NOBLE’s technicians know the process inside and out. They use the latest tools and follow strict quality checks. You get a finish that looks great and lasts.

- Quality: Every part goes through careful inspection. NOBLE checks thickness, adhesion, and hardness. If something is not perfect, they fix it before you see it.

- Environmental Responsibility: NOBLE uses safer chemicals and modern waste systems. They follow all local and national rules. You help protect the planet when you choose them.

- Customer Service: You get clear answers and honest advice. NOBLE listens to your needs and helps you pick the right finish. They keep you updated at every step.

Let’s look at what you can expect when you work with NOBLE:

| Step | What NOBLE Does for You |

| Consultation | Listens to your needs and explains options |

| Preparation | Cleans and polishes every part carefully |

| Plating | Uses advanced methods for even coating |

| Inspection | Checks every detail for quality |

| Delivery | Packs and ships your parts safely |

You might have a special project or a tight deadline. NOBLE can handle custom jobs and rush orders. They have helped restore cars, upgrade factory tools, and even create art pieces. Their team loves a challenge and works hard to meet your goals.

If you care about quality, safety, and the environment, NOBLE is a smart choice. You get peace of mind knowing your parts are in good hands.

FAQ of Chrome Plating

How long does chrome plating last?

Chrome plating lasts anywhere from 2 to 20 years. If you keep your items clean and dry, they will stay shiny longer. Heavy use or inclement weather can cause the plating to wear off more quickly.

What are the main types of chrome plating?

There are three main types: decorative chrome, hard chrome, and fine chrome. Decorative chrome looks shiny. Hard chrome adds toughness. Thin dense chrome provides a smooth, strong finish for specialty parts.

Is chrome plating toxic or harmful?

The process can be risky if not handled correctly. Some chemicals used in plating, like hexavalent chromium, are toxic. They can harm workers and the environment if shops do not follow safety rules.

For you as a user, finished chrome parts are safe to touch and use. The danger comes during the plating process, not after. Good shops use special gear, ventilation, and training to keep workers safe. They also treat waste to protect the planet.

Note: Always choose a plating shop that follows safety and environmental rules. This keeps everyone safe and healthy.

Is chrome plating safe to touch?

Yes, you can safely touch chrome-plated items. The danger comes during the plating process, not after. Once finished, the coating is stable and safe for daily use.

Can chrome plating be done in a DIY context?

You might think about trying chrome plating at home. While small kits exist, real plating is tricky and risky. The chemicals used can be dangerous. They can burn your skin or harm your lungs if you breathe in the fumes. Most home kits do not give you the same shine or strength as a professional shop.

If you want to restore a small part, you can try a DIY kit. These kits work for touch-ups or crafts. Always wear gloves, goggles, and work in a well-ventilated area. Never pour leftover chemicals down the drain. Local laws may ban home plating because of the risks. For big jobs or anything that needs to last, it’s best to use a professional service. You get better results and stay safe.

Can NOBLE chrome plate plastic parts?

We can chrome plate some plastic parts. We will first apply a special plating to the plastic to help the chrome adhere. However, not all plastics can be chrome plated, and this needs to be evaluated by our engineer.

How does NOBLE ensure that processing goes smoothly?

NOBLE makes that happen by following a clear process from start to finish. Their team listens to your needs and explains every step before they begin. You always know what’s happening with your parts.

Here’s how NOBLE keeps things running smoothly:

- Clear Communication: You get updates at every stage. If you have questions, you can call or email and get quick answers.

- Expert Preparation: NOBLE’s technicians clean and inspect every part before plating. They spot problems early and fix them right away.

- Advanced Equipment: The shop uses modern machines that control temperature, timing, and chemicals. This means you get a consistent, high-quality finish.

- Quality Checks: After plating, your parts go through several inspections. NOBLE checks for thickness, shine, and any defects.

- On-Time Delivery: You get your finished parts when you expect them. If there’s a delay, NOBLE lets you know right away.

If you have a special request or a tight deadline, please notify NOBLE in advance. We work with you to meet your goals. NOBLE’s process helps you avoid surprises. You get great results and peace of mind every time.

How do I clean chrome without scratching it?

Use a soft cloth and mild soap. Wipe gently. Dry with a microfiber towel. Never use steel wool or rough pads. These can scratch the shiny surface.

What should I do if Chrome starts to peel?

If you see peeling, stop using the item. Take it to a professional plating shop. They can strip the old layer, fix the surface, and re-plate it for you.

Can I repair small rust spots on chrome?

Yes! You can gently rub small rust spots with aluminum foil dipped in water. This removes the rust without scratching the chrome. For bigger problems, visit a pro.

Is chrome plating expensive?

Chrome plating costs more than regular paint. The price depends on the size and type of part. You pay more up front, but the finish lasts much longer and saves money over time.