- Title Tag: “Vacuum Molding: Process, Applications & Benefits [2024]”

- Meta Description: “Discover the process, applications, and benefits of vacuum molding. Learn how it enhances accuracy and efficiency in manufacturing.”

- Keywords: Vacuum molding, vacuum forming, plastic molding, manufacturing techniques

What is Vacuum Molding?

Vacuum molding is a process used to shape plastic materials into specific forms using a combination of heat, pressure, and vacuum. It involves heating a plastic sheet until it becomes soft and pliable, then draping it over a mold and using a vacuum to pull the material tightly around the mold. Once cooled, the plastic retains the shape of the mold, resulting in a finished part.

The Vacuum Molding Process

1. Material Preparation

The process begins with the selection and preparation of the plastic material. Common materials used in vacuum molding include ABS (Acrylonitrile Butadiene Styrene), polycarbonate, and polystyrene. The plastic is supplied in sheet form and must be cut to the appropriate size before heating.

2. Heating

The plastic sheet is placed in a heating chamber where it is uniformly heated until it reaches a temperature where it becomes soft and flexible. This temperature varies depending on the type of plastic being used, but it is generally between 150°C and 300°C.

3. Forming

Once the plastic sheet is heated to the desired temperature, it is quickly transferred to the mold. The mold can be made from various materials, including aluminum, steel, or even silicone. The mold is often designed to include fine details and contours that the plastic will replicate.

4. Vacuum Application

The key step in the process is the application of the vacuum. A vacuum system is used to remove air between the plastic and the mold, causing the plastic to conform closely to the shape of the mold. The vacuum pressure ensures that the material fills all the contours of the mold, creating a precise and accurate part.

5. Cooling and Removal

After the plastic has been molded and cooled, the finished part is removed from the mold. Cooling can be achieved naturally or with the help of cooling systems to expedite the process. The part is then trimmed and finished to remove any excess material or imperfections.

Applications of Vacuum Molding

Packaging Industry

One of the most common applications of vacuum molding is in the packaging industry. Vacuum-formed packaging provides a cost-effective solution for creating custom-fit trays, blisters, and clamshells. This type of packaging is widely used for consumer products, electronics, and medical devices.

Automotive Industry

In the automotive industry, vacuum molding is employed to produce various interior and exterior components. It is particularly useful for creating complex shapes and contours found in dashboards, door panels, and trim pieces. The lightweight and durable nature of vacuum-molded parts also contributes to overall vehicle efficiency.

Aerospace Industry

Aerospace components often require precision and high performance under extreme conditions. Vacuum molding can be used to manufacture components such as cabin liners and housings that need to meet stringent standards for strength and weight.

Consumer Goods

From household appliances to sporting goods, vacuum molding is used to create a wide range of consumer products. Its ability to produce detailed and complex shapes makes it ideal for items such as custom enclosures, ergonomic grips, and decorative elements.

Advantages of Vacuum Forming

Cost-Effectiveness

Vacuum molding is known for its cost-effectiveness, especially for medium to large production runs. The process has lower tooling costs compared to injection molding, making it an attractive option for producing moderate quantities of parts.

Design Flexibility

The flexibility of vacuum molding allows for the production of parts with complex geometries and intricate details. Designers can experiment with various shapes and sizes without incurring significant additional costs.

Quick Turnaround

The process is relatively fast, with rapid heating and cooling cycles leading to quick production times. This speed is advantageous for industries where time-to-market is critical.

Material Efficiency

Vacuum molding minimizes material waste. The excess plastic, often trimmed from the edges of the formed part, can be reprocessed and reused. This contributes to a more sustainable manufacturing process.

Challenges and Limitations

Size Constraints

While vacuum molding can handle relatively large parts, it has size limitations compared to other methods, such as rotational molding. The size of the mold and the dimensions of the heated plastic sheet can restrict the maximum size of the molded parts.

Thickness Uniformity

Achieving uniform thickness throughout the part can be a challenging task. Thicker areas may require additional heating or longer cooling times, which can affect production efficiency.

Detail Reproduction

Although vacuum molding can produce detailed parts, the level of precision may not always match that of injection molding. Fine details and tight tolerances may require additional processing or refinements.

Vacuum Molding vs. Injection Molding

Vacuum molding and injection molding are two common plastic processing technologies, each with its advantages and disadvantages.

Vacuum Forming:

Advantages: Low mold costs, suitable for small-batch production, flexible design, especially for large thin-walled parts.

Disadvantages: Lower precision, not suitable for complex internal structures, surface quality may not match injection molding.

Injection Molding:

Advantages: High precision, suitable for mass production, capable of producing complex parts, and excellent surface quality.

Disadvantages: High mold costs, long production cycles, not suitable for large parts.

Applications:

Vacuum Molding: Ideal for packaging, automotive interiors, consumer goods, etc.

Injection Molding: Suitable for electronic components, medical devices, precision parts, etc.

Material Selection and Characteristics for Vacuum Molding

1. ABS (Acrylonitrile Butadiene Styrene)

ABS is a commonly used material in vacuum molding, known for its high strength, impact resistance, and ease of processing.

- Characteristics:

Resistant to chemical corrosion, suitable for outdoor use.

Smooth surface, easy to paint and decorate.

- Applications: Automotive interiors, electronic housings, toys, etc.

2. PVC (Polyvinyl Chloride)

PVC is an economical material with excellent chemical resistance and flame retardancy.

- Characteristics:

Strong weather resistance, suitable for outdoor applications.

Low cost, ideal for mass production.

- Applications: Packaging materials, medical devices, building materials, etc.

3. PET (Polyethylene Terephthalate)

PET is an eco-friendly material with high transparency and heat resistance.

- Characteristics:

Recyclable, meeting environmental standards.

High transparency, suitable for food packaging.

- Applications: Beverage bottles, food containers, optical components, etc.

4. PC (Polycarbonate)

PC is a high-performance material known for its high transparency and impact resistance.

- Characteristics:

Heat-resistant, suitable for high-temperature environments.

High impact strength, ideal for safety applications.

- Applications: Safety glass, lighting equipment, electronic components, etc.

Innovations and Future Trends

Advanced Materials

The development of new materials continues to enhance the capabilities of vacuum molding. Advanced polymers and composites are being explored to improve the strength, flexibility, and thermal properties of molded parts.

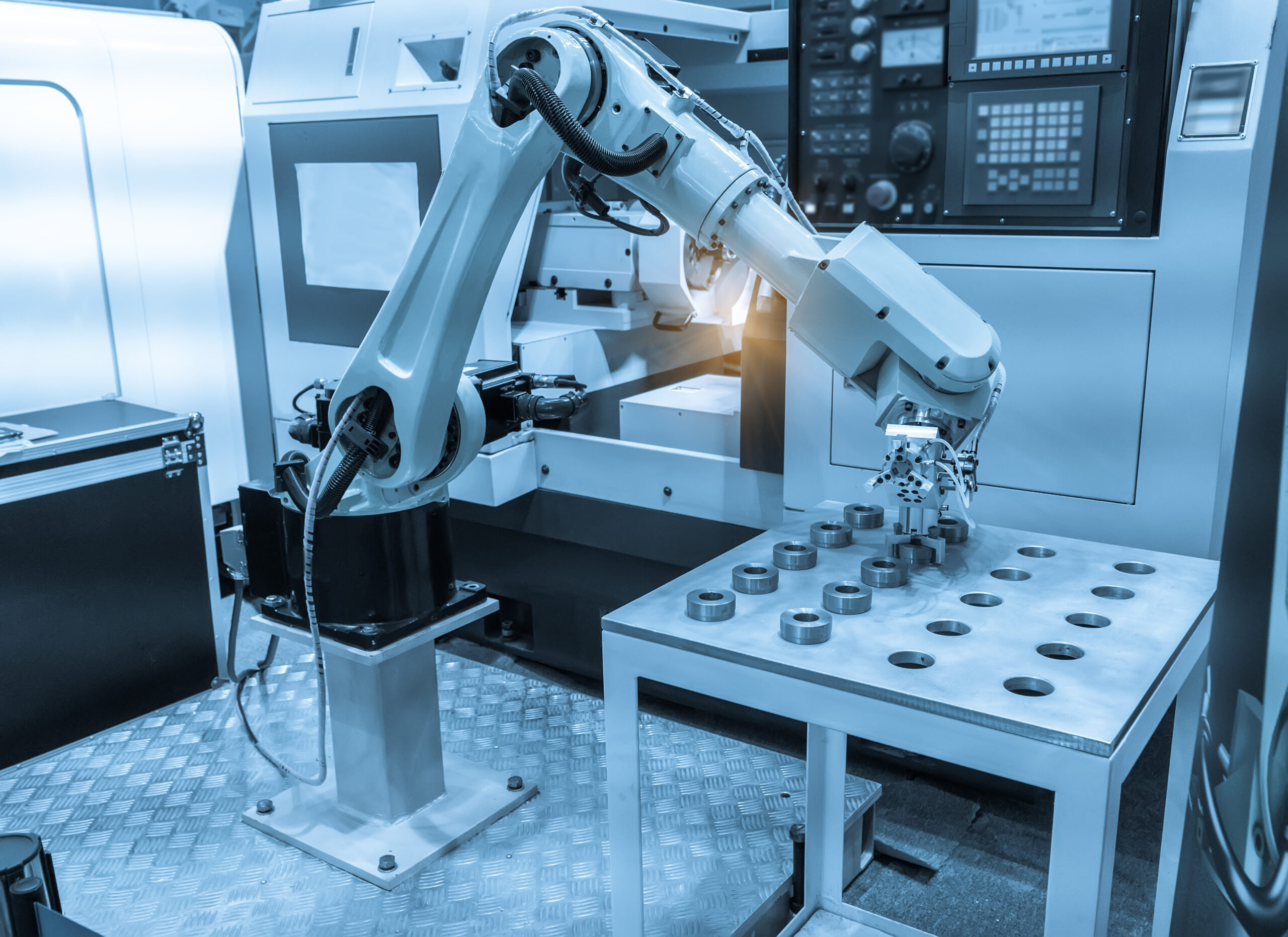

Automation

Automation is transforming the vacuum molding process, with advancements in robotics and computer-controlled systems streamlining production and reducing labor costs. Automated systems also enhance precision and consistency.

Sustainable Practices

The push for sustainability is driving innovations in vacuum molding. Efforts are being made to incorporate recyclable materials and reduce the environmental impact of the manufacturing process. This includes the use of biodegradable plastics and more efficient energy usage.

Integration with Other Technologies

Combining vacuum molding with other manufacturing technologies, such as 3D printing and injection molding, is becoming increasingly common. This hybrid approach allows for greater design freedom and the production of complex parts with enhanced performance characteristics.

Conclusion

Vacuum molding is a powerful and adaptable manufacturing process that offers numerous advantages across a range of industries. Its cost-effectiveness, design flexibility, and quick turnaround make it a popular choice for producing high-quality plastic parts. While there are challenges to overcome, ongoing innovations and advancements in materials, automation, and sustainability are shaping the future of vacuum molding.

As industries continue to evolve and demand for customized and efficient solutions grows, vacuum molding will remain a crucial technique in the realm of plastic manufacturing. Understanding its processes, applications, and future trends equips manufacturers, designers, and engineers with the knowledge to leverage this technology effectively, ensuring continued success in a competitive marketplace.