In the world of metal casting, low-pressure and high-pressure casting stand as two popular techniques, each contributing its strengths and purposes. By reading this guide, you will be better equipped to understand these methods and determine which one aligns best with your production needs.

Introduction to Low-Pressure and High-Pressure Casting

In modern manufacturing, casting processes are indispensable, especially when producing metal components. Low-pressure casting and high-pressure casting are two prevalent techniques, each offering specialized benefits that cater to different material properties and production demands.

Low Pressure Casting

- Definition: The process of low-pressure casting involves the application of molten metal into a mold at pressures typically ranging from 0.5 to 1 bar, ensuring a precise and controlled filling.

- Key Features:

Gentle filling of the mold.

Suitable for complex geometries.

Commonly used for aluminum and magnesium alloys.

High Pressure Casting

- Definition: A high-pressure casting method, where molten metal is injected into a mold under pressures typically varying from 100 to 1000 bar, ensures high precision in the final product.

- Key Features:

Rapid filling of the mold.

Ideal for high-volume production.

Commonly used for zinc, aluminum, and magnesium alloys.

Key Differences Between Low Pressure and High Pressure Casting

1. Pressure Levels

Low Pressure Casting: With Low Pressure Casting, molten metal fills the mold using a low pressure, usually around 0.5 to 1 bar.

High Pressure Casting: In High Pressure Casting, the mold gets filled quickly thanks to the high pressure, usually anywhere from 100 to 1000 bar.

2. Mold Filling Speed

Low Pressure Casting: Low Pressure Casting fills the mold slowly, which helps cut down on turbulence and keeps gas from getting trapped inside.

High Pressure Casting: High Pressure Casting uses a faster filling technique, which is especially effective for creating thin-walled parts that require precision.

3. Mold Material

Low Pressure Casting: In Low Pressure Casting, sand or permanent metal molds are the go-to choice for shaping the material.

High Pressure Casting: For High Pressure Casting, steel molds are used because they’re tough enough to handle the high pressure.

4. Part Complexity

Low Pressure Casting: If you’re working with complex shapes or larger parts, Low Pressure Casting is the way to go.

High Pressure Casting: High Pressure Casting works best for small to medium parts that need thin walls.

5. Surface Finish

Low Pressure Casting: With Low Pressure Casting, you get smoother surfaces and fewer defects thanks to the slow filling.

High Pressure Casting: With High Pressure Casting, you might need to do some extra finishing to smooth out surface imperfections.

Low Pressure Casting vs. High Pressure Casting

Low-pressure and high-pressure casting each come with their own set of advantages, making them fit for different manufacturing purposes. In this comparison, we’ll look at how each method helps with things like quality and cost efficiency.

Advantages of Low-Pressure Casting

Superior Surface Quality

Smooth Finish: The reduction in turbulence results in a smoother surface, minimizing common defects like roughness.

Fewer Imperfections: Lower pressures help to avoid gas entrapment and porosity, ensuring a cleaner, defect-free casting.

Better Mechanical Properties

Improved Strength: By controlling the filling process, parts maintain better strength and structural integrity.

Reduced Stress: Lower pressure casting minimizes the internal stresses that could otherwise weaken the part.

Cost-Effectiveness for Low to Medium Volumes

Lower Tooling Costs: This process is compatible with sand or permanent molds, reducing tooling expenses.

Reduced Waste: The efficient use of material during casting reduces waste, offering further cost savings.

Advantages of High Pressure Casting

High Production Speed

Rapid Cycle Times: The ability to achieve rapid cycle times makes High Pressure Casting highly suitable for high-volume manufacturing applications.

Thin-Walled Parts: High casting is capable of producing thin-walled parts with thicknesses as low as 1 mm, allowing for the efficient production of delicate components.

Precision and Consistency

Tight Tolerances: The high-pressure injection process in casting ensures that the molds are filled precisely, achieving tight tolerances.

Repeatability: High Pressure Casting offers excellent repeatability, ensuring the same high-quality results across large batches.

Cost-Effectiveness for High Volumes

Economies of Scale: By optimizing production for large volumes, High Pressure Casting achieves economies of scale, lowering the cost per unit.

Durable Molds: The use of steel molds, known for their durability, significantly reduces tool replacement costs, making the process more cost-efficient.

Summarize the characteristics of Low-pressure casting and High-pressure casting

| Feature | Low Pressure Casting | High Pressure Casting (Die Casting) |

|---|---|---|

| Pressure Range | Low (0.2 – 1.5 bar) | High (100 – 1500 bar) |

| Mold Type | Reusable metal molds (permanent mold) | Steel dies (complex, high-precision) |

| Filling Method | Molten metal rises into the mold under low pressure | Molten metal is forcefully injected into the mold |

| Part Complexity | Moderate to high complexity | High complexity and fine detail are possible |

| Surface Finish | Good, but may require finishing | Excellent surface finish |

| Porosity | Lower porosity due to gradual filling | Higher porosity risk due to trapped air |

| Wall Thickness | Suitable for medium-to-thick parts | Suitable for thin-walled components |

| Cooling Time | Slower, natural cooling | Fast, with active cooling systems |

| Tooling Cost | Moderate | High (due to complex dies and equipment) |

| Production Volume | Medium to high | Very high (mass production) |

| Material Use | Aluminum, magnesium alloys | Aluminum, zinc, magnesium, copper alloys |

| Mechanical Strength | Higher (due to low porosity) | Lower unless vacuum die casting is used |

| Common Applications | Automotive wheels, cylinder heads, brake parts | Engine blocks, gear housings, and electronics casings |

How to choose low low-pressure casting and high-pressure casting process

| If You Need… | Choose… |

|---|---|

| High-volume production with fine details | High Pressure Casting |

| Structurally sound parts with low porosity | Low Pressure Casting |

| Thin-walled components and rapid cycles | High Pressure Casting |

| Better mechanical strength and density | Low Pressure Casting |

| Cost-effective small-to-medium runs | Low Pressure Casting |

Applications of Low-Pressure and High-Pressure Casting

We’ll now take a look at how these two casting methods are used across different industries, showing their flexibility and effectiveness in meeting particular needs.

Low Pressure Casting

Automotive: Low-pressure casting is applied in the automotive industry for producing critical parts like engine blocks, cylinder heads, and wheels.

Aerospace: The process is widely used in aerospace to create durable structural components and turbine blades.

Industrial: In industrial applications, Low Pressure Casting excels in creating pump housings and valve bodies.

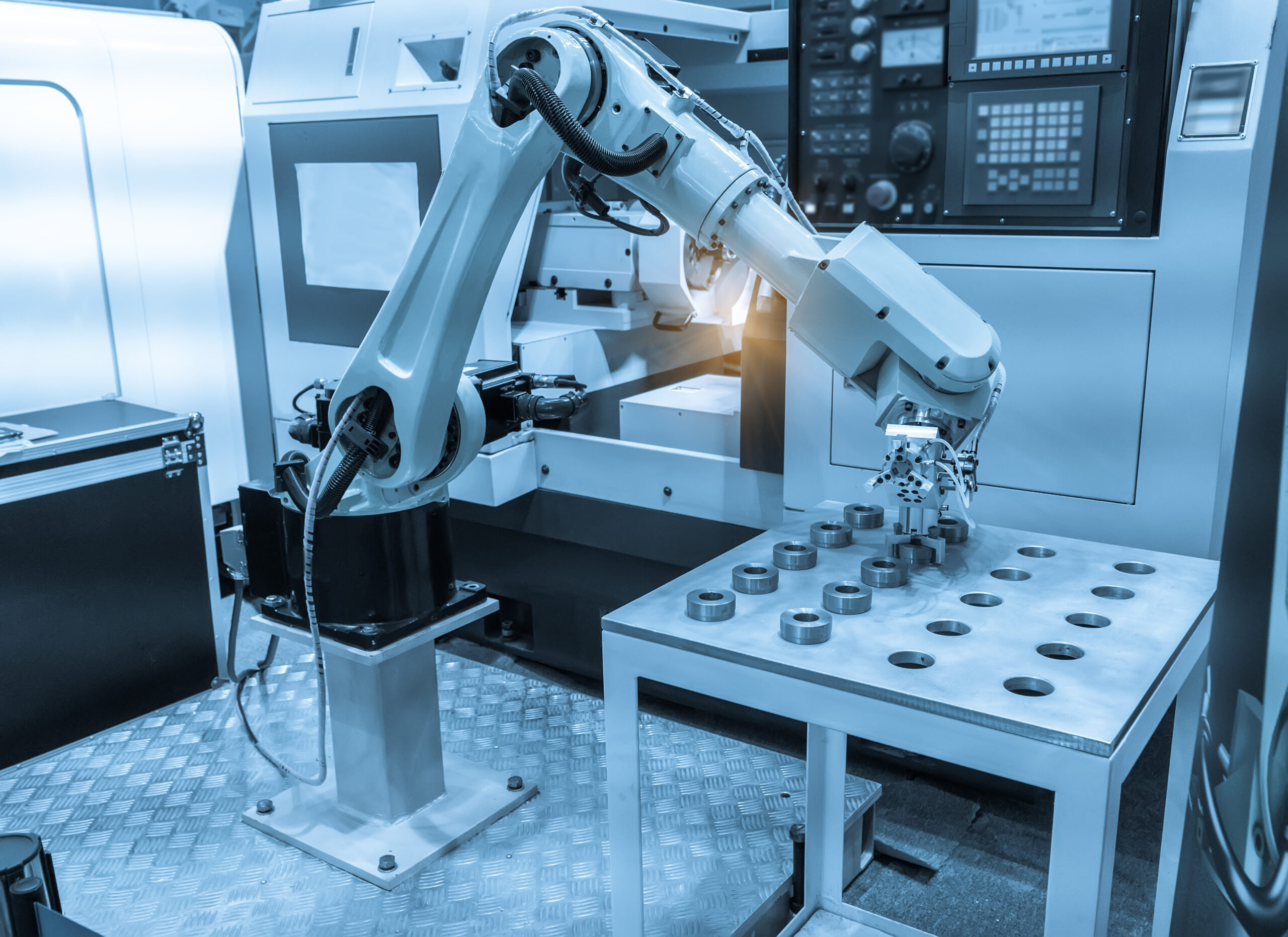

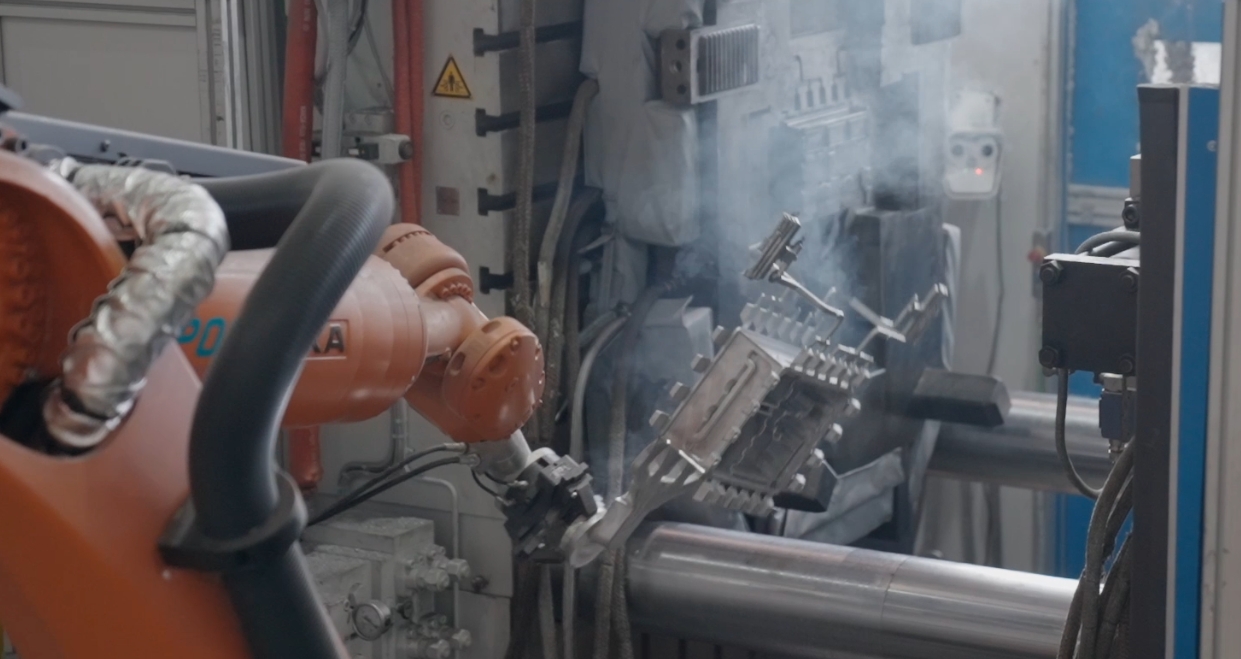

High Pressure Casting

Automotive: High-pressure casting is commonly used for transmission cases and engine brackets in the automotive industry.

Consumer Electronics: In consumer electronics, it is applied to make housings and connectors.

Appliances: In the appliance sector, High Pressure Casting is used to create frames and handles.

Choosing the Right Casting Method

Choosing the right casting method is essential for getting the best results in both production efficiency and product quality. Your choice between low-pressure and high-pressure casting will depend on factors like how complex the part is, how many units you need, the materials used, and your budget.

Part Complexity

Low Pressure Casting: Low-pressure casting is ideal for producing parts with complex shapes and larger sizes, where precision and fine detailing are critical.

High Pressure Casting: High-pressure casting, on the other hand, is better suited for small or medium parts that demand thin walls and high precision.

Production Volume

Low Pressure Casting: Low-pressure casting is more suited for low to medium production volumes, where flexibility and a slower pace are required.

High Pressure Casting: High-pressure casting, with its rapid cycle times, is perfect for high-volume production where speed and consistency are key.

Material Considerations

Low Pressure Casting: Low-pressure casting is ideal for handling aluminum and magnesium alloys, offering better control over metal flow and reducing defects.

High Pressure Casting: High-pressure casting is more versatile, handling a broader range of materials, including zinc, aluminum, and magnesium alloys, and ensuring precision in the final product.

Budget and Tooling Costs

Low Pressure Casting: Low-pressure casting is more cost-effective for smaller production runs due to its lower initial tooling investment.

High Pressure Casting: Although high-pressure casting has higher upfront tooling costs, it becomes more economical in large production runs due to the reduced per-unit costs.

Conclusion

Each casting method—low pressure and high pressure—offers specific advantages, depending on factors like application, part complexity, and production volume. Understanding these differences allows you to make informed decisions that optimize your production efficiency and part quality.