Operating injection molding machines? Learn the 5 critical safety steps to protect workers, prevent accidents, and boost productivity in 2025.

Injection molding machines are central to the plastic manufacturing industry, but their operation comes with inherent risks. OSHA data indicates that over 30% of industrial accidents in this field are caused by these machines. As the global injection molding market is forecasted to reach $47 billion by 2030, the importance of safety protocols cannot be overstated. This guide provides comprehensive insights into the primary risks, actionable safety measures, and evidence-based practices to enhance workplace safety and productivity.

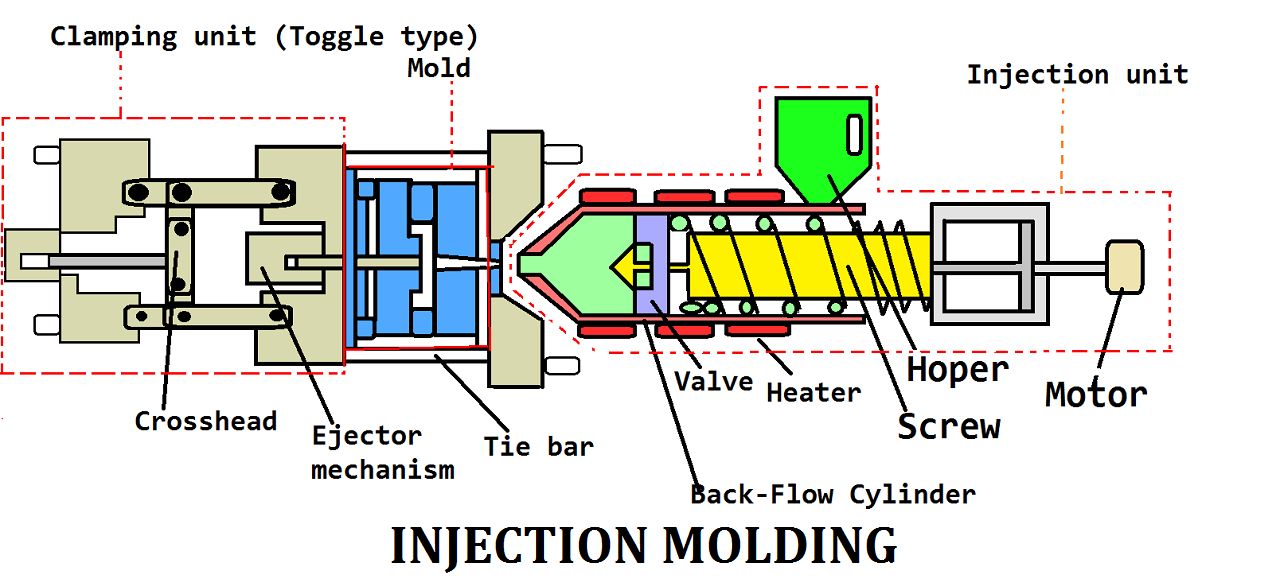

What Is Injection Molding?

Injection molding is a manufacturing process that produces parts by injecting molten material (usually plastic) into a precision-machined mold. As the material cools and hardens, it takes the shape of the mold cavity and is ejected as a solid part. It is particularly suitable for large-scale production, ensuring consistent product quality and meeting complex design requirements.

The process is widely used in the mass production of complex, high-precision parts in industries such as automotive, electronics, medical, packaging, and consumer products.

How Injection Molding Works

Injection molding is a cyclical process used to manufacture plastic parts by injecting molten material into a mold. Here’s how it works:

1. Material Feeding (Hopper)

-

Plastic pellets (resin) are loaded into a hopper.

-

These pellets are typically thermoplastics like ABS, PP, or Nylon.

2. Melting (Heating and Plasticizing)

-

The plastic pellets are fed into a heated barrel.

-

A rotating screw inside the barrel heats, compresses, and melts the plastic through friction and external heaters.

-

The screw also builds pressure to inject the molten plastic forward.

3. Injection (Filling the Mold)

-

Once enough molten plastic is gathered in front of the screw (called a shot), the screw moves forward like a plunger.

-

The plastic is forced at high pressure through a nozzle into the closed mold cavity.

-

The mold is held tightly shut by a clamping unit to prevent leakage.

4. Cooling and Solidification

-

The plastic inside the mold begins to cool and harden into the shape of the cavity.

-

Cooling time depends on the plastic type, part thickness, and mold design.

-

The mold may include cooling channels (circulating water or oil) to speed up this process.

5. Mold Opening

-

Once the part has solidified, the clamp opens the mold, separating the two halves (core and cavity).

6. Part Ejection

-

Ejector pins push the part out of the mold.

-

In some cases, air blasts or robotic arms assist in removal.

-

The mold then resets for the next cycle, and the process repeats.

Ten Advantages of Injection Molding

Here’s a comprehensive guide to the benefits of injection molding, a highly popular manufacturing process used for producing parts in large volumes:

1. High Efficiency and Fast Production

-

Rapid cycle times: Once molds are designed and created, the injection process is fast, often taking just seconds.

-

Automation-friendly: Highly compatible with automated machinery, reducing labor costs.

-

Scalability: Ideal for high-volume production runs with consistent quality.

2. Design Flexibility

-

Complex geometries: Supports intricate part designs that would be difficult or impossible with other processes.

-

Multiple finishes and textures: Molds can be customized to add logos, patterns, or matte/glossy finishes directly to the part.

3. High Precision and Consistency

-

Tight tolerances: Parts can be made with extreme accuracy (as low as ±0.001 inches).

-

Repeatability: Every part produced is virtually identical, which is critical for brand consistency and mechanical fit.

4. Material Variety

-

Compatible with a wide range of thermoplastics, thermosets, elastomers, and even biodegradable materials.

-

Fillers and additives (e.g., glass fibers, colorants) can be used to alter strength, flexibility, or appearance.

5. Low Waste Production

-

Excess material (e.g., from sprues or runners) can often be recycled and reused.

-

Compared to subtractive methods like CNC machining, material waste is significantly reduced.

6. Lower Long-Term Costs

-

Though the initial mold cost is high, the cost per part drops significantly at scale.

-

Durable molds can produce hundreds of thousands to millions of parts over their lifetime.

7. Minimal Post-Processing

-

Finished parts usually come out of the mold in their final shape with little need for secondary processing (like sanding or trimming).

-

Built-in part features like threads, hinges, or holes can be molded directly, reducing assembly costs.

8. Improved Strength and Durability

-

The ability to reinforce parts with fibers or fillers increases structural integrity.

-

Mold design can be optimized for stress distribution, helping to extend product life.

9. Customization and Multi-Material Options

-

Overmolding and insert molding enable a combination of materials in one part (e.g., hard plastic with a soft-touch grip).

-

Allows for color blending and precise control over aesthetics.

10. Environmental Benefits

-

Many plastics used are recyclable, and energy-efficient machines are increasingly common.

-

Advanced processes use bioplastics or recycled feedstock to reduce environmental impact.

✅Summary of the advantages of injection molding

| Benefits of Injection Molding | Description |

|---|---|

| Speed | Short cycle times, ideal for mass production |

| Precision | Tight tolerances and excellent repeatability |

| Design Flexibility | Complex, multi-functional part designs are possible |

| Cost Efficiency | Low per-unit cost at scale |

| Material Options | Wide range of plastics, fillers, and additives |

| Environmental Impact | Low waste, recyclable, and biodegradable options |

| Post-Processing | Minimal or none required |

| Durability | High strength with reinforced materials |

| Automation Capability | Reduces labor costs and increases consistency |

Commonly Used Materials for Injection Molding

Here are some of the most commonly used materials for injection molding, including their properties, applications, and reasons for choosing them for specific uses.

1. Acrylonitrile Butadiene Styrene (ABS)

➤ Properties:

-

Strong and impact-resistant

-

Good dimensional stability

-

Easy to machine and mold

-

Surface finish friendly (good for painting, plating)

➤ Applications:

-

Consumer electronics (keyboard keys, housings)

-

Automotive dashboards and trims

-

Toys (e.g., LEGO bricks)

2. Polypropylene (PP)

➤ Properties:

-

Lightweight and flexible

-

Excellent chemical resistance

-

Fatigue-resistant (living hinges)

-

Food-safe grades available

➤ Applications:

-

-

Packaging (containers, caps)

-

Medical devices (syringes, vials)

-

Automotive battery casings

-

Kitchenware

-

3. Polyethylene (PE)

Types: HDPE (high density), LDPE (low density)

➤ Properties:

-

Excellent impact resistance

-

Moisture and chemical resistant

-

Flexible (especially LDPE)

-

Low cost

➤ Applications:

-

Food and beverage packaging

-

Storage bins

-

Toys

-

Medical tubing and containers

4. Polycarbonate (PC)

➤ Properties:

-

Extremely tough and transparent

-

High impact resistance

-

Good dimensional stability

-

Flame-retardant options

➤ Applications:

-

Safety goggles and lenses

-

Medical device housings

-

Electronic enclosures

-

Automotive light lenses

5. Nylon (Polyamide, PA)

➤ Properties:

-

Strong and wear-resistant

-

Good heat resistance

-

Low friction (self-lubricating)

-

Sensitive to moisture absorption

➤ Applications:

-

Gears and bearings

-

Automotive under-the-hood parts

-

Power tool components

-

Cable ties

6. Polystyrene (PS)

Types: General Purpose PS (GPPS), High Impact PS (HIPS)

➤ Properties:

-

Easy to process and inexpensive

-

Brittle (GPPS) or more durable (HIPS)

-

Glossy surface finish

➤ Applications:

-

Disposable cutlery and cups

-

Cosmetic containers

-

CD/DVD cases

7. Polyethylene Terephthalate (PET)

➤ Properties:

-

Strong and stiff

-

Good gas and moisture barrier

-

Excellent for transparent applications

-

Recyclable

➤ Applications:

-

Water and soda bottles

-

Food packaging

-

Cosmetic jars

8. Polyoxymethylene (POM / Acetal / Delrin)

➤ Properties:

-

High stiffness and dimensional stability

-

Low friction and excellent wear resistance

-

Good chemical resistance

➤ Applications:

-

Gears, bearings, and precision parts

-

Lock components

-

Automotive fuel system parts

9. Bioplastics (PLA, PHB, etc.)

➤ Properties:

-

Biodegradable and eco-friendly

-

Derived from renewable resources

-

Lower thermal stability

➤ Applications:

-

Disposable medical products

-

Eco-friendly packaging

-

Consumer goods

Summary of Materials for Injection Molding

| Material | Strength | Flexibility | Temp Resistance | Transparency | Common Use |

|---|---|---|---|---|---|

| ABS | High | Medium | Moderate | Opaque | Electronics, toys |

| PP | Medium | High | Moderate | Translucent | Packaging, medical |

| PE | Medium | High | Low | Translucent | Containers, tubing |

| PC | High | Low | High | Transparent | Lenses, housings |

| Nylon | High | Medium | High | Opaque | Gears, automotive |

| PS | Low-Med | Low | Low | Clear (GPPS) | Disposables |

| PET | High | Low | Moderate | Clear | Bottles, packaging |

| TPE/TPU | Medium | Very High | Moderate | Varies | Grips, soles |

| POM | High | Low | High | Opaque | Moving parts |

| PPS | High | Low | Very High | Opaque | Electronics, pumps |

| PLA | Medium | Medium | Low | Transparent | Biodegradable items |

1. Top 6 Hazard Zones in Injection Molding Machines

Injection molding machines involve high-speed processes, intense temperatures, and significant pressures. Understanding these hazardous areas is key to preventing accidents:

① Feeding Zone

- Risk: Rotating screws can trap tools or debris, leading to potential injuries.

- Preventive Measures: Utilize magnetic trays for tools and ensure hands and foreign objects are never inserted.

② Barrel & Nozzle

- Risk: The nozzle and barrel can reach temperatures exceeding 300°C, posing burn hazards from molten plastic.

- Preventive Measures: Heat-resistant gloves and face shields are essential for protection.

③ Mold Area

- Risk: The high-speed clamping force (up to 1,000 tons) can cause severe crushing injuries to limbs.

- Preventive Measures: Install light curtains or advanced safety sensors to monitor and protect personnel.

④ Ejector System

- Risk: Pins within the ejector system operate at speeds greater than 15 cycles per minute, presenting the risk of pinning or striking limbs.

- Preventive Measures: Always use automated pickers to handle ejected parts, avoiding manual contact.

⑤ Electrical Panels

- Risk: Exposed wiring in electrical panels can cause electric shocks.

- Preventive Measures: Follow lockout/tagout (LOTO) procedures rigorously during maintenance to prevent accidental exposure.

⑥ Peripheral Equipment

- Risk: Conveyor belts, robots, and other peripheral machinery can crush or pinch limbs.

- Preventive Measures: Mark danger zones using bright, highly visible tape to warn workers.

2. 4 Most Common Accidents & How to Prevent Them

① Crush Injuries (35% of Cases)

- Cause: Workers’ hands are sometimes placed in the mold during clamping.

- Solution: Ensure comprehensive training on waiting for the full machine stop before part removal.

② Burns from Molten Plastic (28% of Cases)

- Cause: Nozzle leaks or improper purging practices.

- Solution: Implement monthly seal inspections and utilize splash guards during operation.

③ Electrical Fires (15% of Cases)

- Cause: Overheated motors or frayed wiring increase fire risks.

- Solution: Conduct weekly inspections and maintain nearby ABC-rated fire extinguishers for emergency use.

④ Toxic Fume Exposure (12% of Cases)

- Cause: The combustion of PVC/ABS materials releases carcinogenic fumes.

- Solution: Install high-efficiency ventilation systems and carbon monoxide detectors to mitigate exposure.

3. 2025 Safety Checklist for Injection Molding

By following these 7 steps, you can reduce accident rates by up to 60% (OSHA data):

- Pre-Shift Inspection: Inspect emergency stop functions, safety guards, and temperature control systems before operation.

- PPE Required: Ensure all personnel are equipped with appropriate protective gear, including gloves, goggles, steel-toe boots, and flame-resistant uniforms.

- Lockout/Tagout: Implement lockout/tagout procedures to isolate electrical power during maintenance or cleaning.

- Speed Limits: Limit machine speed to no more than 80% of the maximum cycle rate to avoid unnecessary strain or accidents.

- Material Safety: Store combustible materials, such as flammable plastics, away from any heat sources to prevent ignition.

- Training: Organize monthly safety drills focusing on emergency response protocols to ensure preparedness.

- Documentation: Maintain a comprehensive log of all incidents and near-misses for ongoing safety analysis and improvements.

4. Case Study: How Factory X Reduced Injuries by 74%

In 2023, a Texas-based plant reduced its injury rate from 14 to 3 per year by implementing these crucial steps:

- Infrared Sensors: The plant added infrared sensors to stop machines if hands enter dangerous zones, preventing serious injuries.

- Low-Smoke Plastics: They switched to low-smoke plastics like PP instead of PVC to protect workers from toxic fumes.

- AI-Powered Predictive Maintenance: AI systems were introduced to identify potential issues and make repairs before machines fail, keeping workers safe and operations smooth.

5. FAQs: Quick Answers to Top Safety Questions

Q: How often should I inspect machines?

A: Machines should undergo daily visual inspections, with a full maintenance check every 500 operating hours to ensure safety and efficiency.

Q: What temperature causes severe burns?

A: Molten plastic at temperatures above 200°C will cause severe burns to the skin in under one second.

Q: Are robots safer than manual operation?

A: Yes, robots minimize human exposure to hazards, reducing risk by up to 90%.

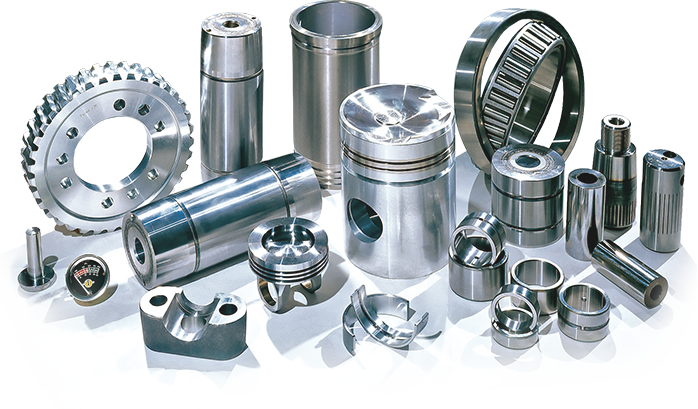

Applications of Injection Molding

Injection molding is widely used in various industries for its low cost and high precision.

1. Automotive Industry

Typical Parts:

-

Dashboards, air vents, and panels

-

Bumpers and grilles

-

Interior trim and door components

-

Electrical housings and connectors

-

Under-the-hood parts (reservoirs, covers)

Why Injection Molding?

-

Durability: High-performance thermoplastics withstand heat and chemicals.

-

Precision fit: Essential for interior components and assemblies.

-

Lightweighting: Replaces metal parts to reduce vehicle weight and improve fuel efficiency.

-

High-volume production: Ideal for mass-market automotive models.

2. Medical & Healthcare

Typical Parts:

-

Syringes and IV components

-

Diagnostic housings (e.g., glucose meters)

-

Surgical instruments

-

Implantable devices (temporary)

-

Laboratory containers (Petri dishes, test tubes)

Why Injection Molding?

-

Sterilizable materials: Can handle autoclave and gamma sterilization.

-

Cleanroom compatibility: Supports Class 7 or 8 cleanroom molding.

-

Biocompatibility: Medical-grade plastics like PEEK, PPSU, and PC.

-

Precision and safety: Tight tolerances are critical for functionality and hygiene.

3. Consumer Goods & Household Products

Typical Parts:

-

Toys (e.g., LEGO bricks)

-

Furniture parts (e.g., chair legs, wheels)

-

Kitchen utensils and containers

-

Tool handles and grips

-

Storage bins and organizers

Why Injection Molding?

-

Strength and safety: Child-safe materials and ergonomic designs.

-

Variety: Supports vibrant colors and intricate detailing.

-

Cost-effectiveness: Ideal for mass-market products.

-

Durability: Resistant to everyday wear and chemicals.

4. Aerospace and Defense

Typical Parts:

-

Interior panels and bezels

-

Lightweight brackets

-

Cable connectors

-

Ventilation components

-

Tooling and jigs

Why Injection Molding?

-

Weight reduction: Advanced thermoplastics like PEEK, PEI, and PPS replace metal.

-

Compliance: FAA and military-grade resin options available.

-

Precision: High tolerances ensure part reliability in harsh conditions.

-

Flame retardance: Specialized materials meet safety regulations.

Construction and Industrial Equipment

Typical Parts:

-

Fasteners, anchors, and spacers

-

Gears, pulleys, and housing components

-

Pipe fittings and connectors

-

Electrical switch housings

-

Handles, knobs, and grips

Why Injection Molding?

-

Impact resistance: Suitable for high-stress environments.

-

Corrosion resistance: Plastics outperform metals in harsh chemical settings.

-

Thermal stability: Insulation and fire resistance where needed.

-

Cost-effective durability: Low maintenance and long service life.

Conclusion: Protect Your Team & Productivity

Injection molding safety isn’t optional. By following this 2025 guide, you’ll prevent injuries, avoid OSHA fines (up to $15,625 per violation), and keep production lines running smoothly.

Looking for an injection molding manufacturer?

If you’re in need of a reliable injection molding manufacturer, look no further! NOBLE specializes in high-quality, efficient injection molding services tailored to meet your unique production needs. With advanced technology and a team of experienced professionals, we ensure precision, speed, and safety in every project.

Whether you’re creating complex prototypes or scaling up for large production runs, we have the expertise to bring your ideas to life.

Contact us today to discuss your project and get a personalized quote. Let’s work together to create top-notch products with outstanding results.