What is CNC machining?

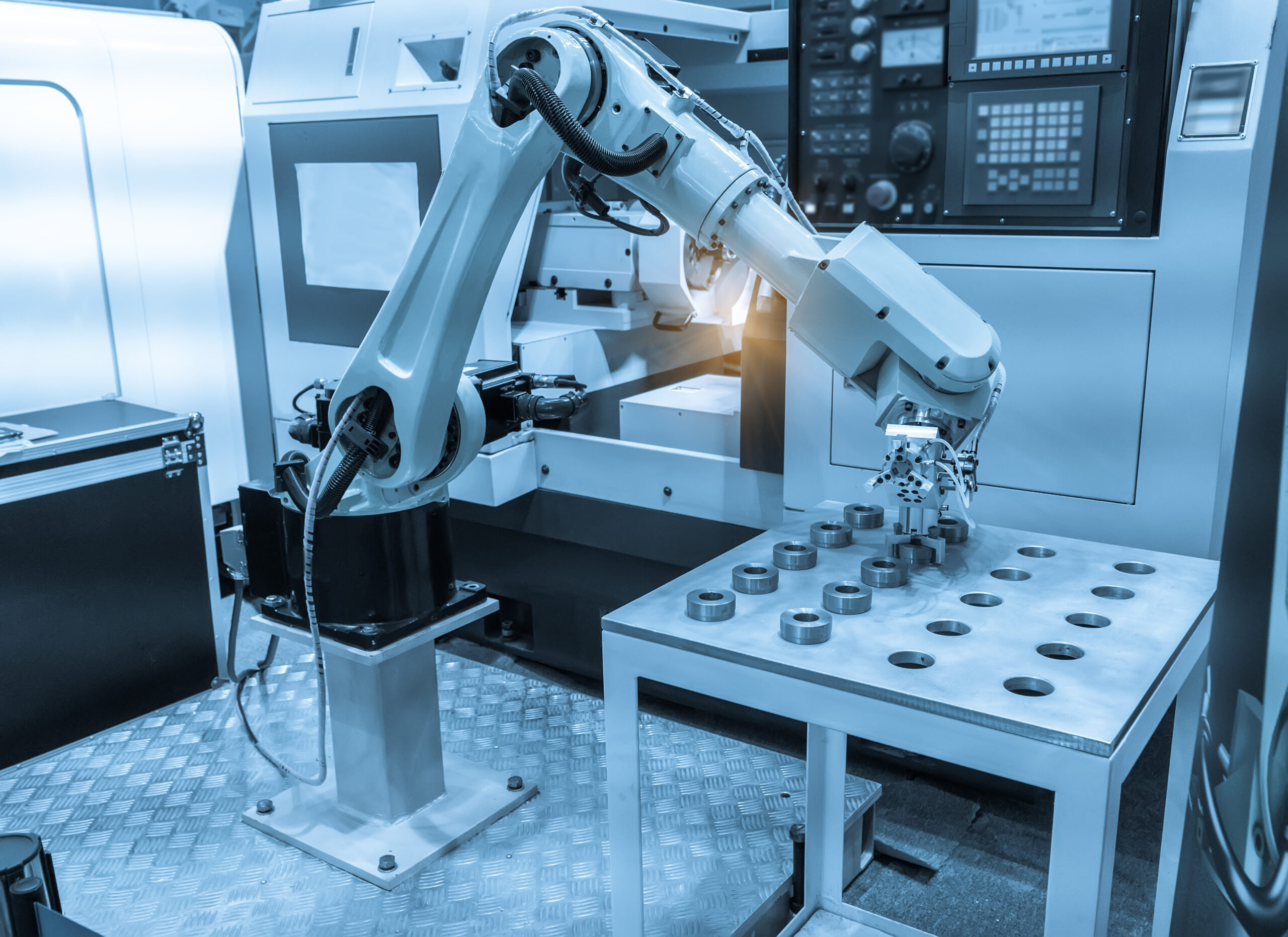

CNC machining is basically a way to make things more precise using computers. You feed a set of instructions into a machine, and it takes care of tasks like cutting, drilling, and milling. This method works with materials like metal, plastic, and wood. The cool thing about CNC is that it removes the guesswork and limitations of manual work, making the process much more automated and smarter overall.

Advantages of CNC machining:

1. High precision and repeatability:

CNC machines are incredibly precise, able to work down to the micron level, which guarantees that every product fits exact specifications and allows for smooth, repeatable mass production. Take the aerospace industry, for instance—CNC machining can make parts so precise that their tolerances are smaller than a hair’s width, ensuring aircraft are safe and reliable.

2. High efficiency:

CNC machining is super automated, running 24/7, which speeds up production and shortens delivery times. In the car manufacturing world, for example, it can quickly handle complex parts like engine blocks and gearbox shells, keeping up with the fast pace of mass production.

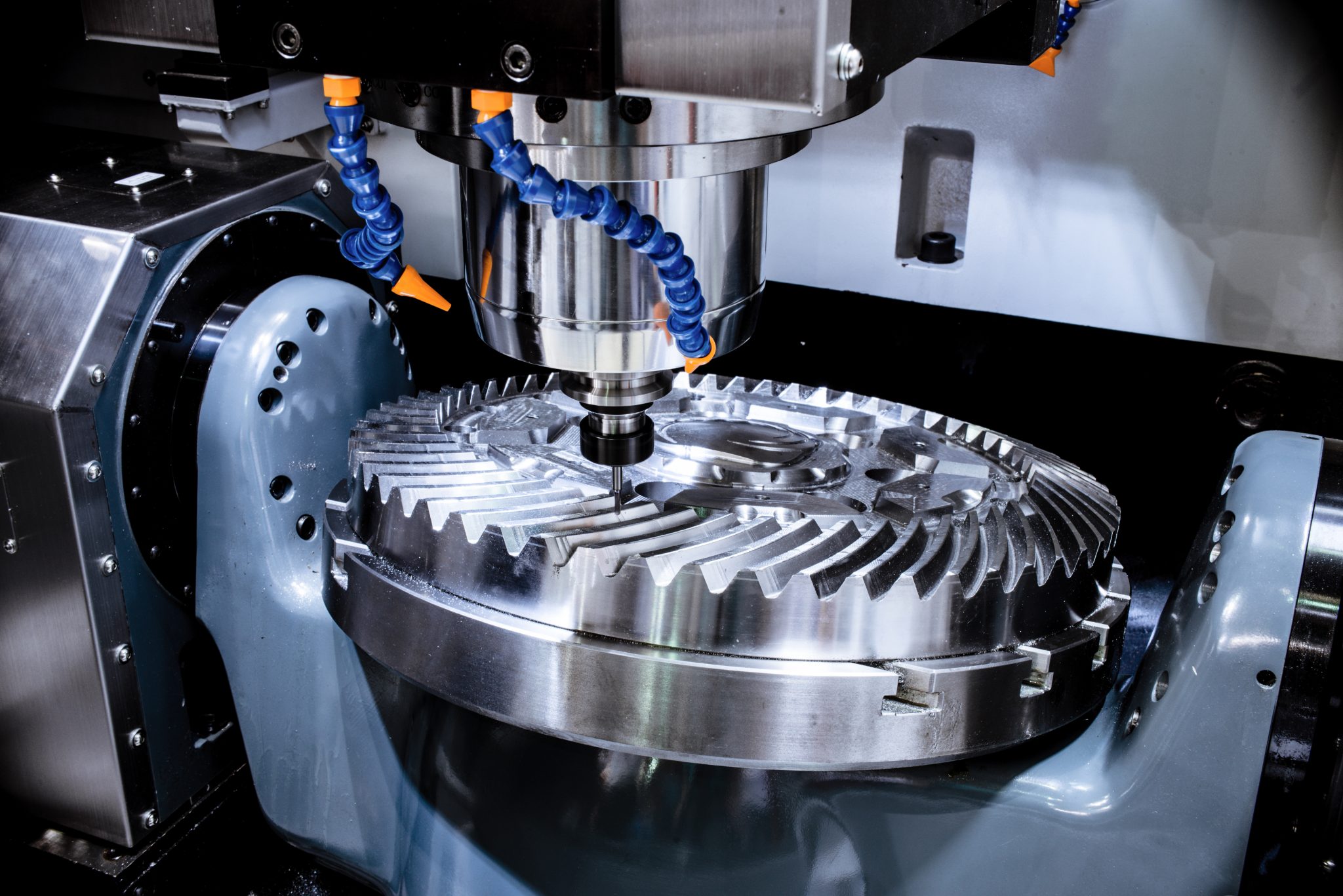

3. Complex parts machining:

CNC machines can easily handle complex shapes and fine details that would be tricky with traditional machining. In the medical field, for example, they’re used to make things like artificial joints and surgical tools with intricate curved surfaces and tiny, detailed structures, helping provide patients with more precise treatments.

4. Cost reduction:

Sure, CNC machines can be pricey to buy at first, but once you have them, they pay off. With their high efficiency, low waste, and lower labor costs, they can help bring down the overall cost of making things. In the electronics world, for example, CNC machining is used to mass-produce precise parts like phone housings and motherboards, making each product cheaper to produce.

5. High flexibility:

CNC machines can be quickly reprogrammed to handle the unique needs of different products, making them perfect for custom orders and small batch runs. For instance, in mold manufacturing, CNC machining can quickly create molds in all sorts of shapes and sizes to meet customer demands, ensuring production flexibility for different products.

Application areas of CNC machining:

CNC machining finds its place in tons of industries, such as:

- Aerospace: manufacturing aircraft engine parts, fuselage structural parts, and other precision components.

- Automotive manufacturing: production of engine blocks, gearbox housings, chassis parts, etc.

- Medical devices: processing artificial joints, surgical instruments, dental implants, etc.

- Electronic products: manufacture of precision parts such as mobile phone housings, computer motherboards, connectors, etc.

- Mould Manufacturing: Producing plastic injection moulds, stamping moulds, die-casting moulds, etc.

- Energy equipment: processing turbine blades, generator parts, etc.

- Precision instruments: manufacturing optical components, sensors, etc.

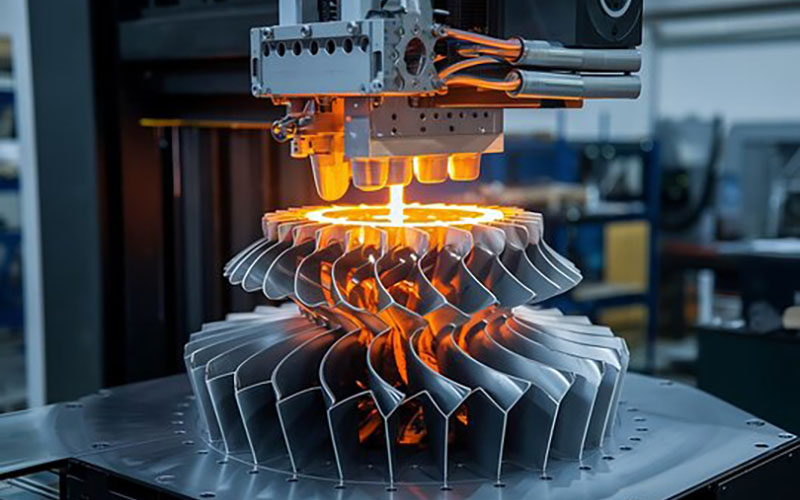

The future of CNC machining:

CNC machining is heading into an exciting future, with all kinds of cool new technologies coming into play. With advances in things like artificial intelligence and IoT, the industry will see a huge boost in automation and productivity, opening up even more possibilities for manufacturing.

- Intelligent: Expect CNC machines to come with smarter sensors and systems, which can monitor the process in real-time and adjust automatically for perfect results.

- Efficient: High-speed cutting and multi-axis technology will make CNC machining even faster, shaving down processing times significantly.

- Precision: Nano-level machining is going to take things to a whole new level, allowing for ultra-precise manufacturing needed for advanced tech products.

Conclusion:

CNC machining is the backbone of modern manufacturing, delivering unmatched precision, efficiency, and flexibility that benefit countless industries. By partnering with expert CNC machining services, you can not only improve the quality of your products but also cut down on costs and increase your market competitiveness. With continuous technological progress, CNC machining is poised to take on an even more significant role in shaping the future of manufacturing, helping usher in the era of Industry 4.0.