Aluminum 3D Printing Service

Custom Aluminum 3D Printing Service

Order custom aluminum 3D printing with fast turnaround times and cost-effective pricing. We offer a variety of aluminum materials and finishes suitable for both prototype development and full production runs.

- ISO 9001 & ISO 13485 Certified Factory

- Advanced Equipment & Competitive Pricing

- Over 10 Years of Experience in Aluminum 3D Printing

- Tight Tolerances of 0.001 mm

- Wide Range of Aluminum Material Options Available

- 24/7 Engineering Support

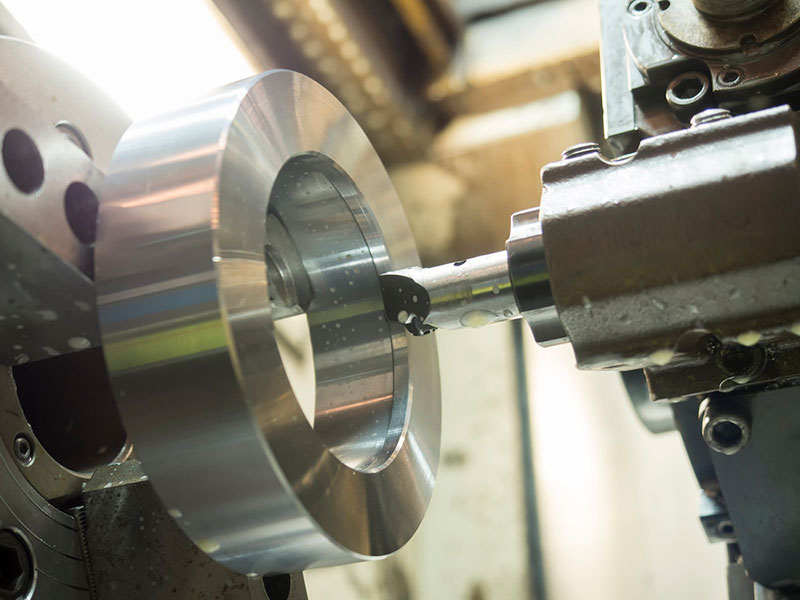

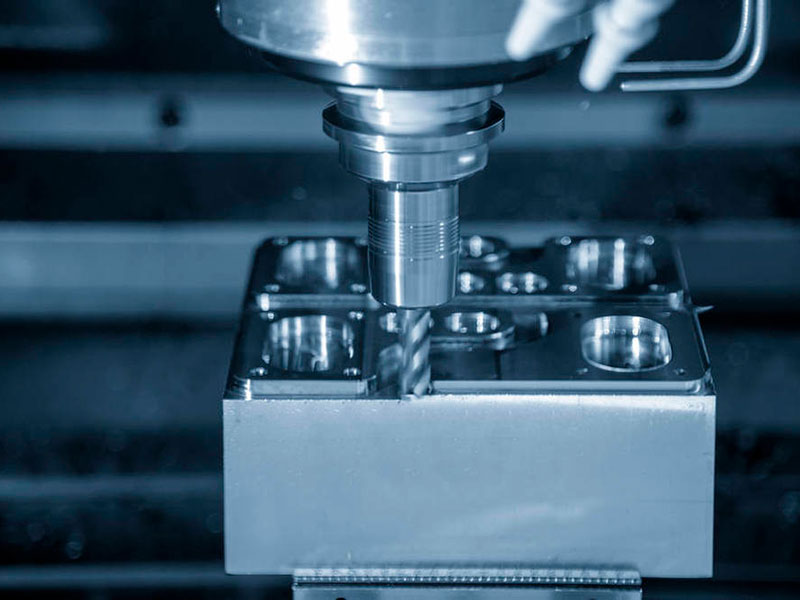

Our Aluminum 3D Printing Capabilities

Aluminum is a versatile and durable material that is widely used in 3D printing. It offers excellent corrosion resistance, making it a top choice for part manufacturing. With its excellent strength-to-weight ratio and superior thermal conductivity, aluminum is commonly used across industries such as automotive, aerospace, medical devices, electronics, consumer goods, and packaging. After 3D printing, aluminum exhibits minimal risk of deformation or surface defects, and it is easy to finish, color, and polish, making it ideal for producing high-quality, precise parts.

| Price | $ |

| Lead Time | <7 days |

| Wall Thickness | 0.75 mm |

| Tolerances | ±0.125mm(±0.005″) |

| Max Part Size | 200x80x100cm(78.74″x31.5″x39.37″) |

| Available Aluminum at NOBLE | Aluminum6061, 2024, 5052, 5083, 6061-T6, 6063, 6082, 7075, 7075-T6.ADC12(A380) |

Characteristics of 3D Printing Materialss

Aluminum is one of the most commonly used materials for 3D printing due to its excellent properties. Below are some key characteristics of aluminum that make it an ideal choice for part manufacturing:

| Features | Info |

| Subtypes | 6061-T6, 7075-T6, 7050, 2024, 5052, 6063, etc |

| Process | 3D printing, CNC machining, sheet metal fabrication |

| Tolerance | With drawing: as low as +/- 0.005 mm No drawing: ISO 2768 medium |

| Applications | Light & economic, used from prototyping to production |

| Finishing Options | Alodine, Anodizing Types 2, 3, 3 + PTFE, ENP, Media Blasting, Nickel Plating, Powder Coating, Tumble Polishing. |

Pros and Cons of Aluminum for 3D Printing

Aluminum is a popular material for 3D printing due to its light weight, excellent machinability, and versatility. It is favored in industries requiring efficient, high-performance parts, especially for short to medium production runs. However, it also has some limitations, such as lower strength compared to steel, wear susceptibility, and potential challenges related to thermal expansion and surface durability. Selecting the proper aluminum alloy and part design can help mitigate these challenges.

Lightweight

Aluminum alloys are much lighter than steel, making them ideal for 3D printing parts that need to be moved quickly or have a reduced weight to support the production of lighter plastic parts. This feature is particularly beneficial in industries like consumer electronics and automotive.

Excellent Machinability

Aluminum is easier to machine than many other metals, allowing for faster part production and high-precision part cavities. This results in lower 3D printing costs and shorter lead times for part manufacturers.

Corrosion Resistance

Aluminum’s natural oxide layer provides excellent protection against corrosion, making it a good choice for parts exposed to humid environments or certain types of plastics that may be corrosive.

Good Strength-to-Weight Ratio

Aluminum alloys, such as 6061 or 7075, provide a good balance of strength and weight, making them suitable for 3D printing parts that require structural integrity without the excessive weight of steel parts.

Versatility

Aluminum alloys are available in a variety of grades and compositions, offering properties such as better weldability, improved surface finish, and resistance to corrosion. This versatility allows for customized part designs that can meet specific product requirements.

Recyclability

Aluminum is 100% recyclable without degradation of its properties, making it an environmentally friendly option for 3D printing parts and contributing to cost savings over time.

Thermal Conductivity

Aluminum has excellent thermal conductivity, which helps improve cycle times in 3D printing by promoting efficient heat transfer. This can enhance production efficiency and part quality, especially for 3D printing parts that require quick cooling.

Cost-Effectiveness

Aluminum parts, especially for low-to-medium volume production, are often more cost-effective than steel parts. They offer a good balance of performance and affordability for applications where high production rates are not critical.

Lower Strength Compared to Steel

While aluminum parts are sufficient for many applications, they are not as strong as steel parts, which can limit their use for high-pressure parting or long production runs. In these cases, steel may be a better choice due to its higher wear resistance.

Softness and Wear Sensitivity

Aluminum is softer than steel, which makes it more prone to wear and surface damage, especially when parting abrasive plastics or running parts with high cycle counts. This may result in the need for more frequent maintenance or repairs.

Tool Wear

Although aluminum is easier to machine, it can still cause tool wear during the initial part creation, especially when dealing with high-strength aluminum alloys or when machining intricate part features at high speeds.

Thermal Expansion

Aluminum’s high coefficient of thermal expansion can lead to dimensional changes during the 3D printing process, particularly when rapid temperature fluctuations occur. This can affect part tolerances and the part’s overall precision.

Relatively Higher Cost for High-Grade Alloys

While aluminum is generally less expensive than steel, high-performance aluminum alloys (such as 7075) used in parts for certain plastics or high-precision applications can still be costly.

Potential for Surface Damage

Aluminum parts may experience surface degradation due to abrasive or chemically reactive plastics, which can impact part longevity. Protective coatings or anodizing treatments can be used to improve surface hardness and corrosion resistance, but these treatments add additional cost and complexity.

Types of Aluminum 3D Printing Materials

NONLE has worked with various aluminum subtypes for 3D printing, offering a wide selection of materials tailored to different part requirements:

Aluminum 6061-T6

6061 aluminum is a versatile alloy commonly used in 3D printing due to its excellent machinability, corrosion resistance, and weldability. It is ideal for creating parts for applications in aerospace, automotive, marine, construction, and consumer goods, offering a good balance of strength and weight.

Yield Strength(MPa): 276

Elongation at Break(%): 17

Hardness(Brinell): 95

Density(G/m³): 2.7

Maximum Temp: 1080° F

Aluminum 7075-T6

Aluminum 7075-T6 is widely used in high-strength applications such as aerospace, military, automotive, and sporting goods, including aircraft structures, marine components, and performance-oriented parts, due to its superior strength-to-weight ratio and resistance to stress corrosion.

Yield Strength(MPa): 503

Elongation at Break(%): 11

Hardness(Brinell): 150

Density(G/m³): 2.8

Maximum Temp: 380° F

Aluminum 5052

This alloy is known for its excellent corrosion resistance, formability and weldability. It is widely used in the marine, automotive, construction and chemical industries. Its excellent formability makes it an ideal choice for CNC machining projects.

Yield Strength(MPa): 193

Elongation at Break(%): 12

Hardness(Brinell): 60

Density(G/m³): 2.68

Maximum Temp: 300° F

Aluminum 6063

6063 aluminum is ideal for CNC machining of architectural applications, window frames, door frames, furniture, and structural parts for irrigation pipes due to its excellent surface finish, good corrosion resistance, and its excellent ease of machining.

Yield Strength(MPa): 214

Elongation at Break(%): 12

Hardness(Brinell): 73

Density(G/m³): 2.7

Maximum Temp: 212° F

Aluminum 6061

6061 aluminum is widely used in aerospace, automotive, marine, construction and industrial applications due to its excellent strength, corrosion resistance and machinability. It is ideal for custom CNC machining of aircraft structures, vehicle components, marine equipment.

Yield Strength(MPa): 276

Elongation at Break(%): 17

Hardness(Brinell): 95

Density(G/m³): 2.7

Maximum Temp: 300° F

Aluminum 2024

Aluminum 2024 is widely used in aerospace, military and high-stress structural applications due to its high strength, fatigue resistance and ability to withstand extreme conditions. It is ideal for CNC machining of aircraft fuselages, wings and military vehicles.

Yield Strength(MPa): 325

Elongation at Break(%): 20

Hardness(Brinell): 120

Density(G/m³): 2.78

Maximum Temp: 935° F

Aluminum 5083

Aluminum 5083 is widely used in marine, transportation and industrial applications due to its excellent corrosion resistance (especially in saltwater environments) and high strength. It is ideal for shipbuilding, pressure vessels and CNC machining of car body parts.

Yield Strength(MPa): 275

Elongation at Break(%): 12

Hardness(Brinell): 75

Density(G/m³): 2.66

Maximum Temp: 775 °F

Aluminum 6082

Aluminum 6082 is widely used in structural applications such as bridges, cranes and industrial machinery due to its excellent strength, corrosion resistance and machinability. It is ideal for CNC machining of transportation equipment and connecting equipment parts.

Yield Strength(MPa): 260

Elongation at Break(%): 11

Hardness(Brinell): 95

Density(G/m³): 2.7

Maximum Temp: 330 °F

Aluminum 7075

7075 aluminum is widely used in high-performance applications, including aerospace, military, and sporting goods, due to its outstanding strength, light weight, and resistance to stress and fatigue. It is ideal for CNC machining of aircraft structures, defense equipment, and bicycle frame parts.

Yield Strength(MPa): 503

Elongation at Break(%): 11

Hardness(Brinell): 150

Density(G/m³): 2.81

Maximum Temp: 775 °F

Aluminum ADC12 (A380)

Aluminum ADC12 (A380) is widely used in the automotive, aerospace and manufacturing industries for its excellent fluidity, castability and corrosion resistance to produce die-cast components and is ideal for CNC machining of engine components, transmission housings, automotive wheels and industrial machinery parts.

Yield Strength(MPa): 160

Elongation at Break(%): 3.5

Hardness(Brinell): 80

Density(G/m³): 2.74

Maximum Temp: 572 °F

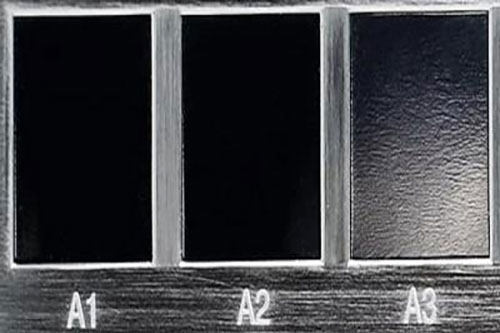

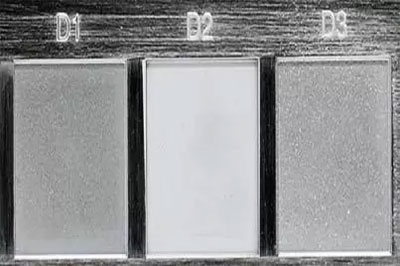

Surface Finishing Options for 3D Printing

Our superior surface finishes can make your custom 3D printing parts stand out even more. We offer a diverse range of finishing solutions to enhance the surface quality of your parts. These coatings also improve the mechanical strength and durability of your parts.

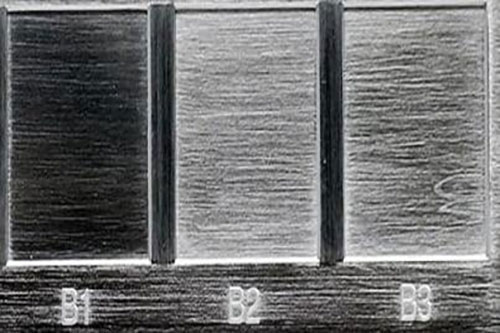

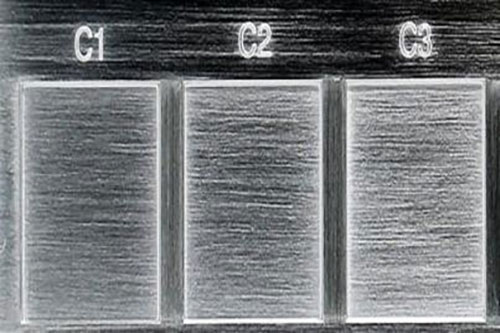

Glossy

A grade finishes are made using a diamond buffing process and yield shiny and glossy surfaces on 3D printi parts.

Semi-glossy

B grade finishes use grit sandpaper to produce parts with a slightly rougher finish than grade A parts. Custom 3D printing plastic parts that undergo B grade finishing have a matte surface texture.

Matte

C grade finishes use grit sanding stones to produce a rough, uneven surface. 3D printing plastic parts that undergo C grade finishing have a matte surface texture.

Textured

D grade finishes use grit and dry glass beads or oxide to produce a very rough textured finish. Depending on the type of material used, products can have a satin or dull finish.

Custom Aluminum 3D Printing Parts Display

Check out our over ten years of custom aluminum 3D printing parts, including precision aluminum prototypes and parts from our valued customers.

Applications of Aluminum 3D Printing

Aluminum 3D printing is widely utilized across various industries, including aerospace, automotive, electronics, medical devices, and robotics, for producing lightweight, high-precision components such as aircraft parts, enclosures, surgical instruments, and robotic components.

Automotive Parts

Aluminum 3D printing is heavily used in the automotive industry to produce lightweight, high-performance components. By utilizing aluminum, manufacturers can reduce the overall weight of vehicles, leading to improved fuel efficiency, better handling, and enhanced vehicle performance.

Aerospace Parts

In the aerospace sector, aluminum 3D printing is employed to manufacture lightweight and strong components, such as fittings, brackets, housings, and interior parts, which are critical for reducing the overall weight of aircraft. Aluminum's strength-to-weight ratio makes it perfect for aerospace applications where both durability and lightness are essential to ensure safe and efficient flight.

Medical Devices

Aluminum 3D printing plays a crucial role in the medical industry by producing lightweight, high-precision components like surgical instruments, diagnostic equipment housings, and implantable devices. Aluminum's biocompatibility, corrosion resistance, and ability to achieve tight tolerances make it an excellent choice for medical device manufacturers requiring high-quality, reliable components.

Robotics Parts

In the robotics industry, aluminum 3D printing is essential for producing precision components such as robotic frames, joints, gears, and connectors. Aluminum's lightweight and strong properties help create efficient and reliable robotic systems that can handle complex movements and dissipate heat effectively, enabling robots to perform specific functions with higher precision and longer operational lifespans.

Industrial Equipment

Aluminum 3D printing is widely used in the production of lightweight and durable components for industrial equipment. It allows for the creation of complex, high-precision parts that are vital to machinery performance and operational efficiency.

New Energy

In the new energy sector, aluminum 3D printing supports the production of lightweight, precise components essential for the development of renewable energy technologies, such as solar panels, wind turbines, and battery housings.

If you are looking for a rapid prototyping manufacturer or a CNC machine shop to fabricate small, medium-volume, or mass-production products, NOBLE is an ideal choice.Our well-trained and experienced staff manufactures parts in line with drawings on modern CNC machines, with the highest accuracy and processing quality in all sizes.In addition, we provide professional design considerations for your CNC machining projects.

Want to get the most professional and fastest service for your CNC machining project? Upload your CAD files now and obtain a quote!