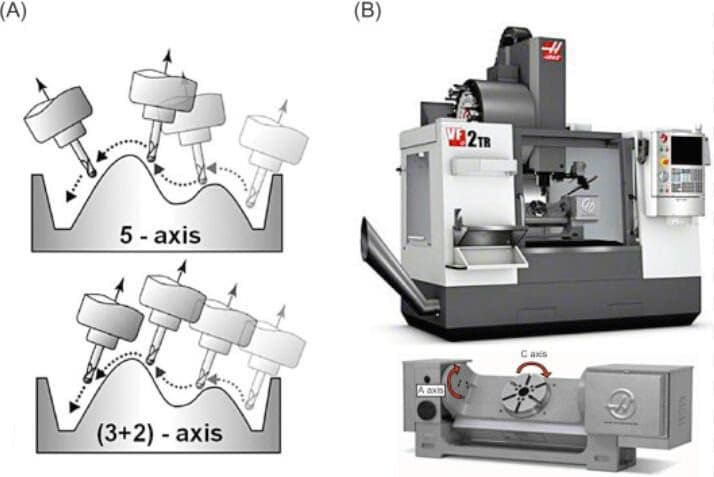

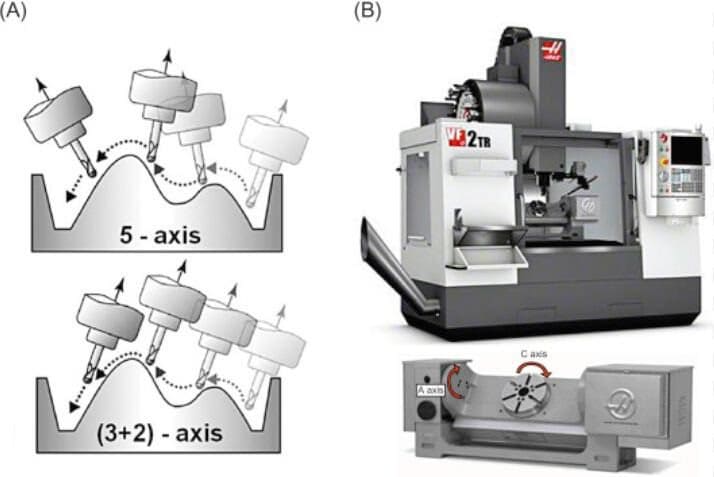

3+2-axis CNC machining helps you make hard parts. It utilizes three straight axes and two rotating axes that remain stationary. You set the rotary axes at an angle. The machine then cuts from that spot. This method is important because it makes work faster and more exact. You can finish more parts quickly and with fewer mistakes.

| Benefit | Description |

| Efficiency | Fewer setups make work faster and easier to reach. |

| Accuracy | Less movement means parts fit together better. |

| Lower Costs | Less cutting time and less waste save money. |

| Higher Complexity | Easier to reach tough spots for detailed work. |

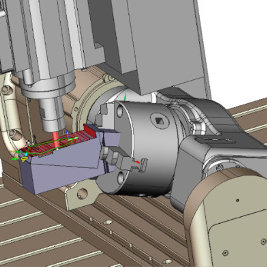

3+2 Axis CNC Machining Basics

Definition

3+2 machining is a way to use a three-axis milling program. The cutting tool stays tilted because the machine locks two rotational axes. That is why it is called 3+2 machining. People also call it ‘positional 5-axis machining.’ The fourth and fifth axes set the tool in one spot. They do not move the tool while cutting.

You use 3+2-axis CNC machining on a 5-axis CNC machine. The machine locks the A and C axes at an angle. This lets you reach more sides of the part. The tool does not move during cutting. Many companies in China use this method for custom work. You can reach tricky surfaces and finish jobs faster.

How It Works

First, you set the rotary axes to the right angle. The machine keeps these axes still. The cutting tool moves along X, Y, and Z axes. The tool does not tilt or spin while cutting. It stays at the angle you picked. This is not like full 5-axis CNC machining. In a full 5-axis, the tool moves and spins at the same time. You can use shorter cutting tools. Shorter tools help you get better accuracy and smoother surfaces.

- You set the part with the rotary axes.

- You lock the axes before you start.

- You run the 3-axis program with the tool at the angle.

This method helps you reach hard spots. You do not need extra setups. You make fewer mistakes. Many shops use 3+2-axis CNC machining for parts that need to fit well and look smooth.

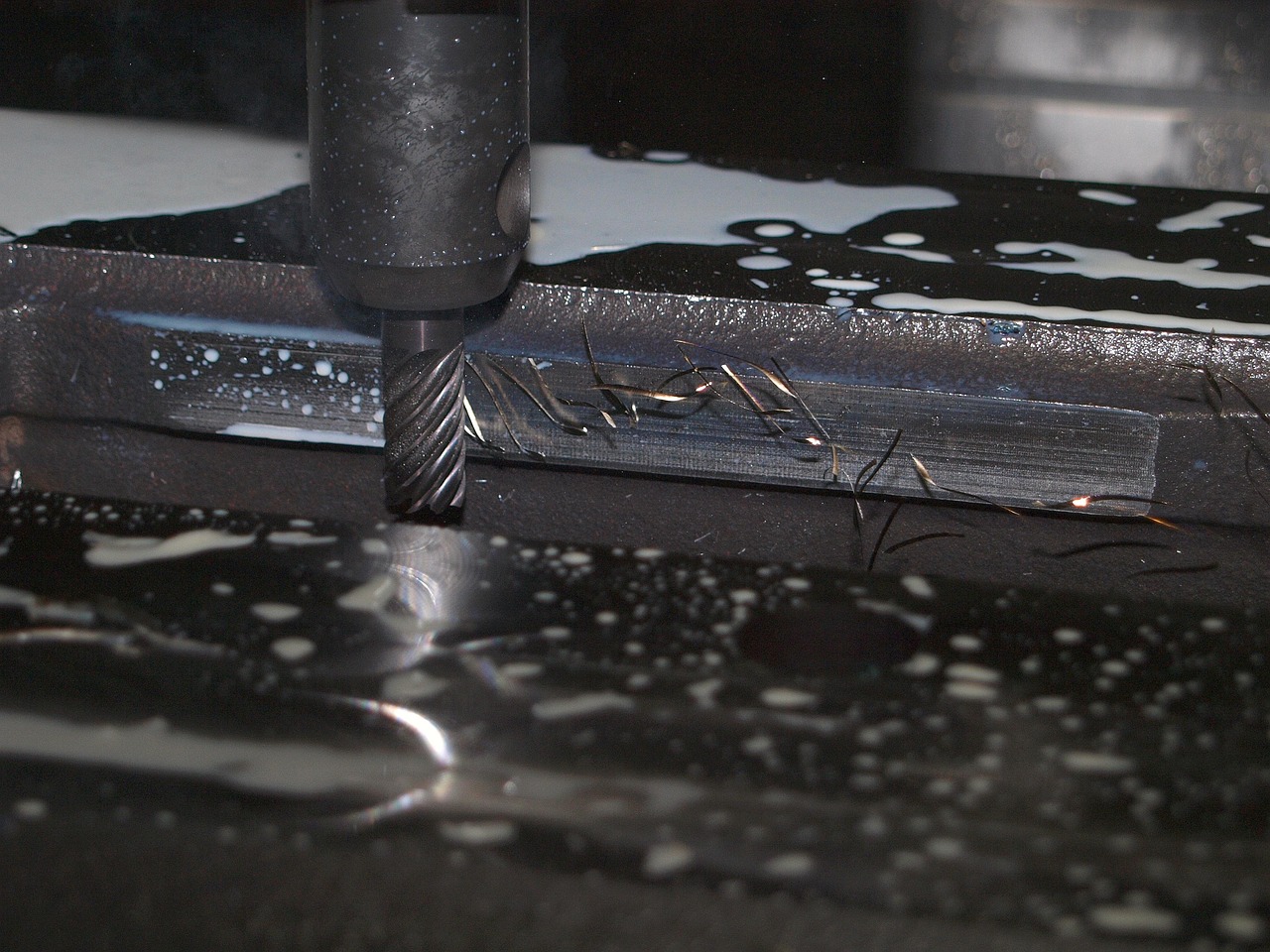

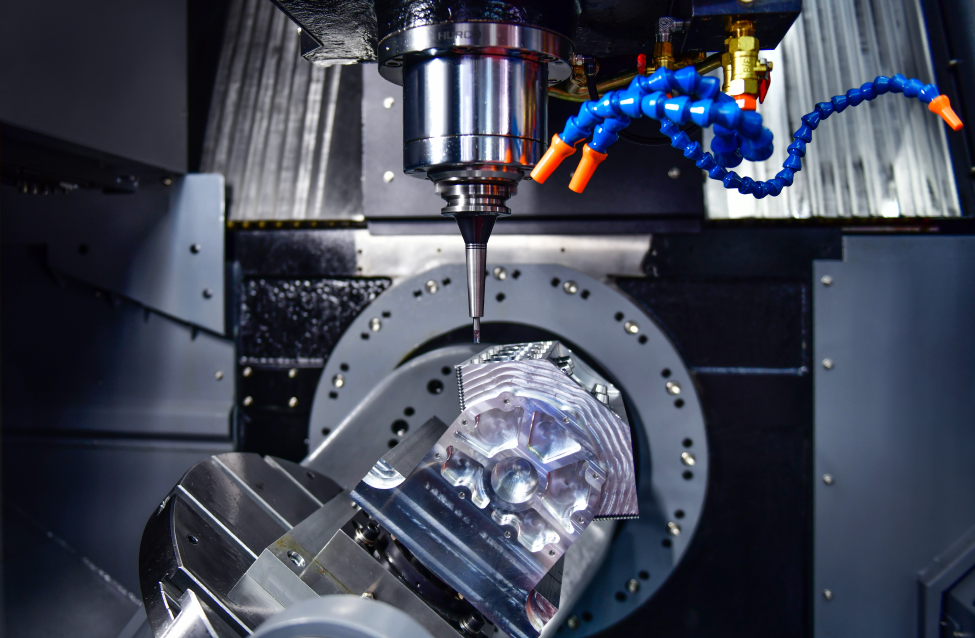

Machine Setup

You get the machine ready by putting the workpiece on the table. You pick the best cutting tool for the job. Shorter tools work better because they do not bend or shake much. This helps you keep the size and shape right.

| Parameter | Impact on Stability and Accuracy |

| Tool Diameter | Bigger diameters make the tool stronger. This helps you cut faster and keeps the tool steady. Smaller diameters are good for careful work but need slower speeds so the tool does not break. |

| Tool Length | Shorter tools do not bend or shake as much. This makes your work more accurate and smooth. Longer tools can bend and shake more, which is not as good. |

You check the rotary axes and lock them. You load the program and start cutting. You can cut faster, and the tool does not bend much. You get better results, especially for tough molds and custom jobs.

Tip: Using short, strong tools in 3+2 axis CNC machining helps you keep parts the right size and get smooth surfaces. Many companies in China use this way for careful and exact work.

Operation Process

Step-by-Step Workflow

You can follow a clear process to run a 3+2-axis CNC machining job. This method helps you make complex parts with fewer errors. Here is a typical workflow:

- Design your part in CAD software. Add any angled or hard-to-reach features.

- Import your model into CAM software. Set the tool orientation for each surface or feature.

- Choose the right angle for the rotary axes. The A and B axes help you orient the part.

- Lock the part at the fixed tilt position. The machine uses the rotary table or head to do this.

- Run the machining cycle. The tool moves in X, Y, and Z directions to cut the feature.

- Reposition if needed. If your part has more angled surfaces, rotate the part again and repeat the process.

You can see that the tool stays locked in a tilted position for each operation. This setup lets you reach more surfaces without moving the part by hand. You save time and reduce mistakes.

Toolpath and Programming

You need to plan your toolpath before you start cutting. The toolpath tells the machine where to move the cutting tool. In 3+2 axis CNC machining, you set the angle of the cutting head before you begin. The cutting head stays at that angle the whole time.

With a 3+2 axis machine, you can cut more complex shapes and handle non-orthogonal features. However, these added 2 axes are static, or stationary. The machinist would set the angle of the cutting head before they start machining the part, and the cutting head will stay at that angle the entire time.

You use CAM software to program the toolpath. You select the surfaces you want to machine. The software helps you pick the best angles for the rotary axes. You can use shorter tools, which makes your cuts more accurate. You do not need to stop and reset the part for each face.

3+2 vs. 3-Axis

You might wonder how 3+2-axis machining compares to traditional 3-axis machining. The main difference is the ability to reach more complex shapes without extra setups.

| Feature | 3+2 Axis CNC Machining | Traditional 3-Axis CNC Machining |

| Workpiece Movement | Remains stationary | Remains stationary |

| Cutting Tool Movement | Moves along two additional axes | Moves along three axes only |

| Complexity of Machining | Allows for more complex geometries | Limited to simpler geometries |

- 3+2 axis machining allows you to create more complex geometries because you can move the cutting tool to different angles.

- Traditional 3-axis machining works well for 2D and 2.5D parts. You need to set up the part again to machine every side.

- With 3+2 axes, you reduce the number of setups. You can finish the part faster and with better accuracy.

This process helps you make parts that fit together well and look smooth. Many shops use this method for custom jobs and precision manufacturing.

3+2 Axis CNC Machining Benefits

Efficiency

You want your shop to run faster and smoothly. 3+2 axis CNC machining helps you do just that. This method lets you machine parts from several sides without stopping to move the workpiece. You set the rotary axes once, and the machine can reach hard angles in one go. This saves you time and effort.

- You spend less time setting up because you do not need to reposition the part for each side.

- The machine can cut from different angles in one setup, so you finish jobs quicker.

- Shorter, stronger cutting tools last longer and work faster, which keeps your shop moving.

When you use 3+2-axis CNC machining, you also reduce idle time. The machine stays busy, and you get more parts done in less time. You can handle more orders, which helps your manufacturing company in China stay ahead. This method also works well for customized machining, where every minute counts.

Tip: If you want to boost your shop’s productivity, try using multi-axis CNC machining. You will see faster cycle times and fewer delays.

Accuracy

You need your parts to fit perfectly every time. 3+2-axis CNC machining gives you better accuracy because the tool stays steady. When you lock the rotary axes, the tool does not shake or bend as much. This means you get smoother surfaces and tighter tolerances.

- Shorter tools do not flex, so you get cleaner cuts.

- The machine holds the part at the best angle, so you can reach tricky spots without errors.

- You avoid mistakes that come from moving the part by hand.

Precision manufacturing depends on accuracy. With this method, you can trust that each part will match your design. Many shops use 3+2 axis CNC machining for aerospace and medical parts, where every detail matters. You can also use it for custom jobs that need exact shapes and sizes.

Cost Savings

You want to save money on every job. 3+2-axis CNC machining helps you cut costs in several ways. You spend less time setting up, so you pay less for labor. The machine does more work in one go, which lowers your energy use.

- You use fewer setups, so you waste less material.

- Shorter tools last longer, so you buy replacements less often.

- You finish jobs faster, so you can take on more work.

This approach also reduces the risk of scrap parts. When you make fewer mistakes, you do not have to throw away as much material. Your shop becomes more efficient, and you keep your customers happy. If you compare this to 5-axis CNC machining, you will see that 3+2-axis CNC machining often costs less for many jobs, especially when you do not need full simultaneous movement.

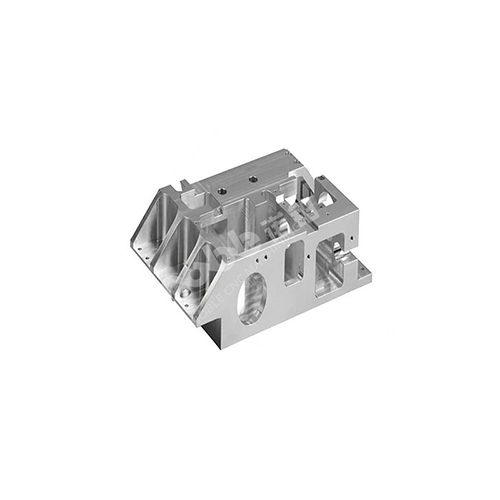

Complex Parts

Making parts with tricky shapes can be hard. 3+2-axis CNC machining makes this easier for you. You can turn the rotary axes to reach tough spots. This means you do not need to move the workpiece a lot. You get smooth cuts and nice finishes, even on odd shapes.

You can count on 3+2-axis CNC machining for jobs that need high accuracy. The machine locks the rotary axes in place. You can use shorter and stronger tools. These tools stop shaking and bending. This keeps your cuts neat and exact.

Many industries use this technology for their hardest jobs. You see it in aerospace, medical, optical, and defense work. These fields need parts with special shapes, deep holes, and tiny details. You can make these features fast and with fewer mistakes.

- Aerospace companies need blades and parts with curved shapes.

- Medical makers need implants and tools with special shapes.

- Optical companies make lenses and cases with exact shapes.

- Defense builders make parts with many sides for special gear.

Multi-axis machining lets you turn and tilt the part. Modern CNC machines control both turning and moving. You can reach every side without stopping to reset the part. This saves you time and lowers mistakes.

- You can cut undercuts, angled holes, and deep pockets in one go.

- You use fewer setups, so you make fewer mistakes.

- You can make harder parts without losing speed or accuracy.

If you work in a factory in China, you know custom machining is important. 5-axis CNC machining lets you make special parts for many jobs. You can do projects that need tough shapes and smooth finishes.

Tip: 3+2-axis CNC machining lets you design new kinds of parts. You can make things that 3-axis machines cannot. This helps you stay ahead and give your customers the best.

More axes mean you can make even harder CNC parts. You can help industries that need fast and exact work. This method helps your business grow and take on the hardest jobs today.

Surface Finishes for 3+2-Axis CNC Machining

3+2-axis CNC machining leaves noticeable tool marks as the block’s surface is removed to create the desired shape. Please select the appropriate surface finish for your custom part. NOBLE offers a variety of common surface finishes to enhance both the functionality and aesthetics of your part.

| Surface Finishes | Features | Option |

| Anodizing | Anodizing improves corrosion resistance, enhancing wear resistance and hardness, and protecting the metal surface. Widely used in mechanical parts, aircraft, and automobile parts, precision instruments, etc. | Materials: Aluminum

Color: Clear, black, grey, red, blue, gold.

Texture: Smooth, matte finish |

| Sand Blasting | Sand blasting results in parts with a smooth surface with a matte texture. Used mainly for visual applications and can be followed by other surface treatments. | Materials: ABS, Aluminum, Brass

Color: N/A

Texture: Matte |

| Powder Coating | Powder coating is a type of coating that is applied as a free-flowing, dry powder. Unlike conventional liquid paint, which is delivered via an evaporating solvent, powder coating is typically applied electrostatically and then cured under heat or with ultraviolet light. | Materials: Aluminum, Stainless Steel, Steel

Color: Black, any RAL code or Pantone number

Texture: Gloss or semi-gloss |

| Electroplating | Electroplating can be functional, decorative or corrosion-related. Many industries use the process, including the automotive sector, in which chrome-plating of steel automobile parts is common. | Materials: Aluminum, steel, Stainless Steel

Color: N/A

Texture: Smooth, Glossy finish |

| Polishing | Polishing is the process of creating a smooth and shiny surface, either through physical rubbing of the part or by chemical interference. The process produces a surface with significant specular reflection, but in some materials is able to reduce diffuse reflection. | Materials: Aluminum, Brass, Stainless Steel, Steel

Color: N/A

Texture: Glossy |

| Brushing | Brushing is a surface treatment process in which abrasive belts are used to draw traces on the surface of a material, usually for aesthetic purposes. | Materials: ABS, Aluminum, Brass, Stainless Steel, Steel

Color: N/A

Texture: Satin |

Applications of 3+2 Axis CNC Machining

Aerospace

3+2 axis CNC machining is used a lot in aerospace. This field needs parts that can handle heat, pressure, and shaking. Every part must fit right and work safely. This technology helps you make shapes that are hard to create. You can also make parts with tight tolerances, which are important for flying.

You often use this method to make:

- Landing gear parts

- Turbine blades and engine covers

- Valve and actuator pieces

- Oxygen system parts

- Electrical connectors and motion controls

- Fuselage and wing ribs

- Missile and cabin parts

You trust 3+2-axis CNC machining for making these important parts. Locking the rotary axes helps you reach tough angles. You do not need to move the part by hand. This lowers mistakes and keeps your work fast. Many companies, like those in China, use this way to meet strict rules and give good results.

Medical Devices

3+2-axis CNC machining is important in the medical field. Hospitals and clinics need safe and accurate devices. Each device must fit the patient well. This method lets you shape metal and plastic with great care. You can make things like surgical tools and custom implants.

Here is how this technology helps you:

| Application/Benefit | Description |

| Precision and Accuracy | You get the right shapes and sizes for medical devices. |

| Customized Implants | You can make implants that fit each patient better. |

| Intricate Surgical Instruments | You create complex tools for careful surgeries. |

| Reliable Diagnostic Equipment | You make parts for machines that help doctors find problems fast. |

3+2-axis CNC machining lets you use machines to make more parts quickly. You also make fewer mistakes, which is very important in medicine. You might use this method to make bone plates, dental implants, or MRI machine parts. The high accuracy helps you do both careful and custom work. That is why medical device makers all over the world choose this method.

Automotive

3+2-axis CNC machining is very useful in making cars. Car makers need strong parts that fit together well. You use this technology to make engine and drivetrain parts. You also make parts for brakes, suspension, and exhaust systems.

Some parts you can make are:

- Engine parts: camshafts, cylinder heads, crankshafts

- Drivetrain parts: gears, shafts, axles

- Suspension parts: control arms, springs, shock absorbers

- Brake parts: rotors, calipers

- Exhaust parts: manifolds, mufflers

- Fuel system parts: injectors, fuel rails

This method helps you make many parts fast or do custom jobs. You keep your quality high and your costs low. With 3+2-axis CNC machining, you can finish work on time and meet safety rules. Many companies in China use this technology to stay ahead in the world market. Sometimes, you need 5-axis CNC machining for even harder shapes. But for most car parts, 3+2 axis CNC machining gives you the best mix of speed and accuracy.

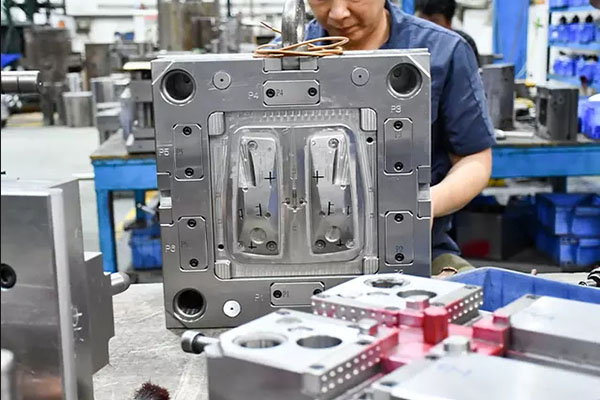

Mold Making

Mold making is very important in precision manufacturing. 3+2-axis CNC machining lets you make molds with hard shapes. This method helps you reach spots that 3-axis machines cannot get to. You set the rotary axes at an angle. The machine can cut deep pockets, undercuts, and curves easily.

Many mold makers use 3+2-axis CNC machining for plastic injection molds. You need to make cavities and cores with tight fits. This technology lets you use shorter and stronger tools. You get smoother surfaces and better accuracy. The tools do not shake, so your molds last longer and work better.

Tip: 3+2-axis CNC machining helps you make cutting tools and dies. You can get sharp edges and detailed features with this method.

If you work in a factory in China, you know speed and quality matter. You want to finish molds fast and avoid mistakes. 3+2-axis CNC machining means you need fewer setups. You lock the rotary axes, and the machine reaches hard angles in one try. You save time and spend less money.

Here is a table that shows how different machining types help with mold making:

| Machining Type | Advantages of Mold Making |

| 3+2 Axis | Easier programming, access to challenging areas, and suitable for complex shapes |

| 5 Axis | Enhanced versatility, machining from multiple angles, and better for intricate features |

| 3 Axis | Common for many tasks, but limited in complex mold requirements |

You can see that 3+2-axis CNC machining is great for custom jobs. You program the machine to tilt and lock at the best angle. You reach deep spots and small details without moving the mold by hand.

- You make complex shapes for plastic injection molding.

- You create cutting tools and dies with high precision.

- You work on molds with curves and undercuts.

If you want to make your work better, try these steps:

- Use 5-axis CNC machining to reach more angles without moving the mold.

- Pick this method for molds with undercuts or small details.

- Get advanced CNC machines to make your work faster and more accurate.

You get more control over how you make molds. You make molds that meet strict rules for quality and performance. You help your company give better products to customers. 3+2 axis CNC machining helps you stay ahead in precision manufacturing.

3+2 Axis CNC Machining vs. 5 Axis CNC Machining

What is 5 Axis CNC Machining

You may wonder how 5-axis CNC machining works. This technology lets you move the cutting tool in five directions at the same time. You use three linear axes—X, Y, and Z. You also use two rotary axes, often called A and B or A and C. The machine can tilt and rotate the tool while it cuts. You get more freedom to shape parts with curves, angles, and deep pockets.

Here is a table that shows how movement works in both systems:

| Axis | Movement Description |

| 5-axis CNC machining | Moves in all directions at once. Uses three straight axes and two rotating axes for complex shapes. |

| 3+2 Axis CNC Machining | Combines three straight axes with two locked rotary axes. Good for flat processing and angled surfaces. |

With 5-axis CNC machining, you can create parts with many surfaces in one pass. You do not need to stop and reset the part. This method helps you finish jobs faster and with fewer errors. Many shops use this technology for precision manufacturing, especially when you need detailed features.

Key Differences

You need to know how these two methods compare. Here are the main differences:

- 5-axis CNC machining lets you move the tool and part at the same time. You can cut curves, holes, and shapes from many angles.

- 3+2-axis CNC machining locks the rotary axes before cutting. The tool stays at a fixed angle. You use this for flat surfaces or angled features.

- 5-axis CNC machining works best for complex shapes and intricate details.

- 3+2-axis CNC machining is more efficient for flat processing tasks.

- You can create multiple surfaces in a single pass with 5-axis CNC machining. This boosts productivity and saves time.

If you work for a manufacturing company in China, you may use both methods. You pick the best one for each job. For customized machining, you often need the flexibility of 5-axis CNC machining. For simpler tasks, 3+2-axis CNC machining gives you speed and accuracy.

Pros and Cons

You want to choose the right method for your shop. Here are the pros and cons of each:

| Method | Pros | Cons |

| 5-axis CNC machining | Handles complex shapes. Cuts many surfaces in one setup. Improves precision manufacturing. | Needs advanced programming. Costs more. Requires skilled operators. |

| 3+2 Axis CNC Machining | Faster setup. Uses shorter tools for better accuracy. Saves money on simple jobs. | Limited to fixed angles. Not ideal for very complex shapes. |

- 5-axis CNC machining gives you more options for customized machining. You can make parts for the aerospace, medical, and automotive industries.

- 3+2 axis CNC machining works well for molds, flat surfaces, and jobs that need tight tolerances.

Tip: If you want to make parts with deep pockets or undercuts, use 5-axis CNC machining. For flat or angled surfaces, 3+2-axis CNC machining is faster and easier.

You can see that both methods help you reach high standards in precision manufacturing. You choose the best one based on your part design, budget, and skill level.

When to Use Each

You have many choices in precision manufacturing. You want the best method for your project. Sometimes, you pick 3+2-axis CNC machining. Other times, you need full 5-axis CNC machining. Each one works better for certain jobs.

If you want to save money, use 3+2 axis CNC machining. These machines cost less to buy. You spend less on setup and repairs. Programming is easier with this method. You do not need to learn hard software. You can finish jobs faster with angled features. Many companies in China use 3+2-axis CNC machining for these reasons.

Here is a table that shows when to use each method:

| Scenario | 3+2 axis CNC machining | 5-Axis CNC Machining |

| Cost Efficiency | Lower machine cost | Higher machine cost |

| Programming Simplicity | Easier to program | Advanced programming needed |

| Cycle Time for Angled Features | Faster for fixed angles | Slower for simple angled cuts |

| Complex, Curved Surfaces | Not ideal | Best choice |

| Multiple Undercuts | Limited | Handles many undercuts |

| Tight Tolerances on Flat Faces | Excellent | Also excellent |

| Customized Machining | Good for simple custom jobs | Best for complex custom jobs |

Pick 3+2 axis CNC machining for flat or angled surfaces. You get faster jobs and do not need to move the part a lot. This method is good when you want to use short, strong tools. These tools help you keep tight sizes and smooth finishes.

If your part has tricky shapes or deep pockets, use 5-axis CNC machining. You can move the tool in more ways. You reach every side without stopping the machine. This method is best for aerospace, medical, and car parts. You also need it for hard custom jobs.

Think about your budget, your skills, and what your project needs. If you run a company in China, you want to save money and make good parts. Use 3+2-axis CNC machining for most jobs. Switch to 5-axis CNC machining for the hardest work.

Tip: Always pick the right machining method for your part design. This saves you time and money. It also helps you get better results in precision manufacturing.

You make better choices when you know what each method does best. You keep your shop running well. You give your customers high-quality parts.

Design Tips

Geometry

When you design a part for 3+2-axis CNC machining, think about its shape. Good shapes help you save time and money. You also get better results in precision manufacturing. If you use standard shapes, the job is easier for any manufacturing company in China. Standard shapes lower tooling costs and make things faster.

You should also check the depth-to-diameter ratio. Keep the depth less than four times the tool’s diameter. This stops the tool from bending. It keeps your part strong and accurate. Try not to use undercuts. Undercuts make the job harder and require special tools. This adds cost and takes more time.

Long tools can reach deep spots, but they shake more. This can hurt your part’s quality. Rounded corners help tools move better. Sharp corners slow things down and can break tools.

Here is a table to help you remember the main points:

| Design Consideration | Description |

| Standard Geometries | Using standard shapes can reduce tooling costs and machining time compared to custom shapes. |

| Depth-To-Diameter Ratio | Keeping the depth no more than four times the diameter of the tool prevents tool deflection. |

| Avoid Undercuts | Undercuts complicate machining and may require specialized tools, increasing time and cost. |

| Tool Length and Reach | Longer tools can access deeper areas but are more prone to vibrations, affecting part quality. |

| Tool Angles and Clearances | Rounded internal corners facilitate better tool access compared to sharp corners, improving machining efficiency. |

Tip: If you want to use 5-axis CNC machining or 3+2 axis CNC machining for customized machining, always check your part’s geometry first. This helps you avoid problems later.

Materials

You need to pick the right material for your part. Some materials are easy to cut, but others are tough. Aluminum and brass are good for fast jobs. They cut cleanly and do not wear out tools quickly. Stainless steel and titanium are harder to machine. These need slower speeds and stronger tools.

If you work with a manufacturing company in China, ask for advice on the best material. The right choice depends on how you will use your part. For example, aerospace parts need strong metals. Medical parts need safe and clean materials.

- Use soft metals for quick jobs and lower costs.

- Pick hard metals for strength and long life.

- Always match the material to your part’s needs.

Note: Harder materials may need 5-axis CNC machining for better results in precision manufacturing.

Tolerances

Tolerances tell you how close your part must match the design. Tight tolerances mean less room for mistakes. 3+2-axis CNC machining gives you high accuracy, just like 5-axis CNC machining. You can expect tolerances of ±0.005 inches (0.13 mm). This is good for most precision manufacturing jobs.

Here is a table that shows how 3+2-axis CNC machining compares to other methods:

| CNC Machining Type | Tolerance Level |

| 3-axis CNC Milling | ± 0.005″ or 0.13 mm |

| 5-axis CNC Milling | ± 0.005″ or 0.13 mm |

| 3+2 axis CNC Machining | Similar to 3-axis and 5-axis |

| Other Methods | Generally looser tolerances |

If you need even tighter tolerances, talk to your shop. Some jobs, like aerospace or medical parts, need the best accuracy. Customized machining lets you set special tolerances for your project.

Tip: Always check your design and talk to your manufacturing company in China about the right tolerance for your part. This helps you get the best results and avoid extra costs.

Programming

Programming for 3+2-axis CNC machining helps you use your machines well. You need to plan each step. This makes sure your machine works smoothly. Your parts will come out right. Good programming makes your shop more productive. It helps you keep up with precision manufacturing needs.

You start by picking the best CAM software. This software lets you set the rotary axes at the right angle. You choose the surfaces you want to machine. You set the tool orientation for each feature. Automation can help you work faster. It helps you avoid mistakes and saves time.

Here are some strategies to help you with 3+2-axis CNC machining:

- Use modern machines and the right tools for each job. This helps you finish tasks faster and keeps your shop competitive.

- Pick high-quality tools. These tools last longer and cut better. You waste less material and get better results.

- Automate your processes when you can. Keep good notes for each job. Use the same steps for programming and try new technologies.

- Use your machines as much as you can. Train your staff so everyone knows how to get the best results.

- Check your machines often. Regular maintenance stops breakdowns and keeps your shop running.

You want the best surface quality and less tool wear. You also want to get close to the final shape during roughing. These goals help you save money and make better products. If you work for a manufacturing company in China, you know every minute matters. Good programming lets you handle more orders and keep your customers happy.

- Make machining faster.

- Get better surface quality.

- Lower tool wear.

- Get close to the final shape in roughing.

You should always test your program before running a full job. Simulate the toolpath in your CAM software. This step helps you find errors and avoid costly mistakes. You can use code blocks to organize your G-code and keep your files neat.

You can use these tips for both 3+2-axis CNC machining and 5-axis CNC machining. Good programming helps with customized machining. It helps you meet strict standards in precision manufacturing. When you plan well, you get better parts and keep your shop running smoothly.

NOBLE’s 3+2 Axis CNC Machining

Capabilities

You want a partner who helps with every step. NOBLE is a top manufacturing company in China. You can count on NOBLE for fast and accurate work. The team knows how to make precise parts. You get help with hard shapes and tight fits. NOBLE’s engineers help you with custom machining, so your parts fit your needs.

When you pick NOBLE, you get many services. You can ask for quick prototypes for new ideas. You can also order big batches for mass production. NOBLE’s experts use smart ways to save time and money. You get their skill with 5-axis CNC machining and other new methods. This means your parts meet strict rules.

Tip: If you need help picking materials or making your design better, NOBLE’s team will help you. You can ask questions at any time during your project.

NOBLE checks every part before it leaves the factory. You get clear inspection reports and updates. This helps you avoid delays and makes sure your parts arrive on time. Many clients around the world trust NOBLE for big projects.

Equipment

You need good machines for great results. NOBLE buys advanced CNC machines for your jobs. The shop has both 3+2-axis CNC machining and full 5-axis CNC machining centers. These machines work with many materials like aluminum, stainless steel, titanium, and plastics.

NOBLE’s equipment list has:

- Multi-axis machining centers for hard shapes

- High-speed spindles for smooth surfaces

- Precision measuring tools for tight fits

- Automated tool changers for fast work

- Special fixturing systems for steady setups

You can see how these machines help with prototypes and big orders. NOBLE’s machines work all day and night to meet your deadlines. The team uses new CAM software to program each job. This makes sure your parts match your drawings.

| Equipment Type | Function | Benefit to You |

| 5-axis CNC machining | Complex, multi-angle cutting | Fewer setups, better accuracy |

| 3+2 axis CNC machining | Fixed-angle, multi-face machining | Faster cycles, lower costs |

| Automated inspection | Quality checks during and after machining | Reliable, consistent results |

You can trust NOBLE to make parts for aerospace, cars, medical, and mold-making. Skilled workers and good machines give you an advantage. When you need a manufacturing company in China that is fast and meets your needs, NOBLE is ready to help.

You now know that 3+2-axis CNC machining helps you make hard parts. It locks two rotary axes and moves the tool in three ways. This makes setups quicker and helps you save money. You also get better accuracy for many jobs. 5-axis CNC machining can move the tool from any angle. This is good for custom parts and special designs. For the best results, use strong CAM software. Make sure your machine is sturdy. You can also ask a trusted company in China, like NOBLE, for help.

FAQs of 3+2 Axis CNC Machining

What is the main difference between 3+2-axis and 5-axis CNC machining?

You use 3+2 axis CNC machining when you lock two rotary axes. The machine cuts at a set angle. In 5-axis CNC machining, all five axes move together. This lets you make more detailed parts.

Can you use 3+2-axis CNC machining for customized machining?

Yes, you can use it for custom jobs. 3+2 axis CNC machining helps you reach tough angles. You can make parts with tricky shapes. Many companies in China use this method for special projects.

Why do you need shorter tools in 3+2-axis CNC machining?

Shorter tools help you cut more accurately. They do not bend or shake much. This makes surfaces smoother and sizes more exact. It is important for making precise parts.

What industries use 3+2-axis CNC machining?

You see 3+2 axis CNC machining in aerospace, cars, medical, and mold making. These jobs need parts with hard shapes and high accuracy. Many companies in China use this technology for these areas.

How does 3+2-axis CNC machining save you money?

You save money because you do fewer setups. The machine works faster and wastes less material. Shorter tools last longer, so you buy fewer replacements. This lowers your costs.

Is 3+2-axis CNC machining better than 5-axis CNC machining?

You pick the best method for your part. 3+2-axis CNC machining is quicker for flat and angled surfaces. 5-axis CNC machining works better for curved shapes and deep holes. Both help with custom jobs.

Can you get tight tolerances with 3+2 axis CNC machining?

Yes, you can get tight tolerances with this method. 3+2-axis CNC machining gives you high accuracy, like 5-axis CNC machining. This is good for custom and precise parts.

Why do manufacturing companies in China use 3+2-axis CNC machining?

Companies in China use 3+2-axis CNC machining because it is fast and accurate. It helps them save money and do custom work. This method fits many industries’ needs.