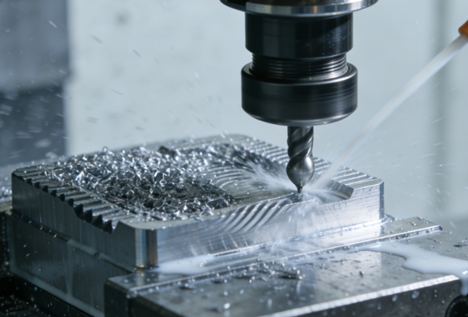

What is the Face Milling Process?

Face milling is a mechanical machining method that uses a rotary milling cutter to perform cutting on the surface of a workpiece. The main purpose of the cutting process is to produce a smooth and flat plane and ensure that this plane is perpendicular to the rotation axis of the tool.

The core process of face milling is that the milling cutter is installed on a plane perpendicular to the spindle, and multiple cutting teeth on its circumference and end face participate in the cutting simultaneously. The workpiece is usually fixed on the worktable and machined by the rotating cutting tool.

The Types of Face Milling Machining Techniques

General Face Milling

General face milling, as the most fundamental and widely used process type in machining, is operated with standard face milling cutter heads.

General face milling is usually equipped with square or circular inserts and achieves complete coverage of the machined surface through slight overlapping movements in the axial and radial directions.

If you need to perform rough or semi-finish machining on materials, general face milling is the preferred process for establishing reference surfaces. It has high machining efficiency, but the surface finish obtained is usually not the best.

Precision milling or high feed milling

High feed milling processes use milling cutters with special small main deflection angles. Its core feature is the adoption of a very high feed rate per tooth, but the cutting depth is very shallow.

Fine milling or high feed milling is very suitable for the machining of thin-walled parts. Although the cutting depth is small, the extremely high feed rate makes the metal removal rate very considerable, and at the same time, it can achieve excellent surface quality, making it an ideal choice for efficient fine machining.

Heavy Duty Face Milling

Heavy-duty face milling employs robust and sturdy milling heads to deliver stable cutting performance even under high impact and extreme loads.

Heavy-duty face milling process is particularly suitable for the first roughening of castings, forgings, and other blanks, which can remove the excess material with the highest efficiency and lay the foundation for the subsequent finishing processes.

Angular Face Milling

Angle face milling is a special face milling process. Its core feature is that it is processed using a face mill with a main deflection Angle not equal to 90 degrees.

Unlike standard face milling, which produces flat faces, angular face milling allows the tool to cut at a specific angle, making it ideal for bevels, chamfers, and angled reference planes.

The Materials Used in Face Milling

Alloy Steel

Steel is the largest category in face milling, ranging from low-carbon steel to high-carbon steel and various alloy steels. They have excellent comprehensive mechanical properties and are the most common materials to be processed.

Stainless Steel

Stainless steel is widely used due to its excellent corrosion resistance. However, it has poor thermal conductivity and is prone to hardening during machining, making it a typical difficult-to-machine material.

When milling stainless steel, sharp-edge cutting tools must be used, along with appropriate chip-breaking groove designs and adequate cooling and lubrication, to prevent tool adhesion and abnormally rapid wear.

Cast Iron

Gray cast iron, ductile iron, and other materials can also be milled. They have high hardness and brittleness, and are prone to producing chips during machining. During the milling process, medium or relatively high cutting speeds are usually required, thus imposing higher demands on the wear-resistant particle wear performance of the cutting tool.

Aluminum Alloy

Aluminum alloy is the most common light metal, which is soft, has good plasticity, and excellent thermal conductivity. However, during the milling process, this material is prone to built-up edge and tends to stick to the tool.

Therefore, when milling aluminum alloys, it is usually recommended to use tools with sharp cutting edges and large rake angles, and adopt process parameters that combine high cutting speed with large feed rate, so as to achieve the unity of efficient processing and excellent surface finish.

Non-metallic and Composite Materials

Engineering plastics such as nylon, polycarbonate, PEEK, etc. They have low hardness but high elasticity and extremely poor thermal conductivity. When milling these materials, the heat generated by friction readily causes workpiece softening and deformation, whilst burr formation is also a significant issue.

Therefore, machining should employ extremely sharp cutting tools with high-speed, shallow-depth cutting parameters, alongside effective chip evacuation and cooling measures.

Essential Tools and Equipment for Effective Face Milling

End mills

An end mill is a multi-edge cutting tool with its cutting edges located on the cylindrical surface and the end face. When performing face milling, a smaller axial depth of cut is usually adopted.

End mills are highly suitable for milling narrow planes, stepped surfaces, etc. It is widely used in multi-functional machining and mold finishing.

Fly Cutters

A fly cutter usually refers to a simple, homemade face milling device. Structurally, one or two indexable inserts are installed at the end of a tool holder. It is very practical in single-piece and small-batch production, maintenance workshops, or when machining local bosses on large workpieces.

Due to the scarcity and asymmetry of the cutting inserts involved, the balance and rigidity of flying cutters are relatively poor, and their cutting efficiency and surface finish are usually inferior to those of standard face mills.

Shell Mills

Shell Mills is one of the most typical and commonly used standard face milling tools.

Shell Mills are the most commonly used tools for milling large planes in manufacturing. Typical applications include: machining machine tool beds, mating surfaces of box parts, reference surfaces of molds, upper surfaces of large plate parts, and any other occasions where a flat surface needs to be obtained efficiently.

Advantages of the Face Milling Process

High Machining Efficiency

Face milling cutters usually have a large diameter, can cover a wide machining width, and are equipped with multiple cutting teeth participating in the cutting simultaneously, so the metal removal rate is very high.

During the rough machining stage, face milling can adopt a large cutting depth and high feed rate approach to quickly remove a large amount of excess material from the workpiece surface, laying a foundation for subsequent processes and significantly reducing the overall machining time of the parts. It is an ideal choice for efficient batch production.

Excellent Surface Quality

Due to the axial and radial overlap of the cutting teeth of the face milling cutter during cutting, the machined surface can be trimmed multiple times with each pass, thus obtaining a smooth and flat surface.

By selecting finely ground cutting inserts, adjusting reasonable cutting parameters, and using high-precision machine tools, it is easy to achieve very high flatness tolerances and excellent surface finish, and even replace some grinding processes, realizing “milling instead of grinding”.

Process Flexibility

The face milling process is highly flexible. By replacing blades with different main deflection angles, materials, and slot types, the same machine tool and tool body can meet the machining requirements of various materials ranging from soft aluminum alloys to high-hardness quenched steels.

Face milling can not only perform heavy-duty rough milling but also achieve high-speed finish milling. It can also complete the machining of inclined and stepped surfaces. One process can cover multiple stages from rough to finish.

Machining Stability

Face milling cutters possess excellent structural rigidity and a secure connection to the spindle, effectively suppressing vibration and chatter during machining. This helps minimise workpiece deformation, making them particularly suitable for machining thin-walled or low-rigidity components. The stability inherent in face milling ensures consistent and predictable machining dimensions.

Good Economic Efficiency

Face milling mainly uses indexable inserts. The tool body can be reused for a long time, and only the inserts with relatively lower costs need to be replaced. This greatly reduces the long-term usage cost and management cost of the tool, and enhances the overall economic benefits.

Disadvantages of the Face Milling Process

High Machine Requirements

Due to face milling, especially heavy-duty rough milling, multiple cutting teeth need to be driven simultaneously to remove a large amount of material, which generates a huge cutting force.

If powerful face milling is carried out on a machine tool with insufficient power or poor rigidity, it is very likely to cause vibration, abnormal wear of the cutting tool, and even damage the accuracy of the machine tool.

Higher Tooling Costs

To achieve efficient face milling, high-quality, large-diameter dedicated face milling cutter heads and a large number of indexable inserts are required. This initial tool investment is considerable.

Face milling machines often require the installation of high-power, high-end CNC machine tools or machining centers, and the cost of equipment purchase is very high.

Limited to Flat Surfaces

The main advantage of face milling cutters is their ability to machine open and wide surfaces. They can remove material fast and keep the surface flat. But when the part has complex curves, deep and narrow pockets, or sharp internal corners, the cutter becomes limited. The tool is usually large, so it may hit the workpiece and cause interference. Because of this, it cannot reach the required areas and cannot cut the surface effectively.

Thin-Wall Deformation Risk

When machining thin-walled parts, slender pieces, or workpieces with insufficient fixture support, strong radial or axial cutting forces can easily cause elastic deformation of the workpiece or even tool deflection. These issues make it hard to keep good dimensional accuracy and flatness. In many cases, the part needs several light cuts or special machining strategies to correct the deformation.

Vibration and Chatter Prone

When milling wide surfaces or when using tool holders with a long overhang, the contact between the tool and the workpiece can become unstable. This unstable condition makes it easy for periodic vibration to appear. This vibration affects cutting smoothness, surface quality, and tool life.

This kind of vibration not only seriously deteriorates the surface quality and leaves obvious vibration marks, but also accelerates tool wear and even leads to chipping, posing a threat to the machining accuracy and safety.

Face Milling vs Peripheral Milling: Key Differences Explained

| Dimension of Comparison | Face Milling | Peripheral Milling |

| Basic Definition | Uses the face and periphery of the cutter to produce a surface perpendicular to the tool axis. | Uses the circumferential teeth to machine surfaces parallel to the tool axis, such as profiles or edges. |

| Tool Type | Face mill (disk-type cutter) with inserts on the face and periphery. | End mill, slab mill, etc., with cutting edges mainly on the circumference. |

| Surface Produced | Flat surfaces (horizontal planes, steps, etc.). | Vertical walls, slots, contoured surfaces, etc. |

| Primary Objective | Efficiently produce large, flat surfaces. | Machine profiles, grooves, or complex 3D features. |

| Typical Applications | Machine tables, housing faces, mold parting surfaces, etc. | Keyways, gear teeth, pockets, part contours, etc. |

| Cutting Force Characteristic | Higher axial force, pressing the workpiece toward the table, generally more stable. | Higher radial force, prone to tool deflection and vibration. |

| Surface Quality | Usually achieves higher flatness and smoother finishes. | May leave tool marks or waves; requires fine-tuning for a better finish. |

Common Face Milling Problems and How to Solve Them

Poor Surface Quality

Regular vibration lines appear on the machined surface; it is abnormally rough, has scratches or roughness.

Solution

- Enhance rigidity: Choose a thicker and stronger knife handle; Ensure the rigidity of the workpiece and fixture.

- Adjust parameters: Alter the cutting speed, feed rate, or depth of cut to break the resonant frequency; Adopt asymmetric cutting width or variable speed cutting.

Short Tool Life

The blade is severely worn, cracked, or damaged, far from reaching its expected lifespan.

Solution

- Optimize parameters: Select the appropriate linear speed and feed rate based on the workpiece material and the recommended value of the blade. Avoid the friction caused by “low-speed light cutting”.

- Dealing with built-up edge: Increase cutting speed; Use a sharp blade with a positive rake Angle; Increase the lubricity of the coolant.

Poor Flatness

The processed plane is uneven, with a depression in the middle and protrusions at the edges, or there are obvious seams between multiple tool passes.

Solution

- Reduce deformation: Select tools and tool holders with greater rigidity; Optimize the clamping scheme to prevent deformation of the workpiece during machining.

- Calibrate the machine tool: Regularly inspect and adjust the verticality of the spindle.

Burrs and Edge Chipping

Burrs or material chipping occur at the edge of the workpiece when it is cut out by the tool.

Solution

- Change the cutting method: Slightly reduce the feed rate before cutting out the edge.

- Optimize cutting tools: Use sharper blades with a positive rake Angle; Make sure the cutting tool is always in good cutting condition, and avoid using worn blades.

- Add processes: Arrange dedicated deburring procedures.

Applications of the Face Milling Process

General machinery

Large-scale machinery is the field where face milling is most widely applied. It is mainly used for machining the beds, worktable,s and guide rail installation surfaces of various types of machine tools.

Automobile

In the automotive industry, face milling is used to machine the cylinder block and cylinder head mating surfaces of engines, transmission cases, and the installation planes of chassis frames.

In rail transport, face milling is used to create precise flat surfaces on important load-bearing parts. These include high-speed locomotive bogies, engine bases, and other key structural components. The process helps ensure stability, strength, and proper assembly in demanding operating conditions.

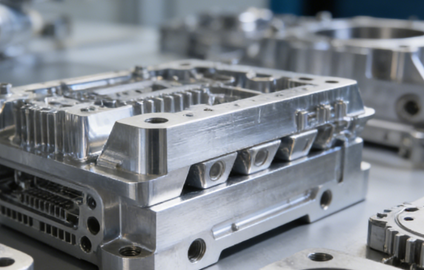

Mold manufacturing industry

Mold manufacturing is highly dependent on face milling. Face milling is used to machine the parting surface of molds. The quality of this plane directly determines the precision of the product and the service life of the mold.

Face milling is also used for machining the reference surfaces of mold bases and templates. High-speed hard milling technology is often adopted as it has extremely high requirements for surface finish, flatness, and machining efficiency.

Aerospace

In the aerospace industry, face milling is used to machine the mating surfaces of wing ribs, bulkheads, and skin panels. It is also applied to engine mounting bases and the precision interface surfaces of spacecraft structural parts. These surfaces must meet very high accuracy requirements, so the process is an important step in aerospace production.

Why Choose NOBLE as Your Face Milling Machining Supplier

The face milling process at NOBLE is designed to deliver high-precision, high-efficiency surface machining for both metal and plastic parts. We adopt advanced CNC milling machines, equipped with rigid spindles and high-quality indexable face milling machines, which can produce flat, smooth, and uniformly sized surfaces with excellent repeatability.

NOBLE selects the most suitable cutter diameter, insert geometry, cutting parameters, and tooling strategy based on the material and tolerance requirements of each project.

NOBLE, with its strong capabilities, stable machining techniques, and strict quality inspection, can handle both small-batch and large-batch production orders while ensuring consistent surface quality of all parts.

FAQs

What materials can be machined with face milling?

Face milling can machine many materials, including aluminium, stainless steel, carbon steel, brass, copper, titanium, and engineering plastics. Proper tool selection and cutting parameters are adjusted based on each material’s hardness and machinability.

What is the difference between face milling and end milling?

Face milling uses a cutter with a large diameter to machine wide and flat surfaces. It is mainly focused on achieving good flatness and high efficiency. End milling, on the other hand, uses smaller tools to cut pockets, slots, and more complex shapes. It is mostly used for detailed contouring and precise features on the workpiece.

What factors affect the quality of a face milling operation?

Tool geometry, spindle speed, feed rate, depth of cut, machine rigidity, coolant usage, and workpiece clamping stability.

What are common applications of face milling?

Face milling is widely used in automotive, aerospace, machinery, mold manufacturing, and precision components.

How to achieve a good surface finish in face milling?

To achieve a smooth surface finish, it is important to use sharp cutting inserts. The feed rate should be set correctly, and the cutter must remain stable during machining. Choosing the right tool path also helps improve the result. For the best surface quality, it is recommended to perform a separate finishing pass with a lower feed rate and shallower depth of cut.